Best drill for icy rocks

When it comes to drilling icy rocks, having the right equipment is crucial. Whether you’re an experienced climber or just starting out, finding the best drill for icy rocks can make all the difference in your safety and efficiency. With the wide range of drills available on the market, it can be overwhelming to choose the right one. In this article, we will explore the top drills that are specifically designed for drilling in icy rocks, helping you make an informed decision.

One of the most important features to consider when choosing a drill for icy rocks is its power and efficiency. The drill needs to have a high torque and power output to effectively penetrate the hard and dense icy surface. Additionally, it should have a durable construction to withstand the harsh conditions of icy environments. Look for drills that are made from high-quality materials and have a sturdy design to ensure longevity and reliability.

Another crucial factor to consider is the drill’s adaptability to different icy rock types. Not all icy rocks are the same, and some can be much denser and harder to drill through. Therefore, it’s important to choose a drill that can handle various types of icy rocks, ensuring versatility and effectiveness. Look for drills that offer adjustable speed and torque settings, allowing you to customize the drilling force based on the specific icy rock you’re working on.

Top Features to Consider

When choosing a drill for icy rocks, there are several key features that you should consider to ensure that you are getting the best tool for the job. These features can help improve the performance and efficiency of your drilling experience, making your work easier and more effective.

- Durable Construction: Look for a drill that is made from high-quality materials, such as hardened steel, to ensure its durability and longevity. This will help it withstand the rigors of drilling through icy rocks without breaking or becoming damaged.

- Powerful Motor: A drill with a powerful motor is essential for effectively drilling into icy rocks. Look for a motor with high torque and wattage to ensure that it has the power necessary to handle the tough and hard nature of icy rocks.

- Variable Speed Control: Having the ability to adjust the speed of the drill is crucial when working with icy rocks. This allows you to slow down the drill when needed, providing more control and precision during drilling.

- Heavy-Duty Chuck: The chuck of the drill is what holds the drill bit securely in place. It is important to choose a drill with a heavy-duty chuck that can grip the bit tightly, preventing any slipping or movement during drilling.

- Vibration Control: Drilling into icy rocks can create significant vibrations, which can be uncomfortable and affect the accuracy of your drilling. Look for a drill with vibration control features, such as rubberized grip handles or anti-vibration technology, to minimize the impact of vibrations on your hands and wrists.

By considering these top features when choosing a drill for icy rocks, you can ensure that you have a reliable and efficient tool that will make your drilling experience easier and more successful.

Power and Durability

When it comes to drilling through icy rocks, power and durability are two essential factors to consider in a drill. The drill needs to have enough power to break through the hard surface of the icy rocks without getting stuck or damaged. Additionally, it must be able to withstand the harsh conditions and repetitive drilling without breaking down or losing its functionality.

Power is crucial in a drill for icy rocks as it determines the efficiency and effectiveness of drilling. A powerful drill can generate enough force to penetrate the tough icy surface, making the drilling process faster and more productive. It allows the drill bit to dig deeper into the rocks, ensuring that it reaches the desired depth with minimal effort.

Durability is equally important as it ensures the drill can withstand the extreme conditions it will encounter while drilling through icy rocks. The drill needs to be constructed with high-quality materials that can withstand the cold temperatures, rough surfaces, and constant drilling. A durable drill will not wear out easily and will be able to withstand the repetitive stress and pressure involved in drilling through icy rocks.

In conclusion, power and durability are essential qualities to look for in a drill for icy rocks. A powerful drill can break through the hard icy surface with ease, while a durable drill can withstand the harsh conditions and repetitive drilling without breaking down. These factors will greatly contribute to the efficiency and effectiveness of the drilling process.

Impact Resistance

When choosing a drill for icy rocks, it is important to consider its impact resistance. This refers to the drill’s ability to withstand the force and pressure exerted on it when drilling into hard and icy surfaces. It is essential to have a drill that is built to be durable and can withstand the tough conditions of drilling through icy rocks.

In order to ensure the impact resistance of a drill, manufacturers often use high-quality materials that are known for their strength and durability. These materials may include hardened steel or other alloys that are designed to withstand heavy impacts and resist any damage. Additionally, the drill may have reinforced components, such as a reinforced gearbox or a reinforced drill bit, to further enhance its impact resistance.

Having a drill with good impact resistance is crucial when drilling into icy rocks. The force and pressure exerted on the drill can cause it to break or malfunction if it is not designed to withstand such conditions. By selecting a drill with excellent impact resistance, you can ensure that it will remain functional and durable, allowing you to effectively drill through icy rocks without any setbacks or issues.

Temperature Resistance

When it comes to drilling through icy rocks, one crucial factor to consider is the temperature resistance of the drill. The extreme cold temperatures can be a major challenge for any drilling equipment. Therefore, it is essential to choose a drill that can withstand and perform effectively in these harsh conditions.

A drill with excellent temperature resistance will have specialized materials and components that can withstand extremely low temperatures without compromising its functionality. It should be able to operate smoothly and efficiently, even in freezing conditions, without any risk of the drill getting damaged or malfunctioning.

One key aspect of temperature resistance is the insulation of the drill. A high-quality drill will have well-insulated parts and components that can effectively protect the internal mechanisms from extreme cold. Additionally, the drill should have a heating system or features that can prevent ice buildup on its surfaces, ensuring optimal performance even in icy conditions.

Furthermore, the materials used in the construction of the drill should be carefully selected to withstand low temperatures. These materials need to be durable and have a high resistance to cold, ensuring that the drill remains in good condition and can withstand the harsh environment it will encounter while drilling through icy rocks.

Ergonomics and Grip

Ergonomics and grip are crucial factors to consider when choosing the best drill for icy rocks. The ergonomic design of a drill ensures that it is comfortable to hold and operate, reducing fatigue and increasing productivity. A well-designed grip allows for a secure and firm hold on the drill, even in slippery or icy conditions.

When working with icy rocks, it is important to have a drill that offers excellent grip. This will prevent the drill from slipping or sliding out of your hand, which could lead to accidents or injuries. A drill with a textured or rubberized grip provides added traction and stability, making it easier to control and maneuver the tool.

Furthermore, an ergonomic handle design ensures that the drill fits comfortably in your hand, reducing strain and discomfort during prolonged use. A well-designed handle will have contours and grooves that conform to the natural shape of your hand, providing a secure and comfortable grip.

Overall, a drill with good ergonomics and grip is essential for safe and efficient drilling on icy rocks. Choosing a drill that prioritizes these features will help to minimize the risk of accidents and maximize productivity in challenging conditions.

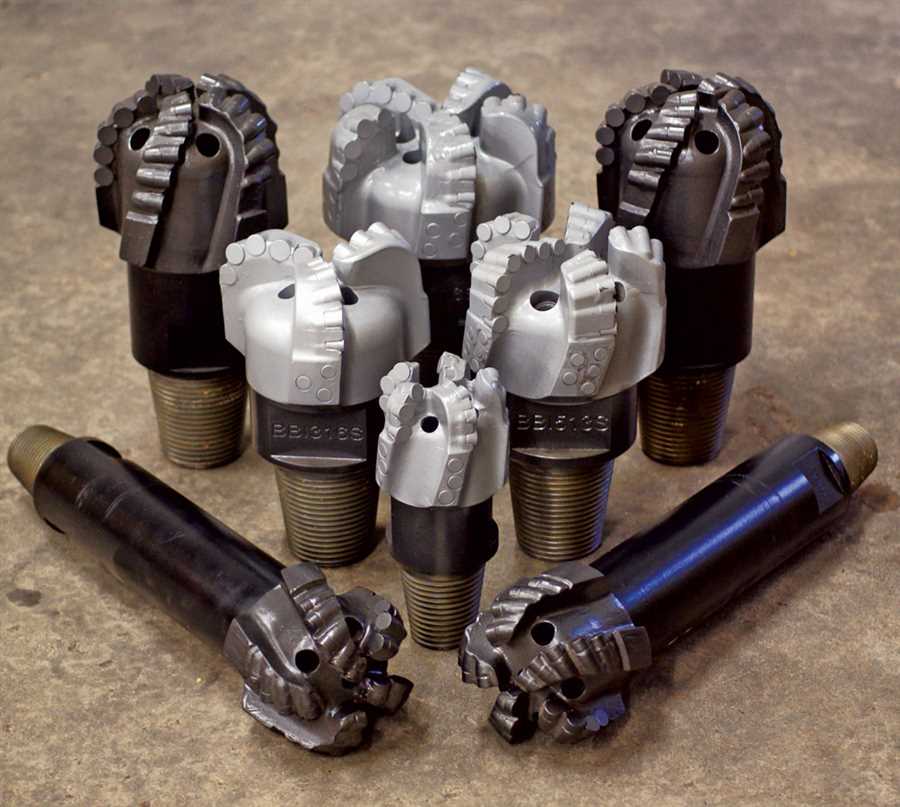

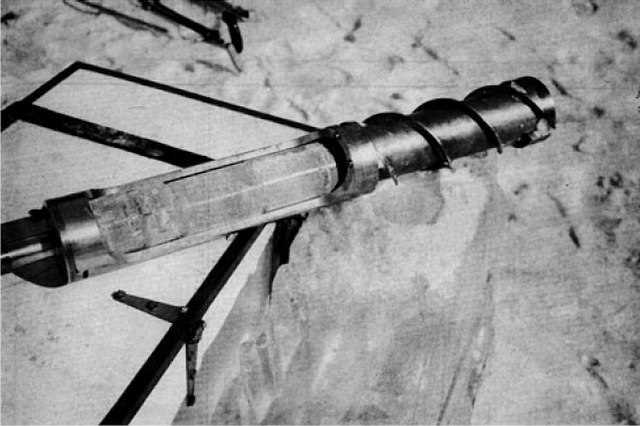

5 Best drill for icy rocks

Features

| Part Number | 8450000 |

| Model | 8450000 |

| Color | silver |

| Size | ø 4, 5, 6, 8, 10 mm |

Features

| Part Number | BLMN201806041883 |

| Model | BLMN201806041883 |

Features

| Size | 1080W Rotary Hammer Drill |

Features

| Part Number | 7119000 |

| Model | 7119000 |

| Color | Black |

Question-Answer:

What is ergonomics?

Ergonomics is the study of designing and arranging objects and environments in a way that optimizes human well-being and performance. It focuses on making things efficient, comfortable, and safe for people to use.

Why is ergonomics important?

Ergonomics is important because it helps minimize discomfort, reduce the risk of injuries, and enhance productivity. By designing objects and environments that are ergonomic, we can improve the overall well-being and performance of individuals.

What is grip?

Grip refers to the way a person holds and controls an object, such as a tool or a handle. It influences the effectiveness, comfort, and safety of using the object.

What is the importance of grip in ergonomics?

Grip plays a crucial role in ergonomics as it affects how efficiently and safely a person can use an object. A proper grip reduces the risk of slippage and strain, allowing individuals to have better control and perform tasks comfortably and effectively.

Conclusion

In conclusion, ergonomics and grip play a crucial role in various aspects of our lives, from everyday activities to professional tasks. By understanding the importance of ergonomics and employing proper gripping techniques, individuals can minimize the risk of injury, improve performance, and enhance overall well-being. Whether it is adjusting the height of a chair or using the correct grip on a tool, there are simple yet effective ways to ensure ergonomic comfort and safety. Additionally, industries and organizations should prioritize ergonomic design and provide training to employees to promote a healthy and productive work environment. By focusing on ergonomics and grip, we can strive for improved efficiency, reduced injuries, and enhanced quality of life.