Best cutting disc for plastics angle grinder

When it comes to cutting plastics with an angle grinder, finding the right cutting disc is crucial. The wrong disc can lead to ineffective cutting, and may even cause damage to the plastic material. That’s why it’s important to choose a cutting disc specifically designed for cutting plastics.

One of the best cutting discs for plastics is the diamond cutting disc. This type of disc is made with a layer of diamond particles on the outer edge, which makes it extremely durable and effective for cutting through plastics. The diamond particles provide a sharp cutting surface that can easily slice through even the toughest plastic materials without causing any damage.

Another excellent option for cutting plastics is the carbide cutting disc. This type of disc is made with carbide, a strong and durable material that is known for its ability to cut through plastics with ease. Carbide cutting discs are designed to be long-lasting and provide clean, precise cuts in a variety of plastic materials.

It’s important to note that when using an angle grinder to cut plastics, safety should always be a top priority. Make sure to wear appropriate safety gear, such as goggles and gloves, and follow all manufacturer instructions for the angle grinder and cutting disc. With the right cutting disc and proper safety precautions, you can achieve clean, precise cuts in plastics with your angle grinder.

Choosing the Right Cutting Disc for Plastics on an Angle Grinder

When it comes to cutting plastics with an angle grinder, selecting the proper cutting disc is crucial to achieve clean and precise cuts. Not all cutting discs are designed to work effectively on plastics, so it’s important to choose the right one for the job.

One of the best cutting discs for plastics on an angle grinder is a diamond cutting disc. Diamond discs are renowned for their ability to cut through hard materials, including plastics. Their sharp diamond particles provide excellent cutting performance while minimizing the risk of melting or distorting the plastic.

- Key Features:

- Diamond coating: A diamond cutting disc is coated with tiny diamond particles, known for their exceptional hardness, making them ideal for cutting plastics without dulling quickly.

- Precision: Diamond cutting discs offer precise cutting results, ensuring smooth edges and reduced plastic deformation.

- Heat dissipation: The diamond particles on the cutting disc help dissipate heat generated during cutting, minimizing the risk of melting the plastic material.

Additionally, when selecting a cutting disc for plastics on an angle grinder, look for discs with a fine grit size. A fine-grit cutting disc will provide a finer cut, reducing the need for further finishing or sanding. Discs with a coarse grit are more likely to cause chipping or splintering of the plastic material.

In conclusion, when cutting plastics with an angle grinder, opt for a diamond cutting disc with a fine grit size. This combination will ensure precise, clean, and distortion-free cuts, making it the best choice for working with plastic materials on an angle grinder.

Factors to Consider When Choosing a Cutting Disc for Plastics

When selecting a cutting disc for plastics to use with an angle grinder, there are several important factors to consider. Choosing the right disc is crucial to ensure clean and accurate cuts while avoiding damage to the material or the tool itself. Here are some key considerations to keep in mind:

- Material compatibility: Different types of plastics have varying levels of hardness and composition. It is important to choose a cutting disc specifically designed for plastics to ensure compatibility and achieve the desired results.

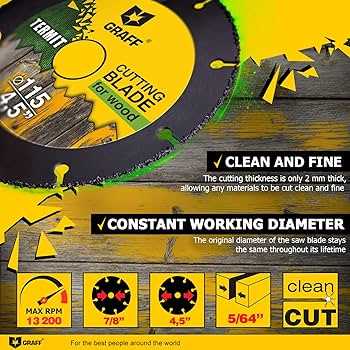

- Disc size and thickness: The size and thickness of the cutting disc can affect the cutting performance and the precision of the cuts. Consider the thickness of the plastic material you will be working with, as well as the depth of cut required, when selecting the disc size and thickness.

- Cutting speed: The speed at which the disc cuts through the plastic can be influenced by factors such as disc material, disc thickness, and the rotational speed of the angle grinder. Ensure the cutting disc you choose is suitable for the speed at which you intend to operate the grinder.

- Quality and durability: Look for cutting discs that are made from high-quality materials and have a reputation for durability. This will ensure that the disc can withstand the demands of cutting through plastics without premature wear or damage.

- Safety features: Consider cutting discs that offer safety features such as reinforced cores, anti-kickback design, and heat dissipation properties. These features can help prevent accidents and enhance user safety during cutting operations.

By taking these factors into account and selecting a cutting disc that is compatible with the specific type of plastic you are working with, you can achieve precise and clean cuts while maximizing the lifespan of your angle grinder.

Top Brands and Models of Cutting Discs for Plastics Angle Grinder

When it comes to finding the best cutting disc for plastics angle grinder, there are several top brands and models to consider. These cutting discs are specifically designed for cutting through various types of plastics efficiently and effectively. Here are some of the top brands and models that you should consider:

1. Bosch X-Lock Plastic Cutting Disc

The Bosch X-Lock Plastic Cutting Disc is a popular choice among professionals and DIY enthusiasts alike. It is known for its durability and cutting precision. This cutting disc features a unique X-Lock mechanism that allows for quick and easy blade changes, saving you time and effort. It is designed to cut through various types of plastics without causing excessive heat or melting.

2. Makita B-46159 Thin Cutting Disc

The Makita B-46159 Thin Cutting Disc is another top choice for cutting plastics with an angle grinder. This cutting disc is known for its high durability and fast cutting speed. It features a thin design that allows for precise and clean cuts in various types of plastics. It is also designed to minimize vibration and noise during operation, providing a comfortable and efficient cutting experience.

3. DeWalt DW8061B5 Cutting Discs

The DeWalt DW8061B5 Cutting Discs come in a pack of five, making them a cost-effective option for cutting plastics. These cutting discs are known for their long lifespan and fast cutting performance. They are designed with reinforced fiberglass for added durability and stability during operation. The thin design of these cutting discs allows for precision cutting in various types of plastics.

4. Diablo DDD045DIA101F Cutting Disc

The Diablo DDD045DIA101F Cutting Disc is a high-quality cutting disc designed specifically for cutting plastics. It is known for its exceptional cutting speed and long lifespan. This cutting disc features a unique diamond grit edge that provides smooth and precise cuts in various types of plastics. It also has a reinforced design for added strength and stability during operation.

These are just a few of the top brands and models of cutting discs for plastics angle grinder. When choosing a cutting disc, it is important to consider factors such as durability, cutting precision, and ease of use. By choosing a reliable brand and model, you can ensure that you have the best tool for your cutting needs.

Comparison of Performance and Features

When it comes to finding the best cutting disc for plastics for your angle grinder, it can be helpful to compare the performance and features of different options. By doing so, you can make an informed decision based on your specific needs and requirements.

Performance: One important factor to consider is the performance of the cutting disc. Look for a disc that is specifically designed for cutting plastic materials, as this will ensure efficient and clean cuts. Consider the disc’s cutting speed, the smoothness of the cuts it produces, and its ability to handle different types and thicknesses of plastics.

Features: In addition to performance, it’s also important to consider the features of the cutting disc. Look for a disc that offers durability and long-lasting performance. Consider whether the disc is reinforced with fiberglass or other materials to enhance its strength and longevity. Additionally, look for features such as a thin kerf design for precision cutting, and special teeth or coatings to minimize heat buildup and prevent melting or burning of the plastic.

By comparing the performance and features of different cutting discs for plastics, you can find the best option for your angle grinder that meets your specific cutting needs and provides long-lasting and efficient performance.

Safety Precautions and Tips for Using Cutting Discs for Plastics

When using cutting discs for plastics with an angle grinder, it is important to take certain safety precautions to prevent accidents and ensure a successful cutting process. Here are some tips to keep in mind:

- Wear protective gear: Before starting any cutting work, always wear the appropriate safety gear, including safety glasses or goggles, gloves, and a dust mask. This will protect your eyes, hands, and respiratory system from any potential hazards.

- Choose the right disc: Select a cutting disc that is specifically designed for cutting plastics. These discs are typically made with materials that are less likely to cause heat buildup or melting of the plastic material. Avoid using cutting discs intended for other materials, as they may be too abrasive or cause excessive friction.

- Inspect the disc: Before using the cutting disc, carefully inspect it for any signs of damage or wear. Check for cracks, chips, or any other abnormalities that could affect its performance. Replace any damaged disc immediately to prevent accidents.

- Secure the workpiece: Ensure that the plastic workpiece is securely clamped or held in place before starting the cutting process. This will prevent it from moving or slipping during cutting, reducing the risk of injury or damage.

- Control the speed: Use the angle grinder at an appropriate speed for cutting plastics. Avoid using high-speed settings, as this can generate excess heat that could cause the plastic to melt or warp. Start at a lower speed and gradually increase if necessary.

- Work in a well-ventilated area: Cutting plastics can produce dust and fumes. It is important to work in a well-ventilated area or use proper ventilation equipment to avoid inhaling any harmful particles.

- Take breaks: Cutting plastics can be strenuous work, especially if you have a large project. Take regular breaks to rest and avoid fatigue, which could lead to accidents or mistakes.

- Dispose of waste properly: After cutting, dispose of any waste material, such as plastic scraps, in a responsible manner. Follow local regulations and guidelines for proper disposal to minimize environmental impact.

By following these safety precautions and tips, you can use cutting discs for plastics with your angle grinder safely and effectively, ensuring a smooth and precise cutting process.

5 Best cutting disc for plastics angle grinder

Features

| Part Number | Cutting Wheel Discs Set |

| Color | Black |

Features

| Part Number | 169872647 |

| Color | Multicolor |

Features

| Part Number | YJP002 |

Features

| Part Number | Cutting Wheel Discs Set |

| Model | Cutting Wheel Discs Set |

| Color | Brown, Black, Silver |

Q&A:

Are there any safety precautions to consider when using cutting discs for plastics?

Yes, there are several safety precautions to keep in mind when using cutting discs for plastics. Firstly, always wear appropriate personal protective equipment such as safety goggles and gloves to protect yourself from any flying debris. Additionally, make sure to secure the plastic material properly before cutting to prevent it from moving around. It is also important to use the correct type and size of cutting disc for the specific plastic you are working with.

What type of cutting disc should I use for plastics?

When working with plastics, it is recommended to use a cutting disc specifically designed for plastic materials. These discs usually have a thinner profile and finer teeth, allowing for smoother cuts without excessive heat buildup. Using a cutting disc designed for metal or other materials may result in melting or damaging the plastic.

How can I prevent the plastic from melting when using a cutting disc?

To prevent the plastic from melting when using a cutting disc, it is important to use a cutting disc with finer teeth and avoid excessive pressure or speed. Slow down the cutting speed and apply light, even pressure to ensure a clean cut without generating excessive heat. Cooling the plastic material with water or a lubricant spray can also help to dissipate heat and prevent melting.

What should I do if the cutting disc gets stuck in the plastic?

If the cutting disc gets stuck in the plastic, do not force it or try to remove it forcefully. Turn off the power tool and wait for the cutting disc to come to a complete stop. Carefully try to reverse the cutting direction to release the disc from the plastic. If this doesn’t work, seek professional assistance or consult the manufacturer for further guidance.

Are there any other tips for using cutting discs for plastics?

Yes, here are a few additional tips for using cutting discs for plastics. Always make sure to choose the appropriate cutting disc size for the task at hand. Avoid excessive speed or pressure, as this can cause the plastic to crack or chip. Prioritize safety at all times and follow the manufacturer’s instructions carefully. Finally, regularly inspect the cutting disc for any signs of wear or damage, and replace it if necessary.

What are some safety precautions to take when using cutting discs for plastics?

When using cutting discs for plastics, it is important to wear personal protective equipment (PPE) such as safety goggles, gloves, and a dust mask to protect yourself from any flying debris or plastic dust. It is also recommended to work in a well-ventilated area to avoid inhaling any potentially harmful fumes. Additionally, ensure that the plastic material being cut is secured and stable to prevent any slips or accidents.

What are some tips for using cutting discs for plastics?

Some tips for using cutting discs for plastics include using the appropriate disc for the type and thickness of plastic being cut. It is important to apply steady and even pressure while cutting to prevent the disc from binding or breaking. To achieve cleaner cuts, start with a shallow cut and gradually increase the depth. It is also recommended to let the cutting disc do the work and not force it through the material. Finally, regularly inspect the disc for any signs of damage or wear and replace as necessary.

Conclusion

In conclusion, when working with cutting discs for plastics, it is important to prioritize safety precautions to prevent accidents and injuries. Always wear appropriate personal protective equipment, such as safety glasses and gloves, to protect yourself from flying debris and potential hazards. Make sure to use the correct type and size of cutting disc for the specific plastic material you are working with. Follow the manufacturer’s instructions and guidelines for safe usage, including speed and pressure recommendations. Regularly inspect cutting discs for any signs of damage or wear and replace them as needed. By taking these safety precautions and following proper procedures, you can effectively and safely use cutting discs for plastics.