5 Creative Ways to Punch a Hole in Metal Without a Drill

When it comes to punching a hole in metal, most people would automatically think of using a drill. However, there are actually several alternative methods that can be just as effective, if not more so, and don’t require a drill at all.

If you find yourself in a situation where you need to punch a hole in metal but don’t have access to a drill, don’t worry. In this article, we’ll explore five creative ways to punch a hole in metal without a drill.

One method involves using a metal punch tool, which is specifically designed for punching holes in metal. Another option is to use a hammer and nail to create a hole, although this method may require some additional effort. Alternatively, you can use a center punch to mark the spot where you want the hole and then use a hammer and chisel to create the hole.

For those looking for an even more creative solution, using a blowtorch to heat up the metal and then using a screwdriver to punch a hole can be an effective method. Finally, if you have access to a plasma cutter or a laser cutter, these tools can also be used to punch a hole in metal without the need for a drill.

Nail and Hammer Method

- Take a sharp nail and a hammer.

- Position the nail where you want the hole to be on the metal surface.

- Hold the nail firmly in place with one hand.

- With the other hand, start tapping the nail lightly with the hammer.

- Gradually increase the force of your taps to penetrate through the metal.

- Continue tapping until the nail has created a hole in the metal.

- If necessary, you can twist the nail slightly to widen the hole.

This method is more suitable for thin and soft metals, as it may take more time and effort to create a hole in thicker or harder metals.

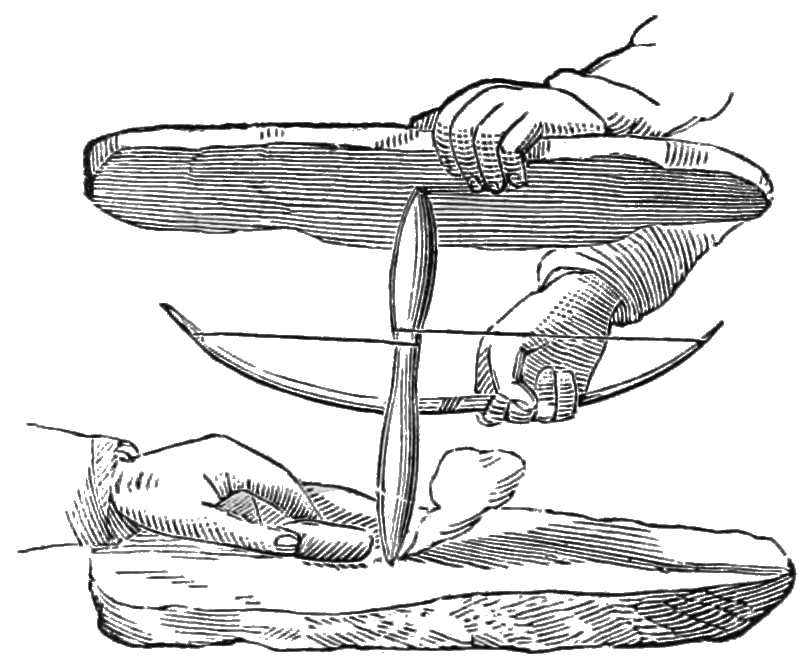

Punch and Hammer Method

The punch and hammer method is a simple and effective way to create a hole in metal without the need for a drill. This method requires minimal tools and can be done by anyone, regardless of their experience with metalworking.

Materials needed:

- Metal punch

- Hammer

- Workbench or sturdy surface

- Protective eyewear

- Work gloves

Step-by-step instructions:

- Put on your protective eyewear and work gloves to protect yourself.

- Place the metal piece on a workbench or another sturdy surface. Ensure that the surface is secure and won’t move during the process.

- Decide on the location of the hole you want to create in the metal.

- Hold the metal punch against the chosen spot on the metal. The punch should be perpendicular to the metal surface.

- Use a hammer to strike the end of the metal punch firmly and directly. Start with gentle taps to create an indentation and then increase the force gradually.

- Continue striking the punch until it pierces through the metal. This may require several strong blows depending on the thickness and hardness of the metal.

- Once the punch has gone through the metal, remove the punch and inspect the hole to ensure it’s the desired size and shape.

- If necessary, use a file or sandpaper to smooth the edges of the hole.

Tips:

- Choose the appropriate size of the metal punch based on the desired hole size.

- Start with light taps and gradually increase the force to avoid damaging the metal or injuring yourself.

- Support the metal piece with a scrap piece of wood or metal to prevent it from bending or warping under the force of the hammer strikes.

- Regularly check the sharpness of the metal punch and sharpen it if necessary to ensure clean and precise holes.

- Take breaks if needed to avoid fatigue and maintain accuracy.

The punch and hammer method is a versatile technique that can be used with various types of metals, including steel, aluminum, and copper. It’s a budget-friendly alternative to using a drill and can be used in situations where a drill is not available or practical. However, keep in mind that this method requires some physical effort and may not be suitable for creating large or numerous holes. With practice and proper technique, you can achieve professional-looking results using the punch and hammer method.

Awl and Mallet Method

If you don’t have a drill or power tools available, you can still punch a hole in metal using a simple awl and a mallet. This method requires a bit of patience and strength, but it can be a great option when you don’t have other tools at hand.

Materials needed:

- Awl

- Mallet

- Metal piece

- Safety goggles

- Gloves

Step-by-step instructions:

- Put on your safety goggles and gloves to protect your eyes and hands during the process.

- Ensure the metal piece is securely positioned on a sturdy surface, such as a workbench or a concrete floor, to prevent it from moving while you work.

- Mark the spot where you want to create the hole using a permanent marker.

- Hold the awl firmly in one hand, with the point aligned with the marked spot on the metal piece.

- Use the mallet to strike the handle of the awl with controlled force. The sharp point of the awl will gradually create a hole in the metal.

- Continue striking the awl with the mallet, exerting firm and consistent pressure, until the hole is punched all the way through the metal.

Tips:

- Choose an awl with a sharp and sturdy point to make the process easier and more efficient.

- Ensure the metal piece is secured properly to avoid accidental movement during the punching process.

- Be cautious, as the awl and mallet method requires physical strength and may cause fatigue.

- Consider practicing on a scrap piece of metal before working on your actual project to get a better feel for the technique.

Using an awl and a mallet is a simple and effective way to punch a hole in metal without a drill. While it may take more time and effort compared to using power tools, it can be a valuable skill to have in situations where drills are not available. Remember to prioritize safety by wearing protective gear and working in a well-lit and well-ventilated area.

Chisel and Hammer Method

The chisel and hammer method is a simple and effective way to punch a hole in metal without using a drill. This method is especially useful for smaller holes or when you don’t have access to a drill.

To use the chisel and hammer method, follow these steps:

-

Mark the hole: Start by marking the location of the hole on the metal surface. Use a pencil or a marker to ensure accuracy.

-

Secure the metal: Place the metal on a stable surface, such as a workbench or a sturdy table. Make sure the metal is secured tightly to prevent any movement during the punching process.

-

Position the chisel: Position the tip of the chisel over the marked location of the hole. Hold the chisel firmly with one hand, ensuring a strong and steady grip.

-

Strike the chisel: Using a hammer, strike the chisel with controlled force. Aim for the center of the chisel’s tip to create a clean and precise hole. Repeat this step several times, applying more force if necessary, until the chisel punches through the metal.

-

Remove the chisel: Once the chisel has punched through the metal, remove it carefully. Inspect the hole to ensure it is the desired size and shape.

It’s important to note that the chisel and hammer method may not be suitable for all types of metal or for larger holes. It is recommended to use this method for thinner or softer metals, such as aluminum or brass. If punching through harder metals, such as steel or iron, it may be necessary to use a different method or to seek professional assistance.

Tips:

- Wear protective gloves and eye goggles to ensure safety during the punching process.

- Use a chisel with a sharp and durable tip to ensure effective punching.

- Consider applying lubricant or cutting oil to the chisel’s tip to reduce friction and improve the punching process.

- If the metal is too thick or difficult to punch through, consider using a different method or seeking professional assistance.

The chisel and hammer method can be a handy technique to have in your DIY arsenal when you need to punch a hole in metal without a drill. By following these steps and taking the necessary precautions, you can successfully create holes in metal using basic tools that are easily accessible.

Plasma Cutter Method

Overview

The plasma cutter method is a widely used technique for punching a hole in metal without a drill. This method involves using a plasma cutter, which is a tool that uses an ionized gas to cut through various materials, including metal. It is especially effective for cutting through thick metal sheets or plates.

Step-by-Step Instructions

- Start by wearing the appropriate safety gear, including gloves, goggles, and a face shield, to protect yourself from sparks and debris.

- Position the metal sheet or plate securely on a workbench or another stable surface.

- Set up the plasma cutter according to the manufacturer’s instructions. This typically involves connecting the cutter to a power source and ensuring the gas supply is properly connected.

- Adjust the cutting settings on the plasma cutter based on the thickness of the metal. The manufacturer’s instructions should provide guidance on the appropriate settings for different materials.

- Hold the plasma cutter torch at a 90-degree angle to the metal surface, keeping a steady hand. Start the cutter and slowly move it along the desired path for the hole.

- As you move the plasma cutter along the path, you will notice that the metal is being cut and melted by the ionized gas. Continue moving the torch until a hole is formed.

- Once the hole is complete, turn off the plasma cutter and allow the metal to cool before handling it.

Benefits

The plasma cutter method offers several advantages for punching holes in metal without a drill:

- Efficiency: A plasma cutter can quickly and accurately cut through metal, making it a fast method for hole punching.

- Flexibility: This method can be used to create holes of various sizes and shapes, depending on the desired outcome.

- No need for pre-drilling: Unlike traditional drilling methods, the plasma cutter allows you to punch a hole directly without the need for pre-drilling.

Considerations

While the plasma cutter method is effective, there are a few considerations to keep in mind:

- Safety: Working with a plasma cutter can be dangerous if proper safety precautions are not followed. Always wear the appropriate safety gear and ensure you are familiar with the tool’s operation before use.

- Cost: Plasma cutters can be expensive compared to other tools. If you don’t already own a plasma cutter, you may need to consider the cost of purchasing or renting one.

- Power requirements: Plasma cutters typically require a dedicated power source, so ensure that you have access to the necessary electricity supply.

| Method | Advantages | Disadvantages |

|---|---|---|

| Plasma cutter | Efficient and fast | Expensive and requires safety precautions |

| Punch and die set | Simple and affordable | May require pre-drilling or limited in size options |

| Abrasive cutoff wheel | Portable and versatile | May produce rough edges |

| Plasma arc drilling | High-speed drilling | May require specialized equipment and expertise |

| Electrochemical machining | Produces precise and burr-free holes | Requires specific electrolyte and setup |

FAQ:

Is it possible to punch a hole in metal without using a drill?

Yes, it is possible to punch a hole in metal without using a drill. This article explores five creative ways to achieve this.

What are some alternatives to using a drill for punching a hole in metal?

There are several alternatives to using a drill for punching a hole in metal. Some creative methods include using a hammer and nail, a center punch and hammer, a metal punch set, a plasma cutter, or a metal hole punch tool.

Can a hammer and nail be used to punch a hole in metal?

Yes, a hammer and nail can be used to punch a hole in metal. To do this, place the nail on the desired spot and strike it with a hammer until it penetrates the metal and creates a hole.

What is a center punch and how can it be used to punch a hole in metal?

A center punch is a tool with a sharp point used to mark the center of a hole before drilling. However, it can also be used to punch a hole in metal without a drill. Simply place the center punch on the metal, and use a hammer to strike the punch until it creates a hole.

What is a metal punch set and how can it be used to punch a hole in metal?

A metal punch set is a collection of different punches and dies that can be used to punch holes of various sizes in metal. By selecting the appropriate punch and die, and using a hammer to strike the punch, a hole can be punched in the metal.

Are there any high-tech methods to punch a hole in metal without using a drill?

Yes, there are high-tech methods to punch a hole in metal without using a drill. One such method is to use a plasma cutter, which uses a high-velocity jet of ionized gas to melt and remove metal. Another option is to use a metal hole punch tool, which can be operated manually or through hydraulic or pneumatic power.

Video: