Choosing the Best Drill Bits for Metal: A Comprehensive Guide

Drilling through metal can be a challenging task, but with the right drill bits, you can make it easier and more efficient. Whether you’re a professional mechanic or a DIY enthusiast, having the right drill bits for metal is essential to getting the job done right. In this comprehensive guide, we’ll explore the different types of drill bits available for metal, their features and benefits, and how to choose the best ones for your specific needs.

When it comes to drilling through metal, you’ll encounter different types of metals with varying hardness and thickness. To ensure clean and accurate holes, it’s crucial to use drill bits specifically designed for metal. Typical drill bits for wood or masonry won’t provide the same level of performance and may result in dull bits, chipped metal, or even broken drill bits.

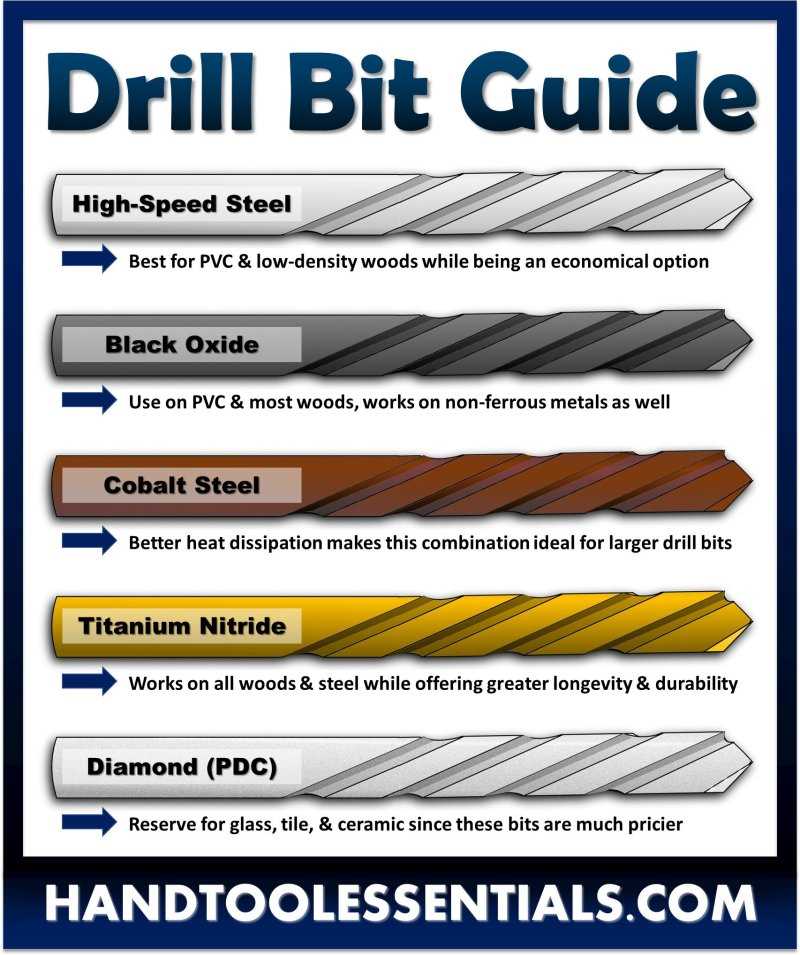

There are several factors to consider when choosing drill bits for metal, including the material, coating, and geometry. High-speed steel (HSS) drill bits are a popular choice for general metal drilling. They are durable, affordable, and can handle most metals. For more demanding applications, cobalt drill bits are ideal. Their heat resistance and hardness make them suitable for drilling into hard metals like stainless steel. Titanium-coated drill bits are another option, providing additional hardness and heat resistance.

Remember to match the drill bit size with the required hole diameter. Using the wrong size drill bit can result in oversize or undersized holes, which can affect the overall strength and appearance of your project.

Additionally, the drill bit’s geometry plays a role in its performance. Twist drill bits, with their spiral flutes, are the most common and versatile option for drilling through metal. They provide excellent chip evacuation and allow for better control. Other options include step drill bits, which can create multiple hole sizes with one bit, and cobalt split-point drill bits, which are designed for more precise drilling.

By considering the material, coating, geometry, and size, you can choose the best drill bits for metal that will provide clean, accurate holes, reduce the risk of bit breakage, and ultimately save you time and effort during your metalworking projects.

Understanding Metal Drilling Basics

When it comes to drilling through metal, it’s important to understand the basics in order to choose the right drill bits and achieve the best results. Here are some key factors to consider:

1. Material of the Metal

The type of metal you are drilling through will determine the type of drill bits you should use. Different metals have different hardness levels and require different cutting speeds and materials for the drill bits. For example, high-speed steel (HSS) drill bits are suitable for drilling through softer metals like aluminum, while cobalt drill bits are better for harder metals like stainless steel.

2. Drill Bit Coatings

Coatings on drill bits can enhance their performance and durability. Some common coatings for metal drill bits include titanium nitride (TiN), titanium aluminum nitride (TiAlN), and black oxide. These coatings can reduce friction, increase hardness, and provide better heat resistance, resulting in longer bit life and improved performance.

3. Drill Bit Geometry

The geometry of a drill bit also plays an important role in metal drilling. The angle and shape of the cutting edge can affect the chip formation, material removal, and overall drilling efficiency. Twist drill bits with a 118-degree point angle are commonly used for general metal drilling, while drill bits with a 135-degree point angle are better for harder metals.

4. Cutting Speed and Feed Rate

The cutting speed and feed rate are crucial factors for metal drilling. The cutting speed refers to the speed at which the drill bit rotates, while the feed rate refers to how fast the drill bit is pushed into the metal. These parameters need to be adjusted based on the metal type, drill bit size, and desired hole diameter. Proper cutting speed and feed rate can prevent overheating, tool wear, and ensure efficient metal removal.

5. Lubrication and Cooling

Using lubrication and cooling methods can greatly improve the drilling process in metal. This can help reduce heat buildup, extend the life of the drill bits, and improve overall drilling performance. Some common lubrication and cooling methods include applying cutting oil, using a coolant, or simply spraying water onto the drilling area to keep the temperature under control.

6. Safety Precautions

Lastly, it’s important to follow safety precautions when drilling through metal. Always wear safety glasses, gloves, and other protective equipment to prevent injuries from flying metal chips. Secure your workpiece properly to prevent slipping or spinning during drilling. And make sure to use the correct drill speed and a stable drilling platform for optimal control and stability.

By understanding these metal drilling basics, you can make informed decisions when choosing drill bits and perform metal drilling tasks with confidence and efficiency.

Different Types of Drill Bits for Metal

When it comes to drilling through metal, having the right tools for the job is essential. There are several different types of drill bits specifically designed for metal, each with its own unique characteristics and uses. Understanding the various types of drill bits available for metal will help you choose the best one for your specific application.

1. Twist Drill Bits

- Twist drill bits are the most common type of drill bits used for metal.

- They have a spiral shape and a sharp point that allows them to cut through metal efficiently.

- Twist drill bits are available in various sizes and lengths, making them versatile for different metal thicknesses.

2. Cobalt Drill Bits

- Cobalt drill bits are made from a high-speed steel alloy that contains cobalt.

- These drill bits are exceptionally hard and durable, making them ideal for drilling through hard metals like stainless steel.

- They can also withstand high temperatures generated during the drilling process, preventing them from melting or losing their hardness.

3. Titanium Drill Bits

- Titanium drill bits are coated with a layer of titanium nitride, which improves their durability and performance.

- These drill bits provide increased strength and can drill through various types of metals, including stainless steel and aluminum.

- The titanium coating also reduces friction and heat, extending the life of the drill bit.

4. Step Drill Bits

- Step drill bits are designed to create holes of different sizes in metal.

- They have a cone-shaped structure with multiple cutting edges at different levels.

- Step drill bits are commonly used for drilling holes in sheet metal, electrical boxes, and conduit.

5. Countersink Drill Bits

- Countersink drill bits are used to create a conical recess on the surface of the metal.

- These recesses allow screws to sit flush with the surface, providing a finished appearance.

- Countersink drill bits typically have a 90-degree angle and come in various sizes.

6. Masonry Drill Bits

- Masonry drill bits are not specifically designed for metal, but they can be used for drilling through soft metals like aluminum.

- These drill bits have a carbide or diamond tip that can penetrate harder surfaces, including concrete and brick.

- However, they may wear out more quickly when used on metal.

Choosing the right type of drill bit for your metalworking projects can make a significant difference in the speed and precision of your drilling. Consider the type of metal you are working with, the thickness of the material, and the specific hole size and shape you need to achieve. By selecting the appropriate drill bit, you can ensure accurate and efficient drilling through metal.

Factors to Consider When Choosing Drill Bits

When it comes to choosing drill bits for metal, there are several factors to consider in order to make the right selection. These factors include:

- Material: The type of material you are drilling into is an important consideration. Different drill bits are designed to handle different types of metal, such as stainless steel or hardened steel. Make sure you choose a drill bit that is specifically designed for the metal you are working with.

- Size: The size of the hole you need to drill will determine the size of the drill bit you should choose. Drill bits come in a variety of sizes and it is important to select the right size for your project.

- Coating: Coating is another important factor to consider when choosing drill bits for metal. Certain coatings, such as titanium nitride or black oxide, can increase the durability and lifespan of the drill bit, as well as improve its performance.

- Point angle: The point angle of the drill bit refers to the angle of the tip. Different point angles are suitable for different materials. For example, a 135-degree point angle is commonly used for drilling into hardened steel, while a 118-degree point angle is suitable for softer materials.

- Shank type: The shank is the part of the drill bit that fits into the drill’s chuck. There are different types of shanks, such as straight shanks or hex shanks. It is important to choose a drill bit with a shank type that is compatible with your drill.

By considering these factors, you can ensure that you choose the best drill bits for your metal drilling needs. Whether you are working with stainless steel, aluminum, or any other type of metal, selecting the right drill bits will help you achieve accurate and efficient results.

Drill Bit Materials for Metal Drilling

When it comes to drilling through metal, choosing the right drill bit material is crucial for achieving optimal results. Different materials offer different advantages and disadvantages, so it’s important to understand the options available.

1. High-Speed Steel (HSS)

- HSS drill bits are the most common type of drill bit material for metal drilling.

- They are made from a combination of high carbon steel and other elements like tungsten and molybdenum.

- HSS bits are known for their durability and can be used for a wide range of metal drilling applications.

- They can withstand high temperatures and are suitable for drilling hard metals like stainless steel.

- However, HSS bits may dull more quickly when drilling through tough metals, requiring more frequent sharpening.

2. Cobalt

- Cobalt drill bits are made from high-speed steel with added cobalt, which improves their performance.

- They are more resistant to heat and can handle drilling through tougher metals like cast iron and titanium.

- These bits have a high red hardness, meaning they can maintain their hardness at elevated temperatures.

- While cobalt bits are more expensive than HSS bits, they offer increased durability and longevity.

- They are an excellent choice for professionals and those frequently drilling through hard metals.

3. Carbide

- Carbide drill bits are the hardest and most brittle option for metal drilling.

- They are made from a fine powder of tungsten carbide and cobalt, which are compressed and sintered.

- Carbide bits are extremely heat-resistant and can maintain their sharpness even at high temperatures.

- They are suitable for drilling through abrasive metals like cast iron, aluminum, and stainless steel.

- However, carbide bits are prone to chipping and require careful handling to prevent breakage.

4. Titanium Nitride (TiN) Coated

- TiN coated drill bits are made from various materials such as HSS or cobalt.

- They feature a thin layer of titanium nitride coating, which enhances their performance.

- TiN coating provides increased hardness, reduced friction, and improved chip evacuation.

- These bits are suitable for drilling through various metals and can last longer than uncoated bits.

- However, the coating can wear off over time, requiring re-coating or replacement of the bit.

When choosing the best drill bit material for metal drilling, it’s important to consider factors like the type of metal being drilled, the desired lifespan of the bit, and the intended application. Each material offers different advantages and choosing the right one can make a significant difference in performance and longevity.

Popular Brands of Drill Bits for Metal

- 1. DeWalt: DeWalt is a well-known brand in the power tool industry and offers a wide range of drill bits for metal. Their drill bits are known for their durability and performance. They have a variety of options for different metal types and thicknesses.

- 2. Bosch: Bosch is another reputable brand that manufactures high-quality drill bits for metal. Their drill bits are known for their precision and reliability. They offer a wide range of options, including cobalt and titanium-coated bits.

- 3. Irwin: Irwin is a trusted brand in the tool industry and offers a variety of drill bits for metal. Their drill bits are known for their strength and durability. They have options for both general-purpose drilling and specialized applications.

- 4. Milwaukee: Milwaukee is a popular brand among professionals and offers a range of drill bits for metal. Their drill bits are known for their excellent performance and long life. They have options for various metal types and drilling applications.

- 5. Makita: Makita is a well-established brand that offers high-quality drill bits for metal. Their drill bits are known for their durability and effectiveness. They offer a variety of options, including cobalt and carbide-tipped bits.

These are just a few of the popular brands that offer drill bits for metal. It’s important to consider factors such as the type of metal you’ll be drilling, the thickness of the metal, and the specific drilling application when choosing the right drill bits for your needs.

Best Drill Bits for Metal on a Budget

If you’re working with metal on a budget, there are still plenty of options available to help you get the job done. While premium drill bits may offer the highest level of performance and durability, there are budget-friendly alternatives that will allow you to complete your projects without breaking the bank. Here are some of the best drill bits for metal on a budget:

1. HSS (High-Speed Steel) Drill Bits

HSS drill bits are a popular choice for drilling through metal due to their affordability and versatility. These bits are made from a high-speed steel alloy, which provides good performance on various metals, including steel, aluminum, and copper. HSS drill bits are typically coated with a black oxide finish to increase their durability and reduce friction.

2. Cobalt Drill Bits

Although slightly more expensive than HSS drill bits, cobalt drill bits offer superior performance and durability, especially when drilling through hard metals like stainless steel. Cobalt drill bits are made from a cobalt alloy, which makes them more resistant to heat and wear. They also have a higher hardness level, allowing them to maintain sharpness for a longer period.

3. Titanium Drill Bits

Titanium drill bits are another budget-friendly option for drilling through metal. These bits are made from high-speed steel coated with a layer of titanium nitride, which provides increased hardness and heat resistance. The titanium coating also reduces friction, allowing for smoother drilling and longer bit life. Titanium drill bits are suitable for drilling through various metals, including steel, aluminum, and brass.

4. Pilot Point Drill Bits

Pilot point drill bits are designed to provide more precise and accurate drilling in metal. These bits have a self-centering pilot point that helps to eliminate the need for a center punch and minimizes walking. Pilot point drill bits are typically made from high-speed steel and offer good performance on different metals. They are an excellent choice for tasks that require clean and accurate holes.

5. Twist Drill Bit Set

If you’re looking for a budget-friendly option that covers a range of sizes, a twist drill bit set is a great choice. These sets usually contain multiple drill bits of various sizes, allowing you to tackle different drilling tasks. Twist drill bits are versatile and suitable for drilling through metal, wood, plastic, and other materials. They are made from high-speed steel or cobalt and offer a good balance between price and performance.

When choosing drill bits for metal on a budget, it’s important to consider the type of metal you’ll be working with and the specific requirements of your project. While budget-friendly options may not offer the same level of performance and durability as premium drill bits, they can still get the job done effectively without breaking the bank.

Tips for Using Drill Bits on Metal

When it comes to drilling through metal, using the right drill bits and techniques is key to getting the job done effectively and safely. Here are some tips to keep in mind:

1. Choose the Right Drill Bit

Selecting the correct drill bit for the type of metal you are working with is crucial. High-speed steel (HSS) drill bits are versatile and can handle a variety of metals, while cobalt bits are specifically designed for harder metals like stainless steel and cast iron. Carbide-tipped drill bits are ideal for drilling into concrete or masonry, but can also work well on softer metals.

2. Use the Appropriate Speed

When drilling through metal, it’s important to use the proper speed setting on your drill. Too high of a speed can cause the bit to overheat and become dull, while too slow of a speed can lead to a poor-quality hole. Refer to the manufacturer’s guidelines or consult an expert to determine the optimal speed for your specific drilling situation.

3. Start with a Pilot Hole

For a clean and precise hole in metal, it’s often recommended to start with a pilot hole. This smaller initial hole helps to guide the larger drill bit and prevents it from wandering or slipping across the surface of the metal. Use a smaller-sized bit and gradually increase the size until you reach the desired hole diameter.

4. Apply Lubrication

When drilling through metal, it’s helpful to use a lubricant or cutting fluid to reduce friction and heat. This not only prolongs the life of the drill bit but also improves the drilling process. Apply the lubricant to the drill bit and the metal surface before starting to drill. Be sure to choose a lubricant suitable for your specific type of metal.

5. Use Proper Technique

To drill through metal effectively, use steady pressure and avoid excessive force that can damage the bit or cause the drill to slip. It’s also important to keep the drill bit perpendicular to the surface of the metal to ensure a straight hole. Take breaks during the drilling process to allow the bit to cool down and prevent overheating.

6. Safety First

Always wear appropriate safety gear, such as safety glasses and gloves, when drilling through metal. Metal shavings and debris can be sharp and potentially harmful. Additionally, be cautious of any sparks that may be produced during the drilling process, especially if working with flammable materials.

7. Maintain and Sharpen Drill Bits

Regularly inspect your drill bits for signs of wear and damage. Dull or damaged bits can be less effective and can cause frustration and delays in your drilling projects. Invest in a drill bit sharpener or take your bits to a professional to ensure they are properly maintained and sharpened.

By following these tips, you can ensure that your drilling projects on metal are successful and efficient. Always take the time to choose the appropriate drill bits and use proper techniques to avoid any issues or damage. Happy drilling!

Maintaining and Sharpening Drill Bits for Metal

Regular maintenance and sharpening of drill bits for metal is essential to ensure their optimal performance and longevity. By taking care of your drill bits, you can save time and money in the long run. Here are a few tips on how to maintain and sharpen your drill bits for metal:

1. Cleaning and Inspection

After each use, it’s important to clean your drill bits thoroughly. Use a wire brush or a soft cloth to remove any debris or metal shavings that may have collected on the surface. Inspect the drill bits for any signs of damage, such as chips or dull edges.

2. Lubrication

Applying lubrication to your drill bits can help reduce friction and heat, which can cause premature wear and tear. Use a high-quality cutting oil or lubricant specifically designed for metal drilling. Apply a small amount of lubrication to the tip of the drill bit before each use.

3. Sharpening

Over time, drill bits can become dull and lose their cutting edge. Sharpening your drill bits regularly will help maintain their performance. There are several methods you can use to sharpen drill bits, including using a grinder, a sharpening stone, or a drill bit sharpener. Follow the manufacturer’s instructions for the specific method you choose.

4. Proper Storage

Storing your drill bits properly is important to prevent damage and keep them organized. Use a drill bit case or a magnetic storage strip to keep your drill bits in one place. Make sure they are clean and dry before storing to prevent rust or corrosion.

5. Replacement

Despite proper maintenance, drill bits will eventually wear out and need replacement. Keep an eye out for signs of excessive wear, such as a loss of cutting efficiency or visible damage. Replace worn-out drill bits promptly to ensure safe and effective drilling.

6. Safety Precautions

When maintaining and sharpening drill bits, it’s important to follow safety precautions to prevent accidents. Always wear safety goggles and protective gloves to protect yourself from metal shavings and sharp edges. Work in a well-ventilated area and keep flammable materials away from the sharpening process.

- Clean your drill bits after each use using a wire brush or soft cloth.

- Inspect the drill bits for any signs of damage, such as chips or dull edges.

- Apply lubrication to the tip of the drill bit before each use.

- Sharpen your drill bits regularly using a grinder, sharpening stone, or drill bit sharpener.

- Store your drill bits properly in a drill bit case or magnetic storage strip.

- Replace worn-out drill bits promptly.

- Follow safety precautions, such as wearing goggles and gloves, when maintaining and sharpening drill bits.

By following these tips, you can ensure that your drill bits for metal stay sharp and perform optimally, allowing you to tackle any metal drilling project with ease.

FAQ:

What types of drill bits are best for drilling through metal?

There are several types of drill bits that are suitable for drilling through metal. Some of the best options include twist drill bits, cobalt drill bits, carbide drill bits, and titanium drill bits.

What is the difference between HSS and cobalt drill bits?

HSS stands for High-Speed Steel, which is a type of tool steel commonly used in drill bits. Cobalt drill bits, on the other hand, have a higher percentage of cobalt in their composition, making them more resistant to heat and wear. This means that cobalt drill bits can drill through harder materials and maintain their sharpness for longer.

How do I choose the right size drill bit for my metal project?

To choose the right size drill bit for your metal project, you need to consider the thickness of the metal and the size of the hole you want to drill. It’s important to select a drill bit that is slightly smaller than the desired hole size to allow for easy drilling and prevent damage to the metal.

What are some tips for drilling through metal with a drill bit?

When drilling through metal with a drill bit, it’s important to use a slow speed and steady pressure to avoid overheating the bit. Lubricating the bit with cutting oil can also help to reduce heat and extend the life of the drill bit. Additionally, using a center punch to create a starting point for the drill bit can make it easier to drill through metal.

Video: