Best drill for ski tuning

When it comes to ski tuning, having the right tools is essential. One of the most important tools you will need is a drill. A good drill can make all the difference in how well your skis perform on the slopes. With so many options available, it can be overwhelming to choose the best drill for ski tuning.

There are several factors to consider when selecting a drill for ski tuning. First and foremost, you want a drill that is powerful and can handle the task at hand. Look for a drill with a high torque and RPM rating, as this will ensure that it can effectively remove material from your skis. Additionally, it’s important to choose a drill that is lightweight and comfortable to hold, as you may be using it for extended periods of time.

Another important consideration is the type of chuck on the drill. A keyless chuck is ideal for ski tuning, as it allows for quick and easy bit changes. This is especially important when you are switching between different types of bits for different tuning tasks. Additionally, look for a drill with variable speed settings, as this will allow you to adjust the drilling speed to suit the specific task at hand.

Overall, the best drill for ski tuning is one that is powerful, lightweight, and has a keyless chuck with variable speed settings. By choosing a drill that meets these criteria, you can ensure that your skis are properly tuned and ready for the slopes. So whether you’re a professional skier or just enjoy hitting the slopes on weekends, investing in a high-quality drill for ski tuning is a must.

Importance of using a drill in ski tuning

In the world of ski tuning, the drill is an essential tool that brings multiple benefits to the skis. By using a drill in ski tuning, one can efficiently and effectively perform various tasks, such as mounting bindings, installing inserts, and repairing the ski base.

One of the primary reasons why using a drill in ski tuning is crucial is for mounting bindings. Bindings are an integral part of the ski setup, as they provide the connection between the skier and the ski. Using a drill allows for precise alignment and positioning of the bindings, ensuring optimal performance and safety while skiing. Without a drill, it would be challenging to securely attach the bindings to the ski, risking potential accidents on the slopes.

Additionally, a drill is necessary for installing inserts into the ski. Inserts are threaded metal cylinders that are placed in the ski to provide a more secure anchor point for bindings. These inserts allow for easier binding adjustments and prevent the need for re-drilling holes in the ski. By using a drill, inserts can be seamlessly installed, ensuring a strong and durable connection between the ski and the binding.

Lastly, a drill is indispensable in ski tuning when it comes to repairing the ski base. Skis often experience damage from rocks, branches, or general wear and tear. With a drill, repairs such as filling in gouges and holes in the base can be easily done. By using the appropriate drill bits and materials, skiers can restore their skis to their optimal condition, ensuring a smooth and enjoyable ride on the slopes.

In conclusion, the importance of using a drill in ski tuning cannot be overstated. It plays a crucial role in mounting bindings, installing inserts, and repairing the ski base. By utilizing a drill, skiers can enhance their skiing experience, ensuring optimal performance, safety, and longevity of their skis.

Factors to consider when choosing a drill for ski tuning

When it comes to choosing a drill for ski tuning, there are several important factors to consider. A drill is a crucial tool for maintaining and tuning skis, and selecting the right one can make a significant difference in the quality of the job. Here are some key factors to keep in mind when choosing a drill for ski tuning:

Power and speed: One of the most important factors to consider is the power and speed of the drill. Ski tuning requires drilling into the ski base, and a drill with high power and speed will make the process more efficient and effective. Look for a drill that has adjustable speed settings to suit different tasks and materials.

Chuck size: The chuck size of a drill determines the maximum diameter of the drill bit it can accommodate. When choosing a drill for ski tuning, consider the size of the drill bits you will be using and make sure the chuck size is compatible. It’s also worth noting that drills with a larger chuck size tend to be more versatile, as they can accommodate a wider range of drill bits.

- Ergonomics: Ski tuning can be a physically demanding task, so it’s important to choose a drill that is comfortable to use for extended periods of time. Look for a drill with a design that fits comfortably in your hand and has features like rubber grips for added stability.

- Weight: Another factor to consider is the weight of the drill. Skis need to be worked on from different angles and positions, so a lightweight drill will be easier to maneuver and control. Look for a drill that is lightweight but still durable enough to withstand the demands of ski tuning.

- Brand and reputation: Finally, it’s always a good idea to consider the brand and reputation of the drill manufacturer. Look for a brand that is known for producing high-quality tools and has a good reputation among ski tuning professionals. Reading reviews and seeking recommendations can also help in making an informed decision.

By considering these factors, you can choose a drill for ski tuning that meets your specific needs and ensures optimal performance and precision when maintaining and tuning your skis.

Top features to consider in a drill for ski tuning

When it comes to finding the perfect drill for ski tuning, there are a few key features that can make all the difference in the quality of your work. Here are some of the top features to consider:

- Power and speed: Look for a drill with sufficient power and speed to handle the tough materials used in ski tuning. A higher RPM (revolutions per minute) rating can help you achieve smoother and more precise results.

- Versatility: An ideal drill for ski tuning should be versatile enough to handle various tasks, such as drilling holes for binding mounts, removing rust and burrs, and polishing the edges. Look for a drill with multiple speed settings and variable torque control.

- Ergonomics: Ski tuning can be a time-consuming task, so it’s important to choose a drill that feels comfortable in your hand and minimizes fatigue. Look for features like a rubberized grip and a lightweight design.

- Durability: Ski tuning can be a demanding process, so you’ll want a drill that can withstand heavy use. Look for a drill made from high-quality materials and with a solid construction that can withstand the rigors of ski tuning.

- Accuracy: Precision is crucial when it comes to ski tuning. Look for a drill with a reliable chuck system that securely holds the bit in place to ensure accurate drilling. A built-in spirit level can also help you achieve straight and level holes.

By considering these top features, you can make an informed decision and choose a drill that will meet your needs and help you achieve professional-quality ski tuning results.

Best drills for ski tuning recommended by professionals

When it comes to ski tuning, having the right drills can make all the difference. Professionals in the ski industry recommend the following drills for optimal ski performance and maintenance:

- Rotary Drill: This drill is perfect for removing excess material from the base of the ski. It allows precise control and accuracy, ensuring a smooth and even surface.

- Edge Bevel Drill: When it comes to sharpening ski edges, the edge bevel drill is a must-have. It allows for consistent edge beveling, creating the ideal angle for maximum performance on the slopes.

- Binding Mount Drill: Mounting ski bindings properly is crucial for safety on the mountain. The binding mount drill ensures accurate and secure installations, providing peace of mind during your ski adventures.

- Hole Filling Drill: Over time, ski bases can accumulate holes and dings. The hole filling drill is essential for repairing these imperfections, ensuring a smooth and seamless surface for optimal glide.

- Stone Grinding Drill: To achieve the perfect base structure, the stone grinding drill is a recommended tool. It allows for precise control over the stone’s movement, resulting in an ideal structure for various snow conditions.

These drills, recommended by professionals in the ski industry, are essential for ski tuning and maintenance. With the right tools at your disposal, you can ensure your skis are always in top shape for the best performance on the slopes.

Tips for using a drill in ski tuning

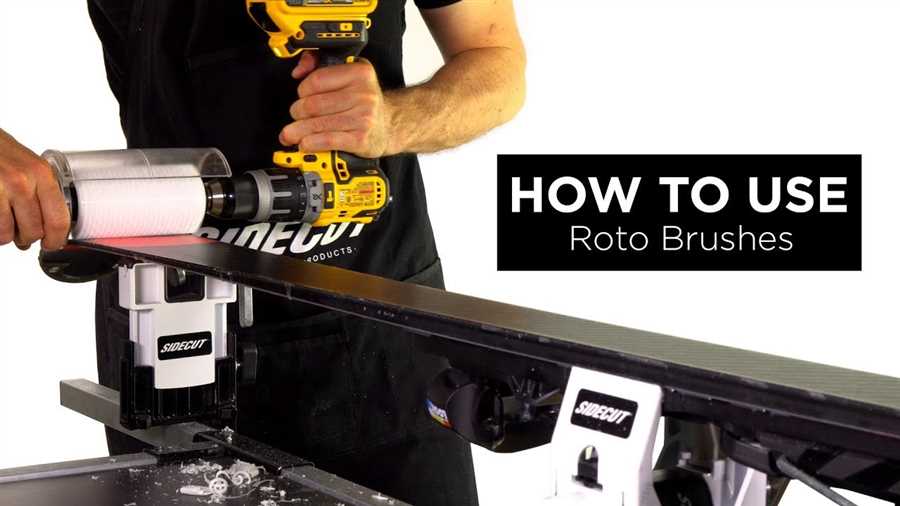

When it comes to ski tuning, using a drill can be an effective tool for various tasks such as binding adjustment, edge sharpening, and mounting. However, it is important to follow certain tips to ensure the best results and avoid any potential damage to your skis.

1. Choose the right drill bit: Different ski tuning tasks require different drill bits. When sharpening edges, a diamond-coated drill bit is recommended for precision and smoothness. For mounting bindings, it is important to use the correct size and type of bit specified by the manufacturer.

- 2. Use the proper speed and pressure: When drilling into the ski, it is important to use the correct speed and pressure. Too much speed or pressure can lead to overheating and damaging the ski. Follow the recommendations provided by the drill manufacturer and take breaks to let the ski cool down if necessary.

- 3. Secure the ski properly: Before using the drill, make sure the ski is securely fastened in a vice or clamp to prevent it from moving or vibrating during the drilling process. This will ensure more accurate and controlled drilling.

- 4. Be mindful of the drill depth: When drilling holes for mounting bindings or other tasks, measure and mark the desired drill depth beforehand to avoid drilling too deeply and penetrating the ski base.

- 5. Clean and lubricate the drill bit: After each use, make sure to clean the drill bit to remove any debris or residue that may accumulate. Lubricating the drill bit with wax or oil can also help reduce friction and improve drilling performance.

Following these tips will help you use a drill effectively in ski tuning, ensuring that your skis are properly maintained and ready for the slopes.

5 Best drill for ski tuning

Features

| Part Number | TX-10-1 |

| Model | . |

| Color | Alpine Ski Vise Blue |

| Is Adult Product |

Features

| Part Number | TX-10-5 |

| Color | Blue |

| Is Adult Product |

Features

| Color | Grey |

| Is Adult Product | |

| Size | 5 Inch |

Features

| Part Number | S2016 |

| Model | S2016 |

| Color | Black |

Question-Answer:

What safety precautions should I take when using a drill for ski tuning?

When using a drill for ski tuning, it is important to always wear safety goggles to protect your eyes from flying debris. Additionally, make sure to keep your fingers and other body parts away from the drill bit to avoid injury.

What type of drill bit should I use for ski tuning?

For ski tuning, it is recommended to use a drill bit specifically designed for the task. A ski-specific drill bit is typically shorter and has a larger diameter compared to regular drill bits, allowing for better control and precision when working on skis.

How should I position the ski when using a drill for ski tuning?

When using a drill for ski tuning, it is best to secure the ski in a ski vice or a sturdy workbench clamp. This will provide stability and ensure that the ski remains in place while you work on it. Make sure the ski is positioned in a way that allows easy access to the area you need to drill.

What speed setting should I use on the drill for ski tuning?

The speed setting on the drill for ski tuning will depend on the task at hand. For drilling holes in the ski, it is generally recommended to use a slower speed setting to maintain control and prevent overheating. However, for other tasks like sharpening edges, a higher speed setting may be more appropriate.

How should I clean and maintain my drill after using it for ski tuning?

After using a drill for ski tuning, it is important to clean the drill bit and any other metal parts to prevent rusting. Use a cloth or brush to remove any debris or wax residue. Additionally, it is a good idea to periodically lubricate the drill’s moving parts with a few drops of oil to keep it running smoothly.

Conclusion

In conclusion, using a drill in ski tuning can be a beneficial and efficient tool for any skier. By following these tips, such as starting with a sharp drill bit, adjusting the speed and pressure based on the task, and using the proper technique, skiers can achieve excellent results in their ski tuning process. Remember to always prioritize safety and take necessary precautions, such as wearing protective gear and working in a well-ventilated area. With these tips in mind, skiers can confidently rely on their drill to help them maintain and improve the performance of their skis.