Best drill speed for aluminum

When it comes to drilling through aluminum, finding the right drill speed is crucial for achieving the best results. Aluminum is a lightweight metal that requires different drilling techniques compared to other materials. The wrong drill speed can lead to inefficient drilling, overheating, and even damaging the drill bit or the workpiece.

The ideal drill speed for aluminum depends on various factors:

1. Diameter of the Drill Bit: The larger the diameter of the drill bit, the slower the speed should be. This is because a larger drill bit removes more material, creating more friction and heat. Slowing down the speed allows for better control and prevents overheating.

2. Type of Aluminum: Different types of aluminum have different hardness levels. Soft aluminum alloys require higher drill speeds, while harder alloys need slower speeds to prevent overheating and ensure cleaner holes.

3. Drill Bit Material: The type of drill bit material also plays a role in determining the optimal drill speed. High-speed steel (HSS) bits are commonly used for drilling aluminum, and they perform best at higher speeds. However, carbide or cobalt bits, which are more heat-resistant, can handle slower speeds.

By considering these factors and adjusting the drill speed accordingly, you can achieve clean, precise holes in aluminum without causing any damage or complications. It is always recommended to start with a lower speed and gradually increase it until you find the optimal balance between control and efficiency.

Understanding aluminum drilling

Drilling aluminum can be a delicate process that requires careful consideration of factors such as drill speed, feed rate, and lubrication. Aluminum, being a soft and lightweight material, can be prone to melting and galling if not drilled correctly.

Drill speed plays a crucial role in aluminum drilling. It determines the rate at which the cutting tool engages with the material and can significantly impact the quality of the hole. Too high of a drill speed can cause the aluminum to overheat, resulting in work hardening and potential damage to the drill bit. On the other hand, too low of a drill speed can lead to inefficient cutting and increased risk of the drill bit clogging. Finding the optimal drill speed for aluminum is essential to achieve clean and precise holes.

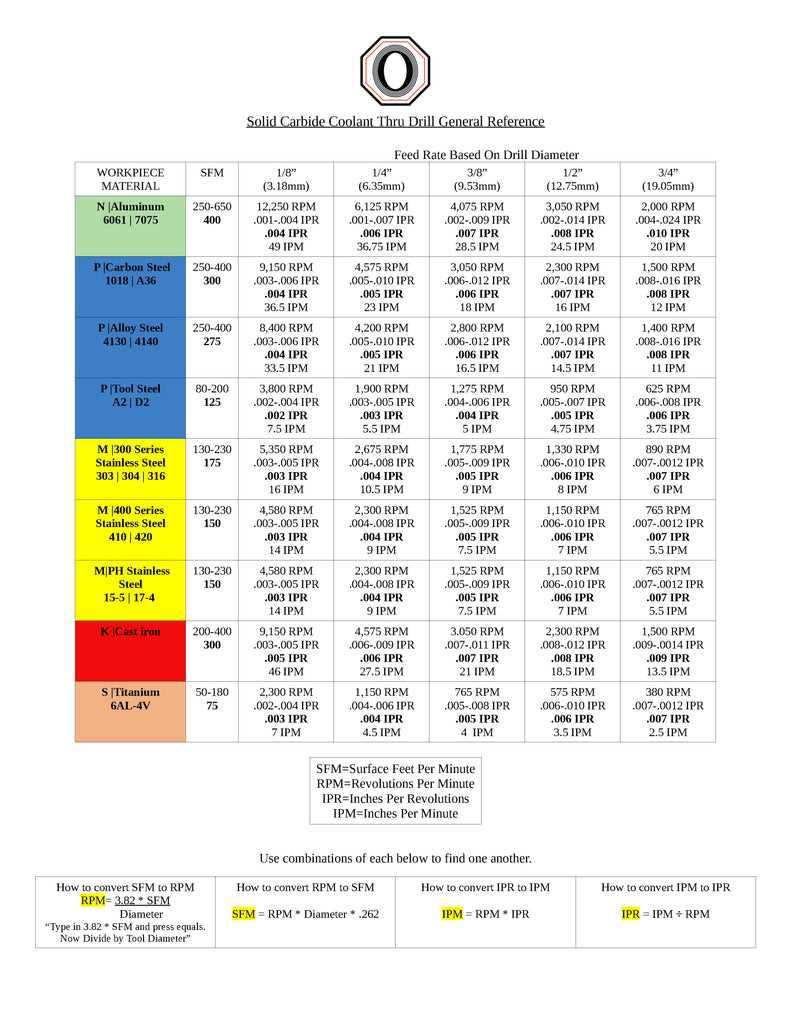

In general, a low to medium drill speed is recommended for aluminum drilling. This typically ranges from 1,000 to 3,000 RPM (rotations per minute). It is important to note that the specific drill speed may vary depending on the diameter of the drill bit and the type of aluminum being drilled. Using a speed chart or consulting the manufacturer’s recommendations can help determine the ideal drill speed for a particular drilling operation.

Lubrication is another critical aspect of drilling aluminum. Applying a suitable cutting fluid or lubricant helps to reduce friction and heat generation during the drilling process. It also helps to remove chips and prevent the drill bit from sticking. Some common lubricants used for aluminum drilling include cutting oils, aluminum-specific lubricants, and even simple solutions such as dish soap or water. Choosing the right lubricant can enhance drilling performance and extend the tool life.

Factors determining drill speed

In order to determine the best drill speed for aluminum, several factors need to be taken into consideration. These factors include the type of drill bit being used, the diameter and length of the hole being drilled, the type of aluminum being drilled, and the desired outcome of the drilling process.

Firstly, the type of drill bit being used can greatly influence the optimal drill speed for aluminum. Different drill bits are designed for different materials and have different cutting speeds. It is important to select a drill bit specifically designed for drilling aluminum in order to ensure the best results. Diamond-coated drill bits, for example, are often recommended for drilling aluminum due to their high speed and durability.

Secondly, the diameter and length of the hole being drilled also play a role in determining the appropriate drill speed. Smaller diameter holes require higher drill speeds, while larger diameter holes require slower drill speeds. Additionally, longer holes may require a faster feed rate to prevent heat buildup and ensure efficient material removal.

The type of aluminum being drilled is another important factor to consider. Different types of aluminum alloys have varying hardness and ductility, which can affect the optimal drill speed. Harder alloys may require slower drill speeds to prevent excessive heat generation and maintain the integrity of the drill bit, while softer alloys may allow for higher drill speeds.

Finally, the desired outcome of the drilling process should also be taken into account when determining the appropriate drill speed. If the goal is to achieve a smooth and precise hole, a slower drill speed may be necessary. On the other hand, if speed is more important than precision, a higher drill speed may be preferred.

Overall, determining the best drill speed for drilling aluminum involves considering a combination of factors, including the type of drill bit, the size and length of the hole, the type of aluminum, and the desired outcome. By taking these factors into account, one can optimize the drilling process for maximum efficiency and effectiveness.

Recommended Drill Speed for Aluminum

When it comes to drilling aluminum, achieving the right drill speed is crucial for optimal results. Aluminum being a softer material compared to others like steel or hardwood, requires a different approach in order to avoid damaging the workpiece or causing excessive heat buildup.

For most aluminum drilling applications, a recommended drill speed is around 1500-2000 RPM (revolutions per minute). This range provides a good balance between cutting efficiency and heat generation. However, it’s important to note that the exact drill speed might vary depending on factors such as the size and thickness of the aluminum material, the type of drill bit being used, and the specific drilling operation being performed.

- Smaller drill bits and thinner aluminum sheets might require higher drill speeds, closer to the upper end of the recommended range, to prevent the bit from getting clogged and ensure clean holes.

- On the other hand, larger drill bits and thicker aluminum blocks may benefit from slightly lower drill speeds to reduce the risk of overheating and prevent the bit from grabbing or becoming jammed.

- Additionally, using lubrication or cutting fluids can help in dissipating heat and extending the tool life, especially when drilling at higher speeds.

It is always a good practice to start with a lower drill speed and gradually increase it until you find the optimal cutting performance and chip evacuation for your specific aluminum drilling task. Testing on a scrap piece of aluminum and adjusting the drill speed accordingly can help in achieving the desired results without compromising the integrity of the workpiece.

Tips for drilling aluminum efficiently

When it comes to drilling aluminum, there are a few key tips to keep in mind in order to achieve efficient results. Whether you are working with thin aluminum sheets or thicker aluminum blocks, following these guidelines can help you get the job done effectively.

Choose the right drill bit

Selecting the correct drill bit is crucial for drilling aluminum efficiently. Carbide or high-speed steel (HSS) drill bits are recommended for aluminum as they are specifically designed to withstand the heat generated during the drilling process. These drill bits have a sharper cutting edge and can easily penetrate the aluminum material without causing damage or generating excessive friction.

Use the appropriate drill speed

Drilling at the right speed is essential for efficient aluminum drilling. A speed too high can cause the drill bit to become too hot and result in melting or warping of the aluminum. On the other hand, a speed too low can lead to inefficient cutting and an excessive build-up of chips. It is recommended to use a medium to high speed setting on your drill, around 1500-2500 RPM, to strike a balance between cutting efficiency and heat generation.

Apply cutting fluid or lubricant

When drilling aluminum, it is beneficial to use a cutting fluid or lubricant to help reduce friction, heat, and potential damage to the drill bit. Lubricating the drill bit ensures smoother drilling and prolongs the lifespan of the drill bit. You can use a commercially available cutting fluid or even a light oil as a lubricant when drilling aluminum.

By following these tips and choosing the right tools and techniques, you can drill aluminum efficiently and achieve accurate and clean results. Remember to always wear appropriate safety gear and take necessary precautions when working with power tools.

5 Best drill speed for aluminum

Features

| Part Number | Drill Bit Set |

| Language | English |

Features

| Part Number | TA01040001 |

Features

| Part Number | HCG-99S |

| Color | 99pcs Titanium Coated Drills |

Q&A:

What type of drill bit should I use for drilling aluminum?

For drilling aluminum, it is recommended to use high-speed steel (HSS) or cobalt drill bits. These types of drill bits are specifically designed for cutting through metal and will provide a clean and efficient drilling experience.

Should I lubricate the drill bit when drilling aluminum?

Yes, it is advisable to use a lubricant when drilling aluminum. Lubricating the drill bit helps to reduce friction and heat buildup, which can lead to longer tool life and more efficient drilling. You can use a cutting oil or even a simple lubricant like WD-40.

What speed should I set my drill to when drilling aluminum?

The speed at which you should set your drill when drilling aluminum depends on the thickness of the aluminum and the size of the drill bit you are using. As a general guideline, a slower speed is suitable for larger drill bits and thicker aluminum, while a higher speed can be used for smaller drill bits and thinner aluminum. It is best to refer to the manufacturer’s recommendations for the specific drill bit and aluminum thickness you are working with.

How can I prevent the drill bit from overheating or getting dull when drilling aluminum?

To prevent the drill bit from overheating or getting dull when drilling aluminum, it is important to use sharp drill bits and apply consistent pressure. Using a lubricant and periodically withdrawing the drill bit to allow it to cool can also help prevent overheating. Additionally, using a lower speed and avoiding excessive force can prevent the drill bit from getting dull too quickly.

Conclusion

In conclusion, drilling aluminum efficiently requires attention to several key factors. Firstly, selecting the right type of drill bit is crucial, with high-speed steel or cobalt drill bits often being the best choice. Secondly, using the correct drilling technique, such as starting with a small pilot hole and gradually increasing the drill bit size, can help prevent overheating and ensure a smooth drilling process. Additionally, maintaining a steady drill speed and applying consistent pressure while drilling will help prevent the aluminum from melting or snagging. Lastly, using a cutting oil or lubricant can significantly improve drilling efficiency by reducing friction and heat buildup. By taking these tips into consideration, operators can achieve optimal results when drilling aluminum materials.