Best diamond drill bit for ceramic pots

When it comes to drilling holes in ceramic pots, using the right tool is essential. A diamond drill bit is one of the most effective options for this task. With its sharp, diamond-coated tip, it can easily cut through tough materials like ceramic, porcelain, and glass without causing cracks or shattering.

One of the best diamond drill bits for ceramic pots is the Bosch GT2000 Glass and Tile Set. This set includes four diamond drill bits of different sizes, ranging from 1/8 inch to 1/2 inch. The bits are made with high-quality materials and have a precision-ground carbide tip, ensuring long-lasting performance and precise drilling.

Another excellent option is the Drilax Diamond Drill Bit Set. This set also contains multiple drill bits of different sizes, allowing you to choose the one that best suits your needs. The bits have a high concentration of diamond particles, making them extremely durable and efficient in cutting through ceramic and other hard materials.

When using a diamond drill bit for ceramic pots, it’s important to follow the proper drilling techniques. Make sure to use a slow speed and apply consistent pressure to the drill. Using water as a lubricant also helps to keep the drill bit cool and prevent overheating. With the right diamond drill bit and drilling technique, you can easily create precise holes in ceramic pots for drainage or other purposes.

Choosing the Best Diamond Drill Bit for Ceramic Pots

Ceramic pots can be a beautiful addition to any garden or home decor. However, drilling holes in ceramic pots can be a challenging task if you don’t have the right tools. One of the best tools for this job is a diamond drill bit. Diamond drill bits are specifically designed to cut through hard materials like ceramic without cracking or shattering them.

When choosing the best diamond drill bit for ceramic pots, there are a few factors to consider. Firstly, it’s important to select a drill bit that is the right size for the holes you need to make. Diamond drill bits come in various sizes, so be sure to choose one that matches the diameter of the holes you want to drill.

Another important factor to consider is the quality of the diamond drill bit. Look for a drill bit with a high diamond concentration. The higher the concentration, the longer the drill bit will last and the faster it will drill through ceramic. Additionally, check if the drill bit has a strong and durable construction, as this will ensure its longevity.

It’s also worth considering the type of drill you’ll be using. Some diamond drill bits are designed for use with a drill press, while others are suitable for hand drilling. Determine which type of drill you have or plan to use and choose a diamond drill bit that is compatible with it.

In conclusion, when choosing the best diamond drill bit for ceramic pots, consider the size of the holes you need, the quality of the drill bit, and the type of drill you’ll be using. By taking these factors into account, you’ll be able to find a diamond drill bit that is efficient and durable, making your drilling tasks on ceramic pots a breeze.

Factors to Consider when Selecting a Diamond Drill Bit

When it comes to drilling through ceramic pots, selecting the right diamond drill bit is essential for achieving clean and precise holes. There are several factors to consider when choosing the best diamond drill bit for your needs.

1. Diamond Coating Quality

The quality of the diamond coating on the drill bit is an important factor to consider. A higher-quality diamond coating will result in a longer-lasting drill bit that can withstand the rigors of drilling through ceramic. Look for a drill bit with a thick and durable diamond coating to ensure durability and efficiency.

2. Drill Bit Size

Another important factor to consider is the size of the diamond drill bit. The size of the hole you need to drill will determine the size of the drill bit you should choose. Make sure to measure the diameter of the hole you require, and select a drill bit size accordingly. It is important to note that larger drill bits may require a more powerful drill for effective drilling.

3. Shank Size

The shank size of the drill bit is also an important consideration. The shank is the part of the drill bit that fits into the drill, and it should be compatible with your drill. Make sure to check the shank size of the diamond drill bit before purchasing to ensure that it will fit into your drill without any issues.

4. Water Cooling System

Drilling through ceramic requires the use of a water cooling system to prevent the drill bit from overheating and to reduce friction. Some diamond drill bits come with built-in water cooling systems, while others may require the use of a separate cooling system. Consider your preferences and the ease of use when choosing a diamond drill bit with or without a water cooling system.

By considering factors such as the diamond coating quality, drill bit size, shank size, and the presence of a water cooling system, you can select the best diamond drill bit for your ceramic pots. These factors will ensure that you achieve clean and precise holes without damaging your ceramic pots.

Understanding the Types of Diamond Drill Bits Available

When it comes to drilling through ceramic pots, diamond drill bits are the go-to tool. However, not all diamond drill bits are the same. There are several different types available, each suited for different purposes and materials. Having a clear understanding of the different types of diamond drill bits can help you choose the best one for your ceramic pots.

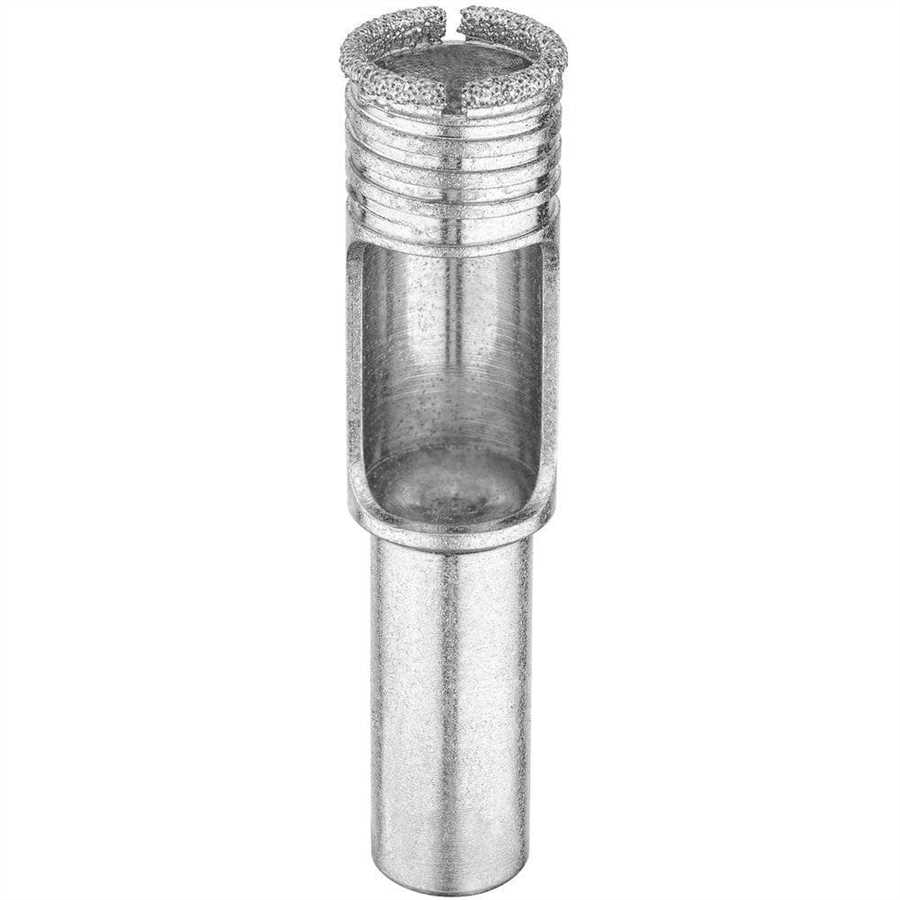

One common type of diamond drill bit is the core drill bit. These drill bits have a hollow center and are typically used for drilling larger holes in ceramic pots. They are effective for creating holes without causing any cracks or damage to the surrounding area. Core drill bits are available in various sizes, allowing you to choose the right one for the specific hole size you need.

Another type of diamond drill bit is the diamond hole saw. This type of drill bit is ideal for drilling smaller holes in ceramic pots. It features a circular shape with diamond-coated edges, allowing for precise and clean drilling. Diamond hole saws are available in different sizes and can be used for various hole sizes.

In addition to core drill bits and diamond hole saws, there are also diamond-coated twist drill bits. These drill bits have a spiral design and are commonly used for drilling through ceramic materials. They are versatile and can be used for drilling both small and large holes. Diamond-coated twist drill bits are known for their durability and ability to create smooth and clean holes in ceramic pots.

Overall, it’s important to understand the different types of diamond drill bits available in order to choose the most suitable one for drilling through ceramic pots. Whether you need to drill large or small holes, there is a diamond drill bit out there that can help you achieve your desired results without damaging your ceramic pots.

Comparing Diamond Drill Bit Sizes

When it comes to drilling ceramic pots, having the right diamond drill bit size can make a big difference. Different sizes of diamond drill bits offer varying levels of precision and efficiency, so it’s important to choose the right one for your project. Here, we will compare diamond drill bit sizes to help you make an informed decision.

1. Small Diamond Drill Bits

Small diamond drill bits, typically ranging from 1mm to 3mm in size, offer excellent precision for intricate designs. These smaller bits are perfect for creating detailed patterns or drilling delicate holes in ceramic pots. They are commonly used by artists and craftsmen who require fine control over their drilling work.

2. Medium Diamond Drill Bits

Medium diamond drill bits, with sizes ranging from 4mm to 8mm, strike a balance between precision and drilling efficiency. These bits are suitable for a wide range of drilling tasks, such as creating drainage holes or installing small fixtures on ceramic pots. They provide enough control for detail work while also allowing for faster drilling speeds.

3. Large Diamond Drill Bits

Large diamond drill bits, usually ranging from 10mm to 25mm, are designed for drilling larger holes or shaping ceramics. These bits offer maximum drilling efficiency and are commonly used in industrial settings or for heavy-duty projects. However, they may not provide the same level of precision as smaller drill bits, so they are better suited for larger-scale tasks.

Ultimately, the choice of diamond drill bit size depends on the specific needs of your ceramic pot drilling project. Consider the level of precision required, the size of the holes or patterns you want to create, and the overall scale of your project to determine the best diamond drill bit size for you.

Evaluating the Quality and Durability of Diamond Drill Bits

Diamond drill bits are a popular choice for drilling into hard materials such as ceramic pots due to their superior strength and durability. However, not all diamond drill bits are created equal, and it is important to evaluate the quality and durability of the drill bit before making a purchase.

One key factor to consider when evaluating diamond drill bits is the quality of the diamond coating. High-quality diamond drill bits feature a thick, even diamond coating that is well-bonded to the drill bit’s surface. This ensures that the diamond coating will not chip or wear off easily, allowing the drill bit to maintain its cutting efficiency over time.

Another important aspect to consider is the design of the drill bit. Look for drill bits that have a strong and sturdy construction, with reinforced shafts and tips. This will help to prevent breakage and ensure that the drill bit can withstand the high pressure and friction that comes with drilling into hard materials.

Additionally, it is worth considering the overall lifespan of the drill bit. While diamond drill bits are known for their durability, some may wear out more quickly than others. Look for diamond drill bits that have a long lifespan and can withstand multiple uses without compromising on performance.

Finally, it is also helpful to read customer reviews and ratings before purchasing a diamond drill bit. This can give you insights into the experiences of other users and help you determine whether a particular drill bit is worth investing in.

Overall, evaluating the quality and durability of diamond drill bits is essential to ensure that you are investing in a product that will deliver long-lasting performance and efficiency when drilling into hard materials such as ceramic pots.

5 Best diamond drill bit for ceramic pots

Features

| Part Number | 16092040MQ |

Features

| Part Number | 2608599039 |

| Model | 2608599039 |

| Color | Na. |

| Size | Ø 6 x 30 mm |

Features

- Always use lubrication (water), otherwise the diamond core drill will burn

- Start your hole diagonally, make a round trace and then hold drill straight

- Perfect for Cutting Accurate Holes in Glass And Ceramics

- Professional Quality Router Bits, Solid Hardened Steel Bodies with Anti-Kickback Design to control the depth of cut and work safely.

- The main function is trimming, three-dimensional clearance angle, slotted.

Features

| Part Number | ADAGA |

| Model | ADAGA |

| Color | 7-yt-m-1pcs |

| Size | One Size |

Features

| Part Number | ADAGA |

| Model | ADAGA |

| Color | 7-yyz-c-1pcs |

| Size | One Size |

Features

| Part Number | 2608576669 |

| Model | 2608576669 |

| Warranty | 2 year manufacturer. |

| Release Date | 2022-01-01T00:00:01Z |

| Size | Size |

| Language | English |

Features

| Part Number | DS-GR-68-ABS |

| Color | Green |

| Size | 68mm + Sechskant-Aufnahme |

Features

| Part Number | DS-GR-68-ABS |

| Size | 82mm |

Features

| Part Number | MOUNTAIN MEN |

Question-answer:,

How can I evaluate the quality of diamond drill bits?

The quality of diamond drill bits can be evaluated by considering factors such as the type of diamond used, the manufacturing process, and the overall design and construction of the bit. High-quality diamond drill bits are typically made with superior diamond material, have a precise and consistent manufacturing process, and feature a durable and robust design.

What is the role of diamond material in the quality of drill bits?

Diamond is the hardest known material, and its presence in drill bits enhances their cutting capabilities. High-quality diamond drill bits use superior diamond material that can withstand high temperatures and pressure, resulting in improved durability and longer tool life.

How important is the manufacturing process in determining the quality of diamond drill bits?

The manufacturing process plays a crucial role in determining the quality of diamond drill bits. A precise and consistent manufacturing process ensures that the diamond is securely bonded to the bit’s base material, resulting in a stronger and more reliable tool. Additionally, a well-controlled manufacturing process helps to eliminate any defects or inconsistencies that could affect the performance and durability of the drill bit.

What factors contribute to the durability of diamond drill bits?

The durability of diamond drill bits depends on factors such as the quality of diamond material, the design and construction of the bit, and the specific application in which the bit is used. High-quality diamond material that is resistant to wear and tear, combined with a robust and well-engineered bit design, can significantly enhance the durability of the drill bit.

How can I determine the durability of a diamond drill bit?

The durability of a diamond drill bit can be determined through testing and evaluation. This involves using the drill bit in various applications and monitoring its performance, such as the speed and ease of drilling, the consistency of the drilled holes, and the overall wear and tear of the bit. Additionally, customer reviews and feedback can also provide insights into the durability and longevity of the drill bit.

What factors should be considered when evaluating the quality of diamond drill bits?

When evaluating the quality of diamond drill bits, some important factors to consider include the diamond quality, the bonding material, the design and geometry of the drill bits, and the overall manufacturing process. Higher-quality diamond drill bits will have diamonds of high-grade hardness and a strong bonding material that securely holds the diamonds in place. The design and geometry of the drill bits should be optimized for efficient drilling and reduced risk of damage or breakage. A comprehensive and meticulous manufacturing process is also crucial in ensuring the overall quality of diamond drill bits.

Conclusion

In conclusion, evaluating the quality and durability of diamond drill bits is crucial for ensuring efficient and effective drilling operations. It is important to consider factors such as the diamond grade, bonding agent, and design of the drill bit when assessing its quality. Additionally, the durability of a diamond drill bit can be determined by evaluating its ability to withstand high temperatures and wear over time. By selecting high-quality diamond drill bits and properly maintaining them, operators can maximize their productivity and achieve optimal drilling results. Continuous improvement in the manufacturing processes and advancements in diamond technology will further enhance the quality and durability of diamond drill bits, making them an indispensable tool for various industries.