Best drillbit to drill thru abs plastic

When it comes to drilling through ABS plastic, it’s important to choose the right drill bit. ABS plastic is known for being tough and durable, but it can also be prone to cracking and splitting if not drilled correctly. That’s why using the right drill bit is crucial for a successful drilling project.

One of the best drill bits for drilling through ABS plastic is a spiral flute, also known as a twist drill bit. This type of drill bit features a twisted design, which allows for easier chip removal and helps prevent the bit from getting clogged with plastic shavings. The sharp point of the spiral flute allows for precise drilling, while the cutting edges ensure a clean and smooth hole.

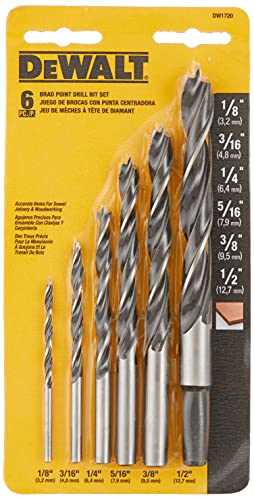

Another option is a brad point drill bit, which has a sharp, pointed tip that helps prevent the bit from wandering or slipping on the plastic surface. This type of drill bit is ideal for creating precise holes in ABS plastic, and it also helps reduce the risk of cracking or splitting the material.

Regardless of the drill bit you choose, it’s important to use a slow drill speed and apply consistent pressure while drilling through ABS plastic. This will help prevent the plastic from overheating and reduce the risk of damage to the material. Additionally, using a lubricant such as cutting oil or water can help reduce friction and extend the life of the drill bit.

Best Drill Bit for Drilling Through ABS Plastic

When it comes to drilling through ABS plastic, it is important to choose the right drill bit to ensure a clean and accurate hole. ABS plastic is a relatively soft material, so using a drill bit that is specifically designed for plastics is essential to prevent the plastic from cracking or melting.

One of the best drill bits for drilling through ABS plastic is a high-speed steel (HSS) bit with a sharp point. These bits are designed to cut through plastic materials with ease, providing clean and precise holes. HSS bits are also durable and long-lasting, making them a reliable choice for drilling through ABS plastic.

It is also recommended to use a drill bit with a smaller diameter to reduce the risk of the plastic material getting caught on the bit and causing damage. Starting with a pilot hole and gradually increasing the size of the bit can help prevent the plastic from cracking or splitting.

Another option for drilling through ABS plastic is to use a spade bit or a step drill bit. These types of bits are specifically designed for drilling through thin materials like plastic, and they provide a clean and smooth hole. However, it is important to use them at a slow speed and apply light pressure to prevent the plastic from melting or warping.

In conclusion, when drilling through ABS plastic, it is best to use a high-speed steel bit with a sharp point or a specialized plastic drill bit. Starting with a smaller diameter and gradually increasing the size of the hole can help prevent damage to the plastic material. By using the right drill bit and following these guidelines, you can achieve clean and accurate holes in ABS plastic without causing any damage.

Understanding ABS plastic

ABS plastic, also known as Acrylonitrile Butadiene Styrene, is a widely used thermoplastic polymer. It is characterized by its strength, durability, and resistance to impact, making it suitable for a variety of applications across different industries.

ABS plastic is composed of three main monomers: acrylonitrile, butadiene, and styrene. These monomers are polymerized to form a long-chain structure, resulting in a material with excellent mechanical properties. ABS plastic is known for being tough and rigid, while also being lightweight and easy to process.

One of the key advantages of ABS plastic is its versatility. It can be easily molded into various shapes and sizes, making it suitable for manufacturing a wide range of products, including automotive components, consumer electronics, toys, and household appliances. Additionally, ABS plastic can be easily machined, drilled, and sanded, further enhancing its usability.

When drilling through ABS plastic, it is important to choose the right drill bit to ensure clean and precise cuts. For drilling small holes, a high-speed steel or carbide drill bit with a sharp point is recommended. These types of drill bits are known for their hardness and ability to maintain their sharpness for longer periods of time.

In summary, ABS plastic is a versatile and durable material that is widely used in various industries. Its excellent mechanical properties, ease of processing, and ability to be machined make it a popular choice for manufacturing different products. When drilling through ABS plastic, it is crucial to select the appropriate drill bit to achieve accurate results.

Factors to Consider When Drilling ABS Plastic

When drilling ABS plastic, there are a few key factors to consider in order to achieve the best results. ABS plastic is a popular choice for many applications due to its durability and impact resistance. However, it can be prone to cracking or melting if not drilled properly. Here are some important factors to keep in mind:

1. Drill Bit Selection

Choosing the right drill bit is crucial when working with ABS plastic. It is recommended to use a high-speed steel (HSS) drill bit with a sharp point. The sharp point will help to create a clean entry point and prevent the plastic from cracking or chipping. Avoid using dull or worn-out drill bits, as they can cause excessive heat buildup and melt the plastic.

2. Drilling Speed and Pressure

When drilling ABS plastic, it is important to use a slow drilling speed to minimize friction and heat generation. Applying excessive pressure or drilling at high speeds can cause the plastic to melt or warp. It is best to start drilling at a low speed and gradually increase the speed as needed. Additionally, using a lubricant such as cutting oil or soapy water can help to reduce heat and friction.

3. Pilot Hole

Creating a pilot hole before drilling the final hole can help to prevent the plastic from cracking or splintering. A pilot hole is a smaller hole that serves as a guide for the drill bit. It can be created using a smaller drill bit or by using a center punch to create a small indentation. Once the pilot hole is created, the larger drill bit can be used to complete the hole.

By considering these factors and taking proper precautions, you can successfully drill through ABS plastic without damaging or compromising its integrity.

HSS drill bits for drilling ABS plastic

When it comes to drilling through ABS plastic, using the right drill bit is crucial to ensure clean and precise holes. High-speed steel (HSS) drill bits are a popular choice for this material due to their durability and ability to handle high speeds.

HSS drill bits are made from a hardened steel alloy, which allows them to withstand the heat generated during drilling. This makes them suitable for drilling through ABS plastic, as the material can be prone to melting or warping if excessive heat is generated.

These drill bits also have a sharp cutting edge, which helps to reduce the amount of force required during drilling. This is important when working with ABS plastic, as excessive pressure can cause the material to crack or chip.

Additionally, HSS drill bits are available in various sizes to accommodate different hole diameters. This allows for greater flexibility when working with ABS plastic, as you can choose the appropriate bit size for your specific application.

In conclusion, when drilling through ABS plastic, using high-speed steel (HSS) drill bits is recommended. Their durability, heat resistance, and sharp cutting edge make them well-suited for this material. Whether you need to drill small or large holes, HSS drill bits provide the precision and reliability you need for successful drilling.

Carbide-tipped drill bits for ABS plastic

When drilling through ABS plastic, it’s important to choose the right drill bit for the job. One highly recommended option is carbide-tipped drill bits. These drill bits are specifically designed to handle the unique properties of ABS plastic, ensuring clean and precise holes without causing damage or melting the material.

Carbide-tipped drill bits are known for their durability and long lifespan. The carbide tip, made of a combination of tungsten carbide and cobalt, provides exceptional strength and resistance to wear. This makes them ideal for drilling through ABS plastic, which can be quite dense and tough.

Advantages of carbide-tipped drill bits for ABS plastic:

- Highly resistant to wear and tear

- Capable of drilling clean and precise holes

- Long lifespan, reducing the need for frequent replacement

- Minimizes the risk of damaging or melting the ABS plastic

- Available in various sizes to accommodate different hole diameters

- Compatible with both hand drills and power tools

When using carbide-tipped drill bits for ABS plastic, it’s essential to use a steady and controlled drilling technique. Applying excessive force or drilling at high speeds can lead to cracking or melting of the plastic. It’s also advisable to use lubricant or coolant to reduce heat buildup and friction during the drilling process.

Step drill bits for ABS plastic

When it comes to drilling through ABS plastic, it is important to choose the right drill bit that will provide clean and accurate holes without causing any damage to the material. One type of drill bit that is commonly used for drilling through ABS plastic is a step drill bit.

A step drill bit is designed with a unique spiral flute design that allows for smooth and efficient drilling. It is made up of multiple different-sized steps, each with a different diameter. This allows the bit to drill holes of various sizes without the need for multiple drill bits.

- The step design of these drill bits reduces the likelihood of the plastic material cracking or chipping during drilling, ensuring a clean and precise hole.

- Step drill bits are also known for their durability, as they are typically made from high-speed steel or cobalt, which can withstand the pressure and heat generated during drilling.

- Furthermore, the self-centering tip of the step drill bit helps to maintain stability and accuracy when drilling through ABS plastic.

When using a step drill bit for ABS plastic, it is recommended to start with the smallest step and gradually work your way up to the desired hole size. This will prevent any unnecessary stress on the plastic and ensure a clean and accurate hole. Additionally, it is important to use a low drilling speed and apply steady pressure to avoid any overheating or melting of the plastic.

In conclusion, when drilling through ABS plastic, a step drill bit is a reliable and efficient choice. Its unique design allows for clean and precise holes, while its durability ensures long-lasting performance. By following proper drilling techniques, you can successfully achieve the desired results without damaging the ABS plastic.

5 Best drillbit to drill thru abs plastic

Features

| Part Number | SDB-ALL |

| Model | SDB-4R |

Features

| Part Number | step-M35 |

| Model | step-M35 |

Features

| Part Number | SDB-ALL |

| Model | HSS-SD-3 |

| Color | Gold |

Features

| Part Number | jig accessory |

| Model | 35mm Forstner foret |

Features

| Part Number | F1120 |

| Model | AM-F1120 |

| Warranty | 3 year manufacturer. |

| Color | Transparent |

| Release Date | 2012-07-25T00:00:01Z |

| Size | 1/4-Inch |

Features

| Part Number | UK13010004-UK13020004 |

| Warranty | Manufacturer warranty for 90 days from the date of purchase |

Question and answer:

What are step drill bits?

Step drill bits are specially designed drill bits that have multiple steps or levels of increasing diameter. They are used for drilling holes of different sizes without the need to change the drill bit.

Can I use step drill bits for drilling ABS plastic?

Yes, step drill bits can be used for drilling ABS plastic. ABS plastic is a relatively soft material, and step drill bits are effective at drilling through softer materials like plastic.

Are there any precautions to take when using step drill bits on ABS plastic?

Yes, when using step drill bits on ABS plastic, it is important to use a slow drill speed to prevent melting or chipping of the plastic. It is also advisable to use a pilot hole before using the step drill bit to reduce the risk of cracking the plastic.

What sizes of holes can be drilled using step drill bits for ABS plastic?

Step drill bits for ABS plastic typically have a range of hole sizes they can drill, starting from small sizes like 1/8 inch and going up to larger sizes like 1 inch or more. The specific range may vary depending on the brand and model of the step drill bit.

Are there any alternative drill bits for drilling ABS plastic?

Yes, there are alternative drill bits that can be used for drilling ABS plastic, such as twist drill bits or brad point drill bits. However, step drill bits are often preferred for drilling plastic because they offer the convenience of drilling multiple hole sizes with a single drill bit.

What are step drill bits used for?

Step drill bits are used to create holes of various sizes in materials like plastic, wood, and metal. They have multiple cutting edges and gradually increase in diameter, allowing for precise hole sizing.

Are step drill bits suitable for drilling ABS plastic?

Yes, step drill bits are suitable for drilling ABS plastic. However, it is important to use a slow drilling speed and light pressure to avoid melting or deforming the plastic. It is also recommended to use a lubricant to keep the drill bit cool during the drilling process.

Conclusion

In conclusion, step drill bits are an excellent tool for drilling holes in ABS plastic. They provide precise and clean cuts, reducing the risk of damaging or cracking the material. The step design allows for drilling a range of hole sizes with just one bit, making it versatile and cost-effective. Additionally, the high-speed steel construction ensures durability and longevity. Whether you’re working on a small DIY project or a large-scale production, using step drill bits for ABS plastic will surely enhance your drilling experience and yield professional results.