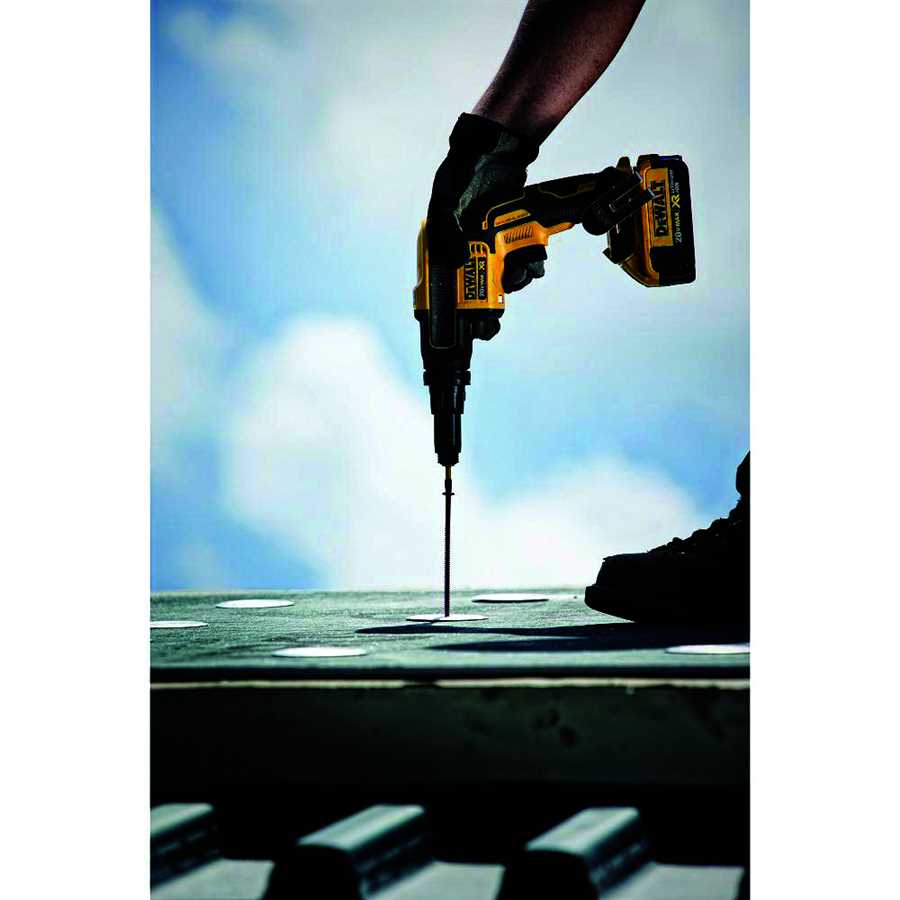

Best drill for metal roof

When it comes to working on a metal roof, having the right tools is essential. Whether you’re a professional contractor or a DIY enthusiast, finding the best drill for metal roof can make a world of difference in your project’s success. With so many options available on the market, it can be overwhelming to choose the right one for your specific needs.

One crucial factor to consider when selecting a drill for a metal roof is power. You’ll want a drill that is powerful enough to penetrate through tough metal surfaces without causing any damage or slipping. Look for a high torque drill with a sturdy motor that can handle the demanding nature of metal roof installations. Additionally, a variable speed feature is beneficial as it allows you to adjust the speed according to the specific task at hand.

Durability is another important aspect to consider when choosing a drill for a metal roof. The tool should be able to withstand the harsh conditions and repetitive use that comes with working on metal roofs. Look for drills made from high-quality materials, such as steel or aluminum, that can resist corrosion and impact. A drill with a robust chuck and a comfortable grip will also ensure longevity and ease of use.

The Importance of Choosing the Best Drill for Metal Roof

When it comes to working on a metal roof, having the right tools is crucial for a successful and efficient job. One of the most important tools in your arsenal is the drill. A good drill specifically designed for metal roofs can make all the difference in terms of ease of use, precision, and durability.

Using the wrong drill for a metal roof can result in a range of issues. Firstly, a regular drill may not have the power or torque required to effectively penetrate the metal surface, leading to frustration and wasted time. Additionally, the wrong drill can cause excessive wear and tear on the drill bit, reducing its lifespan and potentially causing it to break during the job. This can lead to costly interruptions and delays in completing the project.

Choosing the best drill for a metal roof involves considering several factors:

- Power: Look for a drill with high power output to ensure it can easily penetrate metal surfaces. Consider drills with corded or cordless options, depending on your preference and the availability of power sources on the job site.

- Torque: A high torque drill is crucial for efficiently drilling through metal roofs. Look for a drill with adjustable torque settings to match the requirements of your project.

- Durability: Metal roofs can be tough on drills, so choosing one that is built to withstand the challenges is essential. Look for models with durable construction and features like metal gearbox housings and heat-treated gears.

- Speed: Consider drills with variable speed settings to accommodate different drilling needs. This will allow you to adjust the speed according to the thickness and type of metal you are working with.

- Comfort and ergonomics: Working on a metal roof can be physically demanding, so it’s important to choose a drill that is comfortable to handle for extended periods. Look for features like a lightweight design, ergonomic grip, and adjustable handle positions.

Investing in the best drill for a metal roof can save you time, effort, and money in the long run. By considering factors like power, torque, durability, speed, and comfort, you can ensure that you have the right tool for the job. A high-quality drill will make your work easier and more efficient, allowing you to complete your metal roof project with confidence.

Understanding the Unique Challenges of Working with Metal Roofs

Metal roofs are becoming increasingly popular due to their durability, longevity, and aesthetic appeal. However, working with metal roofs presents unique challenges that require specialized tools and techniques. It is important for professionals to understand these challenges in order to ensure a successful and efficient installation or repair process.

1. Difficulties in fastening: Unlike other types of roofs, metal roofs cannot be simply nailed or screwed down. Metal sheets are typically installed with special fasteners, such as clips or hidden screws, to allow for contraction and expansion with temperature changes. This requires precision and knowledge of the specific fastening systems used for metal roofs.

2. Noise and vibrations: Metal roofs are known for being noisy during rainstorms, hail, or other forms of precipitation. This can be a challenge for workers, especially when trying to communicate on the job site. Additionally, the vibrations caused by walking or working on a metal roof can pose safety risks if not properly managed.

3. Slippery surface: Metal roofs can be extremely slippery, particularly when wet or covered in debris. This increases the risk of accidents and falls during installation or maintenance. Proper safety precautions, such as using non-slip footwear and employing fall protection measures, must be followed to mitigate these risks.

4. Expansion and contraction: Metal roofs expand and contract with temperature changes, which can lead to issues such as leaks, noise, and structural damage if not accounted for. It is crucial to use appropriate installation techniques and materials that allow for this movement and prevent potential problems.

5. Metal compatibility: When working on a metal roof, it is essential to consider the compatibility of different metal types. Mixing incompatible metals can result in corrosion and other integrity issues. Professionals should have a good understanding of metal compatibility and take necessary precautions to avoid potential damage.

By understanding and addressing these unique challenges, professionals can ensure a high-quality and long-lasting metal roof installation or repair. It is crucial to use the right tools, follow industry best practices, and prioritize safety to achieve successful outcomes when working with metal roofs.

Key Features to Look for in a Drill for Metal Roof

When it comes to drilling into a metal roof, not all drills are created equal. The right drill for the job will have specific features that make it well-suited for working with metal. Here are some key features to look for in a drill for a metal roof:

- High-speed motor: One of the most important features to consider is a high-speed motor. This will allow the drill to generate enough power to penetrate through metal quickly and efficiently. Look for a drill with a high RPM (revolutions per minute) rating to ensure it can handle the demands of drilling into metal.

- Durable construction: Metal roofs can be tough on tools, so it’s important to choose a drill that is built to withstand the rigors of the job. Look for a drill that has a durable construction, with a sturdy metal housing and robust internal components.

- Variable speed control: Having variable speed control on a drill is essential when working with metal. This feature allows you to adjust the speed of the drill to match the specific requirements of the material you’re working with. It’s especially useful when drilling through different thicknesses of metal.

- Hammer drill function: A hammer drill function can be a valuable feature when drilling into metal. This function adds a pulsating hammering action to the drilling motion, helping to break through tough metal surfaces more easily. It’s especially useful when drilling through thick metal or when encountering resistance.

- Comfort and ergonomics: Working on a metal roof can be physically demanding, so it’s important to choose a drill that is comfortable to use. Look for a drill with ergonomic features, such as a rubberized grip and a lightweight design. This will help reduce fatigue and make it easier to work for extended periods.

When choosing a drill for a metal roof, considering these key features will ensure that you have a tool that is up to the task. A high-speed motor, durable construction, variable speed control, hammer drill function, and comfortable ergonomics are all essential for successful drilling on metal surfaces.

High Power and Torque for Efficient Drilling

When it comes to drilling through metal roofs, having a drill with high power and torque is essential. The power and torque of a drill determine how efficiently it can penetrate metal surfaces, making it crucial for a successful and quick drilling process.

A high-power drill is capable of delivering a significant amount of force, allowing it to easily pierce through even the toughest metal roofs. This power ensures that the drill can quickly create holes without getting stuck or struggling to make progress. Additionally, a powerful drill reduces the need for excessive pressure or multiple attempts, saving both time and effort.

Similarly, torque plays a vital role in metal roof drilling. Torque refers to the rotational force produced by the drill, which is necessary for penetrating the metal surface. A drill with sufficient torque will have no trouble breaking through the roof material, ensuring a smooth and efficient drilling process. Furthermore, high torque allows the drill bit to maintain stability and prevent it from slipping or getting stuck, providing precise and accurate results.

Therefore, when choosing a drill for metal roof applications, it is crucial to prioritize high power and torque. These features will ensure efficient drilling, saving time and effort while delivering reliable and precise results.

5 Best drill for metal roof

Features

| Part Number | 3-XG-047 |

Features

| Part Number | FORTFHL5545 |

| Model | VDTAZ012 |

| Color | Multi-coloured |

| Size | 5.5 x 45mm |

| Language | English |

Features

| Part Number | 2492850 |

| Model | 2492850 |

| Color | White |

| Release Date | 2023-06-04T00:00:01Z |

| Size | 390 g |

| Language | English |

Features

| Part Number | 1966745 |

| Model | 1966745 |

| Color | Others |

| Release Date | 2023-06-04T00:00:01Z |

| Language | English |

Question-Answer:

What are high power and torque in drilling?

High power and torque in drilling refer to the ability of a drilling machine to generate a strong force and rotational energy, respectively, enabling it to efficiently drill through tough materials.

Why are high power and torque important for drilling?

High power and torque are important for drilling because they allow the drilling machine to overcome resistance and penetrate hard materials more effectively. This results in faster drilling speeds and improved efficiency.

How do high power and torque affect drilling efficiency?

High power and torque enhance drilling efficiency by enabling the drill bit to exert more force on the material, reducing drilling time and increasing productivity. They also prevent the drill bit from getting stuck or jammed during the drilling process.

What tools or equipment are commonly used to achieve high power and torque in drilling?

Tools such as electric drills, rotary hammers, and drilling rigs are commonly used to achieve high power and torque in drilling. These tools are designed with powerful motors and gear systems to provide the necessary force and rotational energy.

Are there any disadvantages to using high power and torque in drilling?

While high power and torque offer several benefits in drilling, they can also lead to increased energy consumption, higher equipment costs, and potential safety hazards if not handled properly. It is important to use the appropriate power and torque settings for each drilling task.

Conclusion

In conclusion, high power and torque are essential for efficient drilling. When drilling through tough materials or working on large-scale projects, having a powerful drill that can deliver both high power and torque is crucial. This allows the drill to quickly and effectively penetrate the material, saving both time and effort. High power ensures that the drill can overcome resistance and maintain a consistent drilling speed, while torque provides the necessary force to drive the drill bit into the material. Additionally, a high-power drill can handle a variety of tasks, from drilling large holes to driving screws and fasteners. When selecting a drill, it is important to consider its power and torque capabilities to ensure optimal performance and efficiency in drilling operations.