All About Drill Chucks: How They Work and Why They Matter

Drill chucks are a crucial part of any drilling machine, allowing for the secure attachment of drill bits and other accessories. They play a vital role in ensuring precision and efficiency in drilling operations. Understanding how drill chucks work and why they matter is essential for both professionals and DIY enthusiasts.

A drill chuck is a device that holds the drill bit in place and allows it to rotate. It is typically mounted on the spindle of a drill press or a power drill. The chuck consists of jaws that grip the drill bit securely, preventing it from slipping or wobbling during drilling. The jaws can be tightened or loosened using a chuck key or a keyless mechanism, depending on the type of chuck.

Drill chucks come in various sizes and types, with the most common being three-jaw chucks and keyless chucks. Three-jaw chucks are versatile and widely used, as they can hold a range of drill bit sizes. Keyless chucks, on the other hand, offer quick and easy bit changes without the need for a separate key. Each type of chuck has its advantages and limitations, and the choice depends on the specific drilling requirements.

Having a reliable and well-maintained drill chuck is crucial for achieving accurate and efficient drilling results. A loose or worn-out chuck can lead to wobbly or misaligned drill bits, resulting in imprecise holes. Regular inspection and maintenance of the chuck, such as cleaning and lubricating, are necessary to ensure smooth operation. Additionally, choosing the right chuck for the job, considering factors such as chuck capacity and compatibility, is essential for optimum performance.

In conclusion, drill chucks are integral components of drilling machines that enable secure and precise drilling. They come in various sizes and types, each serving specific purposes. A properly maintained and suitable drill chuck is essential for achieving accurate and efficient drilling results. Understanding how drill chucks work and why they matter is vital for anyone involved in drilling operations.

The Purpose of a Drill Chuck

A drill chuck is an essential component of a drill machine that is used to hold the drill bit securely in place during drilling operations. It is designed to provide a strong grip and prevent the drill bit from slipping or getting loose while drilling into various materials.

Drill chucks are typically available in various sizes and styles to accommodate different drill bits and drilling requirements. They are commonly used in both handheld drills and drill presses.

Key Features of a Drill Chuck

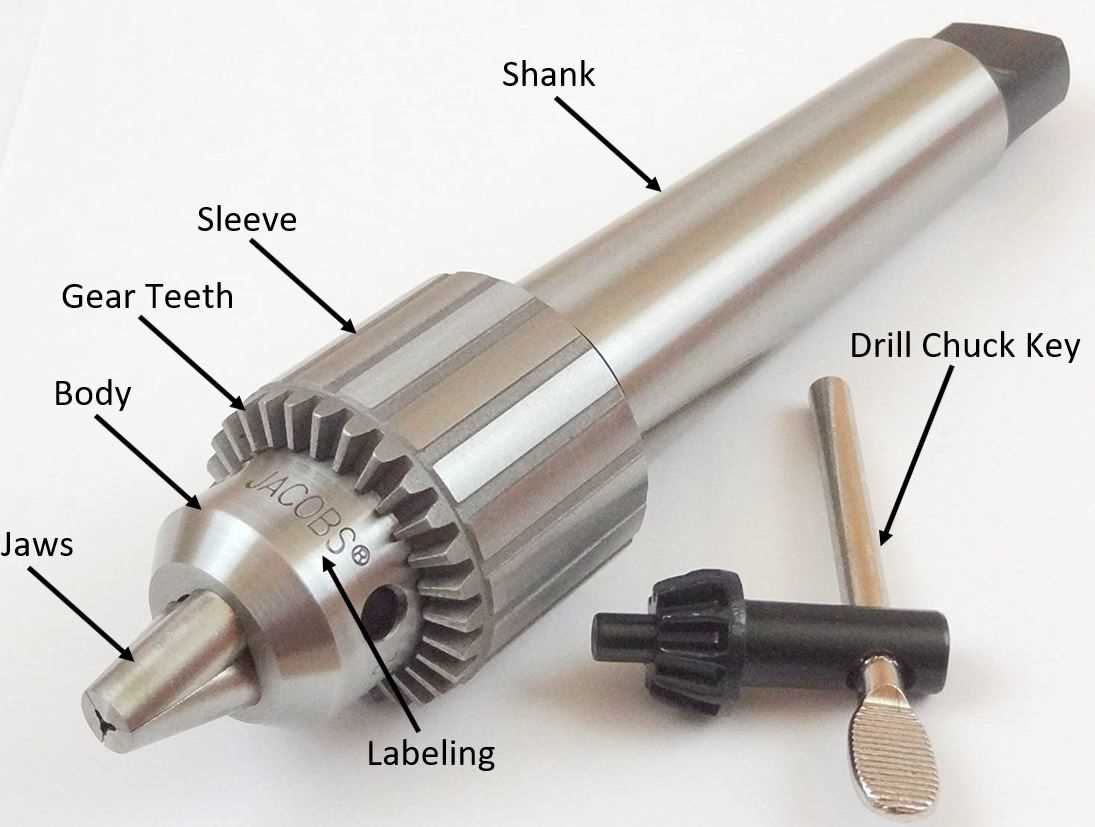

A drill chuck typically consists of the following key features:

- Jaws: These are the movable parts of the chuck that hold the drill bit. They can be tightened or loosened using a chuck key or a keyless system.

- Chuck Key: This is a specialized tool used to tighten or loosen the jaws of the chuck. It is typically used with chucks that have a traditional keyed design.

- Keyless System: Some modern drill chucks feature a keyless design, which eliminates the need for a chuck key. These chucks can be tightened or loosened by hand.

- Threaded Mount: A drill chuck is typically mounted onto the spindle of a drill machine using a threaded connection. This allows for easy installation and removal.

Importance of a Good Drill Chuck

A high-quality drill chuck is essential for achieving accurate and efficient drilling results. It provides stability and precision during drilling operations, ensuring that the drill bit stays in place and drills straight into the desired material.

A reliable drill chuck also enhances safety by reducing the risk of the drill bit slipping or getting ejected during drilling. This minimizes the chances of injury to the operator and damage to the workpiece.

Conclusion

A drill chuck plays a crucial role in any drilling operation by securely holding the drill bit in place. It allows for precise and efficient drilling, enhances safety, and ensures optimal results. Choosing a good quality drill chuck is important for achieving accurate and reliable drilling performance.

Types of Drill Chucks

There are several types of drill chucks available, each designed for different types of drills and drilling applications. The three most common types of drill chucks are:

1. Keyed Chucks

Keyed chucks are the most traditional type of drill chucks and require the use of a chuck key to tighten or loosen the jaws. The chuck key is inserted into the small hole on the side of the chuck, allowing the user to manually rotate the chuck and secure the drill bit.

Keyed chucks offer superior grip and holding power, making them ideal for heavy-duty drilling applications. However, they can be more time-consuming to operate, as the user needs to manually tighten and loosen the jaws using the chuck key.

2. Keyless Chucks

Keyless chucks, as the name suggests, do not require the use of a chuck key. Instead, they feature a mechanism that allows the user to tighten or loosen the jaws by hand.

Keyless chucks are more convenient and faster to use compared to keyed chucks. They are commonly found on cordless drills and other handheld power tools. However, keyless chucks generally have a lower gripping force compared to keyed chucks, which may limit their suitability for heavy-duty drilling tasks.

3. SDS Chucks

SDS (Special Direct System) chucks are specifically designed for use with rotary hammer drills, which are commonly used for drilling into masonry and concrete. SDS chucks feature a unique design that allows for rapid tool changes and provides a secure grip on SDS drill bits.

SDS chucks typically have three modes of operation: hammer drilling, rotary drilling, and hammer only. This versatility makes them well-suited for a wide range of drilling tasks, including drilling into hard materials like concrete.

It’s important to choose the right type of drill chuck for your specific drilling needs and the type of drill you are using. Consider factors such as the type of material you’ll be drilling into, the size of the drill bit, and the level of convenience and ease of use you require.

Keyed Drill Chucks vs Keyless Drill Chucks

Drill chucks are an important component of a drill press or hand-held drill. They are responsible for securely holding the bits in place and allowing for easy tool changes. There are two main types of drill chucks – keyed and keyless. Let’s take a closer look at each type and their characteristics.

Keyed Drill Chucks

A keyed drill chuck requires the use of a specialized key to tighten and loosen the jaws of the chuck. The key is inserted into small holes on the side of the chuck and turned to either close or open the jaws. This design provides a high level of torque and gripping power, making it suitable for heavy-duty drilling applications.

Advantages of Keyed Drill Chucks:

- High gripping power for heavy-duty drilling

- Less likely to slip or come loose during use

- Ability to handle larger drill bits

- More precise control over tightening and loosening

Disadvantages of Keyed Drill Chucks:

- Requires the use of a specialized key

- Takes more time to change drill bits

- More cumbersome to use

Keyless Drill Chucks

A keyless drill chuck does not require the use of a key to tighten or loosen the jaws. Instead, it uses a self-tightening mechanism that allows for quick and easy one-handed operation. To tighten the chuck, you simply hold the drill bit in place and turn the chuck with your hand. To loosen it, you turn the chuck in the opposite direction.

Advantages of Keyless Drill Chucks:

- Quick and easy tool changes

- No need for a separate key

- One-handed operation

- Convenient for light to medium-duty drilling tasks

Disadvantages of Keyless Drill Chucks:

- Lower gripping power compared to keyed chucks

- More prone to slippage with larger drill bits

- May require more frequent readjustment during use

In conclusion, the choice between a keyed or keyless drill chuck depends on the specific needs of your drilling tasks. If you require high torque and precise control, a keyed chuck may be more suitable. On the other hand, if quick and easy tool changes are a priority, a keyless chuck can provide the convenience you need. Ultimately, both types of chucks serve their purpose and are essential for any drilling operation.

How Drill Chucks Work

A drill chuck is a device that holds and tightens the drill bit securely in place during drilling operations. It is an essential component of a drill press or handheld drill.

Key Components

- Jaws: The jaws are the main gripping components of the drill chuck. They are typically made of hardened steel and have a specially designed shape to securely hold the drill bit in place.

- Chuck Body: The chuck body houses the jaws and provides the structure for the entire chuck assembly. It is usually made of cast iron or steel to provide strength and durability.

- Chuck Key: The chuck key is a specialized tool used to tighten or loosen the jaws of the drill chuck. It usually has a T-shaped handle and fits into the keyholes on the chuck body.

Operation

When a drill bit needs to be inserted or removed from the chuck, the chuck key is used to open or close the jaws. By rotating the chuck key in a clockwise direction, the jaws are tightened and grip the drill bit firmly. Conversely, rotating the chuck key counterclockwise loosens the jaws, allowing for easy insertion or removal of the drill bit.

Once the drill bit is securely held in the chuck, it can rotate freely during drilling operations. The drill press or handheld drill provides the necessary power to rotate the chuck and drill bit, allowing for precise and accurate drilling.

Types of Drill Chucks

There are several types of drill chucks available, including:

- Keyed Chucks: These chucks require the use of a chuck key to tighten or loosen the jaws. They provide a strong grip and are commonly used in heavy-duty drilling applications.

- Keyless Chucks: These chucks feature a convenient mechanism that allows for quick and easy tightening or loosening of the jaws without the need for a chuck key. They are commonly found on handheld drills and are ideal for fast and frequent bit changes.

- Impact Chucks: These chucks are specifically designed to withstand the high torque and impact forces generated by impact drills. They have additional features, such as a higher clamping force, to prevent the drill bit from slipping during heavy-duty drilling tasks.

Conclusion

Drill chucks play a crucial role in the functionality of drill presses and handheld drills. Understanding how they work and choosing the right type of chuck for the task at hand is essential for achieving accurate and efficient drilling results.

Compatibility with Different Drill Bits

One of the key factors to consider when choosing a drill chuck is its compatibility with different drill bits. The drill chuck is responsible for holding the drill bit securely in place, so it is important to ensure that the chuck can accommodate the type and size of the drill bits you need to use.

Most drill chucks are designed to be compatible with a wide range of drill bits, but there are some variations to be aware of. The most common type of drill bit is the twist bit, which has a cylindrical shank and a helical fluted cutting edge. These bits are typically compatible with standard drill chucks and can be easily inserted and secured.

However, there are also other types of drill bits that may require specialized chucks. For example, masonry drill bits are specifically designed for drilling into hard materials like concrete, brick, or stone. These bits often have a hex shank and may require a specially designed chuck that can accommodate the hexagonal shape.

Another type of drill bit that may require a specialized chuck is the countersink bit. Countersink bits are used to create a conical recess for screw heads, allowing them to sit flush with the surface. These bits typically have a 1/4-inch hex shank and require a chuck that can hold them securely.

It is also important to consider the size of the drill bits when choosing a chuck. Most standard drill chucks can accommodate drill bits in the range of 1/64 inch to 1/2 inch in diameter. However, if you need to use larger drill bits, such as those used for drilling large holes or forstner bits, you may need to invest in a chuck with a larger capacity.

In some cases, you may also need to consider the type of drill you are using. For example, if you are using a hammer drill, you may need a chuck that is specifically designed to withstand the additional force and vibrations produced by the hammering action.

In summary, when choosing a drill chuck, it is important to consider its compatibility with different types and sizes of drill bits. Make sure to choose a chuck that can securely hold the drill bit you need to use and consider any specialized requirements, such as hex shanks or larger drill bit diameters. By ensuring compatibility, you can ensure safe and effective drilling operations.

Importance of Choosing the Right Drill Chuck

When it comes to drilling, one of the most important factors for success is choosing the right drill chuck. A drill chuck is the part of the drill that holds the drill bit in place and allows it to rotate. It plays a crucial role in the performance and accuracy of the drilling process.

1. Compatibility with Drill and Bits

Choosing the right drill chuck is essential to ensure compatibility with both the drill and the drill bits being used. Different drills have different chuck sizes and types, so it is important to select a chuck that fits securely onto the drill’s spindle. Likewise, drill bits come in various sizes and have different shank styles, so the chuck must be capable of securely gripping the chosen drill bit.

2. Holding Power

The holding power of a drill chuck determines how well it can grip and hold the drill bit in place during operation. A high-quality chuck will have strong gripping power, preventing the drill bit from slipping or wobbling during drilling. This ensures precise and accurate drilling, especially when working with hard or dense materials.

3. Versatility and Ease of Use

Choosing the right drill chuck also means considering its versatility and ease of use. Some chucks feature a keyless design, allowing for quick and easy bit changes without the need for additional tools. This can be especially convenient when working on projects that require frequent bit changes. Additionally, a versatile chuck will be compatible with a wide range of drill bits, enabling the user to tackle various drilling tasks with a single chuck.

4. Durability and Longevity

A drill chuck that is durable and long-lasting is a wise investment. Drill chucks undergo a lot of stress and wear during drilling operations, so it is important to choose a chuck made from high-quality materials that can withstand the rigors of regular use. A sturdy chuck will provide reliable performance over time and reduce the need for frequent replacements.

5. Safety

Lastly, selecting the right drill chuck is crucial for safety. A properly functioning chuck will securely hold the drill bit, reducing the risk of accidents or injuries caused by loose or improperly secured bits. It is vital to choose a chuck that provides a secure and stable grip to ensure safe drilling operations.

| Factors | Importance |

|---|---|

| Compatibility with Drill and Bits | Essential |

| Holding Power | Crucial |

| Versatility and Ease of Use | Convenient |

| Durability and Longevity | Long-lasting |

| Safety | Vital |

In conclusion, choosing the right drill chuck is of utmost importance to ensure compatibility, holding power, versatility, durability, and safety in the drilling process. Considering these factors will help select the right chuck for the specific drilling needs, resulting in more efficient and accurate drilling operations.

Maintaining and Replacing Drill Chucks

Maintaining Drill Chucks

Proper maintenance of drill chucks is essential to ensure their longevity and optimum performance. Here are some tips on how to maintain drill chucks:

- Regularly clean the chuck using a soft cloth and mild detergent to remove any dirt or debris.

- Inspect the chuck jaws for any signs of damage or wear. If the jaws are worn or damaged, they should be replaced.

- Apply a small amount of lubricant to the chuck jaws and key to ensure smooth operation.

- Check the chuck for any misalignment or wobbling during operation. If this occurs, it may be necessary to adjust or replace the chuck.

- Store the drill with the chuck in a clean and dry place to prevent rust or corrosion.

Replacing Drill Chucks

Drill chucks, like any other component, may need to be replaced if they become damaged or worn out. Here’s how to replace a drill chuck:

- Start by removing the chuck key from the chuck, if it is still inserted.

- Rotate the chuck counterclockwise to loosen it from the drill spindle. Some drills may have a retaining screw that needs to be loosened as well.

- Once the chuck is loose, remove it from the drill spindle by pulling it straight out.

- Attach the replacement chuck to the drill spindle by inserting it and rotating it clockwise until it is securely tightened.

- If necessary, tighten the retaining screw, if your drill has one.

- Ensure the new chuck is properly aligned and tightened before using the drill.

It’s important to note that replacing a drill chuck may require specific tools, such as a chuck key or a chuck removal tool. Refer to the drill’s user manual or manufacturer guidelines for detailed instructions on how to replace the chuck.

Conclusion

Maintaining and replacing drill chucks is necessary to ensure the smooth operation of your drill. By following proper maintenance procedures and knowing how to replace a chuck when needed, you can prolong the life of your drill and maintain its optimal performance.

FAQ:

What is a drill chuck?

A drill chuck is a device that holds the drill bit securely in place while drilling. It is mounted on the spindle of a drill press or a power drill.

How does a drill chuck work?

A drill chuck works by tightening or loosening its jaws around the drill bit. This is done using a chuck key or by hand, depending on the type of chuck. The chuck applies pressure on the drill bit, holding it in place while the drill spins.

What are the different types of drill chucks?

There are several types of drill chucks available, including keyed chucks, keyless chucks, and SDS chucks. Keyed chucks require a chuck key to tighten or loosen the jaws, while keyless chucks can be operated by hand. SDS chucks are designed for rotary hammer drills and have a special mechanism for quick and secure bit changes.

Why are drill chucks important?

Drill chucks are important because they securely hold the drill bits in place, ensuring accuracy and stability while drilling. They also provide a connection between the drill bit and the drill, allowing the power from the drill to be transferred to the bit for effective drilling.

What factors should be considered when choosing a drill chuck?

When choosing a drill chuck, factors such as chuck size, chuck type, and the type of drill it will be used with should be considered. The chuck size should match the drill’s spindle size, and the chuck type should be compatible with the type of drilling tasks it will be used for.

Can a drill chuck be replaced?

Yes, a drill chuck can be replaced if it becomes damaged or if a different type of chuck is needed. Most drill chucks can be easily removed and replaced with the use of a chuck key.

Video: