What type of oil should you use for your air compressor?

Choosing the right oil for your air compressor is essential for ensuring its optimal performance and longevity. The oil in an air compressor serves as a lubricant to reduce friction and wear, as well as a coolant to dissipate heat. It also helps to seal the compressors’ internal components, preventing leaks and maintaining a proper compression ratio.

One of the most common types of oil used in air compressors is mineral oil. It is a cost-effective option that provides good lubrication and protection. However, mineral oil has a limited lifespan and may require more frequent changes compared to synthetic oils. Synthetic oils, on the other hand, offer superior performance and durability. They can withstand high temperatures and pressures, resulting in reduced wear and extended oil change intervals.

It is important to check the manufacturer’s recommendations for the specific type and viscosity of oil required for your air compressor. Different air compressors have different requirements, depending on factors such as the compressor’s design, operating temperature, and duty cycle. Using the wrong type of oil can lead to poor performance, increased wear, and even potential damage to the compressor.

In addition to the type of oil, proper maintenance and regular oil changes are crucial for keeping your air compressor running smoothly. Regularly inspecting the oil level and condition, as well as following the manufacturer’s guidelines for oil changes, will help ensure that your air compressor remains in optimal working condition for years to come.

How to Choose the Right Oil for Your Air Compressor

1. Consult the Manual

The first step in choosing the right oil for your air compressor is to consult the manual that came with it. The manual will typically provide specific instructions and recommendations for the type of oil that is best suited for your compressor. It may also specify the viscosity grade and other important details about the oil.

2. Consider the Compressor Type

The type of air compressor you have can also influence the choice of oil. There are different types of compressors, including rotary screw, reciprocating, and centrifugal compressors. Each type may have different lubrication requirements, so it’s important to choose an oil that is compatible with your specific compressor type.

3. Check the Viscosity

Viscosity is an important factor to consider when choosing oil for your air compressor. The viscosity grade determines the thickness of the oil and how well it can lubricate the compressor components. It’s crucial to choose an oil with the right viscosity grade to ensure optimal performance and longevity of your compressor.

4. Look for Synthetic Oils

Synthetic oils are often recommended for air compressors due to their superior lubricating properties and ability to withstand higher temperatures. Synthetic oils provide better protection against wear, corrosion, and oxidation, which can result in longer compressor life and improved performance.

5. Consider Additives

Some oils may contain additives that offer additional benefits, such as anti-wear, anti-foam, or anti-corrosion properties. These additives can help to increase the efficiency and longevity of your air compressor. However, it’s important to check if the additives are compatible with your compressor and follow the manufacturer’s recommendations.

6. Change Oil Regularly

Regardless of the type of oil you choose, it’s important to follow a regular maintenance schedule and change the oil as recommended by the manufacturer. Regular oil changes help to remove contaminants and ensure that the oil continues to provide proper lubrication and protection to the compressor components.

By following these tips and considering the specific requirements of your air compressor, you can choose the right oil that will keep your compressor running smoothly and efficiently for years to come.

“`html

Importance of Using the Correct Oil

Using the correct oil in your air compressor is crucial for ensuring its optimal performance and longevity. The oil plays a vital role in lubricating the internal components of the compressor, reducing friction, and preventing wear and tear. Failure to use the correct oil can lead to various issues, such as decreased efficiency, increased operating temperatures, and even compressor failure.

Choosing the right oil for your air compressor depends on various factors, including the type of compressor, its operating conditions, and the manufacturer’s recommendations. It is essential to refer to the user manual or consult the manufacturer to determine the specific oil requirements for your compressor.

Using the wrong oil in your air compressor can have several negative consequences. It may lead to excessive heat generation, which can result in decreased efficiency and increased energy consumption. The incorrect oil may also not provide adequate lubrication, causing increased friction and wear on the compressor’s components. Over time, these issues can lead to the compressor overheating, breaking down, and ultimately requiring costly repairs or replacement.

Furthermore, using the incorrect oil can void the warranty of your air compressor. Manufacturers usually specify the type of oil that should be used, and deviating from their recommendations can result in the warranty becoming null and void. It is always best to follow the manufacturer’s guidelines to ensure that your warranty remains valid.

Regular maintenance of your air compressor, including proper oil changes, is crucial for its optimal performance and longevity. By using the correct oil and adhering to the manufacturer’s recommendations, you can ensure that your air compressor operates efficiently and reliably, minimizing the risk of downtime and costly repairs.

In conclusion, using the correct oil in your air compressor is of utmost importance. It ensures proper lubrication, reduces friction and wear, and helps maintain optimal performance and efficiency. It is crucial to consult the user manual or the manufacturer to determine the specific oil requirements for your compressor to avoid potential issues and maintain the warranty validity.

“`

Understanding Compressor Oil Specifications

When it comes to choosing the right oil for your air compressor, it’s essential to understand compressor oil specifications. Compressor oil is specially formulated to meet the unique needs of air compressors, which operate in high-temperature and high-pressure environments. The specific type of compressor oil you need depends on various factors, including the compressor’s design and operating conditions.

Viscosity

One of the essential specifications to consider when selecting compressor oil is viscosity. Viscosity refers to the oil’s resistance to flow, and it is crucial for proper lubrication. Compressor oils are available in different viscosity grades, with higher numbers indicating thicker oil. It’s important to choose a viscosity grade that matches your compressor’s requirements to ensure optimal lubrication and efficient operation.

Additives

Compressor oils often contain additives to enhance their performance and protect internal components from wear, corrosion, and oxidation. These additives can improve lubricity, reduce foaming, and improve the oil’s ability to handle high temperatures. When selecting compressor oil, consider the specific additives that are included to ensure they meet your compressor’s needs and provide the necessary protection.

Compatibility

Another essential aspect of compressor oil specifications is compatibility. Some air compressors have specific requirements for the type of oil they can use. It’s crucial to choose an oil that is compatible with your compressor’s materials and seals. Using the wrong oil can lead to lubrication issues, seal damage, and even impair the overall performance of your compressor.

Manufacturer Recommendations

Ultimately, the best way to determine the right compressor oil for your air compressor is by referring to the manufacturer’s recommendations. Manufacturers often provide specific guidelines for oil selection, including viscosity grades and any required additives. Following these recommendations will help ensure that you use the correct oil and maintain the optimal performance and longevity of your air compressor.

- Consider viscosity to ensure proper lubrication.

- Pay attention to additives for enhanced protection.

- Check compatibility with your compressor’s materials.

- Follow manufacturer recommendations for the best results.

By understanding compressor oil specifications, you can make an informed decision when choosing the right oil for your air compressor. Proper oil selection and regular maintenance will help prolong the life of your compressor and ensure efficient operation.

Factors to Consider When Choosing Compressor Oil

1. Viscosity

One of the most important factors to consider when choosing compressor oil is its viscosity. Viscosity refers to the oil’s thickness or resistance to flow. The right viscosity oil will ensure proper lubrication of the compressor’s moving parts, preventing excessive wear and tear. Different compressors require different viscosities, so it’s essential to consult the manufacturer’s guidelines or the equipment’s manual to determine the appropriate viscosity for your specific compressor.

2. Performance Requirements

Another factor to consider is the performance requirements of your air compressor. Different applications may require different types of compressor oils, depending on factors such as temperature, pressure, and operating conditions. For example, if your air compressor operates in high-temperature environments, you may need an oil with a higher viscosity index or a synthetic oil that can withstand higher temperatures without breaking down.

3. Oil Type

There are various types of compressor oils available, including mineral-based oils, synthetic oils, and blends. Mineral-based oils are the most common and economical option, suitable for most general-purpose air compressors. Synthetic oils, on the other hand, offer better performance and are ideal for applications that require high temperatures, extended drain intervals, or specific additives.

4. Additives

Compressor oils may contain additives to enhance their performance and protect the equipment. These additives can include antioxidants, anti-wear agents, rust inhibitors, and detergents. Understanding your compressor’s specific needs and consulting the manufacturer’s recommendations will help you choose an oil with the appropriate additives.

5. Compatibility

Lastly, it’s crucial to ensure that the compressor oil you choose is compatible with your air compressor. Some compressors have specific oil requirements or may recommend a particular brand or type of oil. Using an incompatible oil can lead to poor performance, increased wear and tear, or even damage to the compressor. Always consult the manufacturer’s guidelines or seek professional advice to ensure compatibility.

In conclusion, when choosing compressor oil, consider factors such as viscosity, performance requirements, oil type, additives, and compatibility. Consulting the manufacturer’s recommendations and guidelines will help you select the most appropriate oil for your specific air compressor, ensuring optimal performance and longevity of your equipment.

Different Types of Compressor Oil

When it comes to air compressors, using the right type of compressor oil is essential for optimal performance and longevity. There are several different types of compressor oil available, each with its own unique characteristics and applications.

1. Mineral Oil

Mineral oil is a traditional choice for air compressors and is widely used due to its affordability. It is derived from crude oil and provides good lubrication and heat transfer properties. However, mineral oil can break down at high temperatures and may require more frequent oil changes.

2. Synthetic Oil

Synthetic oil is a more advanced option for air compressors. It is specially formulated to offer high performance and extended service life. Synthetic oil has excellent thermal stability, allowing it to withstand high temperatures without breaking down. It also provides better lubrication and reduces friction, resulting in improved efficiency and reduced wear and tear on the compressor components.

3. Semi-Synthetic Oil

Semi-synthetic oil is a blend of mineral oil and synthetic oil. It combines the affordability of mineral oil with some of the benefits of synthetic oil. Semi-synthetic oil offers better thermal stability and lubrication compared to mineral oil alone, making it a popular choice for air compressors that operate under demanding conditions.

4. Food-Grade Oil

For applications where air compressors are used in the food and beverage industry, food-grade oil is necessary. This type of oil is specifically designed to meet the strict regulations and requirements for food contact. Food-grade oil is non-toxic, odorless, and safe for incidental contact with food products.

5. Compressor Oil Additives

In addition to the different types of compressor oil, there are also various compressor oil additives available. These additives are designed to enhance the performance and protect the compressor against specific issues, such as rust, corrosion, and foam buildup. Adding compressor oil additives can help extend the life of the compressor and improve its overall efficiency.

It is important to consult the manufacturer’s recommendations and specifications to determine the most suitable type of compressor oil for your specific air compressor. Using the right type of oil and performing regular maintenance, including oil changes, will ensure that your air compressor operates efficiently and has a longer lifespan.

Synthetic vs. Conventional Compressor Oil

Choosing the right type of oil for your air compressor is crucial for ensuring its optimal performance and longevity. When it comes to compressor oil, two main options are available: synthetic and conventional. Each type has its own advantages and considerations to keep in mind.

Synthetic Compressor Oil

Synthetic compressor oil is made from artificially engineered polyalphaolefin (PAO) base stocks. PAO oil offers excellent lubrication properties and can withstand a wide range of temperatures, making it suitable for both high and low-temperature applications. It has a higher viscosity index compared to conventional oil, meaning it maintains its lubricating properties over a broader temperature range.

One of the main advantages of synthetic compressor oil is its superior resistance to oxidation and degradation. It is more stable and less prone to breaking down, which leads to longer oil life and reduced maintenance costs. Additionally, synthetic oil has better anti-foaming properties, ensuring efficient lubrication even in high-speed compressors.

Conventional Compressor Oil

Conventional compressor oil, also known as mineral oil, is derived from crude oil through a refining process. It is less expensive compared to synthetic oil, making it a popular choice for budget-conscious users. However, conventional oil has a lower viscosity index, meaning it may become less effective in extreme temperatures, leading to reduced lubrication and wear on the compressor components.

While conventional oil may have a shorter lifespan and require more frequent changes compared to synthetic oil, it still provides sufficient lubrication for standard operating conditions. However, in demanding applications or environments with extreme temperature variations, synthetic oil may be a better choice to ensure optimal compressor performance and reliability.

In summary, when choosing between synthetic and conventional compressor oil, consider factors such as operating conditions, temperature range, and budget. Synthetic oil offers superior performance and longer oil life but comes at a higher cost. On the other hand, conventional oil may be suitable for standard conditions but may require more frequent changes. Ultimately, selecting the right oil type will depend on the specific requirements of your air compressor.

Recommended Oil Brands for Air Compressors

Choosing the right oil for your air compressor is essential to keep it running smoothly and prevent damage. There are several reputable oil brands that are highly recommended for air compressors:

1. Mobil

Mobil is a trusted brand known for its high-quality lubricants. They offer a range of oils specifically designed for air compressors, including synthetic and mineral options. Mobil oils provide excellent protection against wear, corrosion, and oxidation, ensuring optimal performance of your air compressor.

2. Ingersoll Rand

Ingersoll Rand is a well-known manufacturer of air compressors, and they also produce their own line of air compressor oils. These oils are formulated to work seamlessly with their compressors, providing superior lubrication and extending the life of your equipment. Ingersoll Rand oils are often recommended for their compatibility and performance.

3. Royal Purple

Royal Purple is a premium oil brand that offers high-performance lubricants for various applications, including air compressors. Their synthetic oils are designed to provide exceptional protection and lubrication under extreme conditions. Royal Purple oils are known for their durability and ability to handle high temperatures and pressures.

4. Quincy

Quincy is another reputable brand that manufactures both air compressors and compressor oils. Their oils are specifically formulated to meet the demanding requirements of air compressors, providing excellent lubrication and preventing carbon buildup. Quincy oils are well-regarded for their reliability and compatibility with Quincy compressors.

When selecting an oil brand for your air compressor, it’s important to consider factors such as the type of compressor, operating conditions, and manufacturer recommendations. Always consult the manufacturer’s guidelines and specifications to ensure you’re using the right oil for your specific compressor model.

Oil Change and Maintenance Tips for Air Compressors

1. Regular Oil Changes

One of the most important maintenance tasks for air compressors is regularly changing the oil. The frequency of oil changes will depend on the type and usage of the compressor, so consult the manufacturer’s guidelines for recommendations. As a general rule, it is recommended to change the oil every 500 to 1,000 hours of operation.

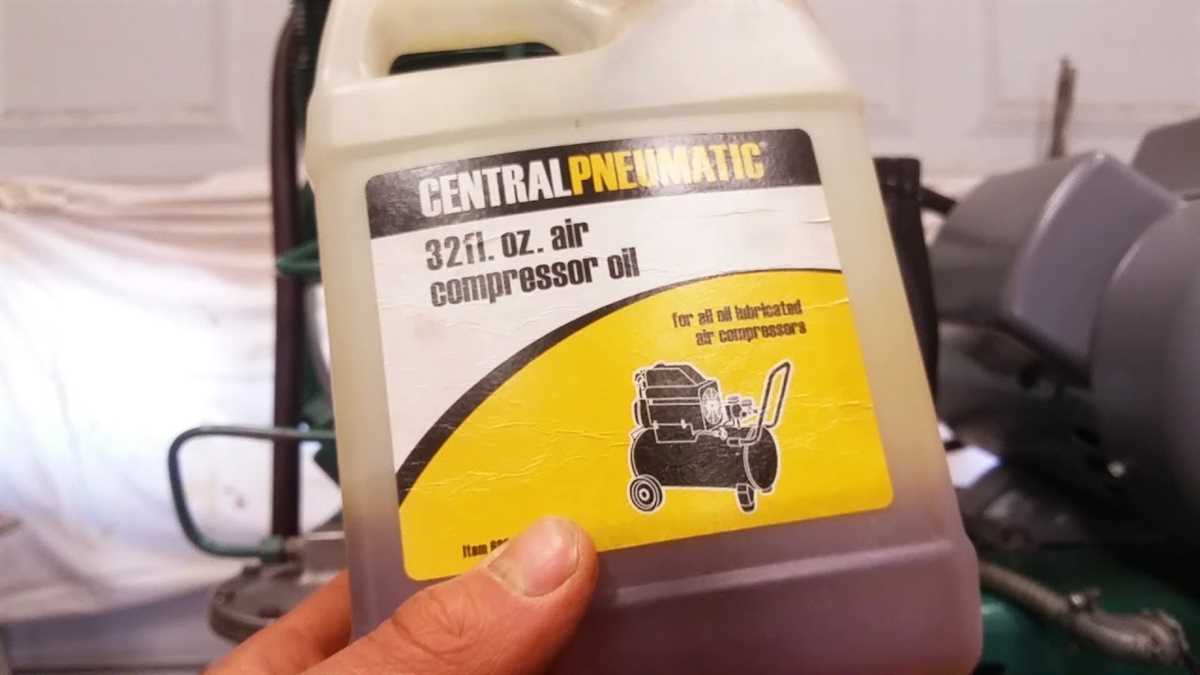

2. Choosing the Right Oil

When it comes to selecting the oil for your air compressor, it is crucial to choose an oil that is specifically designed for air compressors. These oils are formulated to withstand high temperatures, reduce friction and wear, and provide excellent protection against rust and corrosion. Avoid using regular motor oil, as it is not suitable for air compressors and can lead to performance issues and premature wear.

3. Check Oil Levels

Regularly check the oil levels in your air compressor to ensure optimal performance and prevent damage. Most compressors have a dipstick or an oil level sight glass that allows you to easily check the oil level. Keep the oil level within the recommended range indicated by the manufacturer. If the oil level is low, add the appropriate type of oil to bring it back to the correct level.

4. Oil Filter Replacement

In addition to changing the oil, it is important to replace the oil filter as part of regular maintenance. The oil filter helps to remove contaminants and particles from the oil, ensuring that it remains clean and free from debris. Follow the manufacturer’s recommendations for the replacement interval of the oil filter and use a high-quality replacement filter for optimal performance.

5. Clean and Inspect Components

During oil changes or regular maintenance, take the opportunity to clean and inspect the various components of your air compressor. Remove any accumulated dust, debris, or moisture from the intake vents, cooling fins, and other accessible areas. Inspect for any signs of damage or wear, such as leaks, loose connections, or worn-out belts. Address any issues promptly to prevent further damage and ensure the longevity of your air compressor.

By following these oil change and maintenance tips, you can keep your air compressor running smoothly and efficiently, prolong its lifespan, and avoid costly repairs in the long run.

Frequently Asked Questions about Compressor Oil

1. What type of oil should I use for my air compressor?

When it comes to selecting the right oil for your air compressor, it is important to refer to the manufacturer’s recommendations. Different air compressors may require different types of oil, based on their design and operating conditions. Common types of air compressor oil include mineral oil, synthetic oil, and semi-synthetic oil. It is important to choose an oil that is compatible with the compressor’s lubrication system and can withstand the operating temperatures and pressures.

2. How often should I change the oil in my air compressor?

The frequency of oil changes in an air compressor depends on various factors such as the compressor’s usage, operating conditions, and the type of oil being used. In general, it is recommended to change the oil every 500-1,000 hours of operation or at least once a year. However, it is important to regularly monitor the oil level and quality to ensure optimal lubrication and performance. If the oil appears dirty or has a milky appearance, it may be a sign that it needs to be changed sooner.

3. Can I use automotive oil in my air compressor?

Using automotive oil in an air compressor is not recommended. Automotive oils are designed for internal combustion engines and may not provide the necessary lubrication and protection for the compressor’s components. They may also contain additives that can cause foaming or interfere with the compressor’s operation. It is best to use oil specifically formulated for air compressors to ensure optimal performance and longevity.

4. How much oil should I put in my air compressor?

The amount of oil required for an air compressor can vary depending on its size and design. It is important to refer to the manufacturer’s specifications or user manual for the proper oil capacity. In some cases, the oil level may need to be checked by using a dipstick or sight glass. It is important not to overfill the compressor with oil, as it can lead to foaming and inadequate lubrication.

5. What are the consequences of using the wrong oil in my air compressor?

Using the wrong type of oil in an air compressor can have detrimental effects on its performance and longevity. Inadequate lubrication can cause increased friction, heat, and wear on the compressor’s components, leading to premature failure. Using the wrong oil can also compromise the compressor’s seals, resulting in leaks and reduced efficiency. It is crucial to use the recommended oil to ensure the compressor operates smoothly and efficiently.

6. How can I check the oil level in my air compressor?

To check the oil level in your air compressor, first, make sure the compressor is turned off and unplugged. Locate the oil fill cap or sight glass on the compressor’s crankcase. If there is a sight glass, the oil level should be visible through it. If not, remove the oil fill cap and insert a dipstick to check the oil level. The oil level should be within the recommended range indicated by the manufacturer. If the oil level appears low, add the appropriate oil until it reaches the correct level.

FAQ:

What type of oil should I use for my air compressor?

You should use a specifically designed air compressor oil for your air compressor. These oils are formulated to handle the high temperatures and pressures that occur in the compressor.

Can I use regular motor oil in my air compressor?

No, it is not recommended to use regular motor oil in your air compressor. Regular motor oil does not have the necessary properties to withstand the high temperatures and pressures of an air compressor.

How often should I change the oil in my air compressor?

The frequency of oil changes for an air compressor depends on the usage and the manufacturer’s recommendations. It is generally recommended to change the oil every 500-1000 hours of operation or every 3-6 months.

What are the consequences of using the wrong type of oil in an air compressor?

Using the wrong type of oil in an air compressor can lead to decreased efficiency, increased wear and tear on the compressor, and potentially costly repairs. It is important to use the right type of oil to ensure optimal performance and longevity of your air compressor.

Video: