Best material for drill template

When it comes to drilling holes for various projects, having a drill template can make the task much easier and more precise. However, choosing the right material for your drill template is crucial for ensuring its durability and accuracy. In this article, we will explore the best materials for drill templates and discuss their key advantages and disadvantages.

One of the most popular materials for drill templates is acrylic. Acrylic is a lightweight and transparent material that allows for easy alignment and positioning of the drill. It is also highly resistant to cracking and breaking, making it a durable choice for long-term use. Acrylic templates are often laser-cut, which ensures precision and consistency in hole placement. However, acrylic templates may not be suitable for heavy-duty drilling applications or drilling through harder materials.

Another excellent material for drill templates is aluminum. Aluminum is known for its strength, durability, and resistance to corrosion, making it ideal for long-lasting templates. It can be easily machined to create precise and custom hole patterns. Aluminum templates are commonly used in industrial settings or for projects that require drilling through tougher materials, such as metal or hardwood. However, aluminum templates can be heavier and more expensive than other options.

For those looking for a budget-friendly option, plywood can be a viable material for drill templates. Plywood is readily available and easy to work with, allowing for the creation of custom templates in various sizes and shapes. However, plywood templates may not offer the same level of precision and durability as acrylic or aluminum. It is important to note that plywood templates may require reinforcement or frequent replacement, especially in high-impact drilling applications.

In conclusion, the best material for a drill template depends on the specific project requirements and drilling applications. Acrylic offers transparency and ease of use, while aluminum provides strength and durability for heavy-duty drilling. Plywood remains a cost-effective option but may require more frequent replacement. By considering these factors, you can choose the best material for your drill template and ensure accurate and efficient drilling for your projects.

The Importance of Choosing the Best Material for Drill Templates

When it comes to creating precise and accurate holes in a variety of materials, drill templates play a crucial role. These templates are essential tools that guide the drill bit, ensuring that the desired hole is drilled in the correct location and at the right depth. However, not all drill templates are created equal, and the material used for these templates can greatly impact their effectiveness. Therefore, it is essential to carefully consider the material when choosing a drill template.

Durability: One of the key factors to consider when selecting a material for drill templates is durability. As these templates are repeatedly used, they must be able to withstand the pressure and wear associated with drilling. Choosing a material that is strong and resistant to damage, such as steel or hardened plastic, ensures that the drill templates will have a longer lifespan and can be used for multiple projects.

Precision: Another important aspect to consider is the level of precision required for the project at hand. Different materials may have varying levels of dimensional stability, which can affect the accuracy of the drilled holes. For projects that require high precision, materials such as metal or high-density plastic are often preferred. These materials offer excellent dimensional stability, ensuring that the drill templates will maintain their shape and accuracy even after repeated use.

- Strength:

- Durability:

- Precision:

- Compatibility:

- Ease of use:

Compatibility: It is also important to consider the compatibility of the material with the materials being drilled. Certain materials may be more suitable for drilling into specific materials, such as wood or metal. Choosing a material that is compatible with the drilling material can help prevent damage to both the drill bit and the template, ensuring a smooth and efficient drilling process.

Ease of use: Lastly, ease of use is another factor to consider when selecting a material for drill templates. Materials that are lightweight and easy to handle can significantly improve the user experience, making it more comfortable and efficient to complete drilling tasks. Additionally, materials that are easy to mark and measure, such as those with printed or engraved measurements, can further enhance the usability of the drill templates.

In conclusion, choosing the best material for drill templates is essential for achieving accurate and precise drilling results. By considering factors such as durability, precision, compatibility, and ease of use, it is possible to select a material that will enhance the performance and longevity of the drill templates. Investing in high-quality materials for drill templates is a worthwhile decision that can contribute to the success of drilling projects.

Understanding the Role of Drill Templates in Precision Drilling

Drilling precision is a critical aspect of many industries, from construction to manufacturing. Achieving accurate and consistent drill hole placement is essential for ensuring the quality and functionality of various projects. One important tool that aids in this precision drilling process is a drill template.

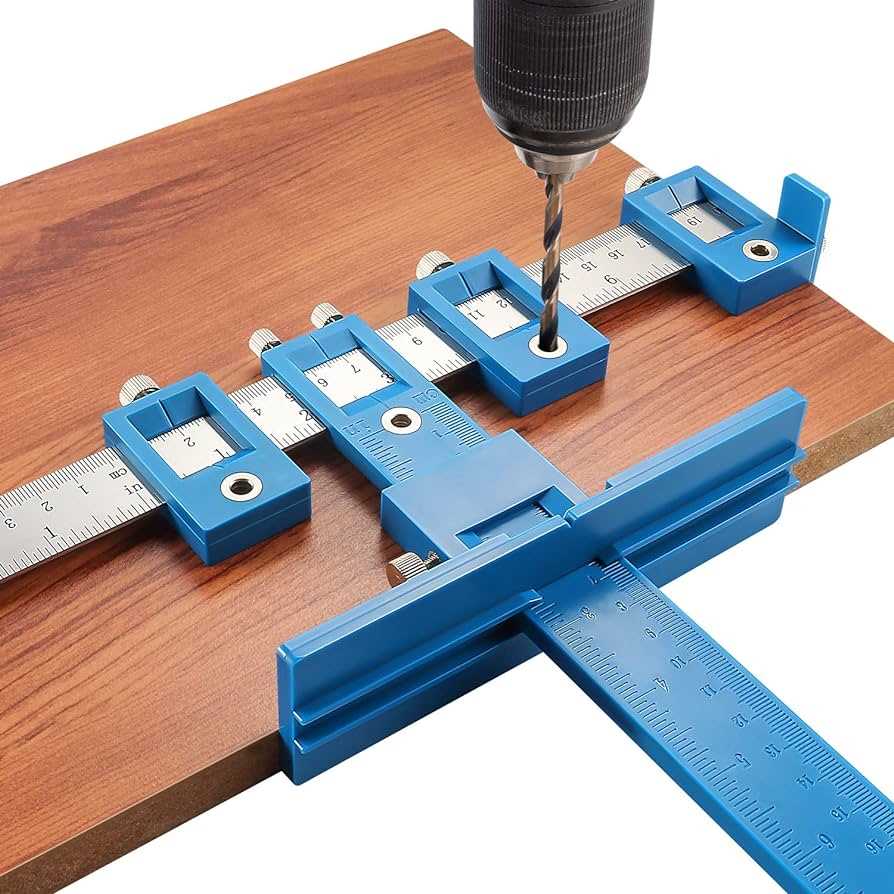

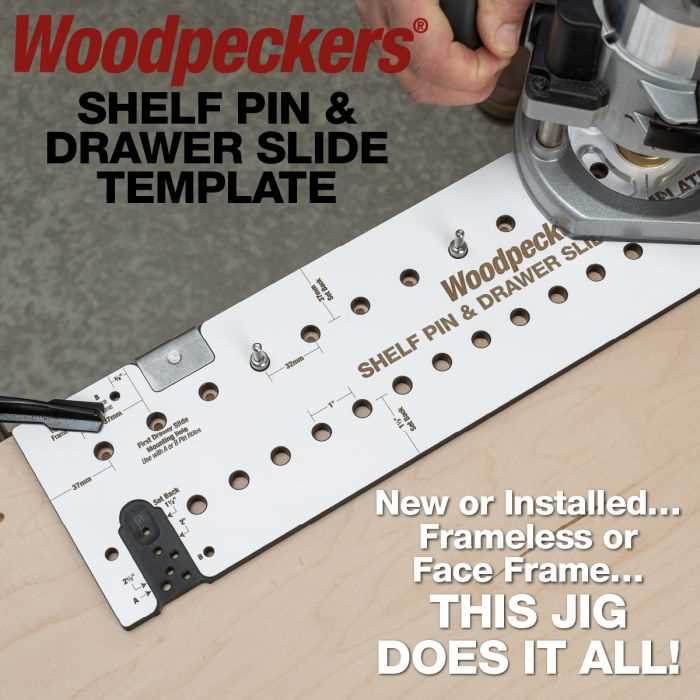

A drill template, also known as a drilling guide or a jig, is a specialized tool used to guide the drill bit during the drilling process. It serves as a template or template-like device that offers a predetermined hole pattern or layout, allowing for precise and repeatable hole placement.

- Materials:

When it comes to choosing the best material for a drill template, several factors need to be considered. One of the key considerations is the material’s durability and resistance to wear and tear. Drill templates are subjected to repetitive use and contact with drill bits, and they need to withstand these factors to maintain accuracy over time.

Metal, such as aluminium or steel, is a commonly used material for drill templates due to its strength and durability. It can withstand the forces exerted during drilling and maintain its shape, ensuring the correct hole pattern is maintained. Additionally, metal templates can be easily cleaned and maintained, improving their longevity.

Another material option for drill templates is plastic. Plastic templates offer advantages such as cost-effectiveness, lightweight design, and easy customization. However, it is important to ensure that the plastic material chosen is strong enough to withstand drilling forces without deforming or breaking.

In conclusion, drill templates play a crucial role in achieving precision drilling. Metal and plastic are popular material choices for drill templates, each offering its own set of advantages. The material selection should be based on factors such as durability, resistance to wear, ease of maintenance, and cost-effectiveness.

Factors to Consider in Selecting Drill Template Materials

When selecting a material for a drill template, there are several important factors to consider. The choice of material will impact the durability, accuracy, and ease of use of the template. Here are some key factors to keep in mind:

- Strength: One of the primary considerations when choosing a material for a drill template is its strength. The material should be able to withstand the pressure and force exerted during drilling without deforming or breaking. Commonly used strong materials for drill templates include steel and aluminum.

- Hardness: The hardness of the material is also crucial as it determines how well the template will resist wear and tear over time. It is important to select a material that has a suitable level of hardness to prevent premature deterioration. Hardened steel or carbide are often chosen for their high hardness.

- Dimensional Stability: The material used for the drill template should maintain its shape and dimensions even under varying environmental conditions such as temperature or moisture. This ensures that the template will consistently provide accurate drill hole placements. Materials like composite or dense plastics are known for their dimensional stability.

- Machinability: Considering the ease of machining is essential, as it directly affects the production process. The material should be easily machinable, allowing for precise and efficient drilling. Aluminum and acrylic are often preferred for their excellent machinability.

- Cost: Lastly, the cost of the material should also be taken into account. The chosen material should be cost-effective, providing a good balance between quality and affordability. Different materials have varying costs, so it is important to consider the budget when making a selection.

By carefully considering these factors, one can make an informed decision when selecting the most suitable material for a drill template. The right choice will ensure a durable, accurate, and efficient drilling process.

Durability and Longevity

When it comes to choosing the best material for a drill template, durability and longevity are two key factors to consider. A drill template needs to withstand the repeated use and pressure that comes with drilling holes in various materials, so it is important to choose a material that is strong and long-lasting.

One option for a durable drill template material is stainless steel. Stainless steel is known for its strength and resistance to corrosion, making it an excellent choice for a tool that is exposed to moisture and other elements. It can withstand constant use without losing its shape or wearing down, ensuring that the drill template will last for a long time.

Benefits of Stainless Steel:

- High strength and durability

- Resistance to corrosion

- Longevity

- Can withstand constant use without wearing down

Another option for a durable drill template material is aluminum. Like stainless steel, aluminum is known for its strength and resistance to corrosion. It is also lightweight, which makes it easy to handle and maneuver during drilling operations. Aluminum drill templates can withstand heavy use without losing their shape or integrity, ensuring that they will last for a long time.

Benefits of Aluminum:

- High strength and durability

- Resistance to corrosion

- Lightweight and easy to handle

- Longevity

Whether you choose stainless steel or aluminum, both materials offer excellent durability and longevity for a drill template. They can withstand constant use without wearing down, ensuring that your drill template will last for many drilling operations to come.

5 Best material for drill template

Features

| Part Number | Z21044 |

| Model | Z21044 |

Features

| Part Number | HRUKG04 |

| Model | HRUKG04 |

Features

| Part Number | MMT-TD01090-2 |

| Color | Red |

Question and answer:

What is durability?

Durability is the ability of a product or material to withstand wear, pressure, or damage over time.

How can I improve the durability of a product?

To improve durability, you can use high-quality materials, reinforce weak points, apply protective coatings, and ensure proper maintenance and care.

What factors affect the longevity of a product?

The factors that affect the longevity of a product include the quality of materials used, the manufacturing process, environmental conditions, and how well it is maintained and cared for.

What is the difference between durability and longevity?

While durability refers to the ability to withstand wear and damage, longevity refers to the length of time a product or material can last before it becomes unusable or ineffective.

How can I determine the durability of a product before purchasing?

You can determine the durability of a product by researching its materials and construction, reading customer reviews, and looking for any certifications or guarantees provided by the manufacturer.

What is durability?

Durability refers to the ability of a product or material to withstand wear, pressure, or damage over time without breaking or deteriorating.

Conclusion

In conclusion, durability and longevity are essential factors to consider when purchasing products, whether it be household items or personal belongings. While it may be tempting to opt for cheaper options, investing in high-quality and durable goods will often save you money in the long run. By choosing products that are built to last, you can reduce waste, minimize environmental impact, and avoid the hassle and cost of frequent replacements. Remember, durability not only benefits you as a consumer but also plays a crucial role in sustainable living and being responsible stewards of our planet. So, next time you’re out shopping, think twice before settling for a disposable or short-lived item – choose durability and longevity instead.