Which is Best: Single Stage or Two Stage Air Compressor?

When it comes to choosing an air compressor, there are two main options to consider: single stage and two stage air compressors. While both options have their advantages and disadvantages, it’s important to understand the differences between the two in order to make an informed decision.

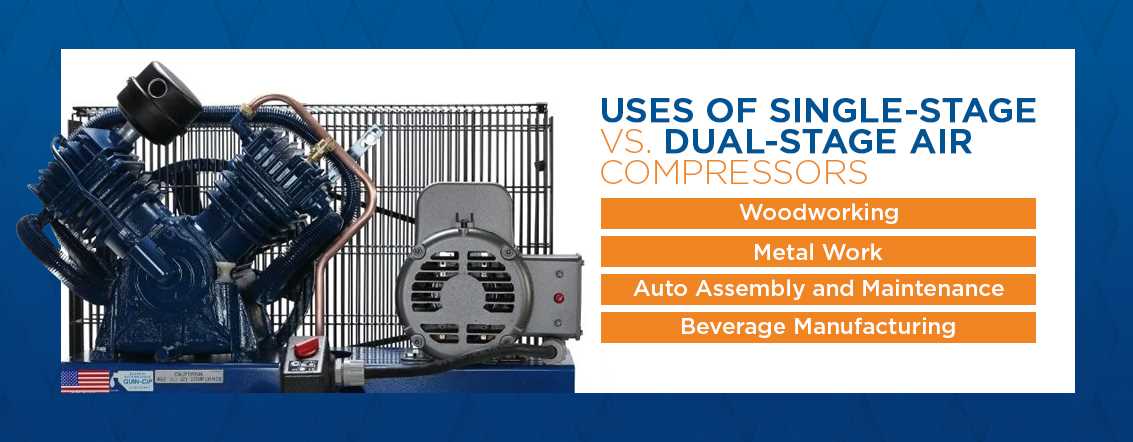

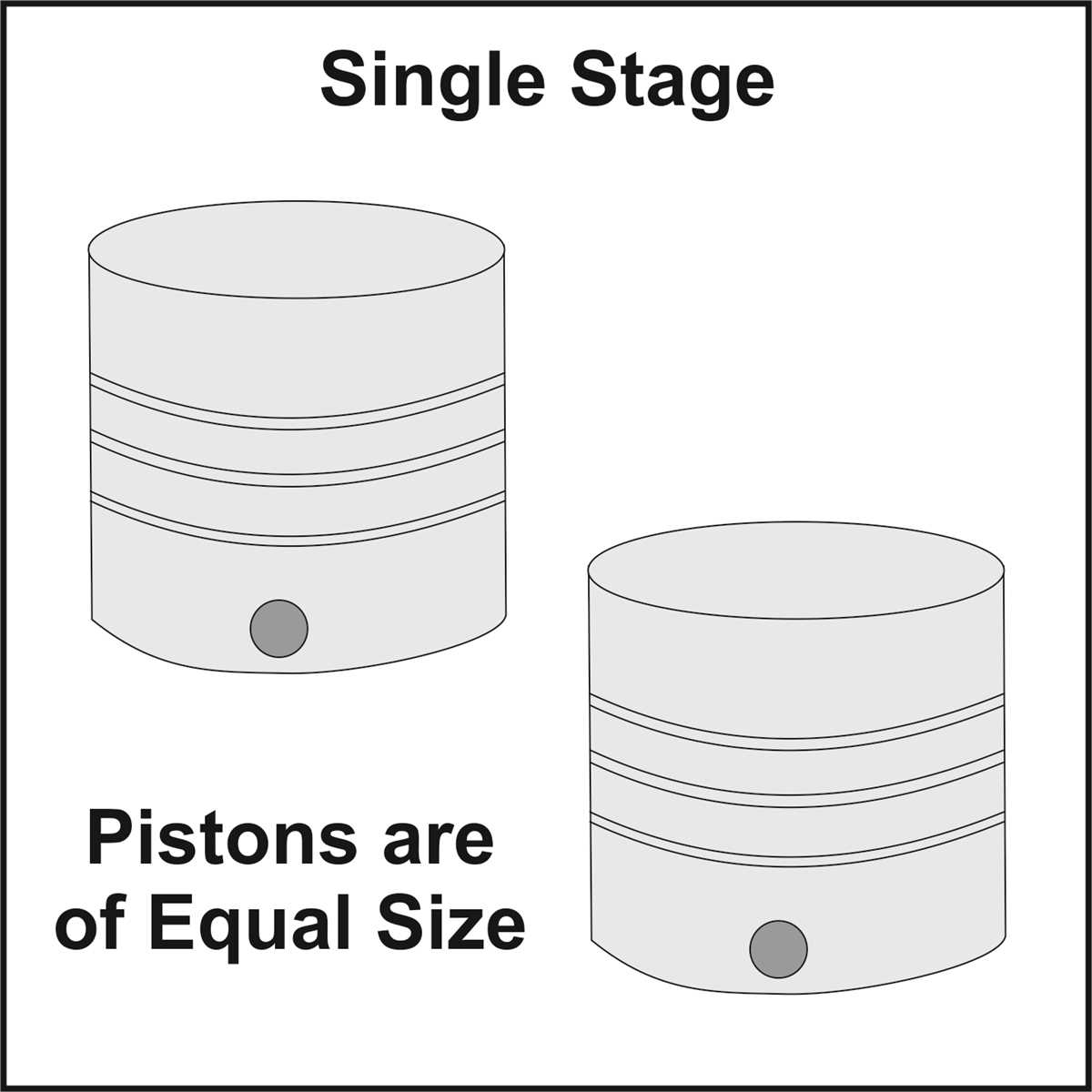

A single stage air compressor operates by compressing air in one stroke, resulting in a single level of pressure. This type of compressor is ideal for light-duty applications, such as inflating tires or operating small power tools. It is generally more affordable and compact than a two stage air compressor, making it a popular choice for homeowners and DIY enthusiasts.

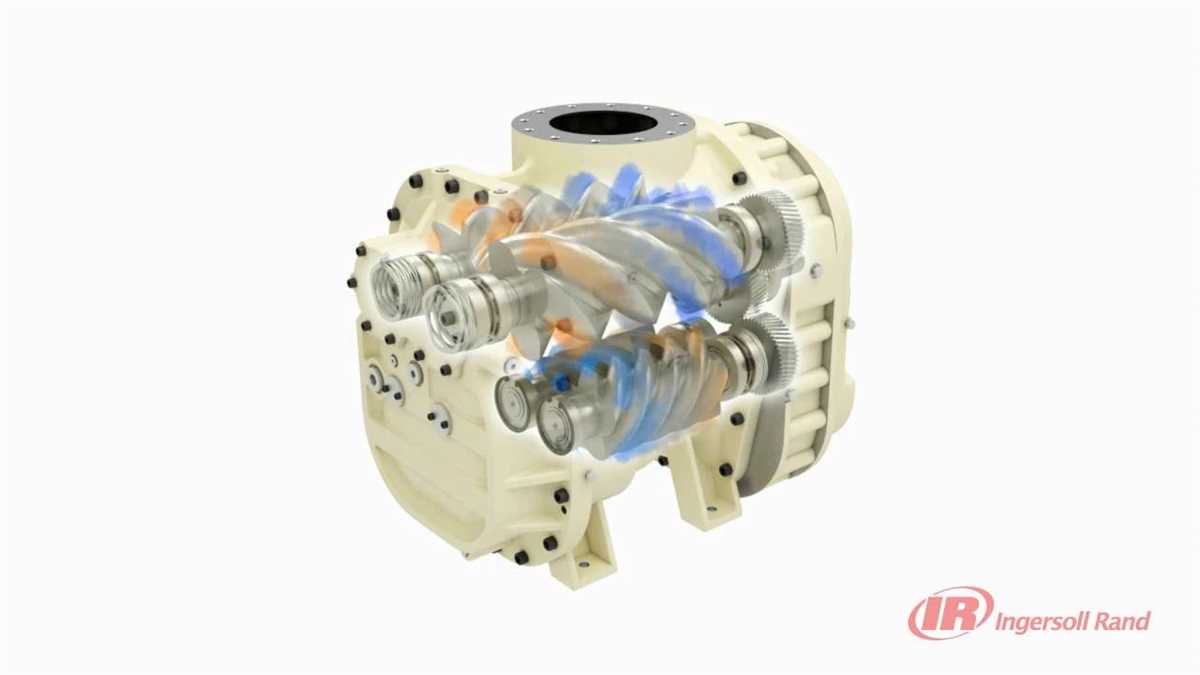

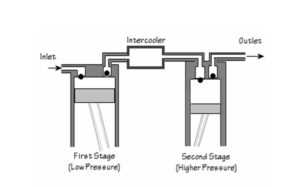

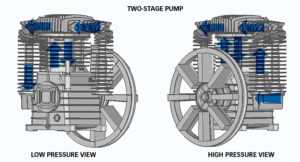

On the other hand, a two stage air compressor operates with two levels of pressure. The first stage compresses the air to an intermediate level of pressure, which is then sent to the second stage for further compression to the desired level. This allows a two stage air compressor to provide higher pressure and greater efficiency, making it suitable for heavy-duty applications such as powering air tools in a professional workshop or industrial setting.

While a single stage air compressor may be sufficient for basic tasks, a two stage air compressor offers advantages in terms of higher pressure levels, greater efficiency, and the ability to handle more demanding applications. However, it’s important to consider factors such as cost, space requirements, and usage needs before making a decision. Ultimately, the choice between a single stage and two stage air compressor depends on your specific requirements and budget.

Benefits of Choosing a Single Stage Air Compressor

When it comes to air compressors, there are two main options to choose from: single stage and two stage. While both types have their advantages, there are some specific benefits to selecting a single stage air compressor.

1. Simplicity and Affordability

A single stage air compressor is typically simpler in design compared to a two stage compressor. This means that it has fewer components and is easier to maintain. Additionally, single stage compressors are generally less expensive than their two stage counterparts, making them a more budget-friendly choice.

2. Compact Size

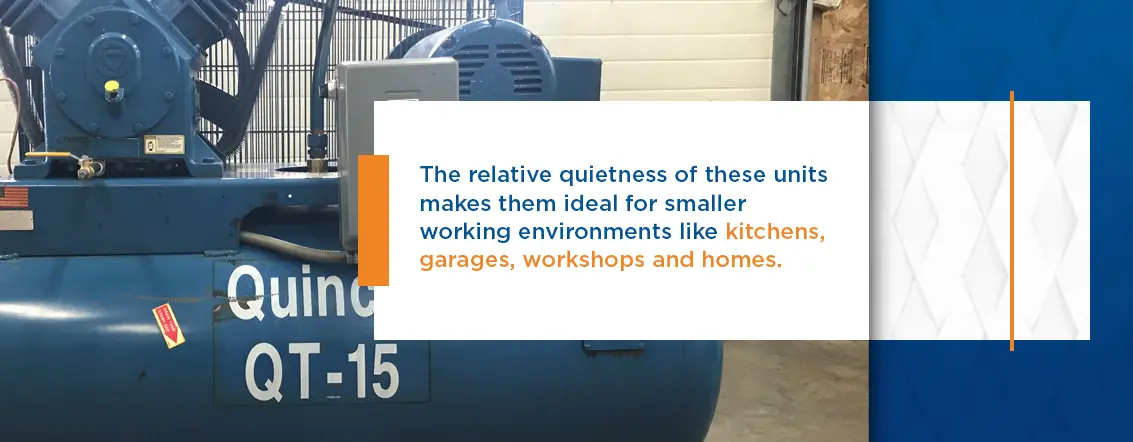

Single stage compressors are usually smaller and more compact than two stage compressors. This makes them easier to transport and store, especially in smaller spaces. Whether you need to take your compressor to different job sites or simply want to save space in your workshop, a single stage compressor is a practical option.

3. Energy Efficiency

While two stage compressors are known for their higher pressure capabilities, single stage compressors are generally more energy efficient. They are designed to operate at lower pressures, which means they use less energy during operation. This can result in cost savings over time, especially if you plan to use your compressor frequently.

4. Versatility

Single stage compressors can handle a wide range of applications and tasks. Whether you need to power pneumatic tools, inflate tires, or operate spray guns, a single stage compressor can meet your needs. They are versatile machines that can handle various jobs, making them a useful addition to any workshop or garage.

5. Ease of Use

Due to their simpler design and operation, single stage compressors are generally easier to use. They typically have fewer controls and settings, making them more user-friendly, especially for beginners. If you are new to air compressors or prefer a hassle-free experience, a single stage compressor is a convenient option.

Overall, choosing a single stage air compressor offers several benefits, including simplicity, affordability, compact size, energy efficiency, versatility, and ease of use. It is important to consider your specific needs and requirements before making a decision, but a single stage compressor can be a practical and cost-effective choice for many applications.

Cost-Effective Solution

When it comes to choosing between a single stage and two-stage air compressor, cost-effectiveness is an important factor to consider. In this regard, single stage air compressors are generally the more affordable option. They have a simpler design with fewer components, resulting in lower manufacturing and maintenance costs.

Additionally, single stage air compressors are typically more energy-efficient compared to two-stage compressors. They require less horsepower to operate and consume less electricity, resulting in lower operating costs over the long term. This makes them a cost-effective choice for small to medium-sized operations or for those on a tight budget.

Furthermore, single stage compressors are easier to install and require less space compared to two-stage compressors. They have a compact design and take up less floor space, making them a practical option for facilities with limited space availability. In addition, their simplicity makes them easier to maintain, resulting in lower maintenance costs.

However, it’s important to note that while single stage air compressors may be more cost-effective upfront, they may not be as efficient or suitable for high-demand applications. Two-stage air compressors are designed to handle heavy-duty tasks and provide higher levels of pressure and airflow. They are better suited for industrial applications that require continuous and high-volume compressed air supply.

In conclusion, while cost-effectiveness is an important aspect to consider, the choice between a single stage and two-stage air compressor ultimately depends on the specific needs and requirements of the application. It is important to carefully evaluate factors such as budget, space availability, energy efficiency, and the nature of the tasks to be performed in order to make an informed decision.

Simplicity and Ease of Use

One of the main advantages of a single stage air compressor is its simplicity and ease of use. With a single stage compressor, there are fewer moving parts and components, making it easier to operate and maintain. This simplicity also translates into a lower initial cost, as there are fewer components to manufacture and assemble.

Additionally, a single stage compressor typically has a smaller footprint and is more portable compared to a two stage compressor. This makes it easier to transport and use in different locations, which can be beneficial for individuals or businesses that require mobility.

Furthermore, single stage compressors usually have simpler controls and settings, which makes them easier to understand and operate. This can be advantageous for individuals who are not familiar with air compressors or who prefer a straightforward and user-friendly machine.

In terms of maintenance, single stage compressors often require less frequent servicing and repairs compared to two stage compressors. The simplicity of a single stage compressor allows for easier troubleshooting and diagnosis of any issues that may arise. This not only saves time and money but also reduces downtime, allowing for uninterrupted operation.

Overall, if simplicity and ease of use are important factors for you, a single stage air compressor may be the best choice. It offers straightforward operation, lower initial cost, and easier maintenance, making it an ideal option for various applications.

Ideal for Small to Medium-Scale Applications

When it comes to small to medium-scale applications, a single stage air compressor is often the ideal choice. These compressors are designed to provide enough power for a variety of tasks without being overly complex or expensive.

One of the main advantages of single stage compressors is their simplicity. With only one piston, these compressors have fewer moving parts, which means they require less maintenance and are less prone to mechanical failure. This can be particularly beneficial for small businesses or individuals who do not have the time or resources to invest in regular maintenance or costly repairs.

Additionally, single stage air compressors are typically more compact and portable than their two-stage counterparts. This makes them easier to transport and store, which can be a major advantage for those who need to use the compressor in different locations or have limited space.

While single stage compressors may not provide as high of a maximum pressure as two-stage compressors, they are still capable of delivering sufficient power for many small to medium-scale applications. They can be used for tasks such as inflating tires, powering air tools, and even painting small surfaces.

Ultimately, the choice between a single stage and two-stage air compressor will depend on the specific needs and requirements of the user. However, for those looking for a reliable and cost-effective option for small to medium-scale applications, a single stage compressor is often the best choice.

Advantages of Using a Two Stage Air Compressor

1. Higher Pressure Output

A two stage air compressor is designed to produce higher pressure output compared to a single stage air compressor. This is due to the fact that the air is compressed in two stages, allowing for greater compression ratios. The higher pressure output makes a two stage air compressor suitable for applications that require high pressure, such as industrial processes, heavy machinery, and pneumatic tools.

2. Improved Efficiency

Two stage air compressors are known for their improved efficiency. The two-stage compression process helps to minimize heat buildup, which can be detrimental to the compressor’s performance. By compressing the air in smaller volumes in each stage, a two stage compressor can maintain lower operating temperatures and reduce the risk of overheating. This not only improves the overall efficiency of the compressor, but also extends its lifespan.

3. Enhanced Reliability

Another advantage of using a two stage air compressor is its enhanced reliability. The two-stage compression process allows for better cooling and lubrication of the compressor, reducing the wear and tear on its components. This results in a longer operational life and a lower risk of breakdowns or malfunctions. Additionally, the use of two cylinders in a two stage compressor provides a backup system in case one cylinder fails, ensuring continuous air supply.

4. Versatility

Two stage air compressors offer greater versatility compared to single stage compressors. The higher pressure output allows for a wider range of applications, including those that require high pressure air tools or equipment. Whether you need to power a heavy-duty impact wrench or operate a pneumatic machine, a two stage air compressor can provide the necessary pressure to get the job done.

5. Reduced Noise Levels

Two stage air compressors are generally quieter compared to single stage compressors. This is because the two-stage compression process distributes the workload between two cylinders, reducing the noise generated by each cylinder. The reduced noise levels make a two stage air compressor more suitable for indoor use or environments where noise pollution must be minimized.

In conclusion, the advantages of using a two stage air compressor include higher pressure output, improved efficiency, enhanced reliability, versatility, and reduced noise levels. These features make a two stage air compressor a preferred choice for applications that require high pressure, such as industrial processes and heavy machinery.

Increased Efficiency and Power

An advantage of a two-stage air compressor over a single stage one is its increased efficiency and power. With two stages of compression, the air is condensed twice, resulting in higher pressure levels. This allows the two-stage compressor to deliver more compressed air per unit of time compared to a single stage compressor.

Additionally, the two-stage compressor operates at a lower temperature due to the intercooling between stages. This helps to reduce the moisture content in the compressed air, improving its quality. The lower temperature also contributes to the overall efficiency of the compressor by reducing heat build-up.

The increased efficiency of a two-stage compressor translates to lower energy consumption and reduced operating costs. It can perform heavy-duty tasks more effectively, making it suitable for applications that require continuous and high-volume compressed air.

Moreover, the additional power provided by the two-stage compression makes it suitable for applications that demand higher pressure levels, such as industrial and manufacturing processes, automotive repair, and painting. The higher pressure output allows for increased airflow, enabling tools and equipment to operate more efficiently and effectively.

In summary, the two-stage air compressor offers increased efficiency and power compared to a single stage compressor. It delivers more compressed air per unit of time, operates at lower temperatures, and is more suitable for heavy-duty tasks and applications that require higher pressure levels. These advantages contribute to improved performance and reduced operating costs.

Suitable for Heavy-Duty Applications

The two-stage air compressor is a popular choice for heavy-duty applications. This type of compressor is designed to handle demanding and continuous operations, making it ideal for industrial and commercial settings.

With its two-stage design, this compressor is able to deliver higher pressure and greater power than a single-stage compressor. This makes it perfect for tasks that require a higher level of air pressure, such as operating heavy machinery, powering pneumatic tools, or running large-scale manufacturing processes.

Furthermore, the two-stage compressor is built with durable materials and components that can withstand the rigors of heavy-duty use. It is designed to handle high-volume air intake and large air storage tanks, providing a constant and reliable source of compressed air for extended periods of time.

In addition, the two-stage compressor typically features a cooling system that helps prevent overheating during prolonged use. This allows for continuous operation without the risk of damage or decreased performance.

Overall, the two-stage air compressor is a highly versatile and efficient choice for heavy-duty applications. It offers increased power, reliability, and durability, making it the preferred option for industries that require a consistent and high-volume source of compressed air.

Provides Higher Pressure

A single stage air compressor is designed to compress air in one stage, which means that it operates at a lower pressure compared to a two stage air compressor. This lower pressure allows for the compressor to be more compact and smaller in size. However, it also means that it cannot provide the same level of pressure as a two stage air compressor.

On the other hand, a two stage air compressor is designed to compress air in two stages, providing higher pressure output. The first stage compresses the air to an intermediate pressure, and then the second stage further compresses it to the desired high pressure. This higher pressure output makes the two stage air compressor suitable for tasks that require greater air pressure, such as powering heavy machinery and equipment.

In addition to higher pressure, the two stage air compressor also offers better overall efficiency. By compressing the air in two stages, it is able to achieve higher compression ratios, resulting in more compressed air being delivered for a given amount of energy input. This improved efficiency can help reduce energy costs and improve the performance of the air compressor.

Furthermore, the higher pressure output of the two stage air compressor allows for longer operation times. Since it provides higher pressure, the compressor can meet the demands of applications that require continuous and uninterrupted air supply. This makes it ideal for industrial settings and tasks that require constant high pressure air.

Overall, while a single stage air compressor is more compact and smaller in size, a two stage air compressor provides higher pressure output and better overall efficiency. It is capable of meeting the demands of tasks that require greater air pressure and continuous operation. Consider the specific requirements of your application when choosing between the two options.

Factors to Consider When Choosing Between Single Stage and Two Stage Air Compressors

1. Efficiency:

One of the most important factors to consider when choosing between single stage and two stage air compressors is efficiency. Two stage air compressors are generally more efficient than single stage compressors. This is because two stage compressors have an additional piston and cylinder, which allows them to compress the air in two stages. This results in higher pressure and better performance.

2. Pressure:

If you require higher pressure for your specific applications, a two stage air compressor might be the better choice. Two stage compressors are designed to provide higher pressure outputs, making them suitable for applications such as industrial manufacturing, heavy construction, and automotive repair.

3. Air Quality:

In certain applications, such as painting or pharmaceutical manufacturing, air quality is of utmost importance. Two stage air compressors are equipped with intercoolers, which help to reduce moisture content in the compressed air. This can result in cleaner and drier air, making them more suitable for applications where air quality is a critical factor.

4. Cost:

When considering the cost, it is important to take into account the initial investment as well as the long-term operating costs. Two stage air compressors generally have a higher initial cost compared to single stage compressors. However, they tend to be more durable and have a longer lifespan, which can result in lower long-term operating costs.

5. Space:

If you have limited space in your workshop or garage, a single stage air compressor might be a more suitable choice. Single stage compressors are generally smaller and more compact compared to two stage compressors, allowing for easier installation and storage in tight spaces.

In conclusion, when choosing between single stage and two stage air compressors, it is important to consider factors such as efficiency, pressure requirements, air quality, cost, and available space. Each type of compressor has its own advantages and drawbacks, so it is essential to assess your specific needs and priorities before making a decision.

Application Requirements

When deciding between a single stage or two stage air compressor, it is important to consider the specific requirements of your application. Different applications have different demands and choosing the right type of compressor can greatly affect its performance and efficiency. Here are some factors to consider:

Required Pressure

One important factor to consider is the required pressure for your application. Certain applications, such as automotive repair or small tool operation, may only require low to moderate pressures. In these cases, a single stage air compressor may be sufficient. However, if your application requires higher pressures, such as for industrial or manufacturing processes, a two stage air compressor may be more suitable.

Air Flow

The required volume of air flow is another critical factor to consider. If your application requires a high volume of air flow, such as for large scale construction or industrial processes, a two stage air compressor may be preferable. Two stage compressors typically provide greater air flow due to the additional compression stage, making them suitable for applications that demand higher volumes of compressed air.

Continuous Operation

If your application requires continuous operation, such as in manufacturing or production lines, a two stage air compressor may be the better choice. Two stage compressors are designed to handle continuous use and can provide a steady supply of compressed air without overheating. On the other hand, single stage compressors may be more suitable for intermittent use or applications that do not require continuous operation.

Energy Efficiency

Energy efficiency is an important consideration for any application. Two stage air compressors are generally more energy efficient due to their ability to deliver higher air volumes at lower pressures. This can result in lower energy costs over time. However, if your application only requires low to moderate pressures and air flow, a single stage compressor may provide sufficient energy efficiency.

When evaluating the application requirements, it is important to consider factors such as required pressure, air flow, continuous operation, and energy efficiency. By carefully assessing these needs, you can make an informed decision between a single stage or two stage air compressor that best suits your specific application.

FAQ:

What is the difference between a single stage and a two stage air compressor?

A single stage air compressor compresses air in one stroke, while a two stage air compressor compresses air in two stages for greater efficiency and pressure.

Which type of air compressor is more suitable for industrial applications?

A two stage air compressor is more suitable for industrial applications because it can deliver higher pressures and handle larger workloads.

Can a single stage air compressor be used for household tasks?

Yes, a single stage air compressor is suitable for household tasks such as inflating tires, powering small tools, or operating airbrushes.

Is a two stage air compressor more expensive than a single stage air compressor?

Generally, yes, a two stage air compressor tends to be more expensive than a single stage air compressor due to its higher performance capabilities.

Which type of air compressor is quieter to operate?

A single stage air compressor is generally quieter to operate compared to a two stage air compressor.

Video: