Best drill for chromium steel

Chromium steel, also known as stainless steel, is a popular material used in a wide range of industries due to its excellent corrosion resistance and durability. Whether you are a professional craftsman or a DIY enthusiast, having the right drill for working with chromium steel is essential for achieving precise and clean cuts.

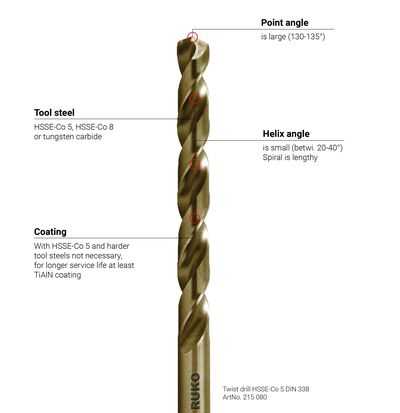

When it comes to choosing the best drill for chromium steel, several factors need to be taken into consideration. Firstly, it is important to look for a drill bit that is specifically designed for drilling into stainless steel. These drill bits are made from high-speed steel or cobalt steel, which are known for their strength and ability to withstand the high temperatures generated during drilling.

Additionally, the drill bit should have a sharp cutting edge and a special coating, such as titanium nitride or black oxide, to enhance its performance and increase its lifespan. It is also recommended to opt for a drill bit with a split point or a pilot point, as this helps to reduce the risk of “walking” or slipping during the drilling process.

The Properties of Chromium Steel

Chromium steel is a type of stainless steel that contains chromium as the essential alloying element. This material is known for its excellent corrosion resistance and high strength. The addition of chromium enhances its resistance to oxidation and scaling, making it suitable for applications in harsh environments. Additionally, chromium steel has a high melting point, which makes it resistant to heat and wear.

One of the notable properties of chromium steel is its exceptional hardness. This material is known for its ability to maintain its strength and durability even under high temperatures and loads. It also has excellent wear resistance, making it suitable for tools and equipment that undergo heavy usage. Chromium steel is often used in manufacturing drill bits, taps, dies, and other cutting tools.

Other properties of chromium steel include:

- Corrosion Resistance: Chromium steel exhibits excellent resistance to corrosion, particularly in acidic environments. This property makes it a popular choice for applications in marine environments and chemical processing industries.

- Magnetic Properties: Unlike other stainless steels, chromium steel is typically magnetic due to its composition.

- Temperature Resistance: Chromium steel can withstand high temperatures without losing its strength and integrity. It can retain its mechanical properties even at elevated temperatures, making it suitable for applications in heat-intensive environments.

- Machinability: Chromium steel is relatively easy to machine, making it a preferred material for various industrial applications. However, its hardness requires special cutting tools and techniques to achieve optimal results.

In conclusion, chromium steel is a valuable material known for its corrosion resistance, high hardness, and temperature resistance. Its unique properties make it suitable for a wide range of applications, including tools, equipment, and components subjected to demanding environments and heavy usage.

Understanding the Strength and Hardness of Chromium Steel

Chromium steel is a type of alloy that is valued for its exceptional strength and hardness. It is commonly used in various industries, including aerospace, automotive, and manufacturing, where strength and durability are crucial. To fully understand the properties of chromium steel, it is important to delve into its strength and hardness.

The strength of chromium steel lies in its composition. It is primarily made up of iron and chromium, with small amounts of other elements such as carbon, nickel, and molybdenum. The addition of chromium enhances the steel’s strength by forming a protective oxide layer on the surface, making it resistant to corrosion and wear. This oxide layer is also responsible for its hardness, as it increases the steel’s resistance to deformation, making it more suitable for applications that require high strength and durability.

To measure the strength and hardness of chromium steel, various tests are conducted, such as tensile tests and hardness tests. Tensile tests determine the steel’s ability to withstand pulling forces, measuring its ultimate tensile strength. Hardness tests, on the other hand, assess the steel’s resistance to indentation or scratching. Chromium steel typically exhibits high tensile strength and hardness, making it suitable for applications that require withstanding extreme conditions and heavy loads.

Understanding the strength and hardness of chromium steel is essential for selecting the best drill for this material. The drill needs to be able to withstand the hardness and strength of the steel to efficiently and effectively bore through it. Considerations such as the drill’s material and design, as well as the drill bit’s coating, are crucial in ensuring successful drilling operations on chromium steel. By understanding the unique properties of chromium steel, one can make informed decisions when it comes to selecting the best drill for various applications.

The Importance of a High-Quality Drill for Working with Chromium Steel

When it comes to working with chromium steel, using a high-quality drill is of utmost importance. Chromium steel is known for its exceptional hardness and resistance to corrosion, making it a popular choice for a wide range of applications. However, its toughness can also make it challenging to machine, especially when using a low-quality drill.

A high-quality drill specifically designed for working with chromium steel is essential for several reasons. First and foremost, it ensures that the drill bit is made from strong and durable materials that can withstand the hardness of the steel. This reduces the risk of the drill bit breaking or wearing down prematurely, which can lead to inefficient work and potential damage to the material being drilled.

Furthermore, a high-quality drill for chromium steel will have specialized features that enhance its performance. This may include advanced coatings or treatments that reduce friction and heat buildup, allowing for smoother and more precise drilling. Additionally, the drill’s design and geometry can optimize chip evacuation, preventing clogging and improving overall efficiency.

Investing in a high-quality drill for working with chromium steel can save both time and money in the long run. By using a drill that is specifically designed to handle the challenges of machining chromium steel, professionals can achieve better results with less effort and reduce the risk of costly errors or tool failures. Whether it’s for drilling holes, creating threads, or any other machining operation, choosing the right drill can make a significant difference in productivity and the quality of the finished product.

Factors to Consider When Choosing a Drill for Chromium Steel

Chromium steel is a highly durable and corrosion-resistant material commonly used in various industries, such as automotive, aerospace, and manufacturing. When working with chromium steel, it is essential to select the right drill to ensure efficient and effective drilling. Here are some important factors to consider when choosing a drill for chromium steel:

1. Drill Bit Material

One of the key factors to consider is the material of the drill bit. Chromium steel is a hard material that requires a drill bit with high hardness and heat resistance. Carbide or cobalt drill bits are often recommended for drilling into chromium steel due to their superior hardness and ability to withstand high temperatures. These materials can provide the necessary strength to penetrate the tough surface of chromium steel without dulling or breaking.

2. Drill Bit Geometry

The geometry of the drill bit also plays a crucial role in drilling into chromium steel. A drill bit with sharp cutting edges and a pointed tip is ideal for creating precise and clean holes in the material. Additionally, a drill bit with a high helix angle and a steep flute design helps to efficiently remove chips and prevent clogging during drilling, ensuring smooth and consistent drilling performance.

3. Cooling and Lubrication

Drilling into chromium steel generates high levels of heat due to the material’s hardness. To prevent overheating and maintain the drill bit’s effectiveness, it is essential to use cooling and lubrication techniques. Using a coolant or cutting oil during drilling helps to dissipate heat, reduce friction, and prolong the life of the drill bit. Additionally, cooling and lubrication contribute to smoother chip evacuation and improve the overall drilling process.

4. Drill Bit Size

The size of the drill bit is another critical factor to consider when working with chromium steel. It is important to select a drill bit that matches the diameter of the desired hole. Using a smaller drill bit may result in increased friction and excessive heat generation, while using a larger drill bit may lead to instability and imprecise hole formation. Choosing the right drill bit size ensures proper hole dimensions and avoids damage to the material.

When drilling into chromium steel, considering factors such as drill bit material, geometry, cooling and lubrication, and drill bit size is essential to achieve accurate and efficient drilling results. By carefully selecting the appropriate drill, you can ensure the longevity of the drill bit and produce high-quality holes in chromium steel.

The Drill Bit Material

When it comes to drilling chromium steel, the choice of the right drill bit material is crucial. Chromium steel is a hard and tough material that requires a drill bit that can effectively penetrate and cut through it. Choosing a drill bit made from the right material can significantly impact the performance and longevity of your drilling operations.

One of the most commonly used materials for drill bits is high-speed steel (HSS). HSS drill bits are known for their durability and versatility. They can effectively drill through a wide range of materials, including chromium steel. HSS drill bits are made from a combination of steel with other metals, such as cobalt, which enhances their strength and heat resistance. These drill bits are suitable for both hand drilling and machine drilling applications.

Another material that is often used for drilling chromium steel is carbide. Carbide drill bits are known for their hardness and ability to withstand high temperatures. These drill bits are made from a combination of tungsten carbide and cobalt, which provides them with superior strength and durability. Carbide drill bits are particularly effective in drilling through hard materials, such as chromium steel.

When choosing a drill bit material for drilling chromium steel, it is important to consider the specific requirements of your drilling operation. Factors such as the size of the hole, the speed of drilling, and the type of equipment being used can all influence the choice of drill bit material. It is also recommended to use a lubricant or cutting fluid during drilling to reduce heat and friction, which can help prolong the life of the drill bit.

5 Best drill for chromium steel

Features

| Part Number | M42 Cobalt-8(19pcs) |

| Model | . |

Features

| Model | TY002 |

| Color | Blue |

Features

| Part Number | 10112 |

| Model | 10112 |

| Color | Black/Bronze |

| Size | 6 pzs |

Features

| Part Number | 10115 |

| Model | 10115 |

| Color | Metallic |

| Size | 6 pzs |

Question-Answer:

What is a drill bit material?

A drill bit material refers to the type of material that the drill bit is made of. Different materials have different properties and are used for specific applications.

What are some common drill bit materials?

Some common drill bit materials include high-speed steel (HSS), cobalt, carbide, and diamond. Each material has its own advantages and is commonly chosen based on the specific drilling needs.

What are the advantages of high-speed steel (HSS) drill bits?

High-speed steel drill bits are known for their durability and versatility. They can be used to drill into a variety of materials, including wood, metal, and plastics. HSS drill bits are also relatively affordable.

When should I use carbide drill bits?

Carbide drill bits are best suited for drilling into hard materials like concrete, brick, and masonry. They are extremely hard and can withstand high heat and friction, making them ideal for heavy-duty drilling tasks.

Conclusion

In conclusion, the choice of drill bit material plays a crucial role in the overall performance and efficiency of the drilling process. Different materials offer various advantages and disadvantages, depending on the specific application and conditions. High-speed steel is a versatile option that provides good performance in general drilling applications. However, for more demanding applications, such as drilling through hard or abrasive materials, carbide or cobalt drill bits may be more suitable due to their enhanced hardness and wear resistance. It is important to consider factors such as material hardness, cutting speed, and feed rate when selecting the appropriate drill bit material, as these factors can significantly impact drilling productivity and tool life. By understanding the properties and characteristics of different drill bit materials, professionals can make more informed decisions and achieve better drilling results.