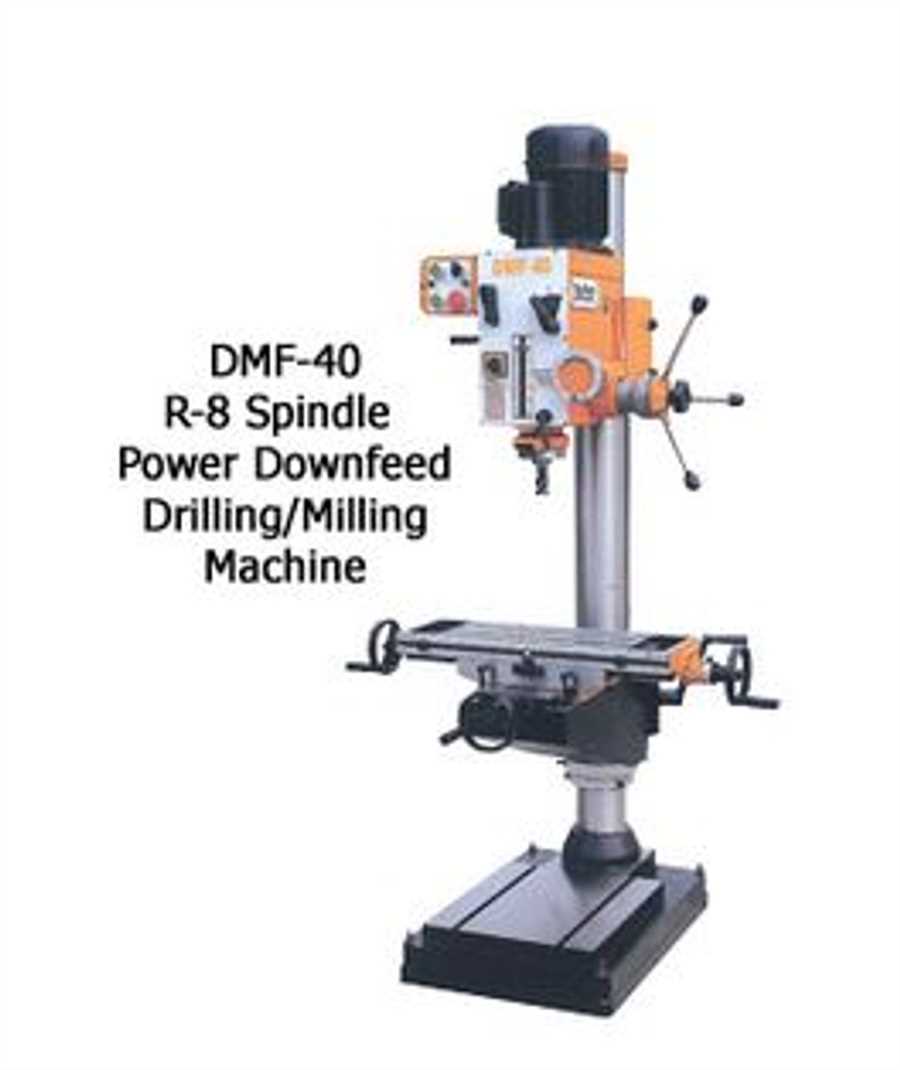

Best vertical drilling machine

When it comes to drilling tasks that require precision and efficiency, a vertical drilling machine is an indispensable tool. Designed specifically for vertical drilling operations, these machines have become a staple in various industries such as construction, manufacturing, and woodworking.

With a vertical drilling machine, you can easily create accurate and perfectly straight holes in a variety of materials, including metal, wood, and plastic. The machine’s vertical orientation allows for greater stability and control, ensuring that each hole is drilled with maximum precision.

One of the key features that make a vertical drilling machine the best choice is its powerful motor. Equipped with a high-performance motor, these machines can effortlessly drill through even the toughest materials. Additionally, many models offer variable speed control, allowing you to choose the optimal drilling speed for each task.

Another important aspect to consider when choosing the best vertical drilling machine is its versatility. Look for a machine that offers adjustable drilling angles and depth settings, as well as a range of drilling accessories. This will allow you to tackle a wide range of drilling projects with ease and efficiency.

In conclusion, a best vertical drilling machine is an essential tool for any professional or hobbyist who requires precise and efficient drilling. With its robust motor, stability, and versatility, this machine will make your drilling tasks a breeze, whether you are working with metal, wood, or plastic.

Benefits of Using a Vertical Drilling Machine for Your Project

A vertical drilling machine is a powerful tool that can greatly benefit your project. Whether you are a professional contractor or a DIY enthusiast, this machine offers several advantages that make it an essential tool in your arsenal. From its precision and versatility to its efficiency and ease of use, here are the key benefits of using a vertical drilling machine for your project.

Precision and Versatility

One of the main advantages of a vertical drilling machine is its precision. This machine allows you to drill holes with great accuracy, ensuring that your project is carried out to the highest standard. With adjustable speed and depth settings, you can easily achieve the desired result, whether you are working with wood, metal, or other materials. Additionally, a vertical drilling machine offers versatility, allowing you to perform various drilling tasks, such as creating holes of different sizes and angles, as well as tapping threads.

Efficiency and Ease of Use

Another benefit of using a vertical drilling machine is its efficiency and ease of use. This machine is designed to save you time and effort by providing a stable and controlled drilling operation. With its vertical orientation, it allows you to work on larger workpieces without any difficulty. The automatic and adjustable feed mechanism ensures a smooth drilling process, reducing the risk of mistakes or accidents. Moreover, the machine’s user-friendly controls and ergonomic design make it easy to operate, enabling you to work efficiently and comfortably.

In conclusion, a vertical drilling machine offers several benefits that can enhance your project. Its precision and versatility enable you to achieve accurate and varied drilling tasks, while its efficiency and ease of use make your work more productive and hassle-free. Whether you are a professional or a DIY enthusiast, investing in a vertical drilling machine is a wise choice that will ultimately lead to better results and successful projects. So, take advantage of this powerful tool and witness the difference it can make in your next project.

Increased Accuracy

The best vertical drilling machines offer increased accuracy, allowing users to achieve precise drilling results. These machines are equipped with advanced technology and features that ensure the drilling process is carried out with utmost precision.

- Enhanced Control: Vertical drilling machines are designed to provide excellent control over the drilling operation. With features such as adjustable speed and depth control, users can easily customize the drilling parameters according to their specific requirements. This level of control helps in achieving accurate drilling results.

- Stable and Rigid Structure: The best vertical drilling machines are known for their stable and rigid structure. This solid construction ensures minimal vibration during drilling, reducing the chances of errors and inaccuracies. A stable machine base also helps in maintaining consistent drilling depth, resulting in precise holes.

- Precision Drill Heads: The drill heads on these machines are engineered for precision. They are designed to minimize any movement or deviation during the drilling process, ensuring accurate hole placement. Additionally, some machines come with advanced features like digital displays and laser alignment systems, further enhancing drilling accuracy.

- Advanced Measurement Systems: To ensure accurate drilling, vertical drilling machines are equipped with advanced measurement systems. These systems help in detecting any misalignment or deviations in the drilling operation and provide real-time feedback to the operator. This allows for immediate adjustments and corrections, resulting in precise drilling.

Overall, the best vertical drilling machines prioritize increased accuracy through features like enhanced control, stable structure, precision drill heads, and advanced measurement systems. These machines are designed to provide users with the necessary tools and technology to achieve precise drilling results in a wide range of applications.

Versatility for Various Materials

The best vertical drilling machines offer a high degree of versatility when it comes to drilling various materials. Whether you’re working with wood, metal, or other materials, a top-quality drilling machine should be able to handle the task effortlessly. With a powerful motor and adjustable speed settings, you can easily switch between different materials and achieve precise drilling results.

When it comes to drilling wood, a good vertical drilling machine should have a sturdy construction and a reliable depth stop mechanism. This ensures that you can drill holes of consistent depth and avoid any damage to the wood. Additionally, the machine should provide you with the option to adjust the speed according to the type of wood you’re working with, giving you optimal control and accuracy.

- When drilling metal, a vertical drilling machine with a robust spindle and a precise chuck is essential. This allows you to securely fasten the metal piece and maintain stability throughout the drilling process, preventing any slipping or wobbling. The machine should also have enough power to handle the tough nature of metal, ensuring efficient drilling without any compromises.

- In addition, a quality vertical drilling machine should offer a range of features that enhance versatility. This can include a tilting table that allows you to drill at different angles, a laser guide system for increased accuracy, and a variety of drill bit sizes to accommodate different hole diameters. These features enable you to tackle a wide range of projects and optimize your drilling experience.

Overall, when searching for the best vertical drilling machine, prioritize its versatility in handling various materials. Look for a machine that excels in drilling wood and metal, with adjustable speed settings and additional features that enhance functionality. With such a machine in your workshop, you’ll have the flexibility to undertake a multitude of projects and achieve exceptional results every time.

Time and Cost Efficiency

In the field of drilling machines, time and cost efficiency are crucial factors that determine the success of any project. The use of the best vertical drilling machine can significantly improve the overall efficiency of drilling operations and minimize both time and cost expenses.

By utilizing advanced technology and innovative features, the best vertical drilling machine offers increased productivity and precision. Its powerful motor and high drilling speed allow for faster drilling, reducing the time required for each hole. Additionally, the machine’s accurate depth control and automatic feeding system ensure precise drilling, eliminating the need for rework and saving valuable time.

Furthermore, the best vertical drilling machine is designed for maximum durability and reliability, minimizing maintenance and repair costs. Its robust construction, high-quality materials, and advanced cooling system contribute to increased machine lifespan and reduced downtime. This not only saves money on repairs but also ensures uninterrupted drilling operations, further enhancing efficiency.

In conclusion, investing in the best vertical drilling machine proves to be a wise decision when it comes to time and cost efficiency. Its advanced features and durable construction enable faster drilling with precise results, minimizing both time and cost expenses associated with drilling operations. With its enhanced productivity and reliability, the best vertical drilling machine becomes an indispensable tool for any project that aims for maximum efficiency and success.

Enhanced Safety Features

The best vertical drilling machines on the market today come equipped with an array of enhanced safety features, ensuring that users can work with confidence and minimize the risk of accidents. These safety features have been carefully designed to meet the highest safety standards and provide both physical and operational protection.

One important safety feature is the emergency stop button, located in a convenient and easily accessible location. This allows the user to quickly halt the machine in case of an emergency or unexpected situation. Another safety feature is the automatic shut-off system, which detects any unusual movements or vibrations and immediately stops the machine to prevent any potential harm.

- Furthermore, vertical drilling machines are equipped with robust protective shields that cover the drill bit and prevent any debris or particles from flying out during operation. These shields provide an essential barrier between the user and the rotating drill bit, reducing the risk of injury.

- Additionally, the machines are built with advanced safety mechanisms that prevent overloading and overheating. These mechanisms monitor the machine’s performance and automatically shut it down if it exceeds safe operating parameters. This not only prevents damage to the machine but also ensures the safety of the user.

- Moreover, many modern vertical drilling machines are equipped with built-in safety interlocks that prevent the machine from starting if all safety guards and shields are not properly in place. This feature ensures that the machine can only be operated when all necessary safety precautions have been taken.

In conclusion, enhanced safety features are an essential aspect of the best vertical drilling machines. These features provide users with peace of mind and help maintain a safe working environment. Investing in a vertical drilling machine with enhanced safety features is a wise choice for anyone looking to prioritize safety and reduce the risk of accidents.

5 Best vertical drilling machine

Features

| Part Number | LJA210816008 |

| Color | Red |

Features

| Part Number | LKBD3J5ZBF2G8DRIK4G |

| Model | 1 |

| Color | Drilling Aids |

| Size | 1 |

Features

| Part Number | SS-1468 |

| Color | Silver |

Features

| Part Number | 778400 |

| Model | 778400 |

| Color | Black |

| Size | 1 Count (Pack of 1) |

Features

| Part Number | 4685000 |

| Model | 4685000 |

| Color | Grey |

| Release Date | 2012-11-23T00:00:01Z |

| Language | English |

Question and answer:

What are enhanced safety features?

Enhanced safety features refer to additional measures and technologies implemented in various products and systems to increase safety levels and reduce the risk of accidents or injuries.

What are some examples of enhanced safety features in cars?

Some examples of enhanced safety features in cars include adaptive cruise control, lane departure warning systems, blind spot detection, and automatic emergency braking.

How do enhanced safety features benefit drivers?

Enhanced safety features benefit drivers by providing them with additional assistance and reducing the chances of accidents. These features can help detect and warn about potential dangers, providing a safer driving experience for the driver and passengers.

Are enhanced safety features only found in cars?

No, enhanced safety features are not limited to cars. They can also be found in various other products and systems such as home appliances, industrial equipment, and even personal protective equipment.

Conclusion

In conclusion, enhanced safety features in technology have made a significant impact on individuals’ lives, workplace safety, and overall society. These advancements have drastically reduced the risk of accidents and injuries, providing a safer and more secure environment for everyone. Whether it is in the form of improved automotive safety features, enhanced surveillance systems, or advanced manufacturing equipment, these innovations have proven to be invaluable. As technology continues to advance, it is crucial to prioritize the development and implementation of enhanced safety features to ensure a safer and more protected future.