Choosing the Correct Hammer Drill Bit Size for 3/8″ Drop-In Anchors

When it comes to installing 3/8″ drop-in anchors, choosing the correct hammer drill bit size is crucial for ensuring a secure and effective installation. Drop-in anchors are commonly used in construction projects to provide a strong and reliable anchoring solution for items that need to be securely fastened to concrete or other solid materials.

Using the wrong hammer drill bit size can result in a loose or unreliable anchor, compromising the integrity of the installation. To determine the correct bit size, you need to consider the diameter of the drop-in anchor, which in this case is 3/8″.

It’s important to note that the hammer drill bit size needed for a 3/8″ drop-in anchor may vary depending on the manufacturer and specific requirements of the project. However, as a general guideline, a 3/8″ drop-in anchor typically requires a 1/2″ hammer drill bit for optimal results.

Using a slightly larger hammer drill bit ensures that the anchor will fit securely in the hole, providing a tight and stable grip. It’s crucial to use a hammer drill bit specifically designed for masonry applications to ensure a clean and precise hole that accommodates the drop-in anchor properly.

In conclusion, choosing the correct hammer drill bit size is essential for a successful installation of 3/8″ drop-in anchors. When in doubt, it’s always recommended to consult the manufacturer’s guidelines or seek advice from a professional to ensure the best results.

Importance of Choosing the Right Hammer Drill Bit Size for 3/8″ Drop-In Anchors

When it comes to installing 3/8″ drop-in anchors, choosing the correct hammer drill bit size is crucial for a successful installation. The size of the drill bit will determine the fit of the anchor in the drilled hole, as well as the overall strength and stability of the anchor once it is installed.

1. Proper Fit

Using the correct hammer drill bit size ensures that the anchor will fit securely in the drilled hole. If the drill bit is too small, the anchor may not fit properly, leading to a loose and unstable connection. On the other hand, if the drill bit is too large, the anchor may not have enough material to grip onto, resulting in a weak and insecure attachment.

2. Maximum Load Capacity

The size of the hammer drill bit also affects the maximum load capacity of the anchor. If the drill bit is too small, it may not create a hole large enough to accommodate the anchor’s specified load capacity. This can result in an anchor that is not able to support the intended weight or force, potentially leading to structural failure or injury.

3. Correct Drilling Speed

Choosing a hammer drill bit with the right size also allows for the correct drilling speed. If the drill bit is too small, it may take longer to drill the hole, as the drill will need to make multiple passes to create the desired size. Conversely, if the drill bit is too large, it may drill too quickly, potentially causing overheating and damage to the drill bit or the surrounding material.

4. Overall Safety

Selecting the correct hammer drill bit size is essential for overall safety during the installation process. Using the wrong size can result in unexpected issues such as the anchor not fitting properly, the drilled hole being too large or too small, or the anchor not being able to support the intended load. These issues can compromise the integrity of the installation and pose safety risks to both workers and users of the anchor.

Conclusion

Choosing the right hammer drill bit size for 3/8″ drop-in anchors is crucial for ensuring a secure and reliable installation. It affects the fit of the anchor, the maximum load capacity, the drilling speed, and overall safety. By taking the time to select the correct drill bit size, you can avoid potential issues and ensure a successful anchor installation that meets the required specifications and standards.

Understanding the Basics of Drop-In Anchors

In construction and renovation projects, drop-in anchors are frequently used to secure objects to concrete surfaces. These anchors are inserted into pre-drilled holes and are designed to expand within the hole, creating a secure and reliable anchoring point.

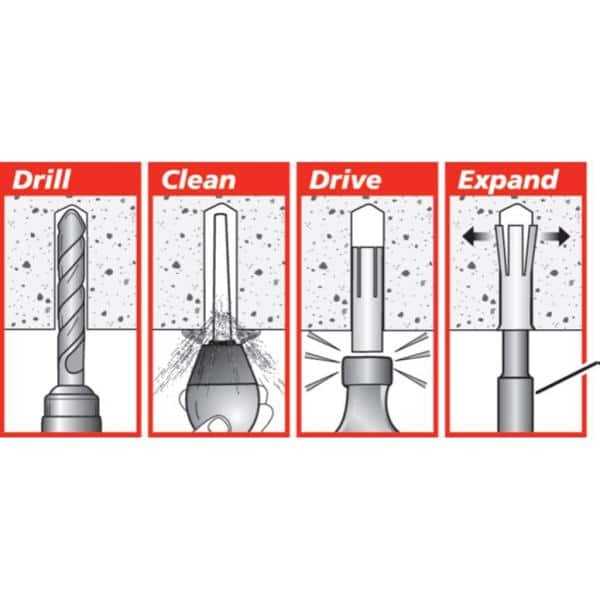

How Drop-In Anchors Work

Drop-in anchors consist of a cylindrical body with a threaded hole in the center. The body is made of a material that is compatible with the concrete being drilled into, such as zinc or stainless steel. The anchor is inserted into a pre-drilled hole and then a setting tool is used to expand the anchor.

Installation Process

- Measure and mark the desired location for the anchor on the concrete surface.

- Use a hammer drill with the correct bit size to create a hole that is slightly deeper than the length of the drop-in anchor.

- Clean out the hole to remove any dust or debris.

- Insert the drop-in anchor into the hole, making sure it is flush with the surface of the concrete.

- Using a setting tool and a hammer or hammer drill, tap the anchor until it is fully expanded and secure within the hole.

Advantages of Drop-In Anchors

Drop-in anchors offer several advantages over other types of anchors:

- High load-bearing capacity: Drop-in anchors are capable of supporting heavy loads, making them suitable for a wide range of applications.

- Easy installation: The installation process for drop-in anchors is relatively simple and requires only basic tools.

- Removable and adjustable: Drop-in anchors can be easily removed and repositioned if needed, making them a versatile choice for construction projects.

Considerations and Limitations

While drop-in anchors are a popular choice for many applications, there are some considerations and limitations to keep in mind:

- Concrete strength: Drop-in anchors are designed specifically for use in solid concrete. They may not be suitable for use in other materials, such as brick or stone.

- Drill bit size: The correct drill bit size is crucial for proper installation and maximum anchor performance. Using the wrong size bit can result in a loose or ineffective anchor.

- Depth of hole: The depth of the hole should be carefully measured to ensure that the anchor is properly seated and able to expand fully.

Conclusion

Drop-in anchors are an effective and versatile option for securing objects to concrete surfaces. By understanding the basics of their operation and installation, you can confidently choose and use drop-in anchors for your construction projects.

Factors to Consider When Choosing Hammer Drill Bit Size

Choosing the correct hammer drill bit size is crucial for achieving the desired results when using 3/8” drop-in anchors. Several factors should be taken into consideration when selecting the appropriate drill bit size:

1. Anchor Size

The first factor to consider is the size of the drop-in anchor you plan to use. Different anchor sizes require different drill bit sizes to ensure a proper fit. Make sure to check the manufacturer’s instructions or guidelines to determine the recommended drill bit size for the specific anchor size.

2. Substrate Material

The type of material you will be drilling into is another important factor. Different materials have different hardness levels, which can affect the drilling process. For softer materials like wood or drywall, a smaller drill bit size may be sufficient. However, for harder materials like concrete or masonry, a larger drill bit size may be necessary.

3. Desired Hole Depth

The depth of the hole you need to drill also plays a role in choosing the appropriate drill bit size. If the hole needs to be deeper, a longer drill bit may be required to ensure the anchor is properly secured.

4. Drill Power

The power of your drill is an important consideration when choosing the drill bit size. Higher-powered drills may require larger drill bits to handle the increased torque and speed. Make sure to use a drill bit that is compatible with your specific drill model to avoid damaging the bit or drill.

5. Application Requirements

Lastly, the specific requirements of your application should be taken into account. Consider factors such as load capacity, environmental conditions, and any additional safety measures. These factors may impact the drill bit size needed to ensure a secure and durable installation.

Conclusion

Choosing the correct hammer drill bit size involves considering factors such as anchor size, substrate material, desired hole depth, drill power, and application requirements. By taking these factors into account, you can ensure that the drill bit you choose is appropriate for the job and will result in a successful installation of 3/8” drop-in anchors.

Optimizing Drill Bit Size for Maximum Efficiency

Choosing the correct drill bit size is essential when it comes to using 3/8″ drop-in anchors. Using the wrong size can result in a loose or unsecure anchor, which can compromise the structural integrity of the installation. However, using the optimal drill bit size can provide maximum efficiency and ensure a reliable installation.

Factors to Consider

- Anchor Size: The size of the drop-in anchor should be the primary factor to consider when determining the drill bit size. In this case, we are working with 3/8″ drop-in anchors, meaning we need to find a drill bit that matches this diameter.

- Manufacturers’ Recommendations: It is always a good idea to consult the manufacturer’s recommendations for the correct drill bit size. Manufacturers often provide guidelines and specifications for the optimal drill bit size to be used with their drop-in anchors.

- Material Type: The material that you are drilling into will also impact the drill bit size. Different materials have different hardness levels, and drill bits with different sizes and types are better suited for specific materials.

Recommended Drill Bit Sizes

For 3/8″ drop-in anchors, a common drill bit size is 5/16″. This slightly smaller size allows for a snug fit of the anchor into the hole, ensuring a secure installation. However, it is always advised to refer to the manufacturer’s recommendations for the precise drill bit size.

If a 5/16″ drill bit is not available, a 3/8″ drill bit can be used as an alternative. This will provide a slightly larger hole, allowing for easier insertion of the anchor but potentially compromising the overall secureness of the installation.

Drill Bit Size Chart

| Anchor Size | Recommended Drill Bit Size |

|---|---|

| 3/8″ | 5/16″ or 3/8″ |

Always remember to use proper safety precautions, such as wearing protective eyewear and gloves, when using power tools. Additionally, regularly inspect and replace worn drill bits to ensure optimal performance and safety.

By optimizing the drill bit size for 3/8″ drop-in anchors, you can ensure maximum efficiency and a secure installation. Taking into account factors such as anchor size, manufacturer’s recommendations, and material type will help you choose the appropriate drill bit size for your specific situation.

The Consequences of Using Incorrect Drill Bit Size

Using the correct drill bit size is crucial when working with 3/8″ drop-in anchors. Failure to use the appropriate drill bit size can lead to a number of consequences, including:

-

Weakened Hold: Using a drill bit that is too small in diameter can result in a weakened hold for the drop-in anchor. When the anchor is not securely held in place, it will not be able to provide the necessary stability and support for the intended application.

-

Difficulty in Installation: When a drill bit that is too small is used, it can be challenging to properly install the drop-in anchor. The smaller drill bit may cause the hole to be too narrow, making it difficult to insert the anchor into the hole.

-

Inadequate Load Capacity: Using an incorrect drill bit size can also result in a decrease in the load capacity of the drop-in anchor. A smaller hole diameter may compromise the anchor’s ability to support the intended load, potentially leading to failure or damage to the anchor and the surrounding structure.

-

Increased Risk of Failure: When the drill bit size is not appropriate, there is an increased risk of anchor failure. The anchor may not be able to provide the necessary anchoring force, leading to instability and potential collapse of the structure or object being anchored.

It is important to carefully select the correct drill bit size for 3/8″ drop-in anchors to ensure proper installation and optimal performance. Always refer to the manufacturer’s guidelines and specifications for the recommended drill bit size for the drop-in anchors you are using.

Tips for Properly Measuring Drill Bit Size

Choosing the right drill bit size is crucial for a successful installation of 3/8″ drop-in anchors. Here are some tips to help you properly measure the drill bit size:

- Refer to the anchor manufacturer’s instructions: The first and most important step is to check the anchor manufacturer’s instructions for the recommended drill bit size. They will provide you with the exact size needed for the best results.

- Use a measuring tape: If you don’t have access to the anchor manufacturer’s instructions, you can measure the diameter of the anchor itself using a measuring tape. Be sure to measure the widest part of the anchor to get an accurate measurement.

- Consult a drill bit size chart: Another option is to consult a drill bit size chart, which can be easily found online. These charts provide recommendations for drill bit sizes based on the anchor size or the material you will be drilling into.

- Consider the material: The material you will be drilling into also affects the choice of drill bit size. Different materials require different sizes to ensure proper anchoring. Make sure to take this into account when selecting the drill bit size.

- Test the fit: Before drilling into the actual material, it is recommended to do a test fit using a small piece of the same material. This will allow you to verify that the drill bit size is correct and that the anchor fits snugly.

Properly measuring the drill bit size is an essential step in the installation process. By following these tips, you can ensure that you choose the correct drill bit size for your 3/8″ drop-in anchors and achieve a secure and reliable installation.

Available Hammer Drill Bit Sizes for 3/8″ Drop-In Anchors

When it comes to installing 3/8″ drop-in anchors, choosing the correct hammer drill bit size is crucial for a successful anchor installation. The right drill bit size ensures that the anchor hole is the proper diameter to securely hold the anchor in place.

Here are the available hammer drill bit sizes for 3/8″ drop-in anchors:

| Drill Bit Size | Anchor Size |

|---|---|

| 5/16″ | 3/8″ Drop-In Anchor |

| 3/8″ | 3/8″ Drop-In Anchor |

| 7/16″ | 3/8″ Drop-In Anchor |

| 1/2″ | 3/8″ Drop-In Anchor |

When choosing the drill bit size, it’s important to consider the diameter of the anchor and the requirement for a tight fit. It’s recommended to select a drill bit size that is slightly smaller than the anchor diameter to ensure a snug fit.

Depending on the specific brand or manufacturer, the drill bit size for a 3/8″ drop-in anchor may vary. Always refer to the anchor manufacturer’s guidelines or instructions to determine the correct drill bit size for your specific anchors.

Remember:

- Drill bit size affects the diameter of the anchor hole.

- Choose a drill bit size slightly smaller than the anchor diameter for a tight fit.

- Refer to the anchor manufacturer’s guidelines for the correct drill bit size.

By selecting the correct hammer drill bit size, you can ensure a secure and reliable installation of your 3/8″ drop-in anchors.

The Best Hammer Drill Bit Size for Different Substrates

When it comes to drilling holes in different substrates, the size of the hammer drill bit you use can greatly affect the success of your project. Choosing the correct size can ensure that the hole is drilled to the proper depth and diameter, which is essential for installing anchors or fasteners.

Concrete and Masonry

- For drilling into concrete and masonry, the best hammer drill bit size is typically 1/4 inch (6.35 mm) or 3/16 inch (4.76 mm). These smaller sizes provide enough strength and stability for drilling into hard materials without causing them to crack or chip.

- It’s important to note that for larger diameter holes, you may need to use a carbide-tipped drill bit instead of a regular hammer drill bit. Carbide tips are more durable and can withstand the rigors of drilling into tough materials.

Wood

- When drilling into wood, the best hammer drill bit size will depend on the size of the screw or fastener you plan to use. As a general rule of thumb, the drill bit should be slightly smaller in diameter than the screw or fastener to ensure a secure fit.

- For example, if you are using a 1/4 inch (6.35 mm) screw, a 3/16 inch (4.76 mm) hammer drill bit would be a suitable choice. This size will create a hole that allows the screw to grip the wood securely without splitting it.

Metal

- When drilling into metal, the best hammer drill bit size will depend on the thickness and hardness of the metal. For thinner metals, such as sheet metal, a smaller drill bit size like 1/8 inch (3.18 mm) or 3/32 inch (2.38 mm) may be sufficient.

- However, for thicker or harder metals, a larger drill bit size, such as 3/8 inch (9.53 mm) or 1/2 inch (12.7 mm), may be necessary. These larger sizes will provide the necessary strength and stability to drill through the metal without causing excessive heat or damage.

Overall, choosing the correct hammer drill bit size for different substrates is crucial for achieving successful and secure installations. By selecting the appropriate size based on the material you are drilling into, you can ensure that the job is done right the first time.

Importance of Regular Maintenance and Replacement of Drill Bits

1. Ensuring Efficient and Accurate Drilling

Regular maintenance and replacement of drill bits is essential to ensure efficient and accurate drilling. Over time, drill bits can become dulled or damaged, which can result in reduced cutting performance and accuracy. When a drill bit is properly maintained and regularly replaced, it can ensure smooth drilling and precise holes.

2. Extending the Lifespan of the Drill

Maintaining and replacing drill bits can also help extend the lifespan of the drill itself. When drill bits are worn out or damaged, they can put extra strain on the drill motor and other components. This can lead to premature wear and tear on the drill, reducing its overall lifespan. By regularly maintaining and replacing drill bits, you can help protect the drill from unnecessary damage and extend its usability.

3. Avoiding Accidents and Injuries

Dull or damaged drill bits can pose a safety hazard to the user. When a drill bit is not able to cut efficiently, it can cause the drill to slip or bind, increasing the risk of accidents and injuries. By regularly inspecting, maintaining, and replacing drill bits, you can reduce the risk of these accidents and create a safer working environment.

4. Improving Productivity

Efficient and accurate drilling is crucial for maintaining productivity in various industries. Whether you are a construction worker, carpenter, or DIY enthusiast, having a sharp and properly functioning drill bit can help you finish your tasks more quickly and efficiently. By regularly maintaining and replacing drill bits, you can ensure that you are always working at peak productivity.

5. Consistency in Performance

Regularly maintaining and replacing drill bits can help ensure consistent performance. Dull or damaged drill bits can result in uneven and inconsistent drilling, leading to compromised results. By keeping your drill bits in good condition and replacing them as needed, you can achieve consistent and reliable results in your drilling projects.

| Benefits | Description |

|---|---|

| Efficient and Accurate Drilling | Regular maintenance and replacement of drill bits ensure smooth and precise drilling. |

| Extended Lifespan of the Drill | Proper maintenance and replacement protect the drill from unnecessary wear and tear. |

| Accident Prevention | Maintaining and replacing drill bits reduces the risk of accidents and injuries. |

| Improved Productivity | A sharp and properly functioning drill bit helps finish tasks more quickly and efficiently. |

| Consistency in Performance | Maintaining and replacing drill bits ensures consistent and reliable drilling results. |

FAQ:

What is the correct hammer drill bit size for 3/8″ drop-in anchors?

The correct hammer drill bit size for 3/8″ drop-in anchors is usually 3/8″ or 10mm.

Can I use a larger hammer drill bit size for 3/8″ drop-in anchors?

No, it is not recommended to use a larger hammer drill bit size for 3/8″ drop-in anchors as it may result in the anchors not fitting properly and possibly causing damage to the anchoring system.

What will happen if I use a smaller hammer drill bit size for 3/8″ drop-in anchors?

If you use a smaller hammer drill bit size for 3/8″ drop-in anchors, the anchors may not fit properly and may not provide the necessary support for the fixtures or structures being anchored. This can result in a weak and unsafe anchoring system.

How do I determine the correct hammer drill bit size for 3/8″ drop-in anchors?

To determine the correct hammer drill bit size for 3/8″ drop-in anchors, you should refer to the manufacturer’s instructions or consult with a professional who has experience with anchor installation. The size may vary depending on the specific type and brand of anchor being used.

Can I use a drill bit with a different measurement system, such as millimeters, for 3/8″ drop-in anchors?

Yes, you can use a drill bit with a different measurement system, such as millimeters, for 3/8″ drop-in anchors. The equivalent drill bit size for 3/8″ is approximately 10mm. However, it is important to ensure that the drill bit is the correct size and fits the anchor properly to ensure a secure installation.

Are there any specific considerations I should keep in mind when choosing the correct hammer drill bit size for 3/8″ drop-in anchors?

When choosing the correct hammer drill bit size for 3/8″ drop-in anchors, it is important to consider the specific type and brand of anchor being used, as well as the materials and thickness of the structure being anchored. It is also recommended to follow the manufacturer’s instructions and consult with a professional for guidance if needed.

Video: