Best drill bit for not splintering other side

When it comes to drilling, one of the biggest challenges is preventing splintering on the other side of the material. Whether you’re working with wood, plastic, or any other material, splintering can not only ruin the appearance of your project but also weaken its structure. That’s why it’s crucial to choose the right drill bit to minimize or even eliminate splintering.

There are several factors to consider when selecting the best drill bit for preventing splintering. First and foremost, the type of material you’re drilling through plays a significant role. Different drill bit designs and constructions offer varying levels of precision and effectiveness in preventing splintering. Some drill bits are specifically designed for use on wood, while others are better suited for plastic or metal.

Another crucial factor is the cutting edge of the drill bit. Drill bits with sharp edges and precise cutting angles tend to produce cleaner holes with reduced splintering. Look for drill bits that have a sharp point and have been specifically designed for clean hole penetration.

Additionally, the drill bit’s rotation speed and feed rate also play a role in preventing splintering. A slower rotation speed and steady feed rate give the drill bit more time to remove materials and reduce the likelihood of splintering. It’s essential to match the rotation speed and feed rate to the type of material you’re working with to achieve the best results.

Lastly, consider using drill bits with specialized features to prevent splintering. For example, some drill bits have built-in depth stop collars that ensure precise drill depth and prevent over-penetration, which can cause splintering. Others may have special coatings or designs that reduce friction and heat, further minimizing the chances of splintering.

Best Drill Bit for Minimizing Splintering on the Other Side

When working on woodworking or other projects that involve drilling holes, it’s important to choose the right drill bit in order to minimize splintering on the other side of the material. Splintering can occur when the drill bit breaks through the material, causing the fibers to separate and create rough, uneven edges. To achieve clean, professional-looking holes without any splintering, consider the following drill bits:

Brad Point Drill Bits

Brad point drill bits are known for their ability to create clean, precise holes without splintering on the other side. These bits feature a pointed tip that helps to guide the bit through the material, reducing the chances of the fibers splitting. Brad point drill bits are commonly used in woodworking, as they are designed to drill clean holes in wood without causing any tear-out or chipping.

Downcut Spiral Drill Bits

If you’re working with plywood, melamine, or other materials that tend to splinter easily, downcut spiral drill bits are a good option. These bits have flutes that spiral downwards, forcing the chips and debris downwards as well. This downward force helps to prevent the material from splintering as the drill bit cuts through. Downcut spiral drill bits are particularly effective in creating smooth, splinter-free holes in materials with a laminate or veneer surface.

Forstner Drill Bits

Forstner drill bits are often used when precision and clean cuts are essential. These bits have a flat bottom and sharp, edges, allowing them to create flat-bottomed holes with clean edges. The outer rim of the bit also helps to guide the cutting action, reducing the chances of splintering on the other side. Forstner drill bits are ideal for drilling holes in materials like hardwood, as they provide clean and precise results.

When choosing a drill bit, always consider the material you will be working with and the desired outcome. Experimenting with different drill bits and practicing on scrap material can also help you find the best option for your specific project. Remember to always use proper drilling techniques like gradually increasing speed and applying steady pressure to reduce the chances of splintering on the other side.

What Causes Splintering?

Splintering is a common problem when drilling holes in various materials. It occurs when the drill bit breaks or cracks the surface of the material, creating rough and jagged edges that are prone to splintering. There are several factors that can contribute to splintering, including the type of material being drilled, the speed at which the drill is operated, and the condition of the drill bit itself.

Material Type: Different materials have different properties, and some are more prone to splintering than others. For example, soft and brittle materials like wood or plastic are more likely to splinter compared to harder materials like metal or ceramic. The structure and density of the material can also influence splintering. Materials with a fine and even grain are less likely to splinter, while those with a coarse or uneven texture are more susceptible.

Drill Speed: The speed at which the drill is operated can also affect splintering. When drilling too fast, the drill bit may not have enough time to cut through the material cleanly, causing it to chip or crack the surface. On the other hand, drilling too slowly can also lead to splintering as the bit may get caught and create uneven pressure, causing the material to splinter.

Drill Bit Condition: The condition of the drill bit is crucial when it comes to preventing splintering. A dull or damaged drill bit is more likely to cause splintering than a sharp and well-maintained one. A dull bit may not be able to cut through the material cleanly, leading to rough edges and increased splintering. It is important to regularly check and sharpen drill bits to ensure they are in optimal condition.

Summary: Splintering is caused by various factors including the type of material being drilled, the speed at which the drill is operated, and the condition of the drill bit. Understanding these factors and taking appropriate precautions can help minimize splintering and achieve cleaner and neater holes.

Factors to Consider When Choosing a Drill Bit

When it comes to choosing a drill bit, there are several factors that you need to consider to ensure that you get the best results. Here are some key factors to keep in mind:

Diameter:

The diameter of the drill bit plays a crucial role in the success of your drilling project. It is important to select a drill bit with the appropriate diameter for the size of the hole you need to drill. Using a drill bit that is too small may result in a weak hole, while using a drill bit that is too large can cause damage to the surrounding material.

Material:

The material you are drilling into will also influence the type of drill bit you should choose. Different drill bits are designed to work best with specific materials. For example, a masonry drill bit is ideal for drilling into concrete or brick, while a wood drill bit is better suited for drilling into wooden surfaces. Selecting the right drill bit for the material you are working with will help to prevent splintering or damage.

Coating:

The coating of a drill bit can affect its performance and durability. Some drill bits are coated with materials like titanium or cobalt to increase their strength and resistance to heat. These coated drill bits are often more expensive, but they can provide better results when drilling into tough materials. Consider the type of material you will be drilling into and choose a drill bit with a suitable coating for optimal performance.

Speed and Feed Rate:

When using a drill bit, it is important to consider the appropriate speed and feed rate for the material you are working with. If the speed is too high or the feed rate is too slow, it can cause overheating and increase the risk of splintering. On the other hand, if the speed is too slow or the feed rate is too high, it may result in a poor quality hole. Pay attention to the recommended speed and feed rates for the drill bit you are using to achieve the best results.

By considering these factors and selecting the appropriate drill bit, you can minimize the risk of splintering or damaging the material you are working with. It is important to choose a drill bit that is designed for the specific task at hand to ensure success in your drilling projects.

Drill Bits for Minimizing Splintering: A Guide

When working with delicate or fragile materials such as wood veneer, laminate, or plywood, it’s crucial to choose the right drill bit to prevent splintering on the opposite side. Splintering can be unsightly and compromise the structural integrity of the material. Fortunately, there are several drill bits specifically designed to minimize splintering and deliver clean, precise holes.

1. Brad Point Drill Bits

One popular option for minimizing splintering is the brad point drill bit. Typically used for woodworking, these bits have a sharp, centered tip that helps to prevent the wood from splintering as the bit enters the material. Brad point drill bits also have angled spurs around the circumference, which score the wood fibers ahead of the cutting edge, further reducing the risk of splintering.

2. Countersink Drill Bits

If you’re looking to both drill a hole and create a countersink for screws in one step, countersink drill bits are a great choice. These bits incorporate a drill bit and a separate countersink into one tool. The countersink portion is designed to create a beveled edge around the hole, which can help prevent splintering on the opposite side. It’s important to select a countersink drill bit with a matching diameter to your screw size for the best results.

3. Forstner Drill Bits

For drilling larger, precise holes without splintering, consider using forstner drill bits. These bits have a flat bottom and sharp edges that cut clean, smooth holes with minimal splintering. Forstner bits are often used in cabinetry and furniture-making projects, where a clean and precise hole is essential.

4. Router Bits

If you have a router, another option for minimizing splintering is to use router bits. These bits can be equipped with a variety of cutting edges and profiles to achieve different results. When using a router bit, make sure to adjust the speed and feed rate to match the material being drilled to reduce the risk of splintering.

When choosing drill bits to minimize splintering, consider the material you’re working with, the size of the hole, and the desired result. Investing in high-quality drill bits and using proper drilling techniques can help you achieve clean, splinter-free holes in your delicate materials.

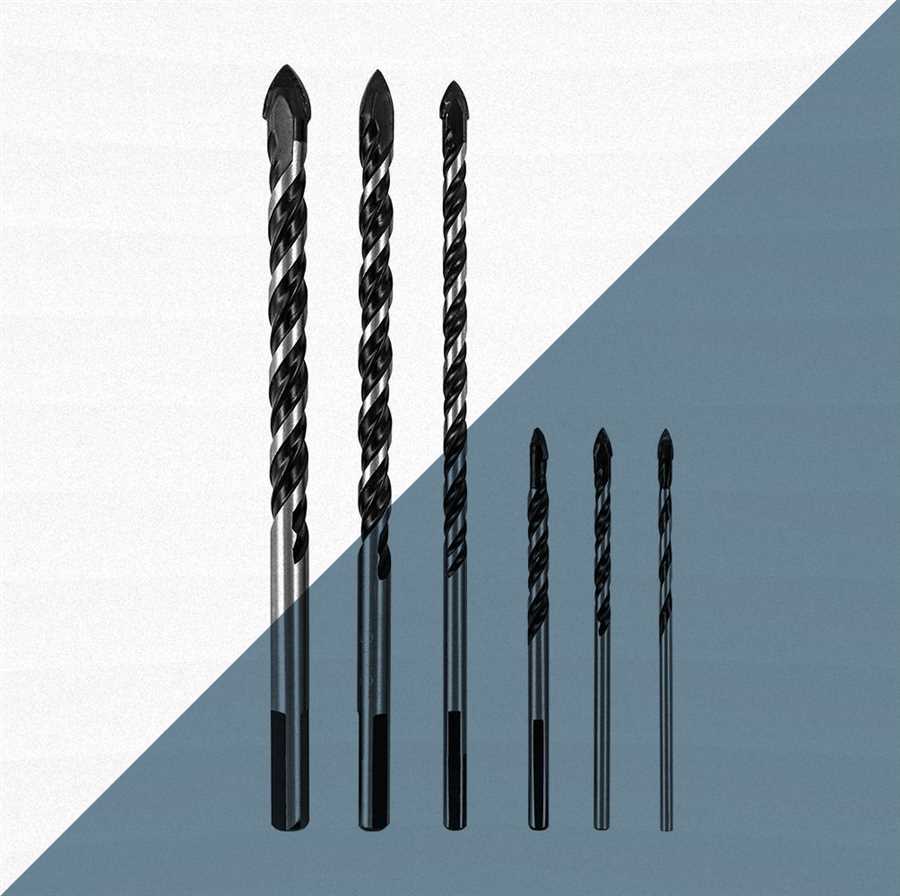

5 Best drill bit for not splintering other side

Features

| Part Number | JN-NEW-018 |

| Model | 1 |

Features

| Part Number | D06252FC |

Features

| Part Number | SDB-ALL |

| Model | HSS-SD-3 |

| Color | Gold |

Features

| Part Number | 2607019327 |

| Model | 0 |

| Color | Black/Gold/Silver |

| Is Adult Product | |

| Release Date | 2018-01-17T00:00:01.000Z |

| Size | 50 Pieces |

Features

| Part Number | 80331012 |

| Model | 80331012 |

Features

| Part Number | 04 |

Question-answer:,

What are the top drill bits for minimizing splintering?

The top drill bits for minimizing splintering are Brad point bits, Downcut spiral bits, Forstner bits, Diamond-coated bits, and Pilot point bits.

How do Brad point bits minimize splintering?

Brad point bits have a sharp tip and two relatively small cutters on the sides, which helps to prevent splintering by scoring the surface before drilling through it.

Why are Downcut spiral bits good for minimizing splintering?

Downcut spiral bits have a flute design that pushes the chips downwards, reducing the likelihood of splintering on the top surface of the material.

What are the advantages of using Forstner bits to minimize splintering?

Forstner bits have a flat bottom design and sharp cutting edges, which allows them to create clean holes with minimal splintering.

How do Diamond-coated bits minimize splintering?

Diamond-coated bits have a hard and abrasive surface that helps to cut through material cleanly, reducing the chances of splintering.

What types of drill bits are best for minimizing splintering?

There are several types of drill bits that are known for minimizing splintering, including brad point bits, Forstner bits, and spade bits with spur cutters. These bits have sharp points and cutting edges that help to create clean holes without causing excessive splintering.

Are there any specific brands of drill bits recommended for minimizing splintering?

While there are many reputable brands that manufacture high-quality drill bits, some popular options for minimizing splintering include Bosch, DEWALT, and Irwin. These brands are known for producing durable and precision drill bits that can help to reduce splintering during drilling.

Conclusion

In conclusion, when it comes to minimizing splintering during drilling, it is essential to choose the right drill bits. Among the top drill bits recommended for this purpose are Brad Point Bits, which feature a sharp, center-point tip that helps prevent splintering. Additionally, Forstner Bits are a great choice as they create clean, flat-bottomed holes with little to no splintering. Countersink Bits are also worth considering as they allow for smooth, flush holes without any splintering. Lastly, Spade Bits, particularly those with a spur cutting edge, are great for drilling larger holes without splintering. By using these top drill bits, one can significantly reduce the risk of splintering and achieve clean, professional-looking holes in their woodworking projects.