7 Tips for Drilling through Metal Studs Safely and Effectively

Drilling through metal studs can be a tricky and potentially dangerous task, but with the right techniques and precautions, you can complete the job safely and effectively. Whether you’re hanging shelves, mounting a TV, or installing electrical outlets, it’s important to know how to work with metal studs to prevent accidents and ensure a successful outcome.

Tip #1: Use the Right Drill Bit

When drilling through metal studs, it’s essential to use a drill bit specifically designed for metal. High-speed steel or cobalt drill bits are ideal for this purpose, as they are strong enough to handle the density and hardness of metal. Avoid using wood drill bits as they may break or become dull quickly.

Tip #2: Determine Stud Location

Before drilling, it’s important to determine the exact location of the metal studs. You can use a stud finder or a magnet to locate the studs behind the wall. Mark the center of each stud with a pencil or tape to ensure accurate drilling.

Tip #3: Take Safety Precautions

Always wear safety goggles and gloves when drilling through metal studs to protect your eyes and hands from debris and sharp edges. Additionally, make sure to secure the workpiece properly to prevent slipping or movement during drilling.

Tip #4: Start with a Pilot Hole

When drilling through metal studs, it’s best to start with a pilot hole. Use a smaller drill bit to create a guide hole that will prevent the larger drill bit from wandering off target. This will help you achieve greater precision and reduce the risk of damaging the stud.

Tip #5: Use the Right Drilling Technique

When drilling through metal studs, apply steady pressure and maintain a consistent speed. Avoid using excessive force, as it can cause the drill bit to break or slip. Keep the drill bit perpendicular to the stud to ensure a straight and clean hole.

Tip #6: Lubricate the Drill Bit

Using a lubricant, such as cutting oil or even soap, can help reduce friction and heat generated during drilling. Apply a small amount of lubricant to the drill bit periodically to keep it cool and prevent it from overheating or becoming dull.

Tip #7: Clean Up and Inspect

After drilling through metal studs, take the time to clean up any debris and inspect the hole for any signs of damage. Remove any metal shavings or burrs with a brush or file, and ensure the hole is clean and smooth before proceeding with the installation.

Remember, drilling through metal studs requires patience, precision, and the right tools. By following these tips, you can safely and effectively drill through metal studs and achieve professional-looking results in your home projects.

Choose the Right Drill Bit

When drilling through metal studs, it is important to choose the right drill bit to ensure safe and effective drilling. Using the wrong drill bit can lead to damaged studs, broken bits, and inefficient drilling.

Consider the Material

The first thing to consider when choosing a drill bit for metal stud drilling is the material of the stud. Most metal studs are made of either steel or aluminum. Steel studs are harder and require a drill bit that is specifically designed for drilling through metal. Aluminum studs are softer and can often be drilled through with a standard drill bit.

Choose the Right Size

It is also important to choose the right size drill bit for the job. The size of the drill bit will depend on the size of the hole you need to make. Make sure to measure the diameter of the hole accurately before selecting a drill bit.

Use High-Speed Steel (HSS) Drill Bits

High-speed steel (HSS) drill bits are designed to withstand the high temperatures generated during drilling and offer excellent hardness and durability. They are suitable for drilling through metal studs and can be used for both steel and aluminum studs.

Consider Titanium-Coated Drill Bits

If you need extra durability and heat resistance, consider using titanium-coated drill bits. These drill bits have a layer of titanium coating that improves their hardness and helps reduce friction and heat buildup. Titanium-coated drill bits are especially recommended for drilling through steel studs.

Ensure Sharpness

Using a dull drill bit can make drilling through metal studs difficult and can cause damage to the studs. Make sure to use a sharp drill bit for clean and efficient drilling. If your drill bit becomes dull during use, it is important to replace it with a new sharp one.

Consider Specialty Drill Bits

In some cases, you may need a specialty drill bit for specific tasks, such as drilling through hardened steel studs. There are drill bits available that are specifically designed for this purpose, such as cobalt drill bits or carbide drill bits. These drill bits offer high durability and are capable of drilling through the toughest materials.

Check the Drill Bit’s Compatibility

Before using a drill bit, always double-check its compatibility with your drill. Some drill bits are designed for specific drill models or chuck sizes. Using an incompatible drill bit can lead to poor performance and potential damage to the drill or bit.

Remember to always wear proper safety gear, such as safety glasses and gloves, when drilling through metal studs. Following these tips and choosing the right drill bit will ensure safe and effective drilling through metal studs.

Find the Studs

Before you start drilling into metal studs, it is important to locate their exact positions. Unlike wooden studs, which can be easily found with a stud finder or by tapping on the wall, metal studs are not as easily detectable. Here are a few methods you can use to locate the studs in your metal stud wall:

1. Use a Stud Finder

One of the easiest ways to find metal studs is by using an electronic stud finder. These tools are designed to detect changes in density behind the wall, helping you locate the studs. Simply run the stud finder along the wall until it beeps or lights up, indicating the presence of a stud. Make sure to use a stud finder that is specifically designed for metal studs.

2. Look for Nail Heads or Screws

An alternative method is to visually inspect the wall for nail heads or screws. Metal studs are commonly secured to the wall with nails or screws, which can be visible even if they are covered with drywall. Look for small indentations or bumps on the wall surface, indicating the presence of a nail or screw. Mark these spots as potential stud locations.

3. Measure from an Outlet or Switch

Another method is to measure the distance between an electrical outlet or switch and the nearest corner of the wall. In most cases, metal studs are placed every 16 or 24 inches apart. By measuring from a known point, you can estimate the spacing and locate the studs along the wall.

4. Use a Magnet

Metal studs are made of steel, which is magnetic. You can use a small magnet to locate the studs by running it along the wall. The magnet will be attracted to the metal studs, helping you identify their exact positions. Keep in mind that this method may not be as accurate as using a stud finder or measuring from a known point.

5. Tap on the Wall

Although not as reliable as other methods, tapping on the wall can sometimes help you locate metal studs. Metal studs create a slightly different sound when tapped compared to other parts of the wall. Tap lightly with your knuckles or a small hammer and listen for a hollow sound, indicating the presence of a stud.

Using one or a combination of these methods, you can find the studs in your metal stud wall and proceed with drilling safely and effectively.

Mark Your Drilling Points

Before you start drilling through metal studs, it’s important to mark the exact points where you want to drill. This will ensure that you make accurate holes and avoid damaging the stud or other materials.

Here are some tips for marking your drilling points:

- Measure twice, drill once: Take the time to measure and mark the exact location of your drilling points. Use a tape measure, square, or any other precise measuring tool to ensure accuracy.

- Use a pencil: Marking your drilling points with a pencil allows for easy correction or adjustment if needed. A pencil mark is also visible on metal surfaces and can be easily wiped off after drilling.

- Consider using a center punch: For more precise drilling, you can use a center punch to create a small indentation on the marked drilling point. This will help to prevent your drill bit from wandering or slipping off the surface.

- Mark multiple points: If you’re drilling multiple holes in a row, it can be helpful to mark all the points at once. This will allow you to make sure they are evenly spaced and aligned.

- Use a level: If you’re drilling multiple holes in a line, use a level to ensure they are straight and level. This is especially important if you’re installing shelves, brackets, or other items that need to be level.

- Mark in different colors: If you’re drilling multiple sets of holes, using different colored pencils or markers can help you keep track of which holes go together. For example, you can mark the first set of holes in blue and the second set in red.

- Double-check your markings: Before you start drilling, double-check your markings to ensure they are accurate and in the correct position. This can help prevent costly mistakes and ensure your project goes smoothly.

Use Proper Technique

When drilling through metal studs, it is important to use the proper technique to ensure your safety and the effectiveness of the drilling.

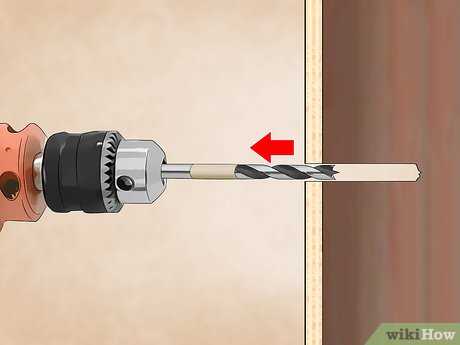

1. Start with a pilot hole

Before drilling a larger hole, it is recommended to start with a pilot hole. This will help guide the drill bit and prevent it from slipping or wandering off the desired path. Use a smaller drill bit, such as 1/8 inch, to create the pilot hole.

2. Use lubrication

Applying lubrication to the drill bit can help reduce friction and heat buildup, making the drilling process smoother and preventing the bit from getting damaged. It is recommended to use cutting fluid or a lubricant specifically formulated for metal drilling.

3. Apply steady pressure

When drilling through metal studs, it is important to apply steady and consistent pressure. Avoid using excessive force, as this can lead to the drill bit getting stuck or broken. Allow the drill bit to do the work and let it penetrate the metal at its own pace.

4. Use a low speed setting

When drilling through metal, it is advisable to use a low speed setting on your power drill. This will help prevent the drill bit from overheating and ensure accurate drilling. High speed can cause the bit to dig too quickly and potentially damage the metal stud.

5. Use a reverse technique for exit holes

When drilling through both sides of a metal stud, it is recommended to use a reverse technique for the exit hole. This means starting the hole on one side, then flipping the stud over and continuing the drilling from the other side. This will help prevent any damage or irregularities to the exit hole.

6. Secure the metal stud

Ensure that the metal stud is securely held in place while drilling. This will help prevent vibrations and movement, which can affect the accuracy of the drilling. Use clamps or other securing methods to keep the metal stud stable.

7. Wear protective gear

Always wear appropriate protective gear, such as safety goggles and gloves, when drilling through metal studs. This will help protect you from any flying debris or metal shavings that may be generated during the drilling process.

By following these proper drilling techniques, you can ensure the safety of yourself and others, as well as achieve effective and accurate drilling through metal studs.

Start with a Pilot Hole

When drilling through metal studs, it is important to start with a pilot hole. This small hole will act as a guide for the larger drill bit and help prevent the stud from shifting or moving during the drilling process.

To create a pilot hole, begin by selecting a drill bit that is smaller in diameter than the final hole size you will need. The exact size of the pilot hole will depend on the material of the stud and the type of fastener you will be using.

- Select the appropriate drill bit for the pilot hole.

- Mark the location on the stud where you will be drilling.

- Secure the stud in place with clamps or other methods to prevent movement.

- Place the tip of the drill bit on the marked spot and apply steady pressure to start drilling.

- Drill into the stud slowly and steadily, ensuring that the drill bit remains perpendicular to the surface of the stud.

- Continue drilling until the pilot hole is complete.

Once the pilot hole is created, you can then switch to a larger drill bit to create the final hole size needed for your specific project. By starting with a pilot hole, you can ensure accurate and secure drilling through metal studs.

Use the Right Speed and Pressure

1. Start with a slow speed

When drilling through metal studs, it is important to start with a slow speed. This allows you to have more control over the drill and prevents the drill bit from overheating. Using a high speed can cause the drill bit to break or become dull, making it less effective in drilling through the metal stud.

2. Gradually increase the speed

Once you have established control over the drill, you can gradually increase the speed. This will help you to drill through the metal stud more quickly and efficiently. However, it is important to pay attention to the drill bit and the metal stud to ensure that you are not applying too much pressure or drilling too fast.

3. Apply consistent pressure

Applying consistent pressure is important when drilling through metal studs. It helps to ensure that the drill bit cuts through the metal smoothly and evenly. However, it is important not to apply too much pressure, as this can cause the drill bit to break or become dull. Use steady and even pressure to maintain control and efficiency.

4. Let the drill do the work

When drilling through metal studs, it is important to let the drill do the work. Do not force the drill or try to push it through the metal too quickly. Instead, let the drill bit do the cutting and allow the weight of the drill to provide the necessary pressure. This will help to ensure a clean and accurate hole without causing damage to the drill or the metal stud.

5. Use the correct drill bit

Using the correct drill bit is crucial when drilling through metal studs. Choose a drill bit specifically designed for metal, such as a cobalt or high-speed steel drill bit. These drill bits are designed to withstand the heat and pressure generated when drilling through metal. Using the wrong type of drill bit can result in poor performance and potential damage to the drill and the metal stud.

6. Lubricate the drill bit

Lubricating the drill bit can help to prolong its life and improve its performance when drilling through metal studs. Apply a small amount of cutting fluid or lubricating oil to the drill bit before starting to drill. This will help to reduce friction and heat, making the drilling process smoother and more efficient.

7. Take breaks if necessary

If you are drilling a large number of holes or if the metal stud is particularly thick or tough, it may be necessary to take breaks during the drilling process. This allows the drill bit to cool down and prevents it from becoming overheated. Taking breaks also gives you the opportunity to assess the progress of the drilling and make any necessary adjustments to speed or pressure.

Wear Protective Gear

When drilling through metal studs, it is important to wear the necessary protective gear to ensure your safety. Metal studs can be sharp and may cause injury if not handled properly.

Here are some essential protective gear to wear:

- Safety goggles: Protect your eyes from flying metal shards or dust.

- Gloves: Wear gloves to protect your hands from cuts or abrasions.

- Ear protection: Use earplugs or earmuffs to prevent hearing damage from the noise generated by drilling through metal studs.

- Dust mask: Inhaling metal dust or particles can be harmful, so wearing a dust mask is crucial to protect your respiratory system.

- Long-sleeved shirt and pants: Protect your skin from potential scratches or cuts by wearing appropriate clothing.

Always make sure to wear the necessary protective gear before drilling through metal studs to ensure your safety and prevent any potential injury.

Bonus Tip: Have a Backup Plan

Despite taking all necessary precautions, drilling through metal studs can still be challenging and unexpected issues may arise. In such cases, it’s essential to have a backup plan to ensure the project can continue smoothly and safely. Here are some ideas for a backup plan:

1. Use a Different Method

If the traditional drilling method is not working or causing damage to the metal studs, consider using alternative methods such as using a hole punch, nibbler, or sheet metal shears. These tools can provide more precision and control, minimizing the risk of damaging the studs or the surrounding area.

2. Seek Professional Help

If you encounter difficulties or feel unsure about drilling through metal studs, it’s always a good idea to consult with a professional. An experienced contractor or handyman can provide guidance and assistance, ensuring the task is completed safely and efficiently.

3. Adjust the Project Plan

If drilling through the metal studs becomes too challenging or risky, it may be necessary to rethink the project plan. This could involve redesigning the location of fixtures or finding alternative ways to hang or support items. Adapting the plan can help avoid potential damage or risks while still achieving the desired outcome.

4. Practice on Scrap Pieces

Before drilling into the actual metal studs, it’s recommended to practice on scrap pieces of similar material. This allows you to familiarize yourself with the drilling process and test different techniques without the risk of damaging the structure. It’s always better to make mistakes on practice pieces rather than on the actual studs.

5. Have Extra Supplies On Hand

Having extra drill bits, screws, and other necessary supplies nearby can be a lifesaver if something goes wrong during the drilling process. If a drill bit breaks or a screw becomes stripped, having replacements readily available will save time and frustration.

Remember, having a backup plan not only ensures the safety of the project but also offers peace of mind. Keep these tips in mind and be prepared for any unexpected challenges that may arise when drilling through metal studs.

FAQ:

Is it safe to drill through metal studs?

Yes, it is safe to drill through metal studs if you follow the proper safety precautions. Metal studs are commonly used in construction projects and can be drilled through as long as you use the correct tools and techniques.

What tools do I need to drill through metal studs?

To drill through metal studs, you will need a power drill with a drill bit designed for metal, such as a cobalt drill bit. Additionally, you may need a stud finder to locate the exact position of the stud.

How do I find the center of a metal stud?

To find the center of a metal stud, you can use a stud finder or a magnet. Move the stud finder or magnet along the surface of the wall until it indicates the presence of the metal stud. Once you’ve found the edges of the stud, mark the center point between them.

What is the recommended drilling speed for metal studs?

The recommended drilling speed for metal studs is generally slower than drilling through wood. It is best to start at a lower speed and gradually increase if needed. This helps to prevent overheating of the drill bit and ensures a clean and precise hole.

Can I use a regular drill bit to drill through metal studs?

While it is possible to use a regular drill bit to drill through metal studs, it is highly recommended to use a drill bit specifically designed for metal, such as a cobalt drill bit. Regular drill bits may not be as effective and can break or become dull quickly when used on metal.

What precautions should I take when drilling through metal studs?

When drilling through metal studs, it is important to wear safety goggles to protect your eyes from any flying debris. Additionally, be sure to secure the stud in place to prevent it from moving or vibrating during the drilling process. Finally, make sure to use the correct drill bit and drilling technique to avoid damaging the stud or your tools.

Video: