Best drill bits for stuck rusted metal bolts

Rusted metal bolts can be a real headache when trying to remove them. The corrosion can cause the bolts to become stuck, making it difficult to loosen or remove them with traditional tools. However, with the right drill bits, you can easily and efficiently remove these stubborn bolts.

When it comes to removing stuck rusted metal bolts, it’s important to choose the right drill bits that are specifically designed for this purpose. One of the best options is cobalt drill bits. These drill bits are made from a mixture of cobalt and steel, which gives them extra strength and durability. They are perfect for drilling through tough materials like rusted metal, and their high heat resistance makes them less likely to break or dull.

Another excellent choice is titanium drill bits. These bits are coated with titanium nitride, which makes them extremely hard and resistant to corrosion. Titanium drill bits are known for their ability to drill through metal without getting dull, which makes them ideal for removing stuck rusted bolts. The titanium coating also reduces friction, allowing the bit to drill through the metal more easily.

Carbide drill bits are also a great option for removing stuck rusted bolts. These drill bits are made from a combination of tungsten and carbon, which makes them incredibly strong and durable. Carbide drill bits are designed to withstand high temperatures and can easily drill through tough materials like rusted metal. They are also less likely to break or chip, making them a reliable choice for tackling stubborn bolts.

Understanding the Challenge of Stuck Rusted Metal Bolts

When dealing with stuck rusted metal bolts, it is important to understand the unique challenges that these situations present. Rust acts as a bonding agent, making it difficult to remove the bolt without causing further damage or breakage. This can be frustrating and time-consuming, especially if you lack the appropriate tools or knowledge. However, with the right approach and equipment, you can increase your chances of success.

1. Corrosion and Rust: Rusted metal bolts are typically the result of corrosion caused by moisture. When exposed to water or damp environments for prolonged periods of time, metal surfaces can develop rust, which weakens the bolt’s integrity. The presence of corrosion can make it challenging to loosen or remove the bolt using traditional methods.

2. Tightened Over Time: Over time, metal bolts tend to become tighter and more firmly stuck in place. This is often due to a combination of factors such as the natural expansion and contraction of metal with temperature changes, as well as the continuous application of pressure or force on the bolt. As a result, removing rusted bolts requires additional effort and specialized tools.

- 3. Breaking Free: When attempting to remove a stuck rusted metal bolt, the goal is to break the bond between the rust and the bolt. This can be achieved by applying penetrating oil, such as WD-40, allowing it to seep into the rusted areas and loosen the corrosion. Additionally, using the correct drill bits and drilling techniques can help create small fractures in the rust, making it easier to unscrew the bolt.

- 4. Safety Considerations: When working with stuck rusted metal bolts, it is crucial to prioritize safety. Protective measures, such as wearing gloves and safety goggles, should be taken to prevent injuries. Additionally, it is important to use the appropriate tools and follow proper techniques to avoid damaging the surrounding surfaces or causing the bolt to break. If necessary, seeking professional assistance may be advisable to ensure a successful and safe removal.

The Importance of Choosing the Right Drill Bits

When it comes to removing stuck rusted metal bolts, having the right drill bits can make all the difference. Using the wrong drill bits can result in frustration, damaged equipment, and wasted time. Therefore, it is crucial to choose the appropriate drill bits for the job at hand.

1. Compatibility with Material

One of the key factors to consider when selecting drill bits is their compatibility with the material you will be drilling into. Different drill bits are designed for specific materials, such as wood, metal, or concrete. By using drill bits that are specifically suited for rusty metal, you can ensure a more effective and efficient drilling process.

2. Durability and Strength

Another important aspect to consider is the durability and strength of the drill bits. Rusty metal bolts can be quite tough to dislodge, so using drill bits that are made from high-quality materials can help prevent breakage or bending. Look for drill bits that are specifically designed to handle tough materials and that have a hardened steel construction.

Furthermore, considering the coating or treatment of the drill bits can also be beneficial. Some drill bits come with coatings that provide additional protection against rust and corrosion, which can be particularly useful when dealing with stuck rusted metal bolts.

3. Size and Compatibility with Drill

Lastly, it is essential to choose drill bits that are compatible with your drilling equipment. Check the size and shank diameter of the drill bits to ensure they fit properly in your drill. Using drill bits that are too small or too large can result in inefficient drilling and potential damage to the equipment.

In conclusion, selecting the right drill bits for removing stuck rusted metal bolts is crucial for a successful outcome. Consider the compatibility with the material, the durability and strength of the drill bits, and ensure they are the correct size and compatible with your drill. By taking these factors into account, you can enhance your drilling experience and improve your chances of effectively removing stuck rusted bolts.

Factors to Consider When Choosing Drill Bits for Rusted Metal Bolts

When it comes to dealing with stuck rusted metal bolts, having the right drill bits can make all the difference. However, not all drill bits are created equal, and it’s important to consider a few key factors when choosing the right ones for this particular task.

1. Material: The type of material the drill bits are made of is crucial when dealing with rusted metal bolts. Look for drill bits that are specifically designed for drilling through hardened steel or other tough metals. These bits are usually made from high-speed steel (HSS) or cobalt steel, which have the necessary strength and durability to handle the job.

2. Coating: Another factor to consider is the coating on the drill bits. Look for bits with a coating such as titanium nitride (TiN) or black oxide. These coatings provide additional hardness and reduce friction, making it easier to drill through rusted metal bolts without overheating or dulling the bits.

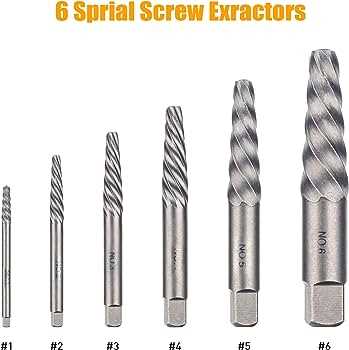

3. Size and Type: The size and type of drill bits you choose will depend on the size and condition of the rusted metal bolts. For smaller bolts, a set of twist drill bits in various sizes should suffice. However, for larger or more stubborn bolts, consider using a set of cobalt drill bits or step drill bits. These specialty bits are designed to handle thicker and harder materials.

4. Shank Design: The shank design of the drill bits is also important to consider. Look for bits with a hex shank or a reduced shank. These designs provide a more secure and precise fit in the drill chuck, reducing the chance of slipping or wobbling while drilling.

5. Reviews and Recommendations: Finally, it’s always a good idea to read reviews and seek recommendations from professionals or experienced DIYers who have dealt with similar situations. Their feedback can provide valuable insights into the performance and durability of different drill bits for rusted metal bolts.

By considering these factors and choosing drill bits that are specifically designed for rusted metal bolts, you can increase your chances of successfully removing stuck bolts without damaging your tools or the surrounding materials.

Material composition of the drill bits

The drill bits used for removing stuck rusted metal bolts are typically made from high-speed steel (HSS), cobalt steel, or carbide. These materials are chosen for their strength, durability, and ability to withstand the harsh conditions encountered when drilling into rusted metal.

High-speed steel (HSS) is one of the most commonly used materials for drill bits. It is a type of tool steel that contains a combination of carbon, tungsten, and other elements. HSS drill bits are known for their heat resistance and longevity. They can withstand high temperatures generated during drilling, making them suitable for drilling through rusted metal bolts.

Cobalt steel is another popular choice for drill bits in situations where increased heat resistance is required. It is an alloy composed of cobalt and high-speed steel. The addition of cobalt enhances the strength and heat resistance of the drill bits. Cobalt steel drill bits are often used when drilling through hardened steel or stainless steel bolts.

Carbide drill bits are known for their exceptional hardness and durability. They are made from a compound composed of tungsten carbide particles bonded together with a metal matrix. Carbide drill bits can effectively drill into tough materials such as rusted metal bolts. They are particularly suitable for drilling into hardened steel or other abrasive materials.

In summary, the drill bits used for removing stuck rusted metal bolts are typically made from high-speed steel, cobalt steel, or carbide. These materials offer excellent strength, durability, and heat resistance, making them suitable for drilling into tough and rusted metal surfaces.

5 Best drill bits for stuck rusted metal bolts

Features

| Part Number | MAGARET-0446 |

Features

| Part Number | MJ-915 |

| Model | 1 |

| Color | Pack of 7 |

| Is Adult Product | |

| Size | 7 Stück (1er Pack) |

Features

| Part Number | 2608900611 |

| Model | 2608900611 |

| Color | Silver |

| Size | Ø 6 x 100 mm |

Features

| Part Number | SE434105 |

| Model | SE434105 |

| Color | Silver |

| Size | 05 Piece Set |

| Language | English |

Features

| Part Number | SCREW001 |

| Model | SCREW001 |

| Color | Silver |

| Release Date | 2018-01-23T00:00:01Z |

| Size | Standard |

| Publication Date | 2018-01-23T00:00:01Z |

Q&A:

What is the material composition of drill bits?

Drill bits are typically made from high-speed steel (HSS), cobalt steel, carbide, or diamond.

What is high-speed steel (HSS)?

High-speed steel is a type of tool steel that contains alloys such as tungsten, chromium, and vanadium. It is known for its ability to maintain hardness and withstand high temperatures, making it suitable for cutting tools like drill bits.

What is cobalt steel?

Cobalt steel is a type of high-speed steel that contains a significant amount of cobalt. The addition of cobalt improves the hardness, toughness, and heat resistance of the steel, making it ideal for drilling hard materials like stainless steel.

What is carbide?

Carbide refers to a compound made of carbon and a metallic element, usually tungsten or titanium. In the context of drill bits, carbide usually refers to tungsten carbide, which is a very hard and brittle material. Drill bits made of carbide are suitable for drilling through hard materials like concrete or masonry.

What are diamond drill bits?

Diamond drill bits are made with small particles of synthetic diamond embedded in the tip. Diamond is the hardest known material, which allows these drill bits to drill through extremely hard materials such as glass, ceramic, or hardened steel. Diamond drill bits are often used in specialized applications where other drill bits would quickly wear out or fail.

Conclusion

In conclusion, the material composition of drill bits is a crucial factor in determining their performance and longevity. The choice of materials, such as high-speed steel, cobalt, carbide, or diamond, depends on the specific application and the type of material to be drilled. Each material offers different qualities, such as hardness, heat resistance, and durability. Understanding the material composition of drill bits is essential for selecting the right tool for the job and ensuring efficient and effective drilling operations. It is also essential to consider the cost and availability of different materials when choosing the drill bits for a particular project. Overall, the proper selection and utilization of drill bits with the appropriate material composition can significantly improve drilling efficiency and reduce costs in various industries.