What is the ideal CFM for an air compressor?

When it comes to choosing the right air compressor for your needs, one important factor to consider is the CFM, or cubic feet per minute. CFM is a measurement of how much air a compressor can deliver in a minute, and it is a crucial specification to understand in order to ensure that your compressor will be able to meet the demands of your particular application.

The ideal CFM for an air compressor depends on several factors, including the type of tools or equipment you will be using, the specific tasks you will be performing, and the pressure requirements of those tools or tasks. It is important to choose an air compressor with a CFM rating that is sufficient to power your tools without any loss of performance or efficiency.

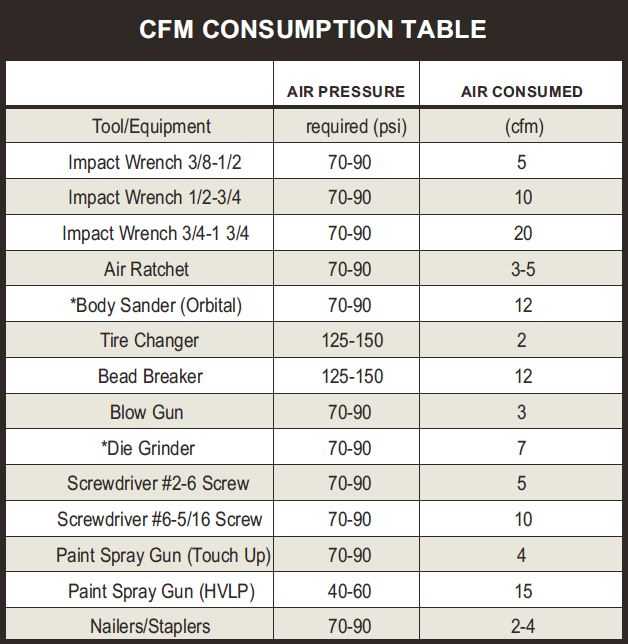

One way to determine the ideal CFM for your air compressor is to check the CFM requirements of your tools. Most power tools will indicate their CFM requirements in their product specifications or on their packaging. It’s important to note that the CFM requirement of a tool can vary depending on the specific model, so it’s always a good idea to check the manufacturer’s recommendations.

In addition to the CFM requirements of your tools, you should also consider the duty cycle of your air compressor. The duty cycle is the amount of time that the compressor can be used continuously before it needs to rest and cool down. It’s important to choose an air compressor with a duty cycle that matches the demands of your application to avoid overheating and potential damage to the compressor.

In summary, when choosing an air compressor, it is important to consider the CFM requirements of your tools, the specific tasks you will be performing, and the duty cycle of the compressor. By understanding these factors and choosing an air compressor with the appropriate CFM rating, you can ensure that your compressor will be able to deliver the necessary airflow for your application.

The Importance of CFM in Air Compressors

An air compressor is a vital tool in various industries, ranging from construction and manufacturing to automotive and woodworking. One of the essential factors to consider when choosing an air compressor is the Cubic Feet per Minute (CFM) rating. CFM refers to the volume of air that an air compressor can deliver per minute, and it plays a crucial role in determining the compressor’s performance and efficiency.

Efficiency and Power

The CFM rating directly affects the efficiency and power of an air compressor. A higher CFM rating means that the compressor can deliver a larger volume of air, providing more power for pneumatic tools and equipment. This is particularly important in applications that require continuous and high-volume air supply, such as operating air grinders, sanders, or spray guns.

For instance, a compressor with a low CFM rating may struggle to power a high-demand tool like a paint sprayer, leading to insufficient pressure and poor-quality finish. On the other hand, a compressor with a higher CFM can maintain stable pressure, ensuring consistent and professional results.

Avoiding Damage and Overheating

Proper CFM rating selection is also crucial to prevent damage to the air compressor itself. If the CFM rating is too low for the tools or equipment being used, the compressor will have to run continuously to keep up with the demand, leading to overheating and premature wear and tear. Overheating can cause damage to the compressor’s motor, valves, and other crucial components, resulting in costly repairs or even replacement.

By choosing an air compressor with an adequate CFM rating, users can ensure that the compressor can provide the necessary airflow without straining or overheating, prolonging its lifespan and reducing maintenance costs.

Air Tool Compatibility

Another important aspect of CFM rating is compatibility with specific air tools. Different air tools have varying CFM requirements, and it is crucial to choose an air compressor that can meet or exceed these requirements. The CFM rating represents the compressor’s maximum airflow capacity, and it determines whether the tool can operate at its optimal performance, delivering the necessary torque and speed.

For example, a pneumatic nail gun may require a certain CFM to maintain the necessary pressure to drive nails effectively. Choosing an air compressor with a CFM rating that matches or exceeds the tool’s requirement ensures smooth operation without performance issues.

In conclusion, the CFM rating of an air compressor is a fundamental factor that affects its performance, efficiency, and compatibility with various tools. By selecting an air compressor with the appropriate CFM rating, users can maximize the power, prevent damage, and ensure optimal operation of pneumatic tools and equipment.

The Basics of CFM

CFM stands for Cubic Feet per Minute and is a measurement used to determine the air flow capability of an air compressor. It indicates the volume of air that the compressor can deliver per minute. CFM is an important factor to consider when choosing an air compressor as it directly impacts its performance and efficiency.

Understanding CFM Ratings

When looking at air compressors, you will often come across CFM ratings. These ratings indicate the air flow capacity of the compressor at a specific pressure level. It’s important to note that CFM ratings can vary depending on the pressure level chosen. Higher pressure levels typically result in lower CFM ratings.

For example, a compressor with a CFM rating of 10 at 90 psi may have a lower CFM rating of 8 at 120 psi. It’s essential to consider the CFM rating that corresponds to the required pressure level for your specific applications in order to ensure sufficient air supply.

Matching CFM and Tools

When selecting an air compressor, it is crucial to match the CFM rating of the compressor with the CFM requirements of the tools or equipment you plan to use. Each air tool or equipment has a specific CFM requirement, which determines the amount of air flow needed to operate it effectively.

If the CFM rating of the compressor is lower than the CFM requirement of your tools, the air supply may not be sufficient, leading to decreased performance and potential damage to the tools. On the other hand, if the CFM rating of the compressor is higher than the CFM requirement, it is generally not a problem, as the excess air flow can be regulated with the use of pressure regulators or valves.

Finding the Ideal CFM

To determine the ideal CFM for an air compressor, you need to consider the CFM requirements of the tools you plan to use together. Add up the CFM requirements of all the tools and select an air compressor that can deliver the total CFM needed.

It’s also important to consider any future tools or equipment you may want to add to your workshop or job site and ensure that the air compressor has a sufficient CFM rating to accommodate their CFM requirements as well. It’s better to choose an air compressor with a slightly higher CFM rating to allow for flexibility and ensure optimal performance.

Conclusion

CFM is a crucial measurement when choosing an air compressor as it determines the air flow capability of the compressor. Understanding CFM ratings, matching CFM with tools, and finding the ideal CFM are essential steps to ensure a properly functioning and efficient air compressor for your specific needs.

Choosing the Right CFM for Your Air Compressor

Understanding CFM

The CFM, or cubic feet per minute, is a measurement of the amount of air that an air compressor can deliver. It indicates how quickly the compressor can supply air to pneumatic tools and equipment. Choosing the right CFM is crucial for ensuring optimal performance and efficiency.

Assessing Your Needs

Before selecting an air compressor, it is important to assess your specific needs. Consider the types of tools and equipment you will be using, as they will have different air requirements. Make a list of all the tools and their recommended CFM ratings, and calculate the total CFM needed.

Finding the Appropriate CFM

Once you have determined your total CFM requirement, it is important to find an air compressor that can meet or exceed that value. Keep in mind that it is generally better to have a compressor with a slightly higher CFM rating than your requirement, as this will allow for additional airflow and prevent the compressor from running at maximum capacity all the time.

For example, if your total CFM requirement is 10, it would be advisable to choose an air compressor with a CFM rating of around 12-15. This will provide some room for growth and ensure that the compressor can handle your needs effectively.

Considering Other Factors

While CFM is an important factor to consider, it is not the only one. Other factors such as tank size, motor horsepower, and duty cycle should also be taken into account. A larger tank size can provide a buffer for high-demand tools, while a more powerful motor can deliver consistent performance. Additionally, the duty cycle indicates the amount of continuous operation a compressor can handle.

Conclusion

Choosing the right CFM for your air compressor involves considering your specific needs, assessing the CFM requirements of your tools, and finding a compressor that can meet or exceed those requirements. Taking into account other factors such as tank size, motor horsepower, and duty cycle can further enhance the performance and efficiency of your air compressor.

Industrial Applications and CFM Requirements

Construction

Industrial air compressors are essential tools in the construction industry, where they power pneumatic tools such as jackhammers, nail guns, and concrete breakers. These tools require a significant amount of airflow to operate efficiently. The CFM requirements for construction applications can vary depending on the specific tool and the size of the project. For example, a small nail gun may only require a minimum CFM rating of 2-4, while a larger jackhammer may need a CFM rating of 25-30.

Manufacturing

In manufacturing facilities, air compressors are used for a wide range of applications, including powering pneumatic tools, operating pneumatic machinery, and controlling air pressure in production processes. The CFM requirements for manufacturing applications can vary greatly depending on the specific equipment and processes involved. For example, a small assembly line may require a minimum CFM rating of 10-15, while a large industrial machinery operation may need a CFM rating of 75-100 or more.

Automotive

In the automotive industry, air compressors are used for a variety of tasks, such as operating pneumatic tools, inflating tires, and providing air pressure for painting and finishing operations. The CFM requirements for automotive applications can vary depending on the specific task and the size of the operation. For example, a small auto body shop may require a minimum CFM rating of 15-20, while a large automotive manufacturing plant may need a CFM rating of 50-75 or more.

Food Processing

In the food processing industry, air compressors are used for tasks such as operating pneumatic food processing equipment, controlling air pressure in packaging processes, and maintaining a clean and controlled environment. The CFM requirements for food processing applications can vary depending on the specific equipment and processes involved. For example, a small bakery may require a minimum CFM rating of 5-10, while a large food processing plant may need a CFM rating of 20-30 or more.

Other Industries

There are many other industries that rely on air compressors for various applications, such as mining, oil and gas, pharmaceuticals, and more. The CFM requirements for these industries can vary greatly depending on the specific tasks and equipment used. It is important for businesses in these industries to carefully evaluate their needs and consult with air compressor experts to determine the ideal CFM rating for their specific applications.

CFM Ratings for Different Air Tools

When choosing an air compressor, it’s important to consider the CFM (cubic feet per minute) rating, as it determines the amount of air flow the compressor can deliver. Different air tools have different CFM requirements, so it’s essential to match the tool’s CFM rating with the compressor’s output.

Pneumatic Nail Guns

Pneumatic nail guns are commonly used in construction and woodworking projects. They require a consistent and high volume of air to drive nails into various materials. The CFM rating for a pneumatic nail gun typically ranges from 2 to 8 CFM, depending on the size and power of the gun.

Air Sanders

Air sanders are used for smoothing and finishing surfaces. They require a continuous supply of air to operate effectively and efficiently. The CFM rating for an air sander generally ranges from 6 to 10 CFM, depending on the type and size of the sander.

Air Ratchets

Air ratchets are commonly used in automotive repair and maintenance. They require a good amount of continuous air flow to deliver the necessary torque for loosening or tightening nuts and bolts. The CFM rating for an air ratchet typically ranges from 4 to 8 CFM, depending on the size and power of the tool.

Air Spray Guns

Air spray guns are used for painting and coating applications. They require a steady and high volume of air to atomize paint and achieve a smooth finish. The CFM rating for an air spray gun can vary depending on the type of paint being used, but it generally ranges from 7 to 12 CFM.

Air Impact Wrenches

Air impact wrenches are powerful tools used for loosening or tightening stubborn bolts and nuts. They require a significant amount of air flow to generate the necessary torque. The CFM rating for an air impact wrench typically ranges from 4 to 12 CFM, depending on the size and power of the wrench.

In summary, different air tools have different CFM requirements. It’s important to choose an air compressor with a CFM rating that can meet the needs of the tools you plan to use. If the CFM rating is too low, the tool may not operate at its full potential, while a compressor with a higher CFM rating may be more expensive and unnecessary for smaller tools. Understanding the CFM ratings for different air tools can help you make an informed decision when selecting an air compressor.

Understanding the Relationship Between PSI and CFM

When it comes to air compressors, two important factors to consider are PSI (pounds per square inch) and CFM (cubic feet per minute). These two values are interrelated and understanding their relationship is essential in choosing the right air compressor for your specific needs.

PSI, or pounds per square inch, refers to the amount of pressure that the air compressor is capable of delivering. It measures the force with which the air is delivered. Different tools and equipment have specific PSI requirements, and it is important to choose an air compressor with a PSI rating that meets or exceeds the requirements of the tools you will be using.

CFM, or cubic feet per minute, measures the volume of air that an air compressor can deliver. It indicates how quickly the air compressor can supply air. Matching the CFM rating of the air compressor to the CFM requirements of your tools is crucial for their proper operation. If the CFM rating is too low, the tools may not receive the necessary amount of air and may not perform at their best.

The relationship between PSI and CFM is straightforward. While the PSI rating determines the pressure at which the air is delivered, the CFM rating determines the volume of air that is delivered at that pressure. In simple terms, a higher CFM rating means the air compressor can deliver more air at a given pressure, resulting in better tool performance.

When choosing an air compressor, it is important to strike a balance between PSI and CFM. You need to consider both the maximum PSI requirements of your tools and the CFM requirements for proper operation. It is recommended to choose an air compressor with a slightly higher CFM rating than what your tools require, as this will allow for improved performance and versatility.

To determine the ideal CFM rating for your air compressor, you should first identify the highest CFM requirement among the tools you will be using. Once you have this value, you can add a buffer of around 20-30% to ensure that the air compressor can meet the demands of your tools effectively.

How to Increase CFM Output

1. Increase the size of the air compressor

If you need to increase the CFM output of your air compressor, one option is to upgrade to a larger size. A larger air compressor will typically have a larger motor and larger storage tanks, allowing for a higher CFM output. This can be especially useful if you have increased your air tool usage or if you need to run multiple tools simultaneously.

2. Adjust the pressure settings

Another way to increase the CFM output of your air compressor is to adjust the pressure settings. By increasing the pressure, you can potentially increase the airflow and therefore the CFM output. However, it’s important to note that increasing the pressure beyond the recommended levels can damage your air tools and reduce their lifespan.

3. Clean or replace air filters

Over time, air filters can become clogged with dust and debris, which can restrict the airflow and reduce the CFM output of your air compressor. Regularly cleaning or replacing the air filters can help improve the efficiency of your air compressor and increase its CFM output.

4. Reduce air hose length and diameter

The length and diameter of the air hose can also affect the CFM output of your air compressor. Using a shorter and wider diameter air hose can help reduce pressure drop and increase the CFM output. Additionally, making sure the air hose is properly sealed and free from leaks will also help maximize the CFM output.

5. Upgrade to higher CFM air tools

If you are consistently finding that your air compressor’s CFM output is not sufficient for your needs, you may consider upgrading to higher CFM air tools. Using air tools with a higher CFM requirement will naturally increase the demand and ultimately the CFM output of your air compressor.

By implementing these strategies, you can increase the CFM output of your air compressor and ensure that it meets your specific needs and requirements.

Importance of Proper Maintenance to Maintain CFM Efficiency

Proper maintenance is essential for maintaining the CFM (cubic feet per minute) efficiency of an air compressor. CFM is a measure of the volume of air that an air compressor can deliver at a given pressure. The CFM rating of an air compressor determines its ability to power air tools and equipment effectively.

Regular maintenance tasks such as cleaning, lubricating, and inspecting the air compressor can help ensure that it operates at peak performance and maintains its CFM efficiency. One important maintenance task is to clean or replace the air filters regularly. Over time, air filters can become clogged with dust and debris, restricting the airflow and reducing the CFM output of the compressor.

Lubrication is another critical aspect of air compressor maintenance. The moving parts of an air compressor, such as the pistons and valves, require proper lubrication to operate smoothly and efficiently. Regularly checking and topping up the compressor’s lubricant levels is necessary to prevent excessive wear and tear and maintain CFM efficiency.

Regular inspections of the air compressor are also vital to identify any potential issues or malfunctions that could affect its CFM efficiency. For example, worn or damaged valves, leaking hoses, or loose connections can all impact the performance of the compressor and reduce its CFM output. By addressing these issues promptly through regular inspections, the CFM efficiency of the air compressor can be maintained.

In addition to regular maintenance tasks, it is important to follow the manufacturer’s recommendations for maintenance and servicing. This may include specific intervals for oil changes, filter replacements, and other maintenance procedures. Adhering to these recommendations will help ensure that the air compressor remains in good working condition and maintains its CFM efficiency over time.

In conclusion, proper maintenance is crucial for maintaining the CFM efficiency of an air compressor. Regular cleaning, lubrication, and inspections are necessary to keep the compressor operating at peak performance. By following recommended maintenance procedures and addressing any issues promptly, the CFM efficiency of the air compressor can be preserved for optimal performance.

FAQ:

What is CFM in relation to an air compressor?

CFM stands for Cubic Feet per Minute and it is a unit of measurement used in air compressors to indicate the airflow rate or the amount of air the compressor can deliver.

Why is CFM important when choosing an air compressor?

CFM is important because it determines the compressor’s ability to power air tools and equipment. If the air compressor does not have the required CFM, it may not be able to properly operate the tools and equipment.

What is the ideal CFM for a small air compressor?

The ideal CFM for a small air compressor depends on the specific tasks it will be used for. Generally, a small air compressor with a CFM rating between 0.6 – 5 CFM can handle light-duty tasks such as inflating tires and powering small pneumatic tools.

What is the ideal CFM for a medium-sized air compressor?

The ideal CFM for a medium-sized air compressor depends on the specific tasks it will be used for. Generally, a medium-sized air compressor with a CFM rating between 5 – 10 CFM can handle medium-duty tasks such as running paint sprayers and sanders.

What is the ideal CFM for a large air compressor?

The ideal CFM for a large air compressor depends on the specific tasks it will be used for. Generally, a large air compressor with a CFM rating between 10 – 30 CFM or higher can handle heavy-duty tasks such as operating multiple air tools simultaneously or powering large industrial equipment.

Is it better to have a higher CFM rating for an air compressor?

Having a higher CFM rating for an air compressor can be beneficial as it indicates a greater airflow capacity. This allows the compressor to power a wider range of air tools and equipment. However, it is important to choose the CFM rating that matches the intended usage to ensure optimal performance.

How can I determine the CFM requirements for my air tools and equipment?

To determine the CFM requirements for your air tools and equipment, you can refer to their specifications or consult the manufacturer’s recommendations. It is important to choose an air compressor with a CFM rating that meets or exceeds the highest CFM requirement among the tools and equipment you plan to use simultaneously.

![The Show Goes On [DVD] [2008]](https://m.media-amazon.com/images/I/519Dd2XAivL._SS520_.jpg)