Best drill line about opps

When it comes to drilling operations, having a reliable and efficient drill line is crucial. The drill line is the main component that connects the drill bit to the hoisting system, providing the necessary tension and support for drilling operations. As such, finding the best drill line about opps is essential for ensuring safe and productive drilling operations.

There are several factors to consider when choosing the best drill line for opps. One important factor is the material of the drill line. Different types of materials, such as steel, synthetic, or hybrid, have their own advantages and disadvantages. Steel drill lines are known for their strength and durability, while synthetic drill lines are lighter and easier to handle. Hybrid drill lines combine the best qualities of both steel and synthetic drill lines.

Another important aspect to consider is the diameter and configuration of the drill line. The diameter determines the load capacity of the drill line, while the configuration refers to the number of strands and the type of lay (regular or lang lay). The choice of diameter and configuration depends on the specific drilling operations and the load requirements.

Additionally, it is crucial to consider the application-specific requirements and industry standards. Drill lines used in oil and gas drilling operations, for example, need to meet certain specifications and certifications to ensure safety and reliability. It is important to choose a drill line that complies with these standards and can withstand the harsh conditions of drilling operations.

Overall, finding the best drill line about opps requires careful consideration of various factors, such as material, diameter, configuration, and industry standards. By choosing the right drill line, drilling operators can ensure the success and efficiency of their operations while maintaining safety and reliability.

The Importance of Choosing the Best Drill Line for Optimal Performance

When it comes to drilling operations, selecting the most suitable drill line is crucial for achieving optimal performance. The drill line is the lifeline of any drilling system, as it provides the necessary strength and durability to withstand the demanding conditions of the job. Choosing the best drill line can have a significant impact on the efficiency, safety, and overall success of a drilling project.

One of the key factors to consider when selecting a drill line is its tensile strength. The drill line needs to be able to handle the high forces and stresses that are generated during drilling operations. A high tensile strength ensures that the drill line can withstand the weight of the drill string and the torque applied during drilling, without snapping or failing. Opting for a drill line with low tensile strength can lead to costly downtime and potential accidents.

Durability is another important aspect to consider when choosing a drill line. The drill line is constantly subjected to abrasion and wear from the contact with drilling fluids, rocks, and other materials in the wellbore. A durable drill line with excellent resistance to abrasion and corrosion will have a longer lifespan, reducing the frequency of replacements and maintenance. This not only saves time and money but also contributes to the overall efficiency of the drilling operation.

Flexibility is also a critical factor to take into account. The drill line must have the necessary flexibility to bend and adapt to the curved path of the wellbore. A flexible drill line allows for easier maneuverability and reduces friction, resulting in smoother drilling operations and reduced wear on other components of the drilling system. Additionally, a flexible drill line is less prone to kinking or tangling, preventing potential accidents and downtime in the drilling process.

In conclusion, selecting the best drill line is essential for achieving optimal performance in drilling operations. Considering factors such as tensile strength, durability, and flexibility can help ensure that the drill line can withstand the challenging conditions of drilling and contribute to the efficiency, safety, and success of the project.

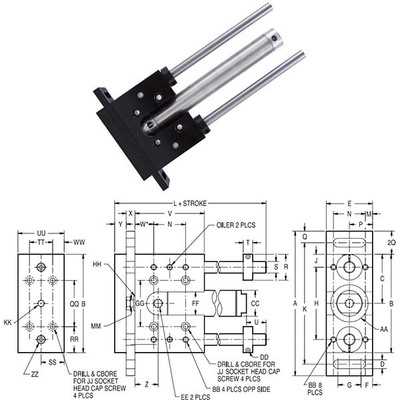

Understanding the Role of the Drill Line in Drilling Operations

In drilling operations, the drill line plays a crucial role in facilitating the drilling process. The drill line is a strong, high-tensile steel cable that connects the drilling rig to the drilling bit. It is responsible for transmitting power from the rig to the bit, allowing the bit to penetrate the earth’s surface and extract valuable resources.

One important function of the drill line is to provide the necessary tension and support to the drill string. As the drill string is lowered into the wellbore, the drill line helps maintain the required weight on the bit, ensuring efficient drilling. Additionally, the drill line helps control the movement and positioning of the drill string, enabling operators to accurately target and access specific zones within the drilling area.

To ensure reliable drilling operations, the drill line must possess certain characteristics. It needs to have high strength, durability, and resistance to wear and corrosion. The drill line should also have low stretch and flexibility to ensure efficient power transmission from the rig to the bit. These properties allow the drill line to withstand the high stresses and demands of drilling operations, ensuring safe and productive drilling processes.

In conclusion, the drill line plays a critical role in drilling operations by facilitating the power transmission, supporting the drill string, and enabling precise drilling. Understanding the importance of the drill line and its characteristics is essential for ensuring successful and efficient drilling operations.

Factors to Consider When Selecting a Drill Line

When choosing a drill line for your operations, there are several important factors to consider. The right drill line can greatly impact the efficiency and effectiveness of your drilling operations, so it’s crucial to make an informed decision. Here are some key factors to keep in mind:

- Strength and durability: One of the first things to consider is the strength and durability of the drill line. It should be able to withstand the forces and pressures involved in drilling without breaking or wearing down easily. Look for drill lines that are made from high-quality materials and have a reputation for being durable.

- Flexibility and responsiveness: Another important factor is the drill line’s flexibility and responsiveness. It should be able to accurately respond to the commands of the drilling equipment, allowing for precise control and maneuverability. A flexible and responsive drill line can make your drilling operations more efficient and reduce the risk of accidents or mistakes.

- Resistance to abrasion and corrosion: Drill lines are exposed to harsh conditions, including friction and moisture. Therefore, it’s crucial to choose a drill line that has resistance to abrasion and corrosion. This will ensure that the drill line can withstand the wear and tear of drilling operations and maintain its performance over time.

- Compatibility with drilling equipment: It’s essential to select a drill line that is compatible with your drilling equipment. The drill line should have the right dimensions, connections, and fittings to seamlessly integrate with your equipment. Using a compatible drill line will ensure smooth operation and minimize the risk of equipment failure.

- Cost-effectiveness: Lastly, consider the cost-effectiveness of the drill line. While it’s important to invest in a high-quality and reliable drill line, it’s also important to consider your budget and choose a drill line that offers the best value for money. Compare prices, warranties, and customer reviews to make an informed decision.

By taking these factors into consideration, you can select a drill line that meets your operational needs and delivers optimal performance. Remember to prioritize strength, durability, flexibility, compatibility, and cost-effectiveness when making your decision.

The Impact of Drill Line Quality on Operational Efficiency

Efficiency is a key factor in the success of any drilling operation. One often overlooked aspect that can significantly impact the overall efficiency of the operation is the quality of the drill line. The drill line is responsible for transmitting power from the drilling rig to the bit, and any issues with its quality can lead to inefficiencies and downtime.

One of the main ways in which drill line quality affects operational efficiency is through its strength and durability. A high-quality drill line will be able to withstand the demanding conditions of drilling operations, including high torque and tension. This means that it will be less prone to breaking or wearing out, reducing the need for frequent replacements or repairs. On the other hand, a low-quality drill line may be more susceptible to failure, leading to unplanned downtime and costly delays.

In addition to strength and durability, the quality of the drill line also affects the accuracy of drilling operations. A well-maintained and properly tensioned drill line will allow for precise control over the drilling process, ensuring that the bit goes exactly where it needs to. This is crucial for operations that require precise positioning, such as directional drilling. A low-quality drill line, on the other hand, may exhibit inconsistencies in tension or suffer from excessive stretch, leading to deviations in the drilling path and potentially compromising the overall accuracy of the operation.

To summarize, the quality of the drill line plays a crucial role in the operational efficiency of drilling operations. A high-quality drill line, built to withstand the demanding conditions of drilling, can minimize downtime and ensure continuity in operations. Additionally, a well-maintained drill line enables precise control and accuracy, contributing to the overall success of the drilling operation. Therefore, investing in a high-quality drill line is not only a financial decision but also a strategic one that can positively impact the efficiency and effectiveness of drilling operations.

5 Best drill line about opps

Features

| Part Number | PL/11 |

| Color | Transparent |

| Is Adult Product | |

| Size | 3lb - 0.11mm |

Features

| Part Number | BX10-028-BSP |

| Model | BX10-028-BSP |

| Warranty | No hassle warranty for any products proved to be faulty. |

| Color | Blue |

| Release Date | 2017-09-18T00:00:01Z |

| Size | 28mm-BSP |

| Language | English |

Features

| Part Number | BX10-038 |

| Model | BX10-038 |

| Warranty | No hassle warranty for any products proved to be faulty. |

| Color | Blue |

| Release Date | 2017-09-18T00:00:01Z |

| Size | 38mm |

| Language | English |

Question-Answer:

What is drill line quality?

Drill line quality refers to the level of reliability, durability, and performance of the drill line used in drilling operations. It encompasses factors such as the strength of the line, its resistance to wear and tear, and its ability to handle heavy loads without failure.

How does drill line quality impact operational efficiency?

The quality of the drill line directly affects operational efficiency. High-quality drill lines with superior strength and durability can withstand harsh operating conditions and minimize downtime due to line failure or replacement. This leads to increased uptime, decreased operational disruptions, and improved productivity.

What are the consequences of using low-quality drill lines?

Using low-quality drill lines can have several negative consequences. They may fail prematurely, leading to costly downtime for repairs and replacements. Low-quality lines are more prone to wear and tear, requiring more frequent maintenance and increasing operational costs. They can also compromise the safety of drilling operations, leading to accidents and injuries.

How can drill line quality be improved?

Drill line quality can be improved by using high-quality materials and manufacturing processes. Conducting regular inspections and maintenance can also help identify and address any potential issues before they escalate. Investing in advanced technology and equipment can further enhance drill line quality and operational efficiency.

Are there any industry standards or certifications for drill line quality?

Yes, there are industry standards and certifications that ensure drill line quality. Organizations such as the American Petroleum Institute (API) have established guidelines and certifications for drill line manufacturers. Compliance with these standards and certifications indicates that the drill line meets certain quality and performance criteria.

How does drill line quality impact operational efficiency?

Drill line quality plays a crucial role in operational efficiency. High-quality drill lines ensure smooth and reliable drilling operations, reducing downtime and increasing productivity. Conversely, poor-quality drill lines are more prone to failures and breakages, leading to frequent disruptions and decreased operational efficiency.

What are the benefits of using high-quality drill lines?

Using high-quality drill lines offers several benefits for operational efficiency. Firstly, they have greater structural strength and durability, reducing the risk of line failures and the need for frequent replacements. Secondly, high-quality drill lines exhibit better resistance to wear and corrosion, resulting in longer service life and decreased maintenance requirements. Lastly, reliable and efficient drill lines minimize downtime and increase drilling productivity, contributing to overall operational efficiency.

Conclusion

In conclusion, the quality of drill line plays a crucial role in the operational efficiency of drilling operations. High-quality drill lines, made with durable materials and advanced manufacturing techniques, offer a range of benefits such as increased drilling speed, reduced downtime, and improved safety. These lines are less prone to wear and tear, resulting in longer lifespans and fewer replacements. Moreover, their superior strength and performance enable smoother drilling operations, ensuring better precision and accuracy. Investing in high-quality drill lines is essential for any drilling operation aiming to optimize efficiency and minimize costs in the long run.