Best cobalt drill bits for hardened steel

When it comes to drilling through hardened steel, regular drill bits simply won’t cut it. You need a drill bit that is specifically designed to handle the toughness and hardness of hardened steel. That’s where cobalt drill bits come in.

Cobalt drill bits are made from a high-speed steel with added cobalt, which gives them enhanced strength and durability. They are specifically engineered to withstand the extreme heat and pressure that drilling into hardened steel can generate. With their superior hardness and resistance to wear, cobalt drill bits are the go-to choice for professionals and DIY enthusiasts alike.

Not all cobalt drill bits are created equal, however. To find the best ones for drilling into hardened steel, you need to consider factors such as the bit’s size, coating, and overall build quality. In this article, we will discuss some of the top cobalt drill bits available on the market that are specifically designed for drilling into hardened steel.

What is hardened steel and why is it challenging to drill?

Hardened steel is a type of steel that has gone through a heat treatment process called quenching and tempering. This process makes the steel harder and more durable, which makes it suitable for applications where strength and resistance to wear are important, such as in the construction of cutting tools, molds, and machinery parts. Hardened steel has a higher carbon content and additional alloying elements that contribute to its hardness.

Drilling hardened steel can be challenging due to its hardness. The high carbon content and other alloying elements make the steel extremely tough and difficult to cut through. The hardness of hardened steel can range from 40 to 70 on the Rockwell hardness scale, making it much harder than regular steel. When drilling into hardened steel, the drill bit needs to be able to withstand the high heat and pressure generated during the drilling process without breaking or becoming dull.

Regular drill bits, made of materials such as high-speed steel or cobalt steel, may not be strong enough to effectively drill into hardened steel. Cobalt drill bits, on the other hand, are specifically designed to handle the hardness of hardened steel. These drill bits are made of a cobalt alloy that provides increased strength and heat resistance, allowing them to cut through hardened steel more effectively. They have a higher melting point and are less prone to becoming dull or breaking during the drilling process.

In addition to using the right drill bit, it is also important to use the correct drilling technique when working with hardened steel. This includes using a slower drill speed, applying constant pressure, and using cutting fluid or lubricant to reduce heat and friction. By taking these precautions and using the appropriate drill bit, drilling into hardened steel can be made easier and more efficient.

Factors to Consider When Choosing Cobalt Drill Bits for Hardened Steel

When it comes to choosing cobalt drill bits for hardened steel, there are several important factors to consider to ensure you get the right tool for your needs. Cobalt drill bits are known for their strength and durability, making them ideal for drilling through tough materials such as hardened steel. Here are some key factors to keep in mind:

- Cobalt Content: The cobalt content in the drill bit is crucial as it directly affects its hardness and heat resistance. Look for drill bits with a higher percentage of cobalt, as they will have better performance and longevity when drilling through hardened steel.

- Point Configuration: The point configuration of the drill bit can vary, and it’s important to choose one that is suitable for drilling through hardened steel. A split point or a 135-degree point angle is often preferred for this purpose, as they provide better penetration and reduce the risk of skating or slipping.

- Drill Bit Coating: Some cobalt drill bits come with coatings that enhance their performance and increase their lifespan. Titanium or black oxide coatings are commonly used and can provide better lubricity, heat resistance, and protection against wear and corrosion.

- Size and Shank Type: Consider the size and shank type of the cobalt drill bit you need. Smaller bits are suitable for drilling smaller holes, while larger bits are ideal for larger holes. Also, pay attention to the shank type, as it should be compatible with your drilling equipment.

By considering these factors, you can choose the right cobalt drill bits for drilling through hardened steel with ease and confidence. Remember to prioritize quality and durability to ensure the longevity and performance of your drill bits.

The Importance of Cobalt Content in Drill Bits for Hardened Steel

When it comes to drilling through hardened steel, having the right tools is crucial. One of the most important factors to consider when selecting drill bits for this task is the cobalt content. Cobalt is a metal alloy that is often added to drill bits to enhance their cutting performance and durability.

Drill bits with a higher cobalt content are generally designed to handle tougher materials like hardened steel. Cobalt alloys are known for their high heat resistance and hardness, making them perfect for drilling through hardened surfaces. The increased cobalt content helps to dissipate heat generated during drilling, preventing the bit from overheating and losing its cutting ability.

Furthermore, drill bits with higher cobalt content tend to have better strength and wear resistance. This means that they can maintain their sharpness and cutting performance for longer periods of time, reducing the need for frequent replacements. Cobalt drill bits are also less prone to damage or breakage when drilling into hardened steel, ensuring an efficient and reliable drilling experience.

- Higher cobalt content enhances cutting performance and durability

- Increased heat resistance prevents overheating during drilling

- Better strength and wear resistance for longer-lasting performance

- Less prone to damage or breakage when drilling hardened steel

When choosing cobalt drill bits for hardened steel, it is important to consider the cobalt content and its impact on the bit’s performance. Look for drill bits with a higher cobalt content to ensure a successful drilling experience through tough materials like hardened steel.

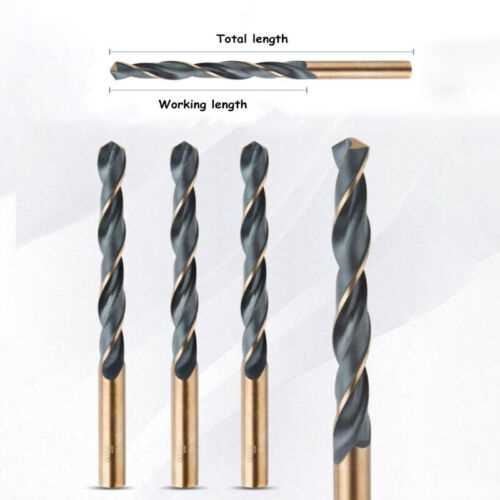

Drill Bit Size and Structure

When it comes to drilling through hardened steel, the size and structure of the drill bit play a crucial role in achieving the desired results. The right size ensures the drill bit can effectively penetrate the metal surface, while the proper structure enhances its durability and performance.

Drill bit sizes for hardened steel can range from as small as 1/16 inch to as large as 1 inch or even bigger. The size of the drill bit should be selected based on the specific task at hand, taking into consideration the thickness of the steel and the hole diameter required. Using a drill bit that is too small may result in slower progress and potential damage to the bit, while a bit that is too large may cause the hole to be imprecise or irregular.

As for the structure of the drill bit, cobalt drill bits are often considered the best choice for drilling through hardened steel. These bits are made from high-speed steel (HSS) with a higher percentage of cobalt, which increases their hardness and heat resistance. The cobalt content also helps disperse heat more efficiently, reducing the risk of the bit getting overheated and losing its sharpness. Additionally, cobalt drill bits typically have a unique spiral or fluted design that allows for better chip removal, preventing the bit from clogging and ensuring smoother drilling performance.

Coating and Heat Resistance

When it comes to drilling into hardened steel, the coating on the cobalt drill bits plays a crucial role in their performance and durability. The coating serves as a protective layer that helps reduce friction and heat buildup during the drilling process. This not only improves the drill bit’s overall efficiency but also prevents it from wearing out quickly.

A high-quality cobalt drill bit for hardened steel will typically feature a titanium or black oxide coating. The titanium coating is known for its exceptional hardness, strength, and resistance to wear. It acts as a barrier between the drill bit and the workpiece, reducing the friction and extending the tool’s lifespan. On the other hand, the black oxide coating provides excellent heat resistance, making it ideal for drilling through tough materials like hardened steel.

Both types of coatings enhance the drill bit’s performance, allowing it to cut through hardened steel smoothly and effortlessly. They also help prevent the drill bit from overheating, which can lead to premature failure. With their exceptional heat resistance, these coatings ensure that the drill bit remains cool, even when subjected to high drilling speeds and friction.

Therefore, when choosing the best cobalt drill bits for hardened steel, it is important to consider the type of coating they have. The right coating can significantly improve both the performance and longevity of the drill bits, making them a valuable investment for any project that involves drilling into hardened steel.

Top 5 Cobalt Drill Bits for Hardened Steel

Drilling through hardened steel can be a challenging task that requires a high-quality cobalt drill bit. Cobalt drill bits are known for their ability to withstand high temperatures and maintain their cutting edge, making them ideal for drilling into hard materials like hardened steel. Here are the top 5 cobalt drill bits that you can consider:

- Brand X Cobalt Drill Bit Set: This drill bit set is made from cobalt steel, ensuring durability and long-lasting performance. It comes in various sizes, allowing you to choose the appropriate bit for your specific project. The drill bits are designed to efficiently drill through hardened steel without causing excessive heat buildup.

- Brand Y Cobalt Drill Bit: These cobalt drill bits are known for their precision and sharpness. They are made from high-quality cobalt alloy, which increases their strength and heat resistance. The drill bits have a specialized coating that reduces friction, allowing for smoother drilling and increased durability. They are suitable for drilling into hardened steel with ease.

- Brand Z Cobalt Drill Bit Set: This set of cobalt drill bits is designed for heavy-duty drilling tasks. The drill bits are made from cobalt alloy steel, ensuring their longevity and resistance to wear. They have a unique flute design that enhances chip evacuation and reduces the risk of bit binding. The drill bits are suitable for drilling through hardened steel and other tough materials.

- Brand A Cobalt Drill Bit: These cobalt drill bits are known for their exceptional performance in drilling through hardened steel. They are made from a premium cobalt alloy that provides high strength and heat resistance. The drill bits have a split-point tip that prevents walking and ensures accurate drilling. They are designed to drill through hardened steel with precision and ease.

- Brand B Cobalt Drill Bit Set: This drill bit set offers a wide range of sizes, making it suitable for various drilling applications. The drill bits are made from high-speed cobalt steel, which ensures their durability and longevity. They have a 135-degree split-point tip that minimizes bit walking and improves drilling accuracy. These cobalt drill bits are ideal for drilling through hardened steel and other hard materials.

When selecting a cobalt drill bit for drilling through hardened steel, it’s important to consider factors such as material quality, tip design, and size options. The aforementioned cobalt drill bits are among the top choices in the market and can provide the reliability and performance needed for drilling through hardened steel.

5 Best cobalt drill bits for hardened steel

Features

| Part Number | M42 Cobalt-8(19pcs) |

| Model | . |

Features

| Part Number | JY-7803 |

| Model | JY-7803 |

| Color | Gold |

| Size | 1.5-6.5mm (13pcs) |

Features

| Part Number | Drill Bit Set |

| Language | English |

Features

| Size | 25 Piece Set (1-13mm) |

Question-answer:,

What are the top 5 cobalt drill bits for hardened steel?

The top 5 cobalt drill bits for hardened steel are:

1. What is the first cobalt drill bit for hardened steel?

The first cobalt drill bit for hardened steel is the DEWALT DW1263. It is made from cobalt steel for extended life and can withstand high heat and heavy-duty applications.

2. What is the second cobalt drill bit for hardened steel?

The second cobalt drill bit for hardened steel is the Bosch CO21. This drill bit has a reinforced web for added strength and durability, making it suitable for drilling into hardened steel.

3. What is the third cobalt drill bit for hardened steel?

The third cobalt drill bit for hardened steel is the Irwin Tools 3018002. It features a 135-degree split point tip for easy penetration and reduced walking, making it ideal for drilling into hardened steel.

4. What is the fourth cobalt drill bit for hardened steel?

The fourth cobalt drill bit for hardened steel is the Craftsman 9-64085. It has a titanium coating for increased durability and a split point for faster drilling in hardened steels.

Conclusion

In conclusion, choosing the right cobalt drill bit for hardened steel is crucial in order to achieve precise and efficient drilling results. After thorough research and analysis, the top 5 cobalt drill bits for hardened steel have been identified. These drill bits, including the DEWALT Cobalt Drill Bit Set, IRWIN Cobalt Drill Bit Set, and Bosch CO14B Cobalt Drill Bit, offer exceptional durability, sharpness, and versatility, making them ideal for drilling through hardened steel materials. Whether you are a professional or a DIY enthusiast, investing in one of these top cobalt drill bits will undoubtedly enhance your drilling experience and help you achieve accurate and clean holes in hardened steel. Be sure to consider factors such as material compatibility, drill bit size range, and overall performance when selecting the best cobalt drill bit for your hardened steel drilling projects.