Best wire wheel for angle grinder

An angle grinder is a versatile tool that can be used for a wide range of tasks, from cutting and grinding to polishing and buffing. One of the most popular attachments for an angle grinder is a wire wheel, which is perfect for removing rust, paint, and other coatings from metal surfaces.

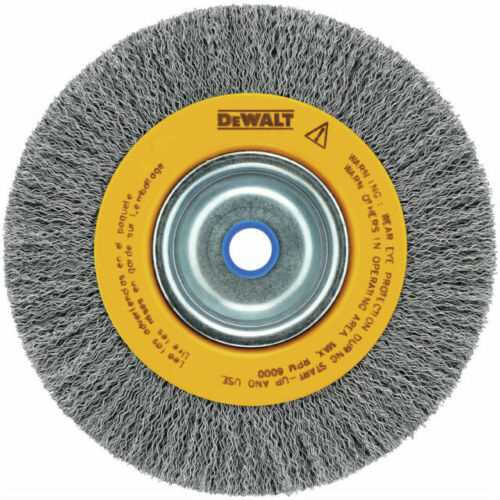

When it comes to choosing the best wire wheel for your angle grinder, there are several factors to consider. The first is the type of wire wheel. There are two main types: crimped wire wheels and twisted wire wheels. Crimped wire wheels are ideal for lighter-duty tasks, while twisted wire wheels are more aggressive and are better suited for heavy-duty applications.

Another important factor to consider is the wire material. Wire wheels are typically made from either carbon steel or stainless steel. Carbon steel wire wheels are more affordable, but they are prone to rusting and can leave residue on the workpiece. Stainless steel wire wheels, on the other hand, are more durable, rust-resistant, and leave a cleaner finish.

In addition to the type of wire wheel and the wire material, it’s also important to consider the size and arbor size of the wheel. Most wire wheels for angle grinders come in sizes ranging from 3 inches to 8 inches, so it’s important to choose a size that is appropriate for your specific needs. The arbor size should also match the arbor size of your angle grinder to ensure a secure fit.

Why you should consider using a wire wheel for your angle grinder

If you own an angle grinder, you may already be familiar with its versatility and ability to handle various tasks. But have you considered adding a wire wheel attachment to your arsenal of tools? A wire wheel can be an incredibly useful accessory for your angle grinder, offering numerous benefits and expanding its capabilities.

One of the main reasons you might need a wire wheel for your angle grinder is for cleaning and removing rust, paint, and other stubborn coatings from metal surfaces. The wire bristles on the wheel are designed to effectively scrape away these tough substances, saving you time and effort compared to using traditional methods like sanding or scraping by hand.

- Versatility: A wire wheel can be used on a variety of materials, making it a versatile option for different applications. Whether you need to clean metal, remove excess welds, or prepare surfaces for painting or welding, a wire wheel can handle the job.

- Efficiency: The rotating wire bristles on the wheel allow for quick and efficient cleaning and surface preparation. They can reach into tight corners and crevices, ensuring thorough removal of debris and coatings.

- Durability: Wire wheels are typically made with sturdy materials, such as stainless steel or brass, that can withstand heavy use without wearing out quickly. This makes them a reliable and long-lasting option for your angle grinder.

- Easy installation: Attaching a wire wheel to your angle grinder is a straightforward process that requires minimal effort. Simply remove the existing grinding disc and replace it with the wire wheel, following the manufacturer’s instructions.

Overall, investing in a wire wheel for your angle grinder can greatly enhance its functionality and make your metalworking tasks more efficient. Whether you are a DIY enthusiast or a professional, this accessory can help you achieve professional-looking results with minimal effort.

Factors to consider when choosing a wire wheel

When it comes to choosing a wire wheel for your angle grinder, there are several important factors to consider. These factors will help you find the best wire wheel for your specific needs and ensure that you get the most out of your angle grinder.

Diameter and arbor size: The first thing you need to consider is the diameter and arbor size of the wire wheel. The diameter determines the size of the area the wheel can cover, and the arbor size determines if it will fit your angle grinder. Make sure to choose a wire wheel with the correct diameter and arbor size for your angle grinder.

Wire type and thickness: The wire type and thickness are also important considerations. The type of wire and its thickness will determine the wheel’s aggressiveness and its ability to remove rust, paint, or other materials. Consider the specific task you have in mind and choose a wire wheel with the appropriate wire type and thickness.

Speed and rpm: The speed and rpm of the wire wheel are crucial factors in its performance. Different wire wheels are designed to work at different speeds, so it’s important to choose a wire wheel that matches the speed and rpm capabilities of your angle grinder. Using a wire wheel at the wrong speed can result in inefficiency, reduced performance, or even damage.

Quality and durability: The quality and durability of the wire wheel are essential considerations. Look for a wire wheel made from high-quality materials that can withstand the demands of your intended tasks. A durable wire wheel will last longer and provide more effective performance, saving you time and money in the long run.

By considering these factors, you can make an informed decision and choose the best wire wheel for your angle grinder. Whether you’re removing rust, paint, or other materials, the right wire wheel can make all the difference in achieving the results you desire.

Material

The type of material used in wire wheels for angle grinders is an important factor in determining their effectiveness and durability. Different materials offer different levels of performance and longevity, so it’s important to choose the right material for your specific needs.

One common material used in wire wheels is steel. Steel wire wheels are known for their durability and strength, making them suitable for heavy-duty applications. They are able to remove rust, paint, and other coatings effectively. However, steel wire wheels may be too aggressive for certain materials, such as softer metals, and can cause damage if used improperly.

Another material option for wire wheels is brass. Brass wire wheels are softer and less abrasive than steel, making them ideal for delicate or finer finishes. They are often used for polishing and cleaning applications, as they are less likely to leave scratches or marks on the surface. However, brass wire wheels may wear out faster than steel wheels, especially when used for heavy-duty tasks.

Additionally, there are wire wheels made from synthetic materials such as nylon or abrasive-impregnated nylon. These wheels offer longer life and are less likely to shed wires compared to traditional wire wheels. They are often used for general cleaning and deburring applications, as well as for removing paint and rust. However, synthetic wire wheels may not be as aggressive as steel or brass wheels, so they may take longer to complete certain tasks.

Size

When choosing the best wire wheel for your angle grinder, one important factor to consider is the size of the wheel. The size of the wire wheel will determine the surface area it can cover and the amount of material it can remove in a given time.

Wire wheels come in various sizes, ranging from small diameter wheels of around 2 inches to larger ones of up to 8 inches. Smaller wire wheels are suitable for precise and detailed work, such as removing paint or rust from small areas. On the other hand, larger wire wheels are more effective for larger surfaces and heavy-duty applications.

The size of the wire wheel also affects the balance and maneuverability of the angle grinder. Smaller wire wheels are lighter and easier to handle, making them ideal for intricate work and tasks that require a delicate touch. However, larger wire wheels may provide more stability and control when working on larger surfaces or dealing with tough materials.

Ultimately, the size of the wire wheel should be chosen based on the specific application and the size of the workpiece. For general-purpose grinding and cleaning tasks, a medium-sized wire wheel, around 4 to 6 inches in diameter, is often a versatile choice that can handle a variety of tasks. However, for more specialized applications, it may be necessary to use smaller or larger wire wheels to achieve the desired results.

Wire Thickness

When choosing a wire wheel for your angle grinder, one important factor to consider is the wire thickness. The thickness of the wire determines its durability and aggressiveness in removing rust, paint, and other stubborn substances from surfaces.

A thicker wire will generally be more durable and able to withstand higher speeds and pressures during use. This makes it suitable for heavy-duty applications and for removing heavy coatings or corrosion. However, a thicker wire may also be less flexible, making it less effective in reaching tight spots or contours.

On the other hand, a thinner wire will be more flexible and able to conform to the shape of the surface being worked on. This makes it ideal for cleaning and polishing delicate materials or for getting into hard-to-reach areas. However, a thinner wire may wear out more quickly and may not be as effective for removing tough or stubborn coatings.

Ultimately, the choice of wire thickness will depend on the specific task at hand and the type of material being worked on. A thicker wire may be preferable for heavy-duty tasks, while a thinner wire may be better suited for detailed work or lighter cleaning and polishing. It is important to consider the specific requirements of your project and select a wire wheel with the appropriate thickness for optimal performance.

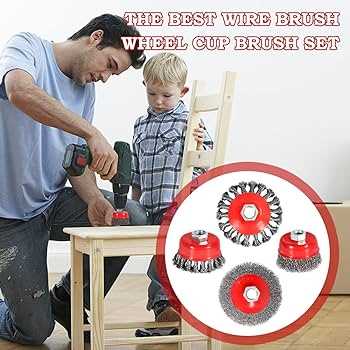

5 Best wire wheel for angle grinder

Features

| Part Number | KDPKDPWB011-2 |

| Size | 115mm / 125mm |

Features

| Part Number | TE242_4PK |

| Model | TE242_4PK |

| Size | 4 Pack |

Features

| Part Number | BLWBS4 |

| Color | Red |

Q&A:

What is wire thickness?

Wire thickness is the diameter or cross-sectional area of a wire, usually measured in gauge or millimeters.

How is wire thickness measured?

Wire thickness is measured using a wire gauge, which is a device that determines the diameter of a wire. The gauge number corresponds to a specific thickness, with a higher number indicating a thinner wire.

What is the standard wire thickness for electrical wiring?

The standard wire thickness for electrical wiring depends on the specific application and the guidelines set by regulatory bodies like the National Electrical Code (NEC) in the United States. The most common wire thicknesses for residential wiring are 14 gauge and 12 gauge.

How does wire thickness affect electrical conductivity?

Thicker wires generally have lower electrical resistance and therefore higher electrical conductivity. Thinner wires, on the other hand, have higher electrical resistance and lower conductivity. This is why thicker wires are often used for carrying higher currents or for long-distance power transmission.

What factors should be considered when selecting the appropriate wire thickness?

When selecting the appropriate wire thickness, factors such as the amount of current to be carried, the length of the wire run, and the type of circuit should be considered. It is important to choose a wire thickness that can handle the expected current without overheating and causing a fire hazard.

Conclusion

In conclusion, wire thickness plays a significant role in various applications and industries. It has a direct impact on the strength, conductivity, and flexibility of the wire. Choosing the right wire thickness is crucial to ensure the efficient functioning and durability of electrical systems, as well as the safety of individuals using them. From household wiring to industrial applications, understanding the importance of wire thickness is essential for professionals and DIY enthusiasts alike. Whether selecting wires for a simple project or making complex electrical installations, considering factors such as current rating, voltage drop, and insulation requirements will help in determining the appropriate wire thickness for each application. Investing time and effort in selecting the right wire thickness will result in improved efficiency, reduced risks, and increased longevity of electrical systems.