Best wood for bow drill eastern us

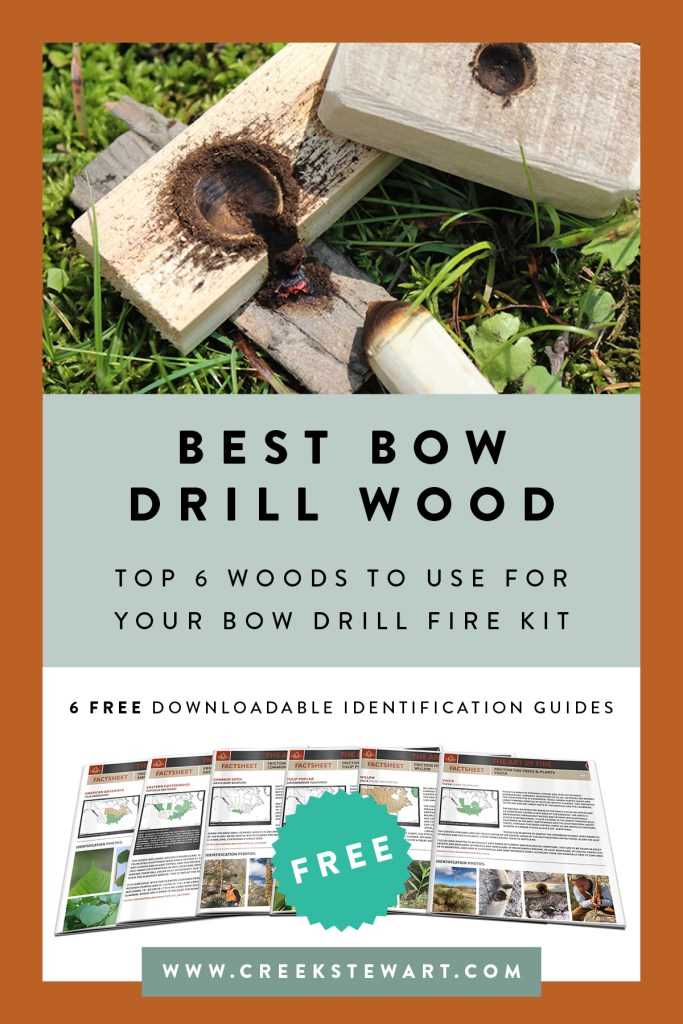

If you’re interested in primitive fire-making techniques, you’ve likely encountered the bow drill method. This ancient technique involves using a wooden bow and a spindle to create friction and generate heat, eventually leading to the creation of fire. One crucial element in this process is the choice of wood, as not all types of wood are suitable for the bow drill. In the eastern United States, several types of wood are commonly used for this purpose, each with its own unique characteristics and advantages.

One of the most popular woods for the bow drill in the eastern US is cedar. Cedar wood is known for its straight grain and low friction properties, making it an excellent choice for generating heat through friction. Additionally, cedar tends to produce long, stringy fibers that easily catch fire, increasing the success rate of fire creation. This makes cedar an ideal wood for beginners or those looking for a reliable option.

Another commonly used wood is tulip poplar. Tulip poplar is a dense hardwood that is readily available in the eastern US. It has a straight grain and a moderate level of hardness, making it suitable for the bow drill’s requirements. The wood shavings produced by tulip poplar are also highly flammable, enabling efficient fire creation. Its availability and ease of use make tulip poplar a popular choice among bow drill enthusiasts in the eastern US.

Lastly, oak wood is another excellent option for the bow drill in the eastern US. Oak is a hardwood known for its strength and durability, making it a suitable choice for the spindle of the bow drill. Due to its high density, oak produces fine dust when friction is applied, which can quickly ignite and sustain a fire. Oak’s reliability and long-lasting qualities make it a preferred choice for those looking for a wood that can withstand repeated use.

Best Wood for Bow Drill in Eastern US

The Eastern United States offers a variety of wood options for building a bow drill, a primitive fire-starting tool. To create a bow drill, you need three main components: a bow, a drill or spindle, and a fireboard or base. Choosing the right type of wood for each component is crucial for obtaining the best results.

Bow: When it comes to selecting wood for the bow, flexibility is key. A good choice for the Eastern US region is hickory, as it is known for its strength and flexibility. The bow should be approximately the length of your arm and have a slight curve to create tension when rotating the drill.

Drill/Spindle: The drill or spindle is the part that generates friction against the fireboard to create an ember. For this component, a hard, straight-grained wood is ideal. Osage orange, also known as hedge apple, is a popular choice in Eastern US because of its density and durability. Other suitable options include dogwood and cedar.

Fireboard/Base: The fireboard provides a stable surface for the drill to create friction, while the base catches the ember. Softwoods with a low resin content are preferred for the fireboard, as they produce less smoke and have a lower chance of igniting prematurely. Eastern red cedar and cypress are common choices in the Eastern US.

Remember, when working with a bow drill, it is essential to find dry wood to ensure optimal fire-starting conditions. Additionally, proper technique, such as applying consistent pressure and maintaining a steady rhythm, is crucial for success. Experimentation and practice will help you determine which wood combinations work best for your specific location and weather conditions.

Factors to Consider

When selecting the best wood for a bow drill in the eastern US, there are several factors that need to be considered. These factors will ultimately determine the success of your fire-making efforts. Here are some important things to keep in mind:

- Density: The density of the wood is crucial as it affects the friction and heat generated during the drilling process. Choose a wood with a medium to high density for optimal results. The harder the wood, the better it will be at producing the necessary friction for creating fire.

- Durability: The durability of the wood is another important factor to consider. You want a wood that is tough and can withstand the pressure and heat generated during the drilling process. Avoid using woods that are prone to splintering or breaking easily.

- Dryness: Dry wood is essential for a successful bow drill. Moisture in the wood can hinder the friction and heat needed to create fire. Look for dead or seasoned wood that has had time to dry out naturally. Avoid using freshly cut or green wood.

- Straightness: Choosing a wood that is straight and free from knots or branches will make it easier to carve and use as a bow drill. A straight wood rod will provide a smooth and even surface for drilling, resulting in more efficient fire-making.

- Availability: Consider the availability of the wood in your area. Look for local woods that are abundant and easy to find. Using readily available wood will make it easier to replace and continue your fire-making efforts.

By considering these factors, you can select the best wood for a bow drill in the eastern US and increase your chances of successfully creating fire in a survival situation.

Eastern US Wood Types

The Eastern US is home to a variety of wood types that are ideal for a bow drill, a traditional fire-starting method. These wood types have specific characteristics that make them suitable for creating a bow drill kit and generating friction to ignite a fire.

Pine: Pine wood, found abundantly in the Eastern US, is one of the top choices for a bow drill. It is known for its resinous properties, which helps produce friction and heat when rubbed against another piece of wood. The resin acts as a lubricant, making it easier to create the necessary friction to start a fire.

Birch: Birch wood, another common tree in the Eastern US, is also a popular choice for a bow drill. Its smooth bark and relatively straight grain make it easy to fashion into a drill and hearth board. Birch is known for burning hot and fast, making it an excellent wood for fire-starting.

Hickory: Hickory wood, mainly found in the Eastern US, is highly regarded for its durability and strength. These characteristics make it a suitable choice for the bow limb, as it can endure the pressure exerted by the bowstring while creating friction. Hickory wood is also known for generating a good amount of heat when used in a bow drill set.

Oak: Oak wood, a staple of the Eastern US, is another preferred option for a bow drill. Its dense and hardwood properties allow for greater longevity when creating a bowstring or drill. Oak wood also produces excellent coals, which can be easily ignited into a fire with tinder.

These are just a few examples of the wood types found in the Eastern US that are suitable for a bow drill. It’s important to consider the specific qualities and characteristics of each wood type to determine which one will work best for your needs and location.

Top Wood Choices for Bow Drill Eastern US

If you are in the Eastern US and looking to make a fire using a bow drill, it is essential to choose the right type of wood for your spindle and fireboard. The success of your fire-making technique depends on the friction generated between these two components, so selecting the best wood choices is crucial.

1. Hardwood:

Hardwood species, such as oak or hickory, are excellent choices for both the spindle and fireboard. They are dense and durable, able to withstand the high temperatures generated by the friction. The hardwood’s density helps create the necessary friction to produce an ember, increasing your chances of success.

2. Softwood:

Softwood species, like cedar or pine, are also suitable choices for the fireboard. They tend to be more readily available in the Eastern US and are easier to work with due to their softer nature. However, it is recommended to use a hardwood spindle, as softwood spindles may wear down quickly due to the increased friction.

3. Dead and Dry Wood:

When selecting wood for your bow drill, it is crucial to use dead and dry wood. Moisture in the wood can hinder friction, making it harder to generate the required heat for an ember. Look for dry branches or fallen trees that have been exposed to the elements for a significant amount of time.

- Remember, regardless of the wood choice, it is essential to prepare your materials properly. Cut them to the right size, remove any bark, and ensure they are as smooth and cylindrical as possible.

- Experimentation is key when it comes to finding the best wood for your bow drill. Be sure to try different combinations of woods and observe how they perform.

Overall, understanding the properties and characteristics of different wood types can greatly improve your success in making a fire with a bow drill in the Eastern US. Choose the right wood, prepare it well, and practice your technique for the best results.

Wood Preparation and Storage

Properly preparing and storing wood is crucial for successful bow drill fire starting in the eastern US. Here are some essential tips to ensure you have the best wood for your bow drill:

1. Wood Selection:

Choose hardwoods such as oak, hickory, or ash for your bow drill set. These woods are known for their density and durability, which are important factors for creating friction and generating heat when using a bow drill.

2. Wood Drying:

It is important to use dry wood for your bow drill set. Moisture in the wood can make it difficult to create enough friction and generate the necessary heat. Cut and collect your wood well in advance to allow it to naturally dry. Split larger logs into smaller pieces to speed up the drying process.

3. Wood Storage:

Store your prepared bow drill wood in a dry and well-ventilated area. A shed or covered area is ideal. Make sure the wood is elevated off the ground to prevent moisture absorption. Keep your wood covered with a tarp or plastic to protect it from rain or snow.

4. Wood Processing:

When processing the wood for your bow drill set, remove any bark or debris, which can interfere with the friction. Cut the wood into precise lengths and shapes according to the specific requirements of your bow drill kit. Smooth out any rough edges or splinters that could affect the spinning motion.

5. Wood Maintenance:

Regularly inspect and maintain your bow drill wood. Check for signs of decay or cracking, as these can affect its performance. Replace any damaged or worn-out parts with fresh wood to ensure optimal results.

By following these wood preparation and storage tips, you can increase your chances of successfully starting a fire with a bow drill in the eastern US.

5 Best wood for bow drill eastern us

Features

| Color | beige |

Features

| Part Number | TE570_5Blades |

| Color | Green |

| Size | Bow Saw + 5 Blades |

Features

| Part Number | TBM001 |

| Model | TBM001 |

| Color | Beech |

| Size | 32.5 x 6cm |

Features

- [Size Reference]: This bow making kit includes 2, 3, 4, 5 and 6 inch templates. There is an 8mm/0.3 inch wide seam allowance in the center. Suitable for all sizes of bows.

- [Bow Making Tool]: these bow making templates come in 5 different sizes, providing you with a comprehensive selection to meet your needs.

- [Multi-functional Tool]: Unleash your creativity with this multi-functional bow making tool. Whether you are designing hair bows, embellishing party decorations, or indulging in DIY crafts, this tool is the perfect choice for you.

- [Quality Material]: our bow making templates are made of high quality plywood, smooth surface, durable and can serve you for a long time.

- [Perfect Gift]: The bow making template kit is a perfect gift for beginners, hand sewing enthusiasts to inspire creativity and do-it-yourself ability.

Features

| Part Number | JDJH-HW20201217 |

| Color | Orange |

Features

| Part Number | Drfeifyao4t7hk8s3 |

| Model | Drfeifyao4t7hk8s3 |

Features

| Part Number | ROU66844 |

| Model | ROU66844 |

| Color | Brown |

| Release Date | 2012-12-13T00:00:01Z |

| Language | Italian |

Features

| Part Number | BAH5112 |

| Model | 51-12 |

| Color | Tan/Brown |

| Size | 12 Inch |

| Language | English |

Features

| Part Number | D04026 |

| Color | Beige |

Question and answer:

Why is wood preparation important?

Wood preparation is important to remove dirt, debris, and moisture from the wood surface, ensuring better adhesion and finish when applying stains, paint, or other treatments.

What are the steps involved in wood preparation?

The steps involved in wood preparation typically include cleaning the wood surface, sanding to remove imperfections, and applying a wood conditioner or primer before applying any stains or finishes.

How do you clean a wood surface?

To clean a wood surface, you can use a mild soap and water solution, or a wood cleaner specifically designed for the task. Gently scrub the surface using a soft brush or sponge, and rinse thoroughly.

Why is it important to store wood properly?

Proper wood storage prevents damage from moisture, mold, insects, and warping. It ensures that the wood remains in good condition and ready for use when needed.

What are the best practices for wood storage?

The best practices for wood storage include keeping it in a dry and well-ventilated area, away from direct sunlight and extreme temperatures. Storing wood off the ground and using proper supports or racks can help prevent warping and moisture damage. It is also important to stack wood in a way that allows for air circulation.

Why is wood preparation important?

Wood preparation is important because it helps to enhance the quality and longevity of wood products. It involves removing moisture, rough surfaces, and any impurities that can affect the strength, aesthetics, and performance of the wood.

Conclusion

In conclusion, proper wood preparation and storage are essential for preserving the quality and durability of wood products. By ensuring that the wood is appropriately seasoned, free from moisture, and protected from pests and decay, we can maximize its strength and longevity. Additionally, storing wood in a well-ventilated and stable environment helps to minimize the risk of warping and shrinking. By following these guidelines, we can optimize the performance and lifespan of our wood materials, whether they are used for construction, furniture, or other purposes. Remember to always prioritize proper wood preparation and storage to ensure the best possible results.