Best drill bit for pilot holes n wood

When it comes to woodworking projects, creating pilot holes is an essential step that ensures accurate and clean results. A pilot hole is a small-diameter hole drilled into wood before inserting a screw or a nail. It helps prevent the wood from splitting and ensures that the fastener goes in straight and flush with the surface. To achieve the best results, it is crucial to use the right drill bit for pilot holes.

One of the best drill bits for pilot holes in wood is a brad-point bit. This type of drill bit has a sharp and pointed tip that allows for precise placement and easy centering. The brad point design also helps prevent the bit from wandering or slipping off the desired spot, resulting in a clean and accurate pilot hole. It is particularly suitable for drilling hardwoods and softwoods, making it a versatile option for various woodworking projects.

Another excellent choice for pilot holes in wood is a self-centering drill bit. This type of bit has a unique design with a tapered guide collar that automatically centers the bit on the desired spot. It eliminates the need for pre-marking or measuring, saving time and effort. The self-centering drill bit is especially useful when working with hinges, hardware installations, or any project that requires precise alignment. It creates clean and perfectly centered pilot holes every time.

Overall, selecting the best drill bit for pilot holes in wood depends on the specific project requirements and personal preferences. Whether choosing a brad-point bit for precision or a self-centering bit for convenience, investing in high-quality drill bits can significantly improve woodworking results and enhance the overall experience.

What is a pilot hole and why is it important in woodworking?

In woodworking, a pilot hole is a small hole that is drilled into a piece of wood before driving in a screw or nail. It is an important step in the woodworking process because it helps prevent the wood from splitting or cracking when the fastener is inserted. A pilot hole allows for a smoother and easier insertion of the screw or nail, reducing the risk of damaging the wood.

When a screw or nail is driven directly into wood without a pilot hole, the wood fibers can be pushed apart, causing the wood to split. This can weaken the overall structure and make it more difficult to securely fasten the materials together. By drilling a pilot hole, the wood fibers are pre-cut and displaced, reducing the chances of splitting and ensuring a tight and secure connection.

A pilot hole also helps to guide the screw or nail into the desired location and prevents it from wandering off course. This is especially important when working with hardwoods or dense materials, as they can be more difficult to drive fasteners into. By starting with a pilot hole, you can ensure that the screw or nail goes straight and true, improving the overall quality and appearance of the finished project.

Overall, a pilot hole is an essential step in woodworking that helps to prevent wood splitting, ensures a tight and secure connection, and improves the accuracy of fastener placement. It is a simple yet effective technique that every woodworker should practice to achieve professional-looking results.

Choosing the Right Drill Bit for Pilot Holes

When it comes to drilling pilot holes in wood, choosing the right drill bit is essential for achieving clean and precise results. Here are some factors to consider when selecting the perfect drill bit for your pilot holes.

1. Material of the Drill Bit

One important aspect to consider is the material of the drill bit. Common options include high-speed steel (HSS), carbon steel, and cobalt. HSS drill bits are durable and versatile, making them suitable for most wood drilling applications. Carbon steel bits are ideal for softwoods, while cobalt bits are excellent for harder wood species.

2. Bit Size

The size of the drill bit is another crucial factor. Typically, the pilot hole should be slightly smaller than the diameter of the screw or nail you plan to use. This ensures a snug fit without splitting the wood. It’s recommended to refer to a pilot hole size chart to determine the appropriate bit size for your specific application.

3. Point Angle

The point angle of the drill bit affects its ability to start the hole smoothly and reduce the risk of tearing or splintering. Common point angles for wood drilling are 118 degrees and 135 degrees. The 118-degree angle is suitable for general-purpose drilling, while the 135-degree angle provides better performance for hardwoods and reduces the need for excessive force.

4. Shank Type

The shank refers to the part of the drill bit that attaches to the drill. Common shank types include straight shank and hex shank. Straight shank bits are compatible with most traditional drills, while hex shank bits offer better grip and are commonly used with impact drivers. Choosing the right shank type depends on the tool you plan to use.

By considering these factors, you can choose the best drill bit for pilot holes in wood and ensure precise and clean results for your woodworking projects.

Factors to consider when selecting a drill bit

When it comes to selecting a drill bit for pilot holes in wood, there are several important factors to consider. These factors will help ensure that you choose the right type and size of drill bit for your specific needs, which is crucial for achieving accurate and clean pilot holes.

1. Material

One key factor to consider is the material of the drill bit. Different materials, such as high-speed steel or carbide, offer different levels of hardness and durability. High-speed steel bits are ideal for most wood drilling applications, but if you’re working with harder woods or need extra durability, carbide bits may be a better option.

2. Size

The size of the drill bit is another important consideration. It’s crucial to choose a drill bit that matches the diameter of the screw or nail you’ll be using. Using a drill bit that is too small can result in a weak and unstable pilot hole, while using a bit that is too large may cause the hole to be too loose and compromise the overall strength of the connection.

3. Shank type

Another factor to consider is the type of shank on the drill bit. There are two main types: round and hex. Round shanks are the most common and can be used with a standard drill chuck. Hex shanks, on the other hand, are designed for use with quick-change drill systems and are known for their quick and easy bit swapping capabilities.

4. Point angle and design

The point angle and design of the drill bit also play a role in achieving clean and accurate pilot holes. A pointed tip with a sharper angle is often better for wood drilling, as it helps prevent the bit from wandering and ensures a clean entry into the wood. Additionally, some drill bits feature special designs, such as spurs or brad points, which help enhance precision and reduce splintering.

By considering these factors and choosing the right drill bit for your pilot hole needs, you can ensure that your woodworking projects are successful and produce high-quality results.

Drill Bits for Pilot Holes in Wood

If you’re looking for the best drill bits to use for pilot holes in wood, you’ll want something that is durable, sharp, and designed specifically for wood. Pilot holes are essential when it comes to preventing wood from splitting, and a good quality drill bit will make the job much easier.

1. Brad Point Drill Bits

One of the top choices for drilling pilot holes in wood is the brad point drill bit. These drill bits have a sharp point at the tip, which helps to accurately locate the hole and prevent it from wandering. The fluted design of the bit also helps to remove wood chips and debris, resulting in clean and precise pilot holes. Brad point drill bits are available in various sizes, so you can choose the one that best suits your needs.

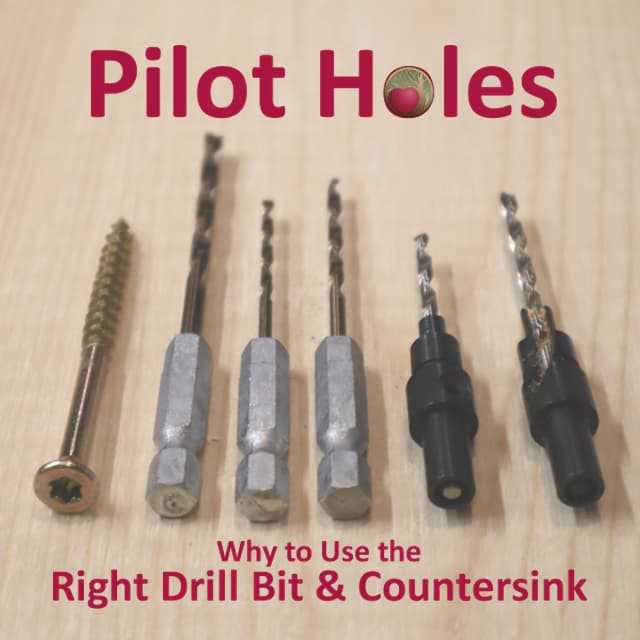

2. Countersink Drill Bits

If you’re looking for a drill bit that can both drill pilot holes and create countersinks, then countersink drill bits are a great option. These drill bits have a tapered cone at the end, which allows them to create a countersink hole for the screw head. The cutting edges of countersink drill bits are sharp and designed to drill clean pilot holes in wood. They come in different sizes, allowing you to choose the perfect fit for your screws.

3. Forstner Drill Bits

Forstner drill bits are another excellent choice for drilling pilot holes in wood. These bits have a flat bottom and cutting edges around the circumference, which allows them to drill precise and flat-bottomed holes. Forstner bits are often used when you need to create clean and smooth holes for dowels or other fittings. They are available in various sizes, making it easy to find the right fit for your project.

Overall, when it comes to drilling pilot holes in wood, brad point, countersink, and Forstner drill bits are among the best options. Each type offers unique features that make them suitable for specific applications. Choose the drill bit that best fits your project requirements and enjoy clean and precise pilot holes in your woodwork.

Pros and Cons of Each Drill Bit for Pilot Holes in Wood

Pilot holes are essential in woodworking projects to prevent wood from splitting and to ensure accurate drilling. Choosing the right drill bit for pilot holes is crucial, as different bits have their own advantages and disadvantages. Here are the pros and cons of each drill bit commonly used for pilot holes in wood:

Brad Point Drill Bits

Brad point drill bits are widely preferred for creating pilot holes in wood. They have a pointed tip that helps in accurately positioning the hole and reducing the chances of wood splitting. These bits leave clean holes and are suitable for various woodworking tasks. However, their sharp tip can be prone to breakage if excessive force or pressure is applied, and they may not be as effective on harder woods.

Twist Drill Bits

Twist drill bits are versatile and commonly used for drilling pilot holes in wood. They have a sharp tip and spiral flute design, which allows for efficient chip removal. These bits can be used with both handheld drills and drill presses. Twist drill bits can be more durable and less prone to breakage compared to brad point bits, but they may not produce as clean and precise holes.

Countersink Drill Bits

Countersink drill bits are designed specifically for creating pilot holes with a wider opening that can accommodate screw heads. They have a tapered tip and fluted design that allows for a snug fit of the screw head. These bits can create a chamfered or cone-shaped hole, which enhances the appearance of the woodworking project. However, countersink drill bits may not provide the same level of accuracy and control as brad point or twist drill bits when it comes to creating precise pilot holes without additional accommodations for screws.

Each drill bit mentioned above has its own advantages and disadvantages. If accuracy and preventing wood splitting are paramount, then brad point drill bits are a great choice. For versatility and durability, twist drill bits are a reliable option. And if the project involves screw fastenings, countersink drill bits can offer both functionality and aesthetic appeal. Ultimately, the choice of drill bit for pilot holes in wood depends on the specific needs, preferences, and requirements of the woodworking project at hand.

5 Best drill bit for pilot holes n wood

Features

| Part Number | Drill Bit Set |

| Language | English |

Features

| Part Number | TA01040001 |

Features

| Part Number | LK-1095 |

Question-answer:,

What are the pros and cons of twist drill bits?

Twist drill bits are versatile and can be used for a wide range of materials. They are also relatively inexpensive. However, they may not provide the cleanest or most precise holes, especially in harder materials.

What are the pros and cons of masonry drill bits?

Masonry drill bits are specifically designed for drilling into brick, concrete, and stone. They are extremely durable and can withstand high heat. However, they may be more expensive compared to other types of drill bits and may not be suitable for drilling into other materials.

What are the pros and cons of spade drill bits?

Spade drill bits are great for drilling large, flat-bottomed holes. They are also relatively inexpensive. However, they may not be as precise as other drill bits and are not suitable for drilling into hard materials.

What are the pros and cons of step drill bits?

Step drill bits are excellent for drilling different-sized holes without needing to change bits. They are also great for thin materials as they reduce the risk of snagging or tearing. However, they may be more expensive compared to other drill bits and may not be suitable for drilling into thick materials.

What are the pros and cons of diamond drill bits?

Diamond drill bits are specifically designed for drilling into hard materials such as glass, tile, and granite. They produce clean and precise holes. However, they can be quite expensive compared to other drill bits and may require the use of water or lubrication during drilling.

Conclusion

In conclusion, it is important to weigh the pros and cons of each type of drill bit in order to determine which one is best suited for your specific needs. HSS drill bits offer durability and versatility, making them a popular choice in many drilling applications. However, they are not as effective when used on harder materials. Carbide drill bits, on the other hand, are extremely durable and excel at drilling into harder materials, but they can be more expensive and are not as versatile as HSS drill bits. Cobalt drill bits offer a good balance between durability and versatility, making them a great choice for a wide range of drilling tasks. Finally, diamond drill bits are the most expensive option, but they offer unparalleled strength and are essential for drilling into extremely hard materials such as concrete or glass. Ultimately, choosing the right drill bit depends on the specific material you are drilling into and the level of durability and versatility you require.