Ways to Increase CFM on an Air Compressor

Increasing the CFM (cubic feet per minute) on an air compressor is a common goal for many users who require higher air flow for their applications. Whether you’re using an air compressor for woodworking, automotive repair, or industrial purposes, a higher CFM can greatly improve the efficiency and performance of your tools.

One of the first and most effective ways to increase CFM on an air compressor is by upgrading the size of the compressor tank. A larger tank can hold more compressed air, allowing for longer run times and greater output. This means that your tools won’t have to wait as long for the compressor to replenish the air supply, resulting in a higher CFM.

Another way to boost CFM is by increasing the horsepower of the compressor. More power means the compressor can compress air more efficiently, resulting in a higher CFM. However, it’s important to note that simply increasing the horsepower without considering other factors, such as tank size and airflow restrictions, may not significantly improve the CFM.

Additionally, optimizing the airflow system of the compressor can help increase CFM. This can be done by minimizing restrictions in the air lines, using larger diameter hoses and fittings, and ensuring proper ventilation and cooling of the compressor unit. By improving the airflow, you can reduce pressure drop and increase the overall CFM output of the compressor.

In conclusion, there are several ways to increase CFM on an air compressor, including upgrading the tank size, increasing the horsepower, and optimizing the airflow system. By implementing these improvements, you can enhance the efficiency and performance of your air tools, allowing for smoother operations and increased productivity.

The Importance of CFM in an Air Compressor

The CFM (cubic feet per minute) rating is a critical factor to consider when choosing an air compressor. CFM indicates the volume of air that the compressor can deliver in one minute. It determines the compressor’s ability to power pneumatic tools and equipment efficiently. Understanding the importance of CFM can help you make informed decisions when selecting an air compressor for your specific needs.

Optimal Performance

Adequate CFM is essential for optimal performance of air tools and equipment. If the CFM rating of the compressor is not sufficient for a particular tool, it may lead to reduced efficiency, slower working speed, and potential damage to the tool itself. For example, a paint sprayer may require a higher CFM to provide a consistent spray pattern and avoid overspray. Therefore, it is crucial to match the CFM rating of the compressor to the requirements of the tools you plan to use.

Faster Operation

An air compressor with a higher CFM rating allows for faster operation and increased productivity. When using pneumatic tools such as impact wrenches or sandblasters, a higher CFM allows these tools to operate at their full potential, delivering greater power and speed. This can significantly reduce the time needed to complete tasks, increasing efficiency and saving valuable working hours.

Compatibility with Multiple Tools

Having an air compressor with a higher CFM rating provides the flexibility to use a wider range of pneumatic tools and equipment. Different tools have varying CFM requirements, and having a compressor with a higher CFM ensures compatibility with a broader selection of tools. This allows for versatility in various applications and avoids the need to invest in multiple compressors for specific tools.

It is important to remember that the CFM rating is not the only factor to consider when choosing an air compressor. Other factors such as tank size, PSI rating, and motor horsepower should also be taken into account to ensure optimal performance for your specific needs.

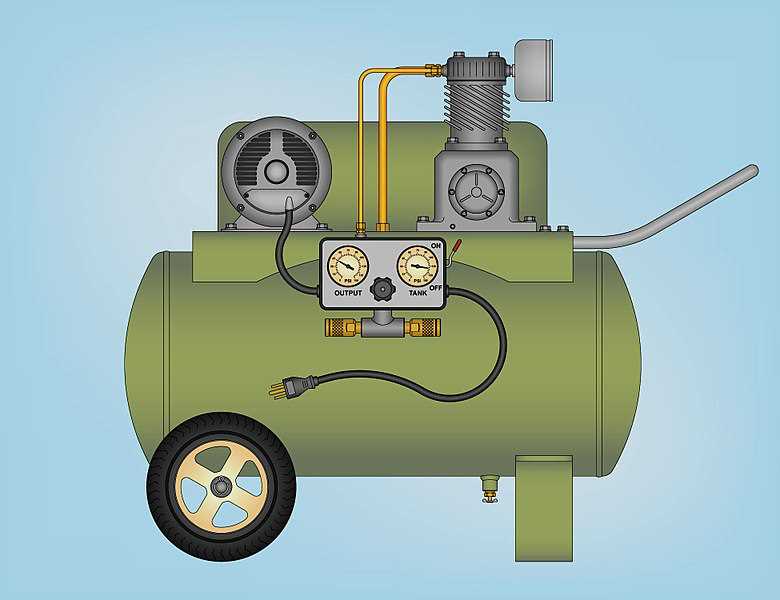

Understanding CFM and its Role in Air Compressors

CFM, or cubic feet per minute, is a metric used to measure the airflow capacity of an air compressor. It refers to the volume of air that the compressor can deliver in one minute. CFM is an essential factor to consider when choosing an air compressor as it determines the compressor’s overall performance and efficiency.

The CFM rating of an air compressor is dependent on various factors such as the size of the compressor’s motor, the tank size, and the pressure rating. A higher CFM rating indicates that the compressor can deliver a larger volume of air, making it suitable for applications that require higher air volumes.

In air compressors, CFM plays a crucial role in determining the compressor’s ability to power pneumatic tools and equipment. Pneumatic tools such as impact wrenches, paint sprayers, and sanders require a certain CFM to operate effectively. Using an air compressor with a lower CFM rating than what is required by the tool can result in poor performance and decreased productivity.

To optimize the CFM output of an air compressor, several steps can be taken. First, ensuring that the compressor’s intake is free from obstructions can help improve airflow and ultimately increase CFM. Additionally, regularly cleaning or replacing the compressor’s air filter can prevent clogs and improve overall performance.

Another way to increase CFM is by properly managing the compressor’s pressure settings. Adjusting the pressure regulator to the optimal level for the specific application can help maximize the compressor’s CFM output. However, it is important to note that increasing the pressure excessively can lead to increased wear and tear on the compressor and may result in decreased overall efficiency.

Ultimately, understanding CFM and its role in air compressors is essential for selecting the right compressor for specific applications and optimizing its performance. By considering the CFM requirements of pneumatic tools and implementing strategies to increase CFM, users can ensure optimal and efficient operation of their air compressors.

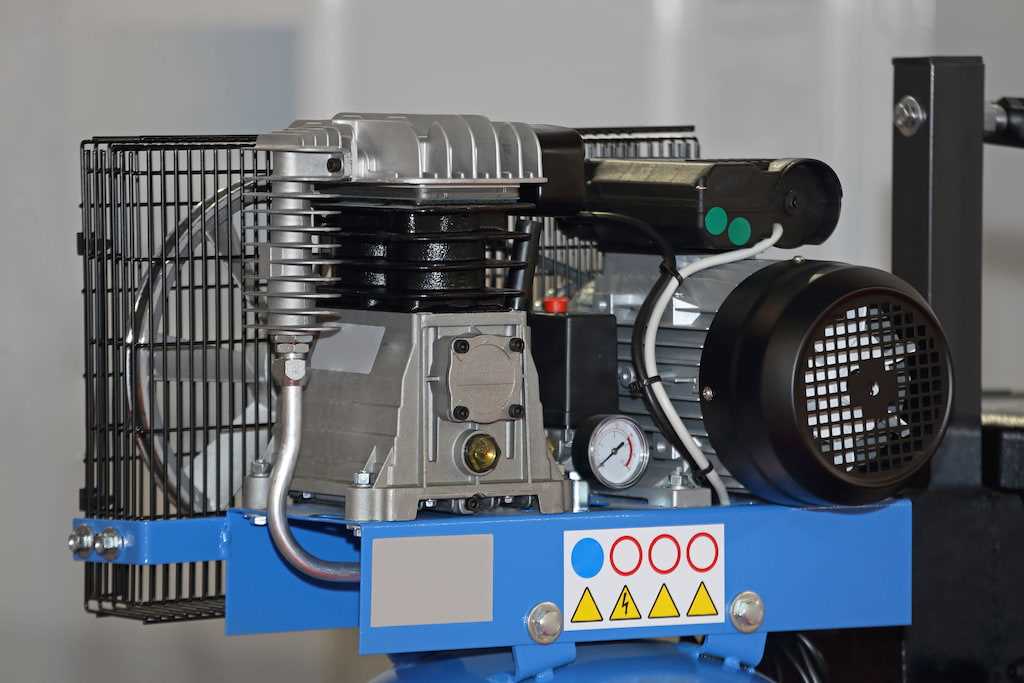

Factors Affecting CFM on an Air Compressor

An air compressor’s CFM, or cubic feet per minute, is a measurement of the volume of air that the compressor can deliver. CFM is an important factor to consider when choosing an air compressor, as it determines the compressor’s ability to power various air tools and equipment. Several factors can affect the CFM output of an air compressor.

1. Horsepower of the Compressor

The horsepower of an air compressor directly affects its CFM output. A compressor with a higher horsepower rating will generally have a higher CFM output. This is because a more powerful motor can drive the compressor pump at a faster rate, allowing it to deliver a larger volume of air.

2. Pump Efficiency

The efficiency of the compressor pump is another factor that can affect the CFM output. A more efficient pump will be able to compress air more effectively, resulting in a higher CFM output. Regular maintenance and proper lubrication of the pump can help ensure optimal efficiency.

3. Tank Size and Pressure

The size of the air tank and the pressure at which the compressor operates can also impact the CFM output. A larger tank can store more compressed air, allowing for a higher sustained CFM output. Additionally, increasing the pressure at which the compressor operates can increase the CFM output, although it may also decrease the overall runtime of the compressor.

4. Air Intake and Filtration

The air intake and filtration system of an air compressor can affect the CFM output by influencing the amount of air that the compressor can draw in. A clean and unrestricted intake filter can ensure a steady flow of air, while a clogged or dirty filter can restrict airflow and reduce the CFM output.

5. Piping and Hoses

The size and condition of the piping and hoses used with the compressor can also impact the CFM output. Smaller or clogged pipes and hoses can create a bottleneck in the airflow, reducing the effective CFM output. Properly sized and maintained pipes and hoses can help ensure maximum CFM delivery.

Overall, several factors can affect the CFM output of an air compressor, including the horsepower of the compressor, pump efficiency, tank size and pressure, air intake and filtration, and piping and hoses. Understanding these factors can help you choose the right air compressor for your needs and maximize its CFM output.

Choosing the Right Air Compressor for Increased CFM

When it comes to increasing the CFM (cubic feet per minute) of an air compressor, choosing the right compressor is crucial. CFM is a measure of the volume of air that is delivered by the compressor in a minute. By selecting the right compressor, you can maximize the air flow, ensuring that your tools and equipment receive the necessary amount of air to operate efficiently.

Consider the CFM Requirements

Before selecting an air compressor, it is important to consider the CFM requirements of your tools and equipment. Each tool typically has a specific CFM rating, which indicates the minimum amount of air it needs to operate effectively. By adding up the CFM requirements of all your tools, you can determine the minimum CFM rating your air compressor should have.

Look for a High CFM Rating

To increase the CFM on an air compressor, you need to look for a compressor with a high CFM rating. The higher the CFM rating, the more air the compressor can deliver. This is particularly important if you are using multiple tools simultaneously or if you are working on projects that require a large volume of air.

Consider the Tank Size

In addition to the CFM rating, the size of the air compressor’s tank is also important. A larger tank can hold more air, allowing for a continuous flow without interruption. This is especially useful if your tools require a constant supply of air. By having a larger tank, you can ensure that the tools receive a consistent airflow, even during peak usage.

- Choose a compressor with a high CFM rating

- Consider the CFM requirements of your tools

- Look for a compressor with a larger tank size

- Determine the amount of air needed for your specific projects

By following these guidelines and selecting the right air compressor, you can increase the CFM and ensure that your tools and equipment receive the necessary amount of air for optimal performance.

Increasing CFM through Proper Maintenance and Upkeep

Regular Cleaning of Filters and Vents

One of the most effective ways to increase CFM on an air compressor is through regular cleaning of filters and vents. Over time, dust and debris can accumulate in these areas, restricting airflow and reducing the overall CFM output. By regularly cleaning the filters and vents, you can ensure that the air compressor operates at its maximum capacity, thus increasing the CFM.

Checking for Air Leaks

Air leaks can significantly impact the CFM output of an air compressor. Even small leaks can cause a decrease in airflow and ultimately reduce the overall CFM. Therefore, it is crucial to regularly check for any air leaks and promptly repair them. Inspect the hoses, fittings, and connections for any signs of leakage and seal them properly to increase the CFM.

Proper Lubrication

Proper lubrication is essential for the smooth and efficient operation of an air compressor. Lubricating the moving parts, such as pistons and valves, reduces friction and minimizes energy loss, ultimately increasing the CFM. Make sure to follow the manufacturer’s recommendations for lubrication frequency and use the appropriate lubricant for your specific air compressor.

Optimizing the Air Pressure

Adjusting the air pressure to optimal levels can also help increase the CFM output. High pressure settings can result in unnecessary energy consumption, while low pressure settings can limit the airflow. It is important to find the right balance by adjusting the pressure regulator according to the specific requirements of your air tools or equipment, thereby maximizing the CFM.

Professional Inspection and Maintenance

Regular professional inspection and maintenance of the air compressor is crucial for maximizing CFM. Trained technicians can identify any underlying issues or potential problems that may be affecting the CFM output. They can perform necessary repairs, adjustments, or parts replacements, ensuring that the air compressor operates at its peak performance and delivers the highest CFM possible.

In conclusion, increasing CFM on an air compressor can be achieved through proper maintenance and upkeep. Regular cleaning of filters and vents, checking for air leaks, proper lubrication, optimizing air pressure, and professional inspection and maintenance are all essential steps in maximizing the CFM output. By implementing these measures, you can ensure that your air compressor operates efficiently and effectively, delivering the required airflow for your applications.

Upgrading the Components to Boost CFM

If you want to increase the CFM (cubic feet per minute) of your air compressor, one effective way to achieve this is by upgrading its components. By replacing certain parts with more efficient ones, you can enhance the overall performance of the compressor and achieve a higher CFM rating.

1. Replace the cylinder head

The cylinder head is a critical component of an air compressor as it plays a crucial role in compressing the air. By upgrading to a larger and more efficient cylinder head, you can increase the capacity of the compressor and boost the CFM output. Look for a cylinder head with larger valves, better flow characteristics, and superior sealing properties.

2. Upgrade the motor

The motor is responsible for powering the air compressor, and upgrading it can have a significant impact on the CFM output. Consider replacing the existing motor with a higher horsepower motor that can deliver more power and torque. A more powerful motor will enable the compressor to operate at higher speeds, resulting in increased air flow and CFM.

3. Install a larger air tank

The size of the air tank directly affects the CFM output of an air compressor. By installing a larger air tank, you can store a larger volume of compressed air, which can be released at a higher flow rate, thereby increasing the overall CFM. Look for a tank that is larger in capacity and designed to handle higher pressure levels.

4. Upgrade the air filters and intake system

Air filters and intake systems play a crucial role in ensuring clean and efficient air intake. By upgrading to high-flow air filters and improving the intake system, you can enhance the airflow into the compressor, leading to increased CFM. Look for filters with a larger surface area, lower restriction, and improved filtration efficiency.

5. Consider a two-stage compressor

If you require a significant boost in CFM, you may consider upgrading to a two-stage compressor. Two-stage compressors have an additional piston that delivers compressed air to the second stage, resulting in higher CFM output. This type of compressor is more efficient and is capable of delivering higher volumes of compressed air.

By upgrading the components of your air compressor, you can increase its CFM output and ensure better performance for your air tools and equipment. Each upgrade should be carefully chosen to match your specific needs and the specifications of your compressor.

Optimizing Air Flow and Ventilation for Better CFM

When it comes to increasing the CFM (cubic feet per minute) on an air compressor, optimizing air flow and ventilation is crucial. By improving the efficiency of the air flow, you can ensure a higher output of compressed air, resulting in increased CFM.

1. Clearing Obstructions

One of the simplest ways to optimize air flow is by clearing any obstructions in the air compressor system. This includes removing any debris, dust, or obstructions that may be blocking the intake or exhaust vents. A clean and clear airflow path will ensure better performance and increased CFM.

2. Upgrading Air Filters

Another way to improve air flow and ventilation is by upgrading the air filters. Higher quality air filters with better filtration can help remove contaminants and improve the quality of the air being compressed. This can result in smoother airflow and a higher CFM output.

3. Increasing Pipe Diameter

If you’re looking to optimize air flow and ventilation in the piping system, consider increasing the pipe diameter. Larger pipes have a higher capacity for airflow, allowing for better CFM. By upgrading to larger diameter pipes, you can reduce pressure drops and improve the overall efficiency of the compressed air system.

4. Proper Ventilation

In addition to optimizing the air compressor itself, it’s important to ensure proper ventilation in the compressor room. A well-ventilated space will help dissipate heat and prevent the compressor from overheating. This can improve the overall efficiency and performance of the air compressor, resulting in better CFM.

In conclusion, optimizing air flow and ventilation is key to increasing the CFM on an air compressor. By clearing obstructions, upgrading air filters, increasing pipe diameter, and ensuring proper ventilation, you can maximize the efficiency and output of your compressed air system. Higher CFM means more power and productivity for your air compressor.

FAQ:

What is CFM? How does it relate to an air compressor?

CFM stands for Cubic Feet per Minute, and it is a unit of measure that indicates the airflow rate of an air compressor. CFM is an important factor to consider when choosing an air compressor, as it determines the ability of the compressor to supply the necessary volume of air for various applications.

What are some ways to increase the CFM on an air compressor?

There are several ways to increase the CFM on an air compressor. One option is to upgrade the power source, such as using a larger motor or a higher voltage electrical supply. Another way is to improve the compressor’s intake and exhaust systems to reduce air resistance. Additionally, using larger air lines and fittings, as well as maintaining proper compressor maintenance, can help increase the CFM.

Is it possible to increase the CFM of an air compressor without making any modifications?

No, it is not possible to increase the CFM of an air compressor without making any modifications. The CFM is primarily determined by the size and design of the compressor and its components. However, there are ways to optimize the performance and efficiency of an air compressor to get the most out of its existing CFM rating.

What are the benefits of increasing the CFM on an air compressor?

Increasing the CFM on an air compressor can have several benefits. It allows for a higher airflow rate, which is essential for applications that require a larger volume of air. This can improve the productivity and efficiency of tools and equipment powered by the air compressor. Additionally, it can reduce the risk of the compressor overheating or experiencing pressure drops during operation.

Are there any limitations to increasing the CFM on an air compressor?

Yes, there are limitations to increasing the CFM on an air compressor. The compressor’s design and components set a maximum limit on the CFM that it can produce. Attempting to increase the CFM beyond this limit can lead to equipment damage or failure. It is important to consult the manufacturer’s guidelines and seek professional advice before making any modifications to the air compressor.

Video: