What is an air compressor

An air compressor is a machine or device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in compressed air. This compressed air can then be used for a variety of purposes such as powering tools and machinery, inflating tires, or supplying clean air for breathing.

An air compressor typically consists of a motor, a pump, and a tank. The motor provides the power to drive the pump, which compresses the air and stores it in the tank. The compressed air is then released in a controlled manner when needed.

There are different types of air compressors, including reciprocating compressors, rotary screw compressors, and centrifugal compressors. Reciprocating compressors use pistons to compress the air, while rotary screw compressors use screws. Centrifugal compressors, on the other hand, use a rotating impeller to accelerate the air and then convert the kinetic energy into pressure.

One of the key advantages of using an air compressor is its versatility. Compressed air can be easily transported through hoses to different locations, allowing for flexible use in various industries and applications. Additionally, air compressors can be used in both small-scale and large-scale operations, making them suitable for a wide range of tasks.

In conclusion, an air compressor is a powerful machine that converts power into compressed air for various applications. With its ability to provide consistent and reliable power, an air compressor has become a vital tool in many industries around the world.

How does an air compressor work

An air compressor is a device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air. It works by drawing in air from the surrounding atmosphere and compressing it to a higher pressure. This compressed air can then be used for various applications in industries, construction sites, automotive repair shops, and more.

Compressor types

There are different types of air compressors, including reciprocating, rotary screw, and centrifugal compressors. Each type operates differently and is suitable for specific applications.

Reciprocating compressor

A reciprocating compressor works by using a piston within a cylinder to compress the air. As the piston moves downward, it creates a vacuum that draws air into the cylinder. When the piston moves upward, it compresses the air, increasing its pressure. This compressed air is then stored in a tank for future use.

Rotary screw compressor

A rotary screw compressor uses a pair of screws (rotors) to compress the air. As the rotors rotate, air is drawn into the screw element and trapped between the rotors and the casing. The screws then compress the air by reducing the space between them. This compressed air is discharged into a receiver, where it is stored for use.

Centrifugal compressor

A centrifugal compressor utilizes a rotor with radial blades that spin at high speeds. The spinning motion creates centrifugal force, which accelerates the air and converts its kinetic energy into pressure. The air is then directed into a diffuser, where its velocity is reduced, causing an increase in pressure. This compressed air is then sent to a storage tank or directly to the application.

Applications

Air compressors have numerous applications, including powering pneumatic tools, inflating tires, providing air for HVAC systems, and operating machinery in manufacturing plants. They are also used in diving operations, paint spraying, sand-blasting, and many other industrial processes that require compressed air.

In conclusion, an air compressor works by drawing in air and compressing it to a higher pressure. The type of compressor used determines the compression method employed. These devices are essential in various industries and provide a reliable source of compressed air for a wide range of applications.

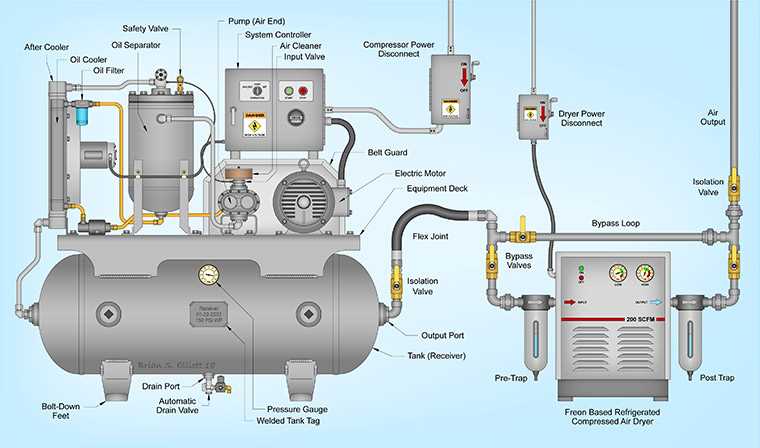

Main components of an air compressor

An air compressor is a device that converts power into potential energy stored in compressed air. It consists of several main components that work together to compress the air.

1. Motor

The motor is the power source of the air compressor. It can be an electric motor or a gasoline engine. The motor provides the energy needed to operate the compressor’s internal mechanisms.

2. Compressor Pump

The compressor pump is the heart of the air compressor. It is responsible for drawing in air and compressing it. There are different types of compressor pumps, including reciprocating, rotary screw, and centrifugal.

3. Air Tank

The air tank is a storage reservoir for the compressed air. It allows for a steady supply of compressed air to be available for use when needed. The size of the air tank can vary depending on the specific application and usage requirements.

4. Pressure Switch

The pressure switch is a control device that monitors the air pressure inside the tank. It automatically starts or stops the motor based on the pressure level. This helps to maintain the desired pressure and prevent over-pressurization.

5. Safety Valve

The safety valve is a critical component that ensures the air compressor operates safely. It is designed to release excess pressure if the pressure switch fails or if the pressure exceeds the maximum allowed level. The safety valve helps to prevent accidents and damage to the compressor.

6. Regulator

The regulator is responsible for controlling the pressure of the compressed air as it is delivered to the tools or equipment. It allows the user to adjust the pressure to the desired level for different applications. The regulator ensures that the air pressure remains consistent and reliable.

7. Gauges

Gauges are used to monitor the pressure levels of the air compressor. They provide a visual indication of the tank pressure and the pressure at the delivery point. Gauges help the user to ensure that the compressor is operating within the desired parameters.

These main components work together to create a reliable and efficient air compressor system. Each component plays a crucial role in the compression and delivery of compressed air for various applications.

Types of air compressors

There are several different types of air compressors that are commonly used in various industries and applications.

Reciprocating air compressors

Reciprocating air compressors work by using a piston and cylinder to compress air. They are often used in smaller applications and are available in both single-stage and two-stage configurations. Single-stage compressors compress the air once, while two-stage compressors compress it twice for higher pressures.

Rotary screw air compressors

Rotary screw air compressors are widely used in industrial settings. They use a pair of interlocking screws to compress air, and they are known for their efficiency and reliability. Rotary screw compressors can be oil-injected or oil-free, depending on the specific application.

Centrifugal air compressors

Centrifugal air compressors are typically used for larger applications where high volumes of compressed air are required. They use centrifugal force to compress air and can provide a continuous flow of compressed air. Centrifugal compressors are commonly used in power plants and other heavy-duty applications.

In addition to these main types, there are also specialized air compressors such as scroll compressors, vane compressors, and portable air compressors that are designed for specific purposes and applications. The choice of the right type of air compressor depends on factors such as required air pressure, volume of compressed air needed, and specific application requirements.

Common applications of air compressors

1. Industrial uses

Air compressors are extensively used in various industries for a wide range of applications. They are used in manufacturing and production processes, such as powering pneumatic tools like air hammers, nail guns, and spray guns. Air compressors are also used in factories for sandblasting, drying surfaces, and painting.

2. Construction and renovation

Air compressors are vital in the construction and renovation industry. They are used to power jackhammers, pneumatic drills, and impact wrenches. Air compressors are also utilized to operate air tools for carpentry, such as nail guns and staple guns. In addition, air compressors are used for cleaning purposes, including blowing off dust and debris.

3. Automotive industry

In the automotive industry, air compressors are widely used for various tasks. They play a crucial role in operating pneumatic tools used for repairing and maintaining vehicles, such as air impact wrenches, air ratchets, and air sanders. Air compressors are also used in car wash stations for cleaning vehicles and inflating tires.

4. HVAC systems

Heating, ventilation, and air conditioning (HVAC) systems often rely on air compressors. They are used in air conditioning units to compress and cool refrigerant gases, allowing for efficient cooling of indoor spaces. Air compressors are also used in air compressors used in HVAC systems.

5. Medical and dental facilities

Air compressors are essential in medical and dental facilities for various applications. They are used in dental chairs to power dental handpieces and suction devices. Medical facilities utilize air compressors for powering medical air systems, aerosol therapy equipment, and ventilators. They are also used for oxygen supply in hospitals and clinics.

6. Food and beverage industry

In the food and beverage industry, air compressors are used for various applications. They are employed in bottling plants for filling bottles with carbonated beverages. Air compressors are also used in food processing factories for operating equipment such as mixing machines and pneumatic pumps. In addition, they are used for food packaging processes like sealing and labeling.

7. Scuba diving

Air compressors play a vital role in the scuba diving industry. They are used to fill scuba tanks with high-pressure breathing air. The air compressors used for scuba diving must meet specific quality standards to ensure the safety of divers while underwater. Without air compressors, scuba diving would not be possible.

8. Power generation

Air compressors are sometimes used in power generation plants. They are used in gas turbines to provide compressed air for combustion. The compressed air helps in achieving efficient fuel combustion and power generation. Air compressors are also used in the air separation process to extract atmospheric gases for various industrial applications.

These are just a few examples of how air compressors are used in various industries and applications. The versatility and usefulness of air compressors make them an essential tool in many fields.

Benefits of using an air compressor

Increased efficiency

One of the main benefits of using an air compressor is increased efficiency. By using compressed air, you can power tools and machinery with ease, allowing for faster and more efficient work. This can result in time and cost savings, as well as increased productivity.

Versatility

Another advantage of using an air compressor is its versatility. Compressed air can be used for a wide range of applications, including inflating tires, powering pneumatic tools, and even cleaning equipment. This versatility makes an air compressor a valuable tool in various industries and settings.

Higher power output

Compressed air has a higher power output compared to other power sources, such as electricity. This means that using an air compressor can provide more power to tools and equipment, allowing for the completion of tasks that require greater force or pressure.

Portability

Many air compressors are designed to be portable, making them easy to transport and use in different locations. This portability is especially beneficial for professionals who need to move around frequently, such as contractors or technicians. Additionally, portable air compressors are often compact and lightweight, making them convenient to store and carry.

Low maintenance

Air compressors generally require less maintenance compared to other types of power sources. With proper care and regular maintenance, an air compressor can last for a long time without any major issues. This can save both time and money on repairs and replacement parts.

Cost-effective

Using an air compressor can also be cost-effective in the long run. While the initial investment may be higher compared to some other power sources, the efficiency, versatility, and durability of an air compressor can result in significant cost savings over time. Additionally, the use of compressed air can eliminate the need for costly fuel or electricity.

Overall, an air compressor offers several benefits, including increased efficiency, versatility, higher power output, portability, low maintenance, and cost-effectiveness. Whether used in a professional setting or for personal projects, an air compressor can be a valuable tool for a wide range of applications.

Choosing the right air compressor

When it comes to choosing the right air compressor, there are several key factors to consider. One important factor is the intended use of the compressor. Air compressors come in a variety of sizes and power levels, so it’s important to choose one that is suitable for the task at hand. For example, small portable compressors are great for inflating tires or powering small tools, while larger industrial compressors are better suited for heavy-duty applications like sandblasting or powering large machinery.

Another factor to consider is the volume and pressure requirements of the air tools or equipment you will be using. Different tools require different levels of air pressure, so it’s important to choose a compressor that can provide the necessary pressure. Additionally, the volume of air needed will determine the size of the compressor’s air tank. If you will be using tools that require a constant supply of air, a larger tank may be needed to ensure a steady flow.

It’s also important to consider the power source of the compressor. Some compressors are electric, while others are gas-powered. Electric compressors are generally more convenient and easier to use, especially for indoor applications where exhaust fumes from a gas-powered compressor may be a concern. Gas-powered compressors, on the other hand, offer greater portability and are better suited for outdoor use or in locations where electricity may not be readily available.

Finally, budget is an important factor to consider when choosing an air compressor. Compressors come in a wide range of prices, so it’s important to determine how much you are willing to spend before making a decision. While it may be tempting to opt for a cheaper option, it’s important to balance cost with quality and reliability. Investing in a higher-quality air compressor may save you money in the long run by providing better performance and lasting durability.

In conclusion, choosing the right air compressor requires careful consideration of factors such as intended use, volume and pressure requirements, power source, and budget. By taking these factors into account, you can select a compressor that meets your specific needs and ensures optimal performance for years to come.

Maintenance and safety tips for air compressors

Regular Cleaning

Regular cleaning is crucial for maintaining the performance and longevity of your air compressor. Dust and dirt can accumulate on the components and hinder its functionality. Use a soft cloth or brush to remove any debris from the exterior surfaces.

Proper Lubrication

Proper lubrication is essential for the smooth operation of an air compressor. Check the manufacturer’s instructions to determine the appropriate lubricant to use. Apply the lubricant to the specified parts as recommended. Regularly monitor the oil level and refill as necessary.

Tighten Connections

Ensure that all connections and fittings are properly tightened, as the vibration from the air compressor can cause them to loosen over time. Check for any signs of leaks and address them promptly. Damaged or worn-out connections should be replaced immediately.

Inspect the Air Filter

The air filter plays a critical role in preventing dust and other contaminants from entering the air compressor. Regularly inspect the air filter for any dirt buildup and clean or replace it as needed. A clogged air filter can lead to decreased efficiency and potential damage to the compressor.

Practice Proper Ventilation

Air compressors generate heat during operation, so it’s important to provide proper ventilation in the compressor’s vicinity. Ensure that the compressor is placed in a well-ventilated area with sufficient airflow. Avoid operating the compressor in dusty or humid conditions, as this can also affect its performance and longevity.

Follow Safety Guidelines

When using an air compressor, following safety guidelines is crucial to prevent accidents or injuries. Always wear appropriate safety gear, such as goggles and gloves, to protect yourself from potential hazards. Familiarize yourself with the specific safety instructions provided by the manufacturer. Never exceed the recommended pressure levels or use the compressor for purposes it is not designed for.

By following these maintenance and safety tips, you can ensure that your air compressor operates efficiently and safely, extending its lifespan and maintaining optimal performance.

FAQ:

What is an air compressor used for?

An air compressor is used to convert power into potential energy stored in pressurized air. It can be used for a variety of applications such as powering pneumatic tools, inflating tires, and operating machinery in various industries.

How does an air compressor work?

An air compressor works by drawing in air, compressing it, and then storing it in a tank at a high pressure. When the compressed air is released, it can be used to power a variety of tools and equipment.

What types of air compressors are there?

There are several types of air compressors, including reciprocating compressors, rotary screw compressors, and centrifugal compressors. Each type has its own advantages and is suitable for different applications.

What are the benefits of using an air compressor?

Using an air compressor has many benefits. It provides a reliable source of power for tools, equipment, and machinery. It is also more efficient and cost-effective compared to other power sources. Additionally, it allows for easy and convenient portability.

Can I use an air compressor at home?

Yes, you can use an air compressor at home. It can be used for various tasks like inflating tires, powering pneumatic tools for DIY projects, and even for cleaning surfaces. However, it is important to choose the right size and type of air compressor that suits your needs and the intended applications.

Video: