Choosing the Best Drill Bits: A Comprehensive Guide

When it comes to drilling, having the right drill bit can make all the difference. Whether you’re a professional contractor or a DIY enthusiast, using the correct drill bit is essential for achieving accurate and efficient results. With so many options available on the market, it can be overwhelming to choose the best drill bits for your specific needs.

So, how do you go about selecting the best drill bits? It starts with understanding the different types of drill bits available and their specific applications. From twist drill bits to spade bits and masonry bits, each type has its own unique features and uses. By familiarizing yourself with the various options, you can make an informed decision based on the specific material you’ll be drilling into.

Another important factor to consider when choosing drill bits is the material they are made of. High-speed steel (HSS) bits are commonly used for drilling into wood, plastic, and softer metals, while cobalt drill bits are suitable for drilling into harder materials like stainless steel and cast iron. Carbide-tipped drill bits are known for their durability and are ideal for drilling into masonry and concrete.

In this comprehensive guide, we’ll take a closer look at the different types of drill bits available, their material composition, and their specific applications. We’ll also provide tips and recommendations to help you choose the best drill bits for your projects, ensuring you achieve the best results every time.

Whether you’re a seasoned professional or a weekend warrior, having the right drill bits in your toolbox is crucial for success. By understanding the various types and materials available, you can confidently tackle any drilling project with ease and precision.

Understanding Drill Bit Types

When it comes to choosing the right drill bit for your project, it’s important to understand the different types available and their specific uses. This knowledge will ensure that you select the appropriate bit for the task at hand, resulting in more efficient and effective drilling.

Twist Bits

Twist bits are the most common and versatile type of drill bit. They have a helical groove, or flute, that allows for better chip evacuation and improved cutting action. Twist bits can be used for drilling into a variety of materials, including wood, plastic, and metal. However, they may not be the best option for drilling through concrete or masonry.

Spade Bits

Spade bits, also known as paddle bits, have a flat, paddle-shaped tip and are primarily used for drilling large holes in wood. They are commonly used for tasks such as drilling holes for wiring or plumbing. Spade bits can be a bit aggressive and may cause splintering or tearout in certain types of wood, so it’s important to use them carefully.

Forstner Bits

Forstner bits are designed for drilling clean and precise flat-bottomed holes in wood. They have a center point and a shearing rim that allows for smooth cutting action. These bits are ideal for drilling holes for dowels, as well as for creating mortises or holes for door hinges. However, they are not suitable for drilling into metal or other hard materials.

Step Bits

Step bits, also called cone bits or unibits, are designed for drilling holes of various sizes in thin materials, such as sheet metal or plastic. They have a tapered shape with multiple cutting edges that allow for easy enlargement of holes. Step bits are particularly useful for electrical or HVAC work, where multiple hole sizes may be needed.

Masonry Bits

Masonry bits are specifically designed for drilling into concrete, brick, or stone. They have a carbide tip that is able to withstand the hardness of these materials. When using masonry bits, it’s important to use a hammer drill or a drill with a hammer function to provide the necessary impact for effective drilling.

Tile Bits

Tile bits, also known as glass and ceramic bits, are designed to drill holes in tiles, glass, ceramics, and other brittle materials. They have a spear-shaped carbide tip that prevents the bit from slipping or skidding on the smooth surface. Tile bits should be used at a slow speed and with minimal pressure to prevent cracking or damaging the material.

Countersink Bits

Countersink bits are used to create a conical recess in a material, allowing for the flush installation of screws or bolts. These bits have a tapered drill bit and a separate countersink cutter. Countersink bits are commonly used in woodworking to create professional-looking finish work.

Conclusion

By understanding the different types of drill bits available and their specific uses, you can make an informed decision when choosing the right one for your project. Whether you’re drilling into wood, metal, concrete, or tile, there is a drill bit designed to meet your needs.

Materials Used in Drill Bits

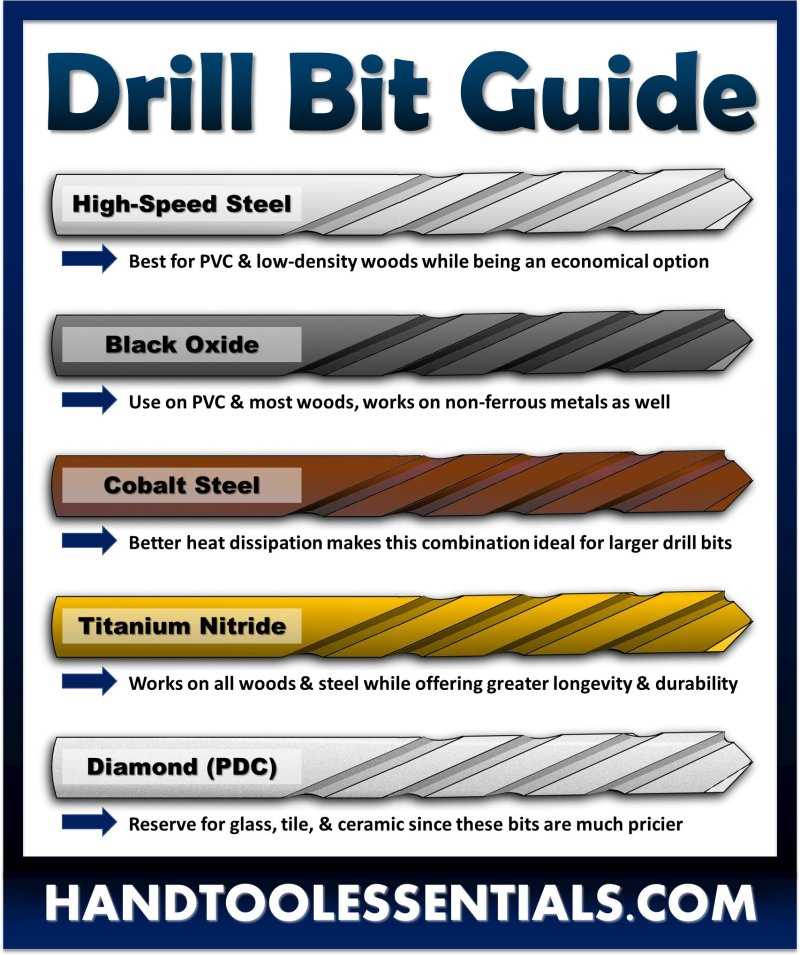

Drill bits are made from a variety of materials, each chosen for its specific properties and suitability for different drilling applications. The material used in a drill bit can significantly impact its performance and durability. Let’s take a closer look at some of the most common materials used in drill bits:

High-Speed Steel (HSS)

High-speed steel (HSS) is the most common material used in drill bits. It is a type of tool steel that contains various metals, such as tungsten, molybdenum, chromium, and vanadium, which enhance its hardness and heat resistance. HSS drill bits are known for their excellent durability and ability to withstand high temperatures during drilling.

Cobalt

Cobalt drill bits are a type of high-speed steel drill bits that contain a higher percentage of cobalt. Cobalt enhances the hardness and heat resistance of the drill bit, making it suitable for drilling hard materials like stainless steel and cast iron. Cobalt drill bits can withstand higher drilling temperatures compared to regular HSS drill bits.

Carbide

Carbide drill bits are made from a compound of tungsten carbide particles embedded in a metallic binder. Carbide is an extremely hard and durable material that is ideal for drilling through tough materials like concrete, brick, and tile. Carbide drill bits maintain their sharpness for a longer time compared to HSS or cobalt drill bits.

Titanium Nitride (TiN) Coated

Some drill bits, especially those made from HSS or cobalt, are coated with a thin layer of titanium nitride (TiN). This coating enhances the hardness of the drill bit and provides increased resistance against wear and heat. TiN coated drill bits are commonly used for drilling into materials like wood, plastic, and metal.

Diamond

Diamond drill bits are perfect for drilling through incredibly hard materials like glass, ceramics, and stone. These drill bits feature diamond particles embedded on the tip or edge, which allows for precise and clean drilling. Diamond drill bits are often used in specialized applications, such as glass art and construction.

Summary

Choosing the right material for your drill bits is essential for achieving efficient and precise drilling results. High-speed steel (HSS) is suitable for most general-purpose drilling applications, while cobalt is best for drilling hard materials. Carbide is ideal for tough materials like concrete, and diamond is perfect for drilling through extremely hard substances. Titanium nitride (TiN) coating can provide added durability and resistance to wear. Consider the material you’ll be drilling and select the appropriate drill bits to ensure optimal performance and longevity.

Drill Bit Coatings: Which One is Right for You?

Drill bit coatings play a crucial role in the performance and longevity of the drill bit. They provide a protective barrier between the bit and the material being drilled, reducing friction, heat, and wear. Choosing the right coating can significantly improve your drilling experience. Here are some of the most common drill bit coatings and their benefits:

Titanium Nitride (TiN) Coating

- Benefits: TiN coating is known for its excellent wear resistance and high temperature resistance. It is ideal for drilling into hard materials like stainless steel and cast iron. The gold-colored coating also helps to reduce friction, allowing for smoother drilling and increased drilling speeds.

- Limitations: While TiN coating is highly durable, it may not be suitable for use with soft materials as the coating can cause excessive heat buildup.

Cobalt Coating

- Benefits: Cobalt coating is extremely hard and provides excellent heat resistance. It can withstand high drilling temperatures and is well-suited for drilling through tough materials like hardened steel and stainless steel. The blue-coated bits are also easy to identify, making them a popular choice among professionals.

- Limitations: Cobalt-coated bits can be more expensive than other coatings, and they may not be necessary for everyday drilling tasks.

Black Oxide Coating

- Benefits: Black oxide coating offers increased durability and improved lubricity. It provides good corrosion resistance and is suitable for general-purpose drilling in materials like wood, plastic, and mild steel. The black coating also helps to reduce friction and heat during drilling.

- Limitations: While black oxide-coated bits are versatile, they may not perform as well as specialized coatings when drilling into harder materials.

Carbide Tipped Coating

- Benefits: Carbide-tipped bits are the go-to choice for drilling into masonry, concrete, and tiles. The carbide coating provides excellent hardness, wear resistance, and heat resistance. These bits are also known for their long lifespan and ability to maintain sharpness even after extended use.

- Limitations: Carbide-tipped bits are not suitable for drilling into metal or wood as they may cause damage to the material.

When choosing a drill bit coating, consider the type of material you will be drilling into and the desired durability and performance. It’s important to match the coating to the specific application in order to achieve the best results.

Drilling Speeds and Feeds: The Key to Efficiency

Introduction

When it comes to drilling, achieving optimal efficiency is crucial. One of the key factors that determines drilling efficiency is the selection of appropriate speeds and feeds. The right speeds and feeds can greatly improve productivity and accuracy, while improper choices can result in poor performance, damaged tools, and wasted time.

Understanding Speeds and Feeds

Speed refers to the rotational speed of the drill bit, usually measured in revolutions per minute (RPM). Feed rate, on the other hand, refers to the rate at which the drill bit moves into the material being drilled, typically measured in inches per minute (IPM). Both speed and feed have a significant impact on the drilling process.

Speed: The speed at which the drill bit rotates affects the cutting action. In general, higher speeds create more heat and friction, which can result in faster material removal and increased drilling efficiency. However, excessive speed can also lead to overheating and tool wear. Therefore, it is important to find the right balance to maximize efficiency without compromising tool life.

Feed: The feed rate determines how quickly the drill bit advances into the material. A higher feed rate increases the chip load and can enhance drilling efficiency. However, excessive feed can cause the drill bit to deflect, resulting in poor hole quality and decreased tool life. It is crucial to choose a feed rate that allows for smooth chip evacuation and prevents tool overload.

Determining the Right Speeds and Feeds

There are several factors to consider when determining the ideal speeds and feeds for a drilling operation:

- Material being drilled: Different materials have different machining characteristics, and therefore, require different speeds and feeds. Harder materials generally require slower speeds and lower feed rates to prevent tool damage.

- Drill bit type: The type of drill bit being used, such as twist drills, step drills, or solid carbide drills, can influence the recommended speeds and feeds. Different drill bits have different cutting geometries and capabilities.

- Drill size: Larger drill bits require slower speeds and lower feed rates to ensure proper chip evacuation and prevent tool overload.

- Cutting conditions: Other factors like coolant usage, machine rigidity, and workpiece stability can also affect the recommended speeds and feeds. It is essential to account for these factors to achieve optimal performance.

Using Speeds and Feeds Tables

To simplify the process of determining the appropriate speeds and feeds, manufacturers provide speeds and feeds tables that offer recommended settings for different materials and drill bit types. These tables list the recommended speed and feed rate combinations based on various parameters, taking the guesswork out of the equation.

It is important to note that speeds and feeds tables are just a starting point. Fine-tuning may be required based on specific application conditions and the desired trade-off between tool life and drilling efficiency. Experimenting with different settings and monitoring the results is crucial to optimize performance.

Conclusion

Choosing the right speeds and feeds is essential for achieving optimal drilling efficiency. By understanding the impact of speed and feed on the cutting process, considering various factors, and consulting speeds and feeds tables, drillers can ensure maximum productivity and tool performance. Proper speeds and feeds not only improve efficiency but also prolong tool life, saving both time and money in the long run.

Choosing the Right Size Drill Bit

When it comes to choosing the right size drill bit, there are a few important factors to consider. The size of the hole you need to drill, the material you are drilling into, and the type of drill you are using are all key considerations.

1. Hole Size

The first step in choosing the right size drill bit is to determine the size of the hole you need to drill. This can be done by measuring the diameter of the hole, either with a ruler or by using a hole gauge. Once you know the diameter of the hole, you can choose a drill bit that matches or is slightly larger than that size.

2. Material

The material you are drilling into is also an important factor to consider. Different materials, such as wood, metal, or concrete, may require different types of drill bits. For example, wood drill bits are designed with a different shape and angle than metal drill bits in order to achieve the best results. Make sure to choose a drill bit that is specifically designed for the material you will be drilling into.

3. Drill Type

The type of drill you are using can also affect the size of drill bit you need. Some drills have a chuck size limit, which restricts the size of the drill bit that can be used. It is important to check the specifications of your drill to ensure that the drill bit you choose is compatible.

4. Bit Types

There are also different types of drill bits available for different drilling applications. Some common types include twist bits, spade bits, and hole saws. Each type of bit is designed for specific tasks and materials, so it is important to choose the right type of bit for your needs.

5. Recommended Bit Sizes

If you are unsure of the best drill bit size to use, there are general recommendations based on the size of the screw or anchor you will be using. For example, if you are drilling a hole for a #8 screw, a 1/8 inch drill bit is typically recommended. However, it is always best to consult the manufacturer’s recommendations for the specific screw or anchor you will be using.

| Screw/Anchor Size | Recommended Drill Bit Size |

|---|---|

| #4 | 3/32 inch |

| #6 | 7/64 inch |

| #8 | 1/8 inch |

| #10 | 3/16 inch |

| #12 | 1/4 inch |

Remember, it is always a good idea to have a set of drill bits in various sizes on hand to ensure you have the right size for any project that may come your way. By considering the hole size, material, drill type, and recommended bit sizes, you can confidently choose the right size drill bit for your next drilling project.

Tips for Proper Drill Bit Maintenance

Proper maintenance of drill bits is essential for their longevity and optimal performance. Here are some tips to help you keep your drill bits in top shape:

1. Clean the Drill Bits Regularly

After each use, it’s important to clean the drill bits thoroughly. Remove any debris or metal shavings that may have accumulated on the surface or inside the flutes of the bit. You can use a wire brush or compressed air to clean the bits effectively. Cleaning the bits will prevent any build-up that may affect their drilling capabilities.

2. Inspect for Damage

Before using the drill bits, always inspect them for any signs of damage. Look for chipped edges, worn-out tips, or bent shafts. Using damaged drill bits can lead to poor drilling results or even accidents. Replace any damaged or worn-out bits immediately to ensure safe and efficient drilling.

3. Store the Bits Properly

Proper storage is crucial for maintaining the quality of your drill bits. Store them in a clean, dry place away from moisture and extreme temperatures. You can use a drill bit storage case or organizer to keep them organized and protected from damage. Avoid storing the bits loosely or in a crowded toolbox where they might rub against each other, causing unnecessary wear and tear.

4. Sharpen the Bits when Needed

Over time, drill bits can become dull and lose their cutting edge. When you notice that the bits aren’t drilling as efficiently as before, it’s time to sharpen them. You can use a drill bit sharpener or a bench grinder to restore the sharpness. Follow the manufacturer’s instructions for the specific type of drill bit you have, and take appropriate safety precautions while sharpening.

5. Use the Right Drill Bit for the Job

Using the wrong drill bit for the material or task at hand can quickly damage the bit. Always choose the right type of drill bit for the specific application, whether it’s drilling in wood, metal, concrete, or other materials. Using the correct bit will not only ensure efficient drilling but also prevent premature wear and tear.

6. Keep the Bits Lubricated

Lubricating the drill bits can greatly extend their lifespan and improve their performance. Apply a few drops of cutting oil or lubricant to the bit before starting the drilling process. This will help reduce friction and heat, preventing the bit from overheating and wearing out quickly. Reapply the lubricant periodically during prolonged drilling to maintain optimal performance.

By following these maintenance tips, you can keep your drill bits in excellent condition and ensure long-lasting performance for all your drilling needs.

Specialty Drill Bits for Unique Applications

In addition to the standard drill bits that are commonly used for general drilling tasks, there are also specialty drill bits available for unique applications. These specialty drill bits are designed to meet the specific needs of different industries and projects. Here are some of the most common specialty drill bits and their unique applications:

1. Hole saw bits

Hole saw bits are used to create larger holes in materials such as wood, plastic, and metal. They consist of a circular saw blade with sharp teeth that can cut through the material, creating a clean and precise hole. Hole saw bits are commonly used in plumbing and electrical work.

2. Masonry drill bits

Masonry drill bits are specifically designed for drilling into materials such as concrete, brick, and stone. They feature a carbide tip that is able to withstand the hardness of these materials, allowing for efficient drilling. Masonry drill bits are commonly used in construction and renovation projects.

3. Glass and tile drill bits

Glass and tile drill bits are designed to drill through fragile materials such as glass and ceramic tiles. They feature a spear-shaped carbide tip that prevents the material from cracking or shattering during the drilling process. Glass and tile drill bits are commonly used in bathroom and kitchen installations.

4. Forstner bits

Forstner bits are used to create flat-bottomed holes with smooth sides in materials such as wood. They have a cylindrical shape with a pilot tip in the center and sharp cutting edges on the sides. Forstner bits are commonly used in fine woodworking and cabinetry projects.

5. Step drill bits

Step drill bits are used to create holes of different sizes in materials such as metal and plastic. They have a conical shape with multiple steps of increasing diameter. Step drill bits are commonly used in electrical and automotive applications.

6. Countersink drill bits

Countersink drill bits are used to create a conical recess in a material for screws to sit flush with the surface. They have a drill bit at the center and a tapered outer section that creates the countersink. Countersink drill bits are commonly used in woodworking and metalworking projects.

7. Auger bits

Auger bits are used to drill deep, large-diameter holes in materials such as wood. They have a helical-shaped blade that helps remove the material as the bit rotates. Auger bits are commonly used in construction and carpentry projects.

8. PCB drill bits

PCB (Printed Circuit Board) drill bits are used to drill small, precise holes in circuit boards. They are made of solid carbide and feature a thin, sharp tip for accurate drilling. PCB drill bits are commonly used in electronics manufacturing.

These are just a few examples of the specialty drill bits available for unique applications. By choosing the right drill bit for your specific project, you can ensure efficient and accurate drilling results.

Top Brands and Best Drill Bit Sets

Bosch

Bosch is a well-known and reputable brand in the power tool industry. They offer a wide range of high-quality drill bits that are designed to be durable and provide excellent performance. Bosch drill bits are known for their precision and effectiveness in drilling through various materials such as wood, metal, and concrete.

DeWalt

DeWalt is another popular brand that is trusted by professionals and DIY enthusiasts alike. Their drill bit sets are designed for versatility and can handle a wide range of drilling tasks. DeWalt drill bits are known for their durability and efficiency, making them a reliable choice for any drilling project.

Makita

Makita is a well-respected brand that is known for its high-quality power tools. Their drill bit sets are no exception, offering excellent performance and durability. Makita drill bits are designed with precision and are capable of drilling through various materials with ease.

Irwin

Irwin is a trusted brand that has been around for many years. They offer a wide selection of drill bit sets that cater to different drilling needs. Irwin drill bits are known for their durability and reliability, making them a favorite among professionals and DIYers.

Best Drill Bit Sets

When it comes to choosing the best drill bit sets, there are several factors to consider. These include the type of materials you will be drilling, the size of the drill bits you need, and your budget. Here are some top drill bit sets that are highly recommended:

- Bosch 60-Piece Black Oxide Metal Drill Bit Set

- DeWalt 80-Piece Drill and Drive Set

- Makita 75-Piece Metric Drill and Screw Bit Set

- Irwin Tools 3018002B Metal Index Set

These drill bit sets offer a variety of sizes and types of drill bits that can handle different drilling tasks. They are made from high-quality materials and are designed to provide long-lasting performance.

FAQ:

What are some factors to consider when choosing drill bits?

There are several factors to consider when choosing drill bits, including the material you’re drilling into, the type of drill you have, the size of the hole you need to make, and the type of bit you need for the job.

What types of drill bits are available?

There are several types of drill bits available, including twist drill bits, spade drill bits, hole saw drill bits, masonry drill bits, and brad point drill bits.

What is the best type of drill bit for drilling into metal?

When drilling into metal, it’s generally best to use twist drill bits made from high-speed steel or cobalt. These bits are designed to withstand the high heat and friction generated when drilling into metal.

What are some tips for choosing the right drill bit size?

When choosing the right drill bit size, it’s important to consider the size of the hole you need to make. You can use a drill bit size chart to determine the appropriate size based on the diameter of the hole. It’s also a good idea to start with a smaller bit and gradually increase the size if necessary.

What is the difference between a brad point drill bit and a twist drill bit?

A brad point drill bit is designed for drilling clean, precise holes in wood. It has a sharp, pointed tip that helps prevent the bit from wandering or slipping off the mark. In contrast, a twist drill bit is designed for drilling into a variety of materials, including wood, metal, and plastic. It has a spiral-shaped groove that helps remove material as you drill.

Video: