Effective Techniques for Cutting Cast Iron Pipe with an Angle Grinder

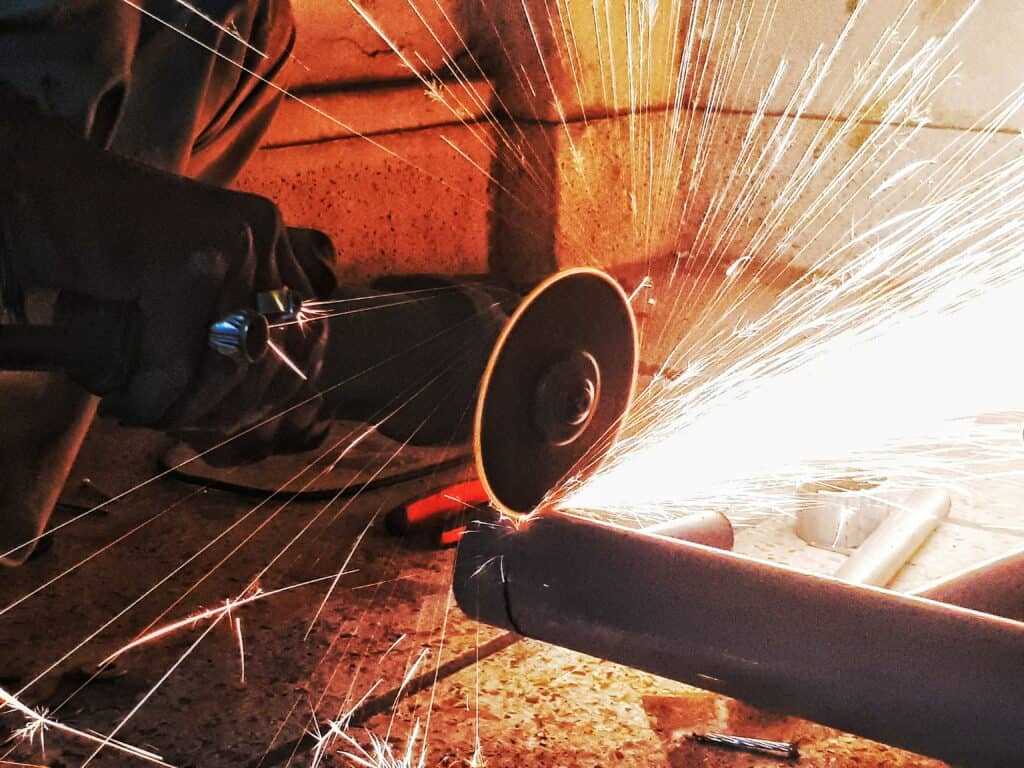

When it comes to cutting cast iron pipes, using an angle grinder can be an effective and efficient method. Cast iron pipes are commonly used in plumbing systems due to their durability and strength, but they can be difficult to cut. However, with the right techniques and tools, you can easily cut through cast iron pipes using an angle grinder.

Before you begin cutting, it is important to have the right safety equipment. Always wear safety goggles and a face mask to protect your eyes and face from sparks and metal shards. Additionally, make sure you are wearing heavy-duty work gloves to protect your hands. Ensuring your safety should be your top priority when working with power tools.

When using an angle grinder to cut cast iron pipes, it is crucial to use a cutting disc specifically designed for metal. These discs are made of abrasive materials that are strong enough to cut through the tough material of cast iron. Make sure the cutting disc is securely attached to the angle grinder before you begin cutting.

When cutting the cast iron pipe, it is important to make clean and precise cuts. Start by making a small incision with the angle grinder, then slowly cut along the marked line. Apply steady pressure and let the grinder do the work. Avoid forcing the grinder through the pipe, as this can cause the cutting disc to wear down quickly.

Remember to take breaks and let the angle grinder cool down periodically. Cutting through cast iron pipes can generate a lot of heat, which can cause the disc to become dull. If you notice the cutting disc starting to lose its sharpness, replace it with a new one to ensure clean and efficient cuts.

Overall, using an angle grinder to cut cast iron pipes can be a quick and efficient method. With the right techniques and tools, you can easily make clean and precise cuts. Just remember to prioritize safety, use the right cutting disc, and take breaks to let the grinder cool down. By following these guidelines, you can successfully cut cast iron pipes with an angle grinder.

What is Cast Iron Pipe?

Cast iron pipe is a type of plumbing pipe that is made from cast iron material. It has been used in plumbing systems for many years due to its durability and strength. Cast iron pipes are commonly found in older homes and buildings, although they are still used in some newer construction projects.

The main characteristic of cast iron pipe is its high resistance to pressure and impact. This makes it a reliable choice for wastewater and sewage systems, as well as other plumbing applications. Cast iron pipe is known for its longevity and ability to withstand heavy loads, making it a popular choice for underground installation.

One of the key features of cast iron pipe is its excellent soundproofing properties. It absorbs noise and vibrations, reducing the transmission of sound throughout the plumbing system. This can be especially beneficial in multi-story buildings or commercial settings where minimizing noise is important.

While cast iron pipe is known for its strength, it does have some drawbacks. One of these is its weight, which can make installation more difficult and labor-intensive. Additionally, cast iron pipe can be more expensive compared to other types of plumbing materials.

Despite these drawbacks, cast iron pipe remains a popular choice for certain applications due to its durability and performance. Proper maintenance and care can help extend the lifespan of cast iron pipe and ensure its continued effectiveness in plumbing systems.

Why Cut Cast Iron Pipe?

Cast iron pipe is commonly used in plumbing systems for its durability and strength. However, there are several reasons why you may need to cut cast iron pipe:

- Repair or replacement: If a section of the cast iron pipe is damaged or corroded, it may need to be cut and replaced.

- Installation of new fixtures or appliances: When adding new fixtures or appliances to a plumbing system, it may be necessary to cut and modify existing cast iron pipe to accommodate the new components.

- Re-routing plumbing lines: During renovations or remodeling projects, it may be necessary to re-route plumbing lines. Cutting the cast iron pipe allows for the creation of new connections and routes.

- Upgrading to newer materials: Cast iron pipe is being phased out in some areas in favor of newer materials such as PVC or ABS pipes. In these cases, cutting the cast iron pipe is necessary to replace it with the newer material.

Whatever the reason, cutting cast iron pipe requires careful planning and the use of appropriate tools and techniques. It is important to follow safety precautions and to use the correct blade or cutting disc for the job.

Choosing the Right Angle Grinder

When it comes to cutting cast iron pipes, choosing the right angle grinder is crucial. The angle grinder you select will determine the efficiency and accuracy of your cuts. Here are a few factors to consider when choosing the right angle grinder:

1. Power

The power of the angle grinder is one of the most important factors to consider. You want a grinder that has enough power to handle cutting through cast iron, which can be a tough and dense material. Look for an angle grinder with a high wattage or amp rating to ensure it can handle the job.

2. Disc Size

The disc size of the angle grinder is another important consideration. For cutting cast iron pipes, you’ll want a grinder with a disc size that matches the thickness of the pipe. A larger disc size allows for deeper cuts, while a smaller disc size provides more control and maneuverability.

3. Speed Adjustability

Having the ability to adjust the speed of the angle grinder is beneficial when cutting cast iron pipes. Different cutting tasks may require different speeds, and being able to slow down or speed up the grinder can make a big difference in the quality of the cuts.

4. Safety Features

Safety should always be a top priority when using power tools. Look for an angle grinder with safety features such as a blade guard and an adjustable handle for better control. Additionally, consider a grinder with a lock-on button to reduce hand fatigue during prolonged cutting sessions.

By considering these factors, you’ll be able to choose the right angle grinder for cutting cast iron pipes effectively and efficiently. Remember to always follow the manufacturer’s instructions and wear appropriate safety gear when using power tools.

Factors to Consider

When cutting cast iron pipe with an angle grinder, there are several factors that need to be considered to ensure an effective cut:

- Type of Angle Grinder: The type of angle grinder being used can affect the cutting process. It is important to choose an angle grinder with a cutting wheel specifically designed for cutting cast iron.

- Cutting Wheel Thickness: The thickness of the cutting wheel can also impact the cutting efficiency. Thicker cutting wheels tend to last longer but may take more time to cut through the cast iron pipe.

- Cutting Speed: The speed at which the angle grinder is operated can affect the cutting effectiveness. A slower cutting speed may result in a cleaner cut, while a faster speed may cause more material to be removed, but may also produce a rougher cut.

- Proper Support: It is important to properly support the cast iron pipe during the cutting process to prevent any movement or vibration that could lead to inaccurate cuts.

- Safety Precautions: Safety should always be a top priority when using an angle grinder. It is important to wear appropriate safety gear, such as goggles and gloves, and to ensure the workspace is clear of any obstacles.

By considering these factors and implementing the necessary precautions, cutting cast iron pipe with an angle grinder can be done effectively and safely.

Recommended Models

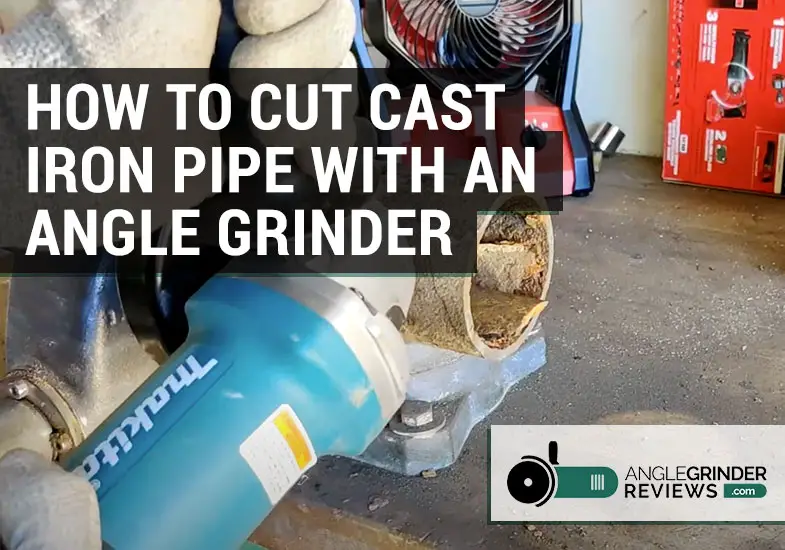

When it comes to cutting cast iron pipes with an angle grinder, having the right tool is crucial. Here are some recommended models that are known for their effectiveness:

- Bosch 1375A 4-1/2-Inch Angle Grinder: This angle grinder is highly recommended for cutting cast iron pipes due to its powerful 6-amp motor. It features a compact design and a comfortable grip, making it easy to maneuver in tight spaces.

- DEWALT DWE402 Angle Grinder: This angle grinder is another excellent choice for cutting cast iron pipes. It features a powerful 11-amp motor and a wheel diameter of 4-1/2 inches. Its ergonomic design and lightweight construction provide comfort and control during use.

- Makita 9557PB Angle Grinder: The Makita 9557PB is a reliable and durable angle grinder that is well-suited for cutting cast iron pipes. It features a 7.5-amp motor and a compact design, making it easy to handle and maneuver.

These recommended models have garnered positive reviews from users and are known for their performance and durability. When choosing an angle grinder for cutting cast iron pipes, it is important to consider factors such as motor power, wheel diameter, and ergonomic design to ensure a smooth and efficient cutting process.

Safety Precautions

1. Wear Protective Gear

Before starting any work with an angle grinder, it is essential to wear proper protective gear. This includes safety goggles or a face shield to protect your eyes from flying sparks and debris. Additionally, wearing hearing protection such as earplugs or earmuffs can help minimize the noise produced by the grinder.

2. Use a Dust Mask

When cutting cast iron pipe with an angle grinder, there will be a significant amount of dust and debris. To protect your lungs from inhaling potentially harmful particles, it is important to wear a dust mask or respirator. This will help prevent respiratory issues and ensure your safety during the cutting process.

3. Secure the Workpiece

Before operating the angle grinder, it is crucial to securely clamp or hold the cast iron pipe in place. This will prevent the pipe from moving or vibrating during the cutting process, reducing the risk of accidents or injuries. Ensuring a stable workpiece will also result in more accurate cuts.

4. Keep a Firm Grip

When using an angle grinder, it is essential to maintain a firm grip on the tool at all times. This will help you maintain control and prevent accidental slips or drops. It is also important to position your body and feet in a stable stance, providing a solid foundation while operating the grinder.

5. Maintain a Safe Distance

It is important to maintain a safe distance from any bystanders while using an angle grinder to cut cast iron pipe. Accidental contact with others can result in serious injuries, so it is necessary to create a clear area around your workspace. Inform others nearby of the potential hazards and keep them at a safe distance during the cutting process.

6. Disconnect the Power

Before changing the cutting wheel or performing any maintenance on the angle grinder, always disconnect the power source. This will prevent any accidental start-ups and ensure your safety during the handling of the tool. Additionally, it is important to follow the manufacturer’s instructions and guidelines for safe operation.

7. Properly Dispose of Debris

After cutting the cast iron pipe, it is important to properly dispose of the debris, including the metallic dust and any leftover pipe sections. Use a broom or vacuum cleaner to clean up the work area, and place the debris in a designated container. This will prevent any potential hazards and keep the workspace clean and organized.

8. Regularly Inspect the Grinder

Prior to each use, inspect the angle grinder for any damages such as loose or worn parts, cracks, or frayed cords. Use the grinder only if it is in good working condition and all safety features are intact. Regular maintenance and inspections will help ensure the safe and efficient operation of the tool.

Protective Gear

When cutting cast iron pipe with an angle grinder, it is important to wear the appropriate protective gear to minimize the risk of injury.

1. Eye Protection: Eye protection is essential when working with tools that generate sparks and flying debris. Safety glasses or goggles should be worn to protect the eyes from any potential hazards.

2. Face Shield: In addition to eye protection, a face shield can provide an extra layer of protection for the face, especially when cutting cast iron pipe. It can protect against larger projectiles or sparks that may come from the cutting process.

3. Respiratory Protection: Cutting cast iron pipe can create dust and metal particles that can be harmful if inhaled. A dust mask or a respirator with appropriate filters should be worn to prevent inhalation of these particles.

4. Gloves: It is important to wear gloves to protect your hands from sharp edges and hot sparks. Heat-resistant gloves are recommended, as they can provide additional protection against the heat generated during the cutting process.

5. Ear Protection: The noise generated by an angle grinder can be loud and potentially damaging to the ears. Earplugs or earmuffs should be worn to protect against noise-induced hearing loss.

6. Clothing: It is advisable to wear long-sleeved shirts and long pants to protect the skin from any sparks or debris. Avoid loose-fitting clothing that can get caught in the grinder.

7. Footwear: Sturdy closed-toe shoes or boots with non-slip soles should be worn to protect the feet from any falling objects or sharp debris.

8. Work Area Protection: Before starting the cutting process, it is important to ensure that the work area is clear of any flammable materials. Using a fire-resistant mat or sheet underneath the cast iron pipe can provide an added layer of protection.

9. First Aid Kit: Accidents can happen even with the best safety precautions. Having a well-equipped first aid kit nearby can be beneficial in case of any minor injuries.

By wearing the appropriate protective gear, you can minimize the risks associated with cutting cast iron pipe and ensure a safer working environment.

Working Environment

Noise Level

The working environment when cutting cast iron pipe with an angle grinder can be quite noisy. The angle grinder produces a loud grinding sound as it cuts through the pipe, so it is important to wear ear protection to minimize the risk of hearing damage. Additionally, working in a well-ventilated area can help reduce noise reflections and make the working environment more comfortable.

Dust and Debris

Cutting cast iron pipe with an angle grinder can produce a significant amount of dust and debris. It is important to wear a dust mask and safety goggles to protect yourself from inhaling the dust particles and getting debris in your eyes. Setting up a containment system, such as a plastic sheet or tarp, can help prevent the dust and debris from spreading throughout the work area.

Lighting

Adequate lighting is crucial when working with an angle grinder to cut cast iron pipe. Insufficient lighting can make it difficult to see the cut line and potentially lead to inaccurate cuts or accidents. Using a bright work light or positioning the work area near a well-lit source can help ensure proper visibility and a safer working environment.

Workbench or Stable Surface

Having a stable workbench or surface is important for maintaining control and stability while cutting cast iron pipe. An angle grinder can produce significant vibrations, and a wobbly surface can make it difficult to maintain a steady hand. Using clamps or vises to secure the pipe and angle grinder can also help improve stability and precision during the cutting process.

Work Area Organization

Keeping the work area organized is essential for a safe and productive working environment. Clearing away any unnecessary clutter or obstacles can help prevent accidents and make it easier to maneuver the angle grinder. It is also important to have any necessary tools and safety equipment easily accessible to ensure a smooth workflow.

Marking and Measuring

Accurate marking and measuring is crucial when cutting cast iron pipe with an angle grinder. Before beginning the cutting process, it is essential to mark the pipe precisely to ensure a clean and accurate cut.

One effective technique for marking the pipe is to use a measuring tape or ruler to measure the desired length. This measurement should be marked on the pipe using a permanent marker or scribe. It is recommended to make multiple marks around the circumference of the pipe to ensure accuracy.

In addition to measuring the length, it is also important to mark the location of the cut. This can be done by measuring the distance from the end of the pipe to the desired cutting point and making a mark. It is helpful to use a straight edge or level to ensure a straight and level cut.

Another useful technique for marking and measuring is to create a template or cutting guide. This can be done by cutting a piece of cardboard or thin plywood to the desired length and shape. The template can then be placed on the pipe to provide a guide for marking and cutting.

Overall, accurate marking and measuring are essential steps when cutting cast iron pipe with an angle grinder. Taking the time to measure and mark the pipe correctly will result in a cleaner and more precise cut, reducing the risk of potential errors or mistakes.

Identifying the Cutting Line

Before you start cutting cast iron pipe with an angle grinder, it is essential to identify the cutting line. This step is crucial to ensure that you make a clean and precise cut. There are several methods you can use to identify the cutting line.

Measuring and marking: One of the simplest ways to identify the cutting line is by measuring and marking it on the pipe. Use a measuring tape or a ruler to determine the desired length of the pipe and make a mark with a permanent marker or a piece of chalk. This will serve as your guide throughout the cutting process.

Using a template: If you need to make multiple cuts on the cast iron pipe, using a template can be helpful. Create a cardboard or paper template with the accurate measurements and align it with the pipe. Trace the outline of the template onto the pipe using a marker or a scribe to establish the cutting line.

Using a guide: Another method to identify the cutting line is by using a guide. This can be a straight edge, a level, or a clamped piece of wood or metal. Place the guide along the pipe where you want to make the cut, ensuring it is straight and aligned. Use the edge of the guide as a reference to mark the cutting line on the pipe.

Inspecting the pipe: In some cases, the cutting line may already be visible on the cast iron pipe. Look for any manufacturer markings or notches on the pipe that indicate the desired cutting line. If present, these markings can serve as a guide for your cut.

By accurately identifying the cutting line on the cast iron pipe, you can ensure a clean and precise cut with an angle grinder. This will make the process of cutting the pipe more efficient and help you achieve the desired result.

FAQ:

What kind of angle grinder should I use to cut cast iron pipe?

You should use a high-quality angle grinder with a powerful motor and a cutting wheel specifically designed for cutting metal.

Can I use a regular cutting wheel to cut cast iron pipe?

No, regular cutting wheels are not designed to handle the hardness of cast iron. You should use a cutting wheel specifically designed for cutting metal.

What safety precautions should I take when cutting cast iron pipe with an angle grinder?

When cutting cast iron pipe with an angle grinder, it is important to wear safety goggles, a face shield, and ear protection. Make sure to secure the pipe firmly in place and avoid cutting near flammable materials.

What is the best technique for cutting cast iron pipe?

The best technique for cutting cast iron pipe is to score the pipe with the angle grinder, then gradually deepen the cut using multiple passes. This will help prevent the pipe from breaking or cracking.

Can I use water to cool the angle grinder while cutting cast iron pipe?

No, using water to cool the angle grinder is not recommended when cutting cast iron pipe. It can cause the metal to heat up too quickly and potentially crack or break.

What should I do if the cutting wheel gets stuck while cutting cast iron pipe?

If the cutting wheel gets stuck while cutting cast iron pipe, you should immediately stop the angle grinder and carefully remove the wheel. It is important to take your time and avoid forcing the grinder, as this could cause damage or injury.

Video: