Best angle grinder wheel for cutting metal

When it comes to cutting metal, having the right tools makes all the difference. One of the most essential tools for cutting metal is an angle grinder, and choosing the right wheel for your cutting needs is crucial. With so many options available on the market, it can be overwhelming to find the best angle grinder wheel for cutting metal. This article will guide you through the top choices and help you make an informed decision.

There are several factors to consider when selecting a grinding wheel for cutting metal. The first is the type of metal you will be cutting. Different metals have different hardness levels, so it’s important to choose a grinding wheel that is suitable for the specific metal you are working with. Another important factor to consider is the grit size of the wheel. A lower grit size is recommended for cutting metal, as it will provide a faster and more aggressive cut.

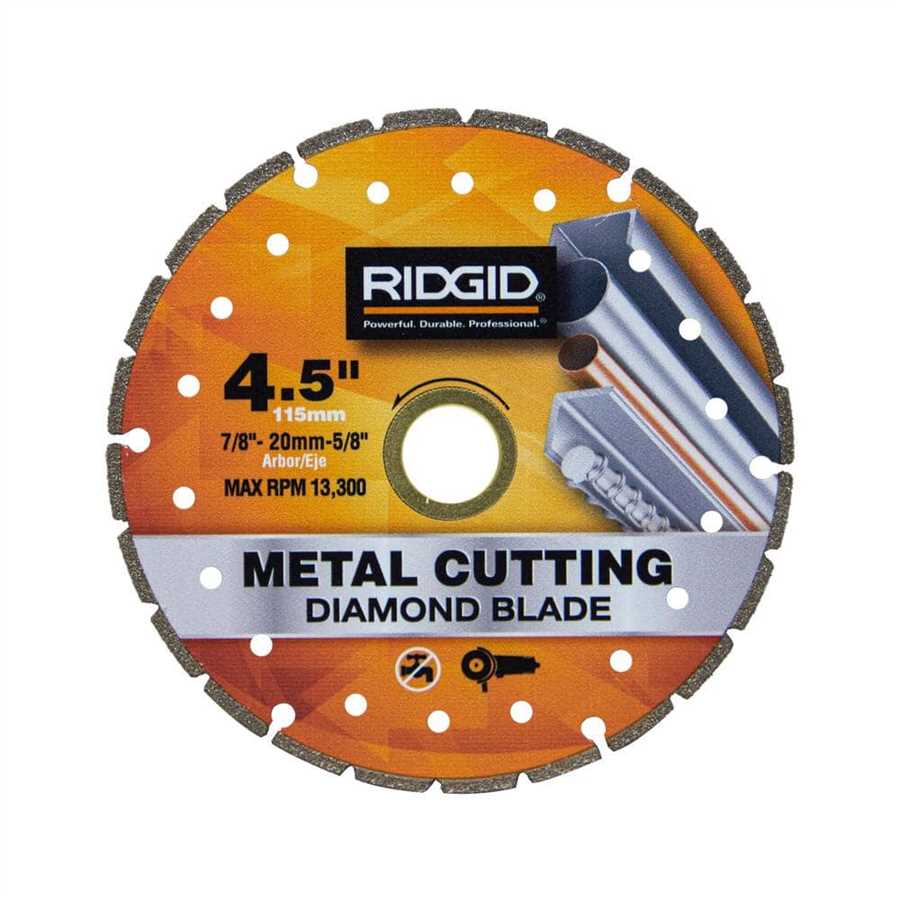

One of the top choices for cutting metal is a diamond wheel. Diamond wheels are highly durable and offer excellent cutting performance. They are ideal for cutting through hard metals such as stainless steel and cast iron. Another popular option is a cutting wheel made of abrasive material, such as aluminum oxide. These wheels offer good cutting performance and are more affordable than diamond wheels.

What is an Angle Grinder Wheel?

An angle grinder wheel is a tool that is attached to an angle grinder, which is a handheld power tool typically used for cutting and grinding tasks. The angle grinder wheel consists of a circular disc with abrasive material bonded to the surface. It is specifically designed for cutting through various materials, including metal, masonry, and wood.

The angle grinder wheel comes in different sizes and types, depending on the specific application. Some common types include cutting wheels, grinding wheels, and flap discs. Cutting wheels are used for cutting through metals, while grinding wheels are used for grinding and smoothing surfaces. Flap discs are versatile and can be used for both cutting and grinding tasks.

When using an angle grinder wheel for cutting metal, it is important to select the right type and size for the job. The material being cut, the thickness of the metal, and the desired result will all factor into the choice of wheel. Different wheels have different characteristics, such as speed, durability, and aggressiveness, which can affect the cutting performance.

In summary, an angle grinder wheel is a versatile tool that is used for cutting and grinding materials. It is an essential tool for metalworkers and other professionals who frequently work with metal. Choosing the right angle grinder wheel is essential for achieving the desired result and ensuring safe and efficient operation.

The Significance of Choosing the Right Angle Grinder Wheel for Cutting Metal

When it comes to cutting metal, having the right angle grinder wheel is of utmost importance. The choice of wheel can greatly affect the efficiency and safety of the cutting process. With various types of wheels available on the market, it is crucial to select the one that best suits the specific metal cutting application.

A suitable angle grinder wheel for cutting metal should be chosen based on factors such as the type of metal being cut, the thickness of the metal, and the desired outcome. Different wheels are designed for different purposes, such as cutting through hardened steel, stainless steel, or aluminum. It is essential to use a wheel that is specifically designed for the type of metal to ensure optimal performance and minimize the risk of damage to the wheel or workpiece.

Furthermore, the quality and durability of the angle grinder wheel should not be overlooked. Investing in a high-quality wheel can significantly improve the cutting experience and produce better results. A wheel made from premium materials and designed to withstand high-speed cutting operations will last longer and offer enhanced performance.

Another crucial factor to consider is the compatibility of the angle grinder wheel with the angle grinder itself. Not all wheels are suitable for all types of grinders, so it is essential to ensure that the wheel is compatible with the specific model of grinder being used. Using an incompatible or incorrectly mounted wheel can lead to accidents, such as wheel breakage or loss of control during cutting.

In conclusion, choosing the right angle grinder wheel for cutting metal is vital for achieving efficient and safe cutting operations. Considering factors such as the type of metal, thickness, desired outcome, wheel quality, and compatibility with the grinder will help ensure optimal performance and minimize potential risks. It is worth investing time and effort in selecting the best wheel for the job to ensure the desired results and a smooth cutting experience.

Factors to Consider when Choosing an Angle Grinder Wheel for Cutting Metal

When it comes to cutting metal, choosing the right angle grinder wheel is crucial for achieving clean and precise cuts. There are several factors that you should consider before making your decision:

- Wheel Material: The material of the angle grinder wheel is an important factor to consider. For cutting metal, it is recommended to choose a wheel made of aluminum oxide or zirconia alumina. These materials offer high durability and can handle the high heat generated during the cutting process.

- Wheel Size: The size of the wheel will determine the depth of cut that you can achieve. Smaller wheels are suitable for detailed and intricate cuts, while larger wheels are more efficient for cutting through thick metal.

- Wheel Thickness: The thickness of the wheel also affects the cutting performance. Thinner wheels are ideal for fast and precise cuts, while thicker wheels are better for heavy-duty cutting tasks.

- Arbor Size: The arbor size of the angle grinder should match the arbor size of the wheel. It is important to choose a wheel with the correct arbor size to ensure proper fitting and secure operation.

- Cutting Speed: Different angle grinder wheels have different cutting speeds. It is important to choose a wheel that is suitable for the speed of your angle grinder to ensure optimal cutting performance and safety.

By considering these factors, you can select the best angle grinder wheel for cutting metal that meets your specific needs and provides you with clean and precise cuts.

Material

When it comes to choosing the best angle grinder wheel for cutting metal, one of the important factors to consider is the material of the wheel itself. Different materials are designed to handle specific types of metals, so it’s important to choose the right wheel for the job.

There are several common materials used in angle grinder wheels for cutting metal, including:

- Aluminum oxide: This is a versatile material that is suitable for cutting various types of metal. It is durable and can withstand high temperatures, making it an ideal choice for general metal cutting tasks.

- Zirconia alumina: This material is known for its aggressive cutting action, making it a great choice for cutting through tough metals such as stainless steel. It is also known for its durability and long life.

- Diamond: Diamond wheels are the go-to choice for cutting hard materials such as concrete and stone. They are not typically used for cutting metal, but they can be used for certain specialized applications.

- Ceramic: Ceramic wheels are known for their exceptional durability and long life. They are suitable for cutting hard metals and are resistant to heat and wear.

Choosing the right material for your angle grinder wheel will depend on the type of metal you are cutting and the specific requirements of your project. It’s always a good idea to consult the manufacturer’s guidelines and recommendations to ensure you are using the appropriate wheel for the task at hand.

Grit

Grit refers to the coarseness of the particles on an angle grinder wheel. The grit level of the wheel determines how smoothly and efficiently it can cut through metal. The higher the grit number, the finer the particles on the wheel, resulting in a smoother cut. On the other hand, a lower grit number means larger particles that can remove material faster but may leave a rougher surface.

When choosing an angle grinder wheel for cutting metal, it is important to consider the specific application and the desired result. Lower grit wheels, such as 24 or 36, are ideal for heavy-duty cutting and removing large amounts of material. They are commonly used on thick metal parts that do not require a smooth finish.

For more delicate or precise cutting tasks, a higher grit wheel, such as 60 or 80, may be more suitable. These wheels are designed to provide a smoother cut, making them ideal for projects that require a finer finish or where a rough surface is not desired. It is important to note that a higher grit wheel may take longer to cut through metal compared to a lower grit wheel.

In summary, the grit of an angle grinder wheel plays a significant role in its cutting performance. The selection of the appropriate grit level depends on the specific task and the desired finish. By understanding the different grit options available, one can choose the best angle grinder wheel for cutting metal based on their project requirements.

Size

When selecting the best angle grinder wheel for cutting metal, size is an important factor to consider. The size of the wheel directly affects its cutting capacity and overall performance. There are various size options available, and choosing the right one depends on the specific cutting requirements and the size of the metal being cut.

The size of the angle grinder wheel is typically measured by its diameter. Smaller diameter wheels, such as 4.5 inches or 5 inches, are commonly used for lighter cutting tasks or when working with smaller metal pieces. These wheels offer more maneuverability and control, making them suitable for precision cutting.

On the other hand, larger diameter wheels, such as 7 inches or 9 inches, are more suitable for heavy-duty cutting tasks or when working with larger metal pieces. These wheels provide greater cutting depth and power, allowing for faster and more efficient cutting. However, they may be less maneuverable and require more strength to handle.

It is important to consider the size of the angle grinder wheel that will best suit your cutting needs. Smaller wheels are ideal for detail work, while larger wheels are better for heavy-duty cutting. Ultimately, the right size wheel will depend on the specific requirements of your metal cutting project.

5 Best angle grinder wheel for cutting metal

Features

| Part Number | indestructible cutting disc |

| Color | 5 Pcs |

Features

| Part Number | 526 |

Features

| Part Number | easyhaha |

| Color | 1pcs Wool Pad |

| Size | 125x22mm |

Features

- * Light weight, good texture and durability

- * Fast polishing, the maximum speed can reach up to 3000 rpm

- * Not easy to deform, long life

- * Made of high quality professional felt, designed for final polishing

- * Widely used in fine polishing of stainless steel, copper, aluminum and other metal and glass, furniture, ceramics, marble and other metal and non-metal

Question-answer:

What is size?

Size refers to the dimensions or magnitude of an object or entity.

How is size measured?

Size can be measured in various units such as inches, centimeters, or pixels, depending on the context.

Why is size important?

Size is important because it helps determine the scale, proportions, and fit of objects, as well as their functionality and usability.

What is size discrimination?

Size discrimination refers to the unfair treatment of individuals based on their body size or weight.

Can size be subjective?

Yes, size can be subjective as it can be influenced by personal perception, cultural norms, and individual preferences.

What is the average size of a human?

The average size of a human varies depending on various factors such as gender, genetics, and geographical location. However, the average height for adult males is around 5 feet 9 inches (175 cm) and for adult females is around 5 feet 4 inches (162 cm).

Conclusion

In conclusion, size plays a significant role in various aspects of our lives. Whether it is the size of our clothes, the size of our homes, or the size of our ambitions, it can shape our experiences and perceptions. From a cultural perspective, size can vary greatly across different societies and can be influenced by societal norms and values. Additionally, size can also have psychological implications, such as body image issues or feelings of inadequacy. It is important to recognize that size does not define our worth or abilities, and that embracing diversity in all its forms can lead to a more inclusive and accepting society. Ultimately, size should not be a factor in determining our self-worth, but rather a unique characteristic that adds to the richness and diversity of the human experience.