What Does an Air Compressor Look Like: Types, Components, and Functions

An air compressor is a device that converts power into potential energy stored in compressed air. It is commonly used in various industries and applications, such as construction, manufacturing, and automotive repair. But what does an air compressor look like, and what are its types, components, and functions?

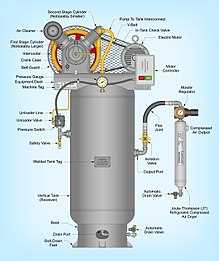

Firstly, let’s talk about the appearance of an air compressor. Most air compressors consist of a motor, a compressor pump, and a tank. The motor is the power source that drives the compressor pump to compress the air. The compressor pump is responsible for pressurizing the air, and the tank acts as a storage reservoir for the compressed air.

When it comes to types, there are several variations of air compressors available in the market. The two main types are reciprocating compressors and rotary screw compressors. Reciprocating compressors work by using pistons to compress the air, while rotary screw compressors use two rotating screws to compress the air. Each type has its own advantages and is suitable for different applications.

The components of an air compressor include not only the motor, compressor pump, and tank but also various other parts that ensure the smooth operation of the compressor. These components may include valves, pressure switches, pressure gauges, safety relief valves, and filters. Valves control the flow of air in and out of the compressor, pressure switches monitor and regulate the pressure, and filters remove impurities from the compressed air.

In terms of function, an air compressor has a wide range of uses. It can be used for pneumatic tools, such as air-powered drills, impact wrenches, and nail guns. It is also used for inflating tires, powering airbrushes, and operating pneumatic machinery. Additionally, air compressors are often used in industrial processes that require compressed air, such as paint spraying, sandblasting, and cooling systems. The versatility and efficiency of air compressors make them an essential tool in many industries.

Air Compressors: Types, Components, and Functions

An air compressor is a mechanical device that serves to convert power into potential energy stored in pressurized air. It is used in various applications, such as powering tools, inflating tires, and providing compressed air for industrial processes. Air compressors come in different types, each with its own components and functions.

Types of Air Compressors

1. Reciprocating Air Compressors: These compressors use a piston driven by a crankshaft to compress air. They are available in both single-stage and two-stage designs and are commonly used for smaller applications and home use.

2. Rotary Screw Air Compressors: These compressors use two rotors to compress air. They are known for their efficiency and are often used in large industrial applications.

3. Rotary Vane Air Compressors: These compressors utilize a rotor with sliding vanes to compress air. They are compact and low-maintenance, making them suitable for applications where space is limited.

Components of an Air Compressor

An air compressor consists of several key components, including:

- Compressor Pump: The main component responsible for compressing air. It can be a reciprocating pump or a rotary pump, depending on the type of compressor.

- Air Tank: A storage tank where compressed air is stored until it is used.

- Motor: The power source that drives the compressor pump.

- Pressure Switch: A device that automatically shuts off the compressor when the desired pressure is reached.

- Cooling System: Compressing air generates heat, so air compressors have a cooling system to prevent overheating.

- Safety Valves: These valves release excess pressure to prevent damage to the compressor.

Functions of Air Compressors

1. Powering Tools: Air compressors are commonly used to power pneumatic tools, such as drills, nail guns, paint sprayers, and impact wrenches. The compressed air provides the necessary force to operate these tools effectively.

2. Inflating Tires: Air compressors are also used for inflating tires, whether it’s for vehicles, bicycles, or sports equipment. The compressed air from the compressor is directed into the tire, increasing its pressure and ensuring proper inflation.

3. Industrial Applications: Air compressors play a crucial role in various industrial processes. They are used in manufacturing, construction, and mining for tasks such as operating machinery, powering pneumatic systems, and providing ventilation.

In conclusion, air compressors come in different types with various components and functions. Understanding these aspects can help determine the most suitable air compressor for specific applications, ensuring efficient operation and optimal performance.

Reciprocating Air Compressor

A reciprocating air compressor, also known as a piston compressor, is a type of air compressor that uses a piston and cylinder to compress air. It is one of the most common types of air compressors used in various industries.

Components:

1. Piston: The piston is a cylindrical component that moves up and down inside the cylinder. It is responsible for compressing the air.

2. Cylinder: The cylinder is a hollow chamber where the piston moves. It provides the space for the compression of air.

3. Crankshaft: The crankshaft is connected to the piston and converts the linear motion of the piston into rotary motion.

4. Connecting Rod: The connecting rod connects the piston to the crankshaft and transfers the force from the piston to the crankshaft.

5. Valves: The valves, including the intake valve and the discharge valve, control the flow of air in and out of the cylinder.

Functions:

1. Compressing Air: The main function of a reciprocating air compressor is to compress air. As the piston moves down, it creates a vacuum in the cylinder, causing air to be sucked in. When the piston moves up, the air is compressed, increasing its pressure.

2. Storing Compressed Air: Reciprocating air compressors are often equipped with a storage tank where the compressed air is stored. This allows for a steady supply of compressed air, even if the demand fluctuates.

3. Powering Tools and Equipment: Compressed air from a reciprocating air compressor can be used to power various tools and equipment, such as pneumatic drills, sanders, and spray guns. It provides a convenient and efficient source of power for these applications.

4. Pressurizing Systems: Reciprocating air compressors are also used in pressurizing systems, such as HVAC systems and pneumatic systems. They help maintain a consistent pressure in the system for efficient operation.

Overall, reciprocating air compressors are versatile machines that play a vital role in many industries. They offer reliable and efficient compressed air for a wide range of applications.

Rotary Air Compressor

A rotary air compressor is a type of air compressor that uses rotating mechanisms to compress air. It is commonly used in industrial settings and is known for its efficiency and reliability. The main components of a rotary air compressor include the rotor, housing, inlet valve, discharge valve, and oil system.

Rotor

The rotor is the central component of a rotary air compressor. It is a rotating element that contains a series of specially designed lobes or screws. As the rotor rotates, it compresses the air by trapping it between the lobes and the housing, reducing its volume and increasing its pressure.

Housing

The housing is the stationary part of the rotary air compressor. It encloses the rotor and creates a sealed chamber where the compression process takes place. The housing also provides support and helps to maintain the alignment of the rotor.

Inlet Valve

The inlet valve is responsible for allowing air to enter the compressor. It opens and closes as needed to control the flow of air into the compressor. The inlet valve is designed to prevent backflow and ensure that only clean, filtered air enters the compressor.

Discharge Valve

The discharge valve is responsible for releasing the compressed air from the compressor. It opens and closes as needed to control the flow of compressed air out of the compressor. The discharge valve is designed to prevent backflow and ensure that the compressed air is delivered to the intended destination.

Oil System

A rotary air compressor often requires an oil system to lubricate and cool the moving parts. The oil system typically includes an oil pump, oil filter, and oil cooler. The oil helps reduce friction and heat, ensuring smooth operation and extending the lifespan of the compressor.

Centrifugal Air Compressor

A centrifugal air compressor is a type of air compressor that uses centrifugal force to compress air. It is also known as a dynamic compressor. This type of compressor is widely used in industrial applications where high volumes of compressed air are required.

Working Principle:

The centrifugal air compressor works by accelerating air using a rotating impeller. The impeller consists of a series of blades that rotate at high speeds. As the impeller spins, it creates a high-velocity airstream. This high-velocity airstream is then directed to a diffuser, where it slows down and the kinetic energy is converted into pressure.

Components:

The main components of a centrifugal air compressor include:

- Impeller: The impeller is the rotating component that accelerates the air.

- Diffuser: The diffuser is the stationary component that converts the high-velocity airstream into pressure.

- Volute: The volute is a curved housing that collects the compressed air and directs it towards the outlet.

- Motor: The motor provides the power to drive the impeller.

Advantages:

The centrifugal air compressor offers several advantages:

- High efficiency: Centrifugal compressors are highly efficient, ensuring maximum air compression with minimal energy consumption.

- Low maintenance: Due to their simple design and fewer moving parts, centrifugal compressors require less maintenance compared to other types of compressors.

- Compact size: Centrifugal compressors are relatively compact in size, making them suitable for applications where space is limited.

- Quiet operation: Centrifugal compressors produce less noise compared to other types of compressors, making them ideal for noise-sensitive environments.

Applications:

Centrifugal air compressors are used in a wide range of industrial applications, including:

- Power generation: Centrifugal compressors are commonly used in power plants to provide compressed air for various processes.

- Petrochemical industry: These compressors are used in petrochemical plants for processes such as refining, liquefaction, and transportation of gases.

- Manufacturing: Centrifugal compressors are used in manufacturing industries for tasks such as pneumatic tool operation, painting, and air blast cleaning.

- Pharmaceutical industry: These compressors are used in pharmaceutical plants for applications such as air purification and sterilization.

In conclusion, the centrifugal air compressor is a versatile and efficient compressor that is widely used in industrial applications. With its innovative design and high-performance capabilities, it plays a crucial role in providing compressed air for various processes in different industries.

Air Compressor Components

1. Compressor Pump

The compressor pump is the heart of an air compressor. It is responsible for compressing the air and delivering it to the storage tank. The pump is typically driven by an electric motor or a gasoline engine and operates using one or more pistons or a rotary screw mechanism.

2. Air Tank

The air tank, also known as the storage tank, is where the compressed air is stored for later use. It acts as a reservoir and helps to maintain a constant supply of compressed air even when the demand fluctuates. The size and capacity of the tank can vary depending on the specific application.

3. Pressure Switch

The pressure switch is an essential component that controls the operation of the air compressor. It monitors the air pressure within the tank and signals the motor to start or stop when the pressure reaches certain predefined levels. This helps to prevent overpressure or low-pressure conditions.

4. Safety Valve

The safety valve is a crucial safety feature that protects the air compressor from excessive pressure. It is designed to automatically release compressed air from the tank if the pressure surpasses the maximum safe level. This helps to prevent any potential damage or accidents due to overpressure.

5. Air Regulator

The air regulator is a component that allows users to control the pressure and flow of the compressed air. It is usually installed downstream of the tank and helps to regulate the pressure for various tools or equipment. The air regulator ensures that the air pressure is suitable for the specific application, providing optimal performance and efficiency.

6. Air Filter

The air filter is responsible for removing dirt, dust, oil, and other contaminants from the intake air before it enters the compressor pump. It helps to prevent damage to the pump and other components, ensuring clean and high-quality compressed air. Regular maintenance and replacement of the air filter are important for the proper functioning of the air compressor.

7. Cooling System

Air compressors often require a cooling system to prevent overheating during operation. This can include a fan or a cooling hood that helps to dissipate heat and maintain the optimal operating temperature. Adequate cooling is necessary to prevent damage to the compressor pump and other critical components.

8. Control Panel

The control panel is where the user can monitor and control various functions of the air compressor. It may include switches, gauges, and indicators to display the air pressure, temperature, and other relevant parameters. The control panel allows for easy operation and adjustment of the air compressor settings.

9. Drain Valve

The drain valve is a small component located at the bottom of the air tank. It is used to release excess moisture and condensation that accumulates in the tank over time. Regular draining of the tank helps to prevent corrosion and maintains the quality of the compressed air.

10. Pressure Relief Valve

The pressure relief valve is another safety device that automatically releases air from the tank in the event of a pressure buildup. It is designed to prevent the tank from rupturing or exploding due to excessive pressure. The pressure relief valve provides an additional layer of safety for the air compressor.

Air Compressor Tank

The air compressor tank is an essential component of an air compressor system. It is a cylindrical or rectangular container that stores compressed air. The tank is typically made of steel or aluminum as these materials are strong and can handle the pressure generated by the compressor. The tank is designed to withstand high pressure and is usually equipped with safety valves to prevent over-pressurization.

The size of the air compressor tank can vary depending on the specific application and requirements. Smaller tanks are suitable for light-duty tasks such as inflating tires or powering small air tools, while larger tanks are used for heavy-duty industrial applications. The capacity of the tank is measured in gallons and determines the amount of compressed air that can be stored.

The main function of the air compressor tank is to store compressed air and provide a reserve of air for the system. When the compressor is running, it fills the tank with compressed air, which can then be used to power pneumatic tools or operate other equipment. The tank acts as a buffer, ensuring a steady supply of compressed air even when the demand fluctuates.

In addition to storing compressed air, the tank also plays a crucial role in moisture removal. As the air is compressed, its temperature increases, causing water vapor to condense. The tank contains a drain valve that allows accumulated moisture to be periodically drained. This helps to prevent corrosion and damage to the system.

Overall, the air compressor tank is a vital component of an air compressor system. It provides a storage space for compressed air, ensures a steady supply of air, and helps to remove moisture from the system. The size and capacity of the tank should be chosen based on the specific application and demand for compressed air.

Air Compressor Pump

An air compressor pump is the heart of an air compressor system. It is responsible for converting mechanical energy into compressed air. The pump plays a crucial role in the overall performance of the compressor and determines its maximum pressure and flow rate.

The pump of an air compressor can be either a reciprocating pump or a rotary pump. Reciprocating pumps use pistons and cylinders to compress the air. They work by pulling air into the cylinder on the intake stroke and then compressing it on the discharge stroke. These pumps are known for their high pressure capabilities and are commonly used in applications that require high-pressure air, such as industrial and manufacturing settings.

On the other hand, rotary pumps use rotating elements to compress the air. One common type of rotary pump is the screw compressor, which consists of two rotating screws that trap and compress the air as they rotate. Rotary pumps are known for their high efficiency and continuous duty cycle, making them ideal for applications that require a steady supply of compressed air, such as pneumatic tools and equipment.

The pump is typically powered by an electric motor or an internal combustion engine. It is connected to an air receiver tank, which stores the compressed air for future use. The pump also has various components, such as valves, seals, and bearings, that help in its operation and ensure a reliable and efficient compression process.

In conclusion, the air compressor pump is a crucial component of an air compressor system. Whether it is a reciprocating pump or a rotary pump, it is responsible for converting mechanical energy into compressed air, determining the maximum pressure and flow rate. Understanding the different types of pumps and their functions can help in choosing the right air compressor for specific applications.

Air Compressor Motor

The air compressor motor is a crucial component of an air compressor. It is responsible for powering the compressor pump and generating the compressed air. There are different types of motors used in air compressors, including electric motors and gas engines.

Electric motors: These motors are widely used in air compressors due to their efficiency and ease of use. They are typically powered by electricity and provide a reliable source of power for the compressor pump. Electric motors are available in various sizes and power ratings to suit different compressor models.

Gas engines: In some cases, air compressors may be powered by gas engines, such as gasoline or diesel engines. These engines provide a portable and versatile power source, making them suitable for use in remote locations or areas without access to electricity. Gas engine-powered air compressors are commonly used in construction sites and outdoor activities.

Motor components and functions

The air compressor motor consists of several components that work together to generate power and drive the compressor pump. These components include:

- Stator: The stator is the stationary part of the motor that contains the windings. It generates a rotating magnetic field when an electric current passes through it.

- Rotor: The rotor is the rotating part of the motor that carries the shaft. It interacts with the magnetic field produced by the stator and converts electrical energy into mechanical energy.

- Shaft: The shaft is connected to the rotor and provides support for the compressor pump. It transfers the rotational energy from the motor to the pump, allowing it to compress the air.

The main function of the air compressor motor is to convert electrical or fuel energy into mechanical energy. This mechanical energy is then used to drive the compressor pump, which compresses the air and stores it in a tank. The motor ensures that the compressor operates efficiently and delivers a steady supply of compressed air for various applications.

Air Compressor Functions

1. Providing pressurized air:

An air compressor’s main function is to provide pressurized air for various applications. It takes in ambient air and compresses it, resulting in a higher pressure output. This compressed air can be used for a variety of purposes, such as powering pneumatic tools, inflating tires, operating industrial machinery, and supplying air to breathing apparatus.

2. Powering pneumatic tools:

One of the primary functions of an air compressor is to power pneumatic tools. Pneumatic tools, also known as air tools, rely on the compressed air generated by the compressor to operate. These tools include impact wrenches, nail guns, paint sprayers, sanders, and drills. The pressurized air provides the necessary force to drive these tools, making them efficient and powerful.

3. Inflating tires and other objects:

An air compressor is also commonly used for inflating tires and other objects that require air. With the appropriate attachments, an air compressor can quickly and effortlessly inflate tires, sports balls, air mattresses, and inflatable toys. This function is especially useful for automotive maintenance and recreational activities.

4. Operating industrial machinery:

Air compressors play a crucial role in various industrial applications. They are used to power machinery and equipment, such as pneumatic actuators, valves, pumps, and conveyors. The pressurized air generated by the compressor can be used for tasks like moving heavy loads, controlling processes, and providing motive power for industrial processes.

5. Supplying air to breathing apparatus:

In certain industries, an air compressor is used to supply clean, compressed air to breathing apparatus. This includes respiratory protection equipment like masks, helmets, and self-contained breathing apparatus (SCBA). The compressor ensures a continuous supply of breathable air, making it essential for safety in environments where air quality is compromised.

6. Industrial cleaning and maintenance:

Another function of an air compressor is to provide high-pressure air for industrial cleaning and maintenance tasks. This includes activities like dusting, removing debris, blowing away dirt, and drying surfaces. Air compressors with higher pressure outputs are often used for these purposes, as the compressed air can effectively dislodge and remove stubborn contaminants.

7. Gas and oil production:

In the oil and gas industry, air compressors are used for various applications, such as gas compression, drilling operations, and process air supply. They help in boosting the pressure of natural gas for transportation, powering drilling rigs, and providing compressed air for other equipment used in the production and processing of oil and gas.

In conclusion, air compressors have a wide range of functions and play a crucial role in various industries and applications. Whether it’s powering tools, inflating objects, supplying air for breathing apparatus, or supporting industrial processes, the versatility of air compressors makes them an essential component in many operations.

FAQ:

What is an air compressor?

An air compressor is a device that converts power into potential energy stored in compressed air.

What does an air compressor look like?

An air compressor typically consists of a metal tank, a motor, a pressure switch, a regulator, and various valves and gauges.

What are the types of air compressors?

There are several types of air compressors, including reciprocating compressors, rotary screw compressors, centrifugal compressors, and scroll compressors.

What are the components of an air compressor?

The main components of an air compressor include the compressor pump, the motor, the air receiver tank, the pressure switch, the pressure regulator, the safety valve, and various pipes and hoses.

How does an air compressor work?

An air compressor works by drawing in air and compressing it using a piston or a rotating screw. The compressed air is then stored in a tank and can be used to power air tools or other devices.

What are the functions of an air compressor?

An air compressor has various functions, such as inflating tires, powering pneumatic tools, supplying clean compressed air for industrial processes, and generating compressed air for breathing apparatus in certain applications.

Video: