Best drill bit angle for stainless steel

When it comes to drilling through stainless steel, choosing the right drill bit angle is crucial. Stainless steel is a tough and durable material that requires a different approach compared to drilling through other metals or materials. The angle of the drill bit plays a significant role in determining the effectiveness and efficiency of the drilling process.

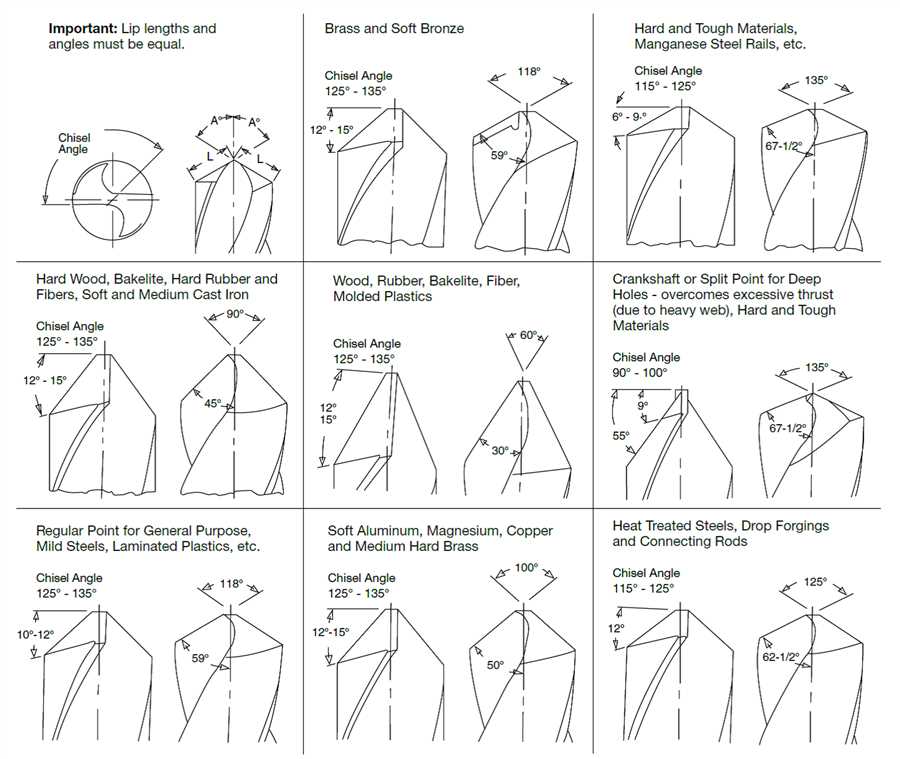

One of the best drill bit angles for stainless steel is 135 degrees. This angle is commonly referred to as the “split point” angle and is considered ideal for drilling through tough materials like stainless steel. The 135-degree angle creates a sharp cutting edge that helps to penetrate the metal more easily, reducing the risk of surface damage or drill bit breakage.

In addition to the 135-degree angle, another popular option is the 118-degree angle. Although not specifically designed for stainless steel, the 118-degree angle is commonly used for general-purpose drilling. It can also be effective when drilling through stainless steel, but may require more pressure and slower drilling speeds compared to the 135-degree angle.

Ultimately, the choice of drill bit angle for stainless steel depends on various factors, including the thickness of the material, the type of stainless steel being drilled, and the equipment being used. It is always recommended to consult the manufacturer’s guidelines or seek professional advice to ensure the best results and prevent any potential damage to the material or equipment.

Choosing the Right Drill Bit Angle for Stainless Steel

When working with stainless steel, it is crucial to use the right drill bit angle to ensure efficient drilling and prevent damage to the material. Stainless steel is a hard and tough metal that requires a specific angle to cut through effectively.

A drill bit with a 135-degree angle is commonly recommended for drilling stainless steel. This angle is considered optimal because it allows for a sharper cutting edge, which can easily penetrate the tough surface of stainless steel. The sharper angle also helps to reduce heat buildup during drilling, preventing the drill bit from becoming dull or overheating.

Another angle option that can be suitable for drilling stainless steel is a 118-degree angle. While not as sharp as the 135-degree angle, the 118-degree angle provides a more robust cutting edge that can handle the harder nature of stainless steel. This angle is often preferred for drilling larger diameter holes or when working with thicker stainless steel sheets.

It’s important to note that using the right drill bit angle is just one factor to consider when drilling stainless steel. Other factors, such as the drill bit material, speed, and lubrication, also play a significant role in achieving the best results. It’s recommended to use high-speed steel or cobalt drill bits specifically designed for stainless steel drilling, and to use cutting oil or lubricant to reduce friction and heat during the drilling process.

Importance of Drill Bit Angle for Stainless Steel

Choosing the right drill bit angle is crucial when drilling into stainless steel. Stainless steel is a tough and hard material, so using the correct drill bit angle can significantly impact drilling performance and the overall quality of the hole.

A proper drill bit angle helps to reduce heat and prevent overheating, which can lead to damage or dulling of the drill bit. The angle of the drill bit determines the cutting action and how efficiently the metal is removed, ensuring a clean and precise hole.

Effective chip evacuation: One of the key benefits of using the right drill bit angle is effective chip evacuation. The angle allows for proper removal of chips or metal shavings, preventing clogging and reducing the risk of a broken drill bit. Proper chip evacuation ensures smooth drilling and prolongs the life of the drill bit.

Improved drilling efficiency: The correct drill bit angle improves drilling efficiency by reducing the amount of force required to drill through stainless steel. This not only saves time and effort but also minimizes the risk of the drill bit getting stuck or breaking during the drilling process. Using a drill bit with the right angle ensures smooth and efficient drilling, resulting in clean and professional-looking holes.

In conclusion, selecting the right drill bit angle is essential when drilling into stainless steel. It helps to reduce heat, improve chip evacuation, and enhance drilling efficiency. Always consult the manufacturer’s recommendations and choose a drill bit with the appropriate angle for the best results when working with stainless steel.

Understanding Drill Bit Angle Measurements

When it comes to drilling into different materials, such as stainless steel, understanding drill bit angle measurements is crucial. The angle of a drill bit refers to the slope or incline of its cutting edge. It plays a significant role in determining the efficiency and effectiveness of the drilling operation.

The most common drill bit angle measurement is the point angle, which refers to the angle between the two cutting edges of the drill bit. This angle is typically measured in degrees and can vary depending on the material being drilled. For example, when drilling into stainless steel, a point angle of around 135 degrees is often recommended. This angle helps to create a sharper cutting edge, allowing for better penetration and chip removal.

Another important angle measurement is the helix angle, which refers to the angle between the cutting edge and the axis of the drill bit. This angle affects the rate at which the drill bit removes material and the efficiency of chip evacuation. In general, a higher helix angle is preferred when drilling stainless steel, as it helps to reduce heat build-up and prevent the drill bit from clogging.

It is worth noting that the optimal drill bit angle for stainless steel may vary depending on factors such as the specific alloy and thickness of the material. Therefore, it is always recommended to consult the drill bit manufacturer’s recommendations or seek expert advice to ensure the best results when drilling stainless steel.

The Best Drill Bit Angle for Stainless Steel

When it comes to drilling through stainless steel, choosing the right drill bit angle is crucial for achieving the best results. Stainless steel is a tough material that requires a specialized approach to drilling in order to avoid chipping or breaking the metal. The angle of the drill bit plays a significant role in determining the success of the drilling process.

One of the most effective angles for drilling through stainless steel is a 135-degree angle. This angle allows for a sharp cutting edge that helps to penetrate the hard surface of the stainless steel without causing excessive friction or heat buildup. The 135-degree angle also provides good chip evacuation, which is important for maintaining the cutting efficiency of the drill bit and preventing clogging.

Drill bits with a 135-degree angle are commonly referred to as “split point” or “self-centering” bits. These bits have a specialized design that helps them to start drilling immediately on contact, minimizing the risk of wandering or drifting off center. This self-centering feature is particularly important when drilling into stainless steel, as it helps to ensure precise and accurate holes.

In addition to the angle, the quality of the drill bit material is also important for drilling through stainless steel. High-speed steel (HSS) drill bits are a popular choice due to their durability and ability to withstand high temperatures. Cobalt drill bits, which contain a high percentage of cobalt, are even more heat-resistant and are ideal for drilling through tough materials like stainless steel.

When drilling through stainless steel, it is essential to use the appropriate drill bit angle to ensure successful and efficient drilling. A 135-degree angle, commonly found in split point or self-centering bits, provides the best combination of sharpness, chip evacuation, and precision. Coupled with high-quality drill bit material like HSS or cobalt, these angles can help you achieve clean and accurate holes in stainless steel.

Tips for Drilling Stainless Steel

When it comes to drilling stainless steel, there are a few important tips to keep in mind in order to achieve the best results. Stainless steel is a durable and high-strength material, which can make it challenging to work with. Here are some tips to help you successfully drill into stainless steel:

1. Use the right drill bit

Choosing the right drill bit is crucial when drilling stainless steel. High-speed steel (HSS) drill bits are commonly used for this material, as they have an increased heat resistance and can withstand the hardness of stainless steel. Cobalt drill bits are another excellent option, as they are specifically designed for drilling into tough materials like stainless steel.

2. Opt for a smaller drill bit angle

When drilling stainless steel, it is recommended to use drill bits with a smaller angle, typically around 135 degrees. This angle helps to reduce the amount of heat generated during drilling, preventing the stainless steel from becoming too hot and potentially damaging the drill bit or workpiece.

3. Use cutting fluid

Applying cutting fluid while drilling stainless steel can greatly improve the overall drilling performance. Cutting fluid helps to reduce heat buildup and friction, making the drilling process smoother and more efficient. It also helps to prolong the life of the drill bit by reducing wear and tear.

4. Use slow and steady drilling speed

When drilling stainless steel, it is important to use a slow and steady drilling speed. This helps to prevent overheating and maintains control over the drilling process. Avoid applying excessive pressure, as this can cause the drill bit to wander or break.

5. Secure the workpiece

Before drilling stainless steel, ensure that the workpiece is securely clamped or held in place. This prevents any movement or vibrations during drilling, which can affect the accuracy of the hole and potentially cause damage to the workpiece.

By following these tips, you can improve your drilling experience with stainless steel and achieve precise and clean holes. Remember to always prioritize safety and wear appropriate protective gear when working with power tools.

5 Best drill bit angle for stainless steel

Features

| Part Number | 2608599039 |

| Model | 2608599039 |

| Color | Na. |

| Size | Ø 6 x 30 mm |

Features

| Part Number | Pangyoo |

| Color | Onecolor |

| Size | Hexagonal |

Features

| Part Number | 2608576669 |

| Model | 2608576669 |

| Warranty | 2 year manufacturer. |

| Release Date | 2022-01-01T00:00:01Z |

| Size | Size |

| Language | English |

Question-answer:,

What type of drill bit should I use for drilling stainless steel?

For drilling stainless steel, it is recommended to use a high-speed steel or cobalt drill bit.

What speed should I set my drill to when drilling stainless steel?

You should set your drill to a slower speed when drilling stainless steel to prevent overheating and damage to the material. Using a speed of around 500-1000 RPM is generally recommended.

Do I need to use cutting oil when drilling stainless steel?

Using cutting oil or lubricant when drilling stainless steel can help reduce friction and heat buildup. It is recommended to use a high-quality cutting oil specifically designed for stainless steel.

How do I prevent drill bits from overheating when drilling stainless steel?

To prevent drill bits from overheating, it is important to take breaks during drilling to let the bit cool down. You can also use cutting oil or lubricant to reduce friction and heat buildup.

What are some tips for drilling stainless steel without breaking drill bits?

To avoid breaking drill bits when drilling stainless steel, make sure to use the correct type of drill bit and a slow speed setting. Applying consistent, even pressure while drilling and using a pecking motion can also help prevent breakage.

What type of drill bit should I use for drilling stainless steel?

When drilling stainless steel, it is recommended to use a high-speed steel (HSS) drill bit or a cobalt drill bit. These types of drill bits are harder and more heat-resistant, making them ideal for drilling into stainless steel.

What lubricant should I use when drilling stainless steel?

When drilling stainless steel, it is important to use a lubricant to reduce heat and friction. Cutting oil or a specially formulated metal drilling lubricant can be used. Apply the lubricant to the drill bit before starting to drill and continue to apply it periodically while drilling to ensure smooth and efficient drilling.

Conclusion

In conclusion, drilling stainless steel requires careful planning and the use of the right tools and techniques. It is important to select the appropriate drill bit and lubricant, as well as to apply consistent pressure and speed during the drilling process. Taking precautions such as wearing safety goggles and using clamps to secure the workpiece can also help ensure a successful drilling operation. With these tips in mind, drilling stainless steel can be a manageable task that produces accurate and clean results.