6 Tips for Drilling Through Rebar in Concrete

When it comes to drilling through rebar in concrete, it can be a challenging task. Rebar, also known as reinforcing steel, is used to strengthen concrete and provide stability to structures. While drilling through rebar may seem intimidating, with the right tools and techniques, it can be done effectively and safely. In this article, we will provide you with six tips to help you drill through rebar in concrete.

1. Use the right drill bit: One of the most important tips for drilling through rebar is to use the right drill bit. Choose a high-quality carbide-tipped drill bit that is specifically designed for drilling through concrete and rebar. These drill bits are stronger and more durable, allowing them to withstand the hardness of the rebar.

2. Mark the drilling area: Before you start drilling, mark the area where you will be drilling. This will help you ensure that you are drilling in the right spot and avoid hitting any important structures or utilities. Use a pencil or marker to clearly mark the area on the concrete surface.

3. Start with a smaller pilot hole: When drilling through rebar, it is recommended to start with a smaller pilot hole. This will allow you to test the durability of the rebar and ensure that you are drilling in the right direction. Once the pilot hole is established, you can gradually increase the drill bit size to create the desired hole diameter.

4. Use the right drilling technique: To drill through rebar effectively, it is important to use the right drilling technique. Apply steady pressure on the drill and use a slow and consistent rotation speed. Avoid using too much force, as this can cause the drill bit to overheat or break.

5. Use water as a lubricant: Drilling through rebar can generate a lot of heat, which can damage the drill bit and reduce its lifespan. To prevent overheating, use water as a lubricant. Simply pour water on the drilling area to keep the drill bit cool and lubricated.

6. Take safety precautions: Lastly, it is crucial to take safety precautions when drilling through rebar. Wear safety goggles to protect your eyes from flying debris, and use a dust mask to avoid inhaling any dust or debris. Additionally, make sure to secure the concrete surface and take measures to prevent any accidents or injuries.

By following these six tips, you can successfully drill through rebar in concrete. Remember to use the right drill bit, mark the drilling area, start with a smaller pilot hole, use the right drilling technique, use water as a lubricant, and take safety precautions. With practice and patience, you can become skilled in drilling through rebar and achieve professional results.

Why is Rebar Present in Concrete?

Reinforced concrete, commonly referred to as concrete with rebar, is a widely used construction material for its high strength and durability. Rebar, short for reinforcing bar, is a steel bar or mesh that is embedded within the concrete structure to provide additional strength and resistance to various forces.

The presence of rebar in concrete serves several purposes:

- Enhances tensile strength: Concrete is known to be strong in compression but weak in tension. By adding rebar, which has high tensile strength, to the concrete mix, the resulting structure becomes better equipped to resist tensile forces.

- Prevents cracking and structural failure: Rebar is strategically placed in areas of the concrete structure where tension forces are likely to occur. This helps distribute and dissipate these forces, preventing cracks and structural failures from developing.

- Increases load-bearing capacity: The presence of rebar in concrete enhances its load-bearing capacity, allowing it to support heavier loads without undergoing deformation or failure.

- Improves overall durability: Rebar provides corrosion resistance and protects the concrete structure from environmental factors, such as moisture and chemical attacks. This significantly enhances the lifespan and durability of the concrete.

- Allows for flexibility in design: The addition of rebar allows for greater flexibility in the design and construction of concrete structures. It enables the construction of complex shapes and forms, while maintaining structural integrity.

- Ensures structural stability: With the presence of rebar, concrete structures can withstand various external forces, such as wind, earthquakes, and vibrations, ensuring their overall stability and safety.

In summary, the inclusion of rebar in concrete plays a vital role in enhancing its strength, durability, and overall performance. It is an integral component in the construction industry, allowing for the creation of safe and long-lasting structures.

Importance of Drilling Through Rebar Safely and Accurately

When working with concrete that contains reinforcing bars (rebar), it is important to drill through the rebar safely and accurately. Rebar is used to strengthen concrete structures and provides additional support and durability. However, drilling through rebar can be challenging, as it requires specialized tools and techniques.

1. Structural Integrity

Drilling through rebar safely ensures the structural integrity of the concrete. Rebar provides strength to concrete by reinforcing it and prevents cracks and fractures. Drilling through rebar haphazardly can weaken the structure and compromise its stability. It is crucial to drill in the right location and avoid damaging the rebar during the drilling process.

2. Safety

Proper drilling procedures ensure the safety of both workers and the overall project. When drilling through rebar, the risk of injuries increases if the process is not carried out accurately. Damaging the rebar can lead to unexpected collapses or structural failures, posing risks to workers and bystanders. Adhering to safety guidelines and using appropriate drilling equipment minimizes these risks.

3. Accuracy

Accuracy is essential when drilling through rebar, as it affects the precision of the project. Whether you are installing electrical conduits, plumbing pipes, or anchor bolts, drilling accurately ensures that the holes are in the correct location. It is important to measure and mark the drilling points accurately to avoid any mistakes or misalignments that can compromise the overall quality of the project.

4. Efficiency

Drilling through rebar safely and accurately can improve the efficiency of construction or renovation projects. By following proper drilling techniques, you can complete the drilling process quickly and move on to the next step without any delays. Efficient drilling saves time, money, and resources, contributing to the overall success of the project.

5. Long-Term Durability

Avoiding damage to rebar during the drilling process ensures the long-term durability of the concrete structure. Damaging or displacing rebar can weaken the concrete, leading to degradation over time. It is important to drill through rebar without causing any fractures or shifting to maintain the structural integrity and longevity of the concrete.

6. Professionalism and Compliance

Drilling through rebar safely and accurately demonstrates professionalism and compliance with industry standards. By following the correct procedures, you show that you have the necessary knowledge and skills to handle drilling projects involving rebar. This adherence to standards enhances your reputation as a reliable and competent professional in the construction industry.

To ensure the importance of drilling through rebar safely and accurately, it is crucial to invest in high-quality drilling equipment, follow safety guidelines, and stay updated with industry best practices. By doing so, you can achieve successful drilling results, improve project outcomes, and maintain the structural integrity of concrete structures.

Selecting the Right Tools for Drilling Through Rebar

When it comes to drilling through rebar in concrete, having the right tools is essential. The strength and density of rebar can make it challenging to drill through, so you need to select tools that are up to the task. Here are some tips for choosing the right tools for drilling through rebar:

1. Rebar-Cutting Drill Bits

One of the most important tools you’ll need is a drill bit specifically designed for cutting through rebar. These drill bits feature a carbide tip that can handle the toughness of the rebar. Look for drill bits that are labeled as rebar-cutting or rebar-focused for best results.

2. Hammer Drill

When drilling through rebar, a regular drill might not provide enough power or force. A hammer drill, on the other hand, combines both rotation and hammering action, making it much more effective for drilling through tough materials like rebar. Invest in a high-quality hammer drill that can deliver enough power for the task at hand.

3. Masonry Drill Bits

In addition to rebar-cutting drill bits, it’s important to have a set of high-quality masonry drill bits. These drill bits are designed to penetrate concrete and other masonry materials, making them essential for drilling through the concrete surrounding the rebar. Look for carbide-tipped masonry drill bits for the best performance.

4. Chisels and Hammers

In some cases, you may encounter rebar that needs to be removed rather than drilled through. In these situations, having chisels and hammers handy can be invaluable. Use a chisel and hammer combination to carefully chip away at the concrete and loosen the rebar for removal.

5. Safety Gear

When working with power tools and drilling through rebar, it’s crucial to prioritize safety. Always wear safety glasses to protect your eyes from debris, and consider wearing a dust mask to prevent inhaling any dust or particles that may be released during drilling. Additionally, wearing heavy-duty gloves can provide extra protection and grip.

6. Inspection Camera

Before you start drilling, it’s a good idea to inspect the area and ensure you have a clear understanding of where the rebar is located. An inspection camera can be a helpful tool for this purpose. Use the camera to visually inspect the concrete and identify the precise location of the rebar, which will help you plan your drilling path.

By selecting the right tools for drilling through rebar, you can ensure a successful and efficient drilling process. Invest in high-quality drill bits, a hammer drill, and other necessary tools, and always prioritize safety when working with power tools.

Understand the Position and Thickness of Rebar

Before drilling through a concrete surface that contains rebar, it is essential to have a thorough understanding of the position and thickness of the rebar. This knowledge will help you choose the right drilling technique, tools, and accessories for the task at hand.

1. Use a Rebar Locator

One way to determine the position of rebar in concrete is by using a rebar locator. These devices use electromagnetic waves to detect the presence and location of rebar within the concrete. By scanning the surface with a rebar locator, you can map out the position of the rebar before drilling.

2. Inspect the Drilled Holes

Another method to understand the position and thickness of rebar is by inspecting the holes that have already been drilled. By examining the drilled holes, you can identify any resistance or obstruction, which may indicate the presence of rebar. Additionally, you can measure the depth of the drilled holes to estimate the thickness of the rebar.

3. Consult Construction Drawings

If available, construction drawings can provide valuable information about the position and thickness of rebar in the concrete. These drawings typically include details about the reinforcement layout, such as the spacing, size, and orientation of the rebar. By referring to these drawings, you can gain a better understanding of the rebar’s positioning.

4. Seek Professional Assistance

If you are unsure about the position and thickness of rebar in the concrete, it is advisable to seek professional assistance. Contractors or structural engineers with experience in this field can provide expert advice and guidance. They may use methods such as ground-penetrating radar or visual inspections to accurately determine the rebar’s position.

5. Measure Rebar Size

Measuring the size of the rebar is crucial for choosing the appropriate drilling technique and tools. Rebar size is typically represented by a number, such as #3 or #4, which corresponds to the bar’s diameter measured in eighths of an inch. Use a caliper or measuring tape to determine the rebar’s size accurately.

6. Consider Rebar Spacing

Rebar spacing refers to the distance between individual bars in the reinforced concrete. Understanding the spacing is essential because it affects the drilling technique and tool selection. If the rebar is closely spaced, you may need to use a diamond-tipped drill bit or a rebar cutter to ensure clean and precise drilling.

By thoroughly understanding the position and thickness of rebar before drilling, you can take the necessary precautions and select the appropriate tools and techniques to ensure a successful drilling operation.

Proper Technique for Drilling Through Rebar in Concrete

When drilling through concrete that contains rebar, it is important to use the proper technique to ensure a successful and safe drilling process. Here are some tips to guide you:

1. Use a High-Quality Diamond Drill Bit

To effectively drill through rebar in concrete, it is essential to use a high-quality diamond drill bit. Diamond bits are specifically designed for drilling through tough materials like rebar. They have diamond particles embedded in the tip, which helps them cut through the metal smoothly.

2. Identify and Mark the Location of the Rebar

Before drilling, it is crucial to identify the location of the rebar in the concrete. This can be done using a rebar locator or by visually inspecting the surface for signs of reinforcement. Once the rebar is located, mark its position on the concrete using a marker or chalk.

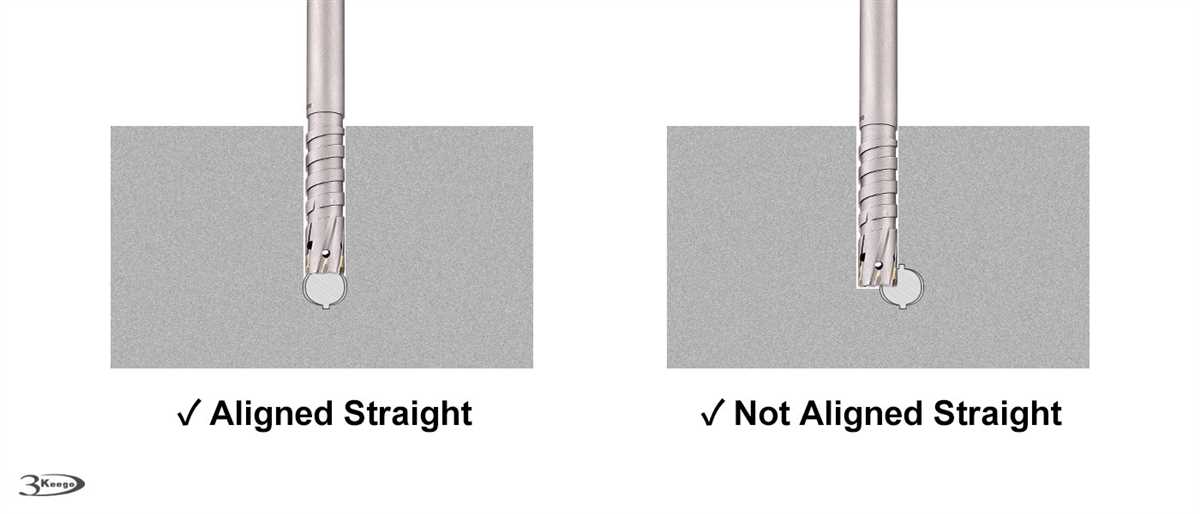

3. Slowly Drill Through the Concrete

Start drilling at a slow speed to prevent the drill bit from overheating. Apply steady pressure while drilling to maintain control. It is essential to drill straight and avoid tilting the drill, as this can cause the bit to bind or break.

4. Use Coolant or Water to Keep the Bit Cool

Drilling through rebar can generate a significant amount of heat, which can damage the diamond drill bit. To prevent overheating, use a coolant or water to lubricate and cool down the bit during the drilling process. This will help prolong the life of the drill bit.

5. Clear Out Debris Regularly

While drilling, debris can accumulate in the hole, obstructing the drilling process. Make sure to clear out the debris regularly by backing the drill out and blowing away the loose material. This will help maintain a clean and efficient drilling operation.

6. Choose the Right Drill Speed

The speed at which you drill through the rebar can affect the drilling process. It is recommended to use a slower speed when drilling through rebar to avoid putting excessive strain on the drill and to ensure clean and precise holes.

By following these proper techniques, you can successfully drill through rebar in concrete and complete your project with ease. Remember to prioritize safety at all times and wear protective gear, such as goggles and gloves, when working with power tools.

Safety Precautions When Drilling Through Rebar

1. Wear the Proper Protective Gear

Before starting any drilling project that involves rebar, it is essential to wear the appropriate protective gear. This includes safety glasses or goggles to protect your eyes from flying debris, gloves to protect your hands, and a dust mask to avoid inhaling any dust particles that may be generated during the drilling process.

2. Inspect the Rebar Before Drilling

Prior to drilling, it is important to thoroughly inspect the rebar to ensure that there are no cracks, bends, or other signs of damage. Damaged rebar may not provide the necessary support and stability, which could result in accidents or equipment failure during drilling. If any defects are found, it is crucial to replace or repair the rebar before proceeding.

3. Use a Suitable Drill Bit

When drilling through rebar, it is crucial to choose a suitable drill bit. Consider using a carbide-tipped masonry drill bit, as it is specifically designed to penetrate through hard materials like concrete and rebar. Using the right drill bit can help prevent unnecessary wear and tear on your drill and ensure smooth and efficient drilling.

4. Secure the Workpiece

Prior to drilling, make sure to secure the workpiece firmly in place to prevent any movement or slipping during the drilling process. This can help maintain accuracy and reduce the risk of accidents or injury. Consider using clamps or a vise to hold the workpiece securely in place.

5. Drill at a Slow and Steady Pace

When drilling through rebar, it is important to maintain a slow and steady pace. Applying excessive force or drilling too quickly can cause the drill bit to overheat, dull prematurely, or even break. Additionally, drilling too fast can result in less control over the drilling process, increasing the risk of accidents or damage to the rebar or surrounding concrete.

6. Avoid Over-Drilling

Avoid over-drilling when working with rebar. Once you have successfully drilled through the rebar, stop applying pressure and remove the drill bit from the hole. Over-drilling can cause unnecessary damage to the rebar, compromising its structural integrity.

By following these safety precautions when drilling through rebar, you can help ensure a safe and successful drilling experience.

Maintenance and Care for Drilling Tools

Proper maintenance and care for drilling tools are essential for their longevity and optimum performance. By following these tips, you can ensure that your drilling tools remain in good condition and continue to deliver excellent results.

1. Cleaning

After each use, it is crucial to clean your drilling tools to remove any debris or residue. Use a brush or compressed air to remove dust and dirt from the tool’s exterior. For more stubborn dirt or grease, you can use a mild detergent solution and a cloth to wipe it clean. Make sure to dry the tool thoroughly before storing it.

2. Lubrication

Lubricating your drilling tools regularly is key to maintaining their smooth operation. Apply a few drops of machine oil or lubricating spray to the moving parts, such as the chuck and gears. This will help reduce friction and prevent wear and tear.

3. Inspection

Regularly inspect your drilling tools for any signs of damage or wear. Check the power cord for any fraying or exposed wires and replace it if necessary. Examine the chuck for any cracks or looseness. Inspect the drill bit for sharpness and replace it if it is dull or damaged. Any faulty or worn-out parts should be replaced immediately to prevent further damage.

4. Storage

Store your drilling tools in a clean and dry environment, away from moisture and extreme temperatures. Use protective cases or toolboxes to keep them organized and protected from impact or accidental damage. Make sure the cords are neatly coiled to prevent tangling.

5. Safe Handling

When working with drilling tools, always follow the manufacturer’s guidelines for safe handling. Use the appropriate safety gear, such as goggles and gloves, to protect yourself from flying debris and potential injuries. Avoid overloading the tool or using it for purposes it is not designed for.

6. Regular Maintenance

In addition to the cleaning and inspection routine, it is recommended to perform regular maintenance on your drilling tools. This includes checking and adjusting the chuck’s tightness, cleaning or replacing air filters if applicable, and inspecting and tightening any loose screws or bolts. Follow the manufacturer’s recommendations for specific maintenance procedures.

By following these maintenance and care tips for drilling tools, you can ensure their longevity, reliable performance, and safety during use. Regular attention and proper handling will extend the life of your tools and provide you with efficient and accurate drilling results.

FAQ:

What is rebar and why is it used in concrete?

Rebar, short for reinforcement bar, is a steel bar or mesh of steel wires used as a tension device in reinforced concrete and masonry structures. It helps to strengthen concrete and prevent cracking or failure under tension or bending forces.

What are the different types of drill bits that can be used for drilling through rebar?

There are several types of drill bits that can be used for drilling through rebar in concrete, including carbide-tipped masonry drill bits, diamond core drill bits, and cobalt drill bits.

Can a regular drill be used for drilling through rebar?

No, a regular drill may not have enough power or the proper type of drill bit to effectively drill through rebar. It is recommended to use a hammer drill or a rotary hammer drill with a suitable drill bit for drilling through rebar.

What safety precautions should be taken when drilling through concrete with rebar?

When drilling through concrete with rebar, it is important to wear safety goggles, ear protection, and a dust mask to protect yourself from flying debris and noise. It is also essential to secure the work area and use clamps or a vise to prevent the concrete from moving during the drilling process.

Can water be used to cool the drill bit while drilling through rebar?

Yes, using water as a coolant can help to keep the drill bit and rebar from overheating, especially when using diamond core drill bits. It helps to lubricate the drill bit and prolong its life while preventing damage to the rebar.

What is the recommended drilling speed for drilling through rebar in concrete?

The recommended drilling speed for drilling through rebar in concrete can vary depending on the type of drill bit and the thickness of the rebar. It is generally recommended to start at a slower speed and gradually increase the speed as needed to avoid overheating the drill bit or damaging the rebar.

What should be done if the drill bit gets stuck in the rebar while drilling?

If the drill bit gets stuck in the rebar while drilling, it is important not to force it or apply excessive pressure, as this can cause the drill bit to break. Instead, try gently tapping the drill bit with a hammer or using a rotary hammer drill in reverse to loosen the stuck bit.

Video: