Understanding the Purpose and Function of a 3 Phase Air Compressor

A 3 phase air compressor is a powerful tool that is widely used in various industries for its efficiency and reliability.

Unlike single phase air compressors, which rely on a single alternating current (AC) to power the motor, a 3 phase air compressor utilizes three separate AC power lines. This allows for a more balanced and consistent power supply, resulting in a smoother operation and increased performance.

One of the main advantages of a 3 phase air compressor is its ability to generate higher levels of compressed air at a lower energy consumption compared to single phase compressors. This is especially beneficial for applications that require continuous and heavy-duty operation, such as manufacturing plants, construction sites, and automotive workshops.

In addition to its efficiency, a 3 phase air compressor also offers greater reliability and durability. The use of three power lines distributes the load evenly among the motor windings, reducing the risk of overheating and extending the lifespan of the compressor. This makes it a cost-effective investment for businesses looking for a long-term solution for their compressed air needs.

In conclusion, a 3 phase air compressor is a versatile and efficient tool that is essential for many industrial applications. Its ability to generate higher levels of compressed air while consuming less energy makes it a valuable asset for businesses looking to increase productivity and reduce operating costs. With its reliability and durability, a 3 phase air compressor is a worthy investment for any industry.

The Basics of Air Compression

To understand the purpose and function of a 3 phase air compressor, it is essential to grasp the basics of air compression. Air compression is the process of reducing the volume of a gas to increase its pressure. It is widely used in various industries, including manufacturing, construction, and automotive, to power tools and machinery.

How does air compression work?

The process of air compression involves three main stages: intake, compression, and discharge.

- Intake: During the intake stage, the compressor draws in atmospheric air through an intake valve. The air is then filtered to remove any contaminants, such as dust or moisture.

- Compression: In the compression stage, the air is compressed using a piston or other mechanisms. The compression increases the pressure of the air while reducing its volume. The compressed air is stored in a tank or receiver for future use.

- Discharge: The compressed air is released from the tank or receiver through a discharge valve. It is then directed through pipes or hoses to the desired location or equipment.

Why is air compression important?

Air compression is vital for many industrial applications due to its unique properties and advantages. Compressed air can be easily stored and transported, making it a versatile source of power. It can be used to operate machinery, tools, and equipment, such as pneumatic drills, sanders, painting systems, and more.

Furthermore, compressed air is clean and does not leave behind residue or waste, making it suitable for applications where cleanliness is crucial, such as in food processing or pharmaceutical industries. It also offers a high power-to-weight ratio, allowing it to deliver a significant amount of power in compact systems.

In summary, air compression is a fundamental process that enables the use of compressed air in various industries. Understanding how it works and its importance can help in comprehending the purpose and function of a 3 phase air compressor and its role in powering essential tools and equipment.

Why 3 Phase Power is Important

Three phase power is an important aspect of electrical systems, especially for industrial applications. Unlike single phase power, which consists of a single alternating waveform, three phase power consists of three alternating waveforms that are 120 degrees out of phase with each other. This arrangement offers several advantages over single phase power.

Increased Power Capacity

One of the main advantages of three phase power is its increased power capacity. The three overlapping waveforms allow for a continuous flow of power, resulting in a smoother and more efficient operation of electrical devices and machinery. This increased power capacity is particularly beneficial for heavy-duty equipment, such as air compressors, which require a large amount of power to operate effectively.

Better Power Distribution

Another key benefit of three phase power is its ability to distribute power more evenly across a system. With single phase power, there can be fluctuations in voltage and current, resulting in an uneven distribution of power. In contrast, three phase power provides a balanced distribution of power, minimizing the risk of overloading any one phase and ensuring a more stable power supply.

Cost Savings

Three phase power can also lead to cost savings in certain applications. Due to its increased power capacity and better power distribution, three phase systems can operate more efficiently, requiring less energy overall. This can result in lower electricity bills and reduced energy consumption, making three phase power an economical choice for industrial facilities that rely on high-power equipment.

In conclusion, three phase power plays a crucial role in industrial applications, offering increased power capacity, better power distribution, and potential cost savings. Its advantages make it a preferred choice for powering heavy-duty machinery and equipment, such as air compressors, and ensure a reliable and efficient operation of electrical systems.

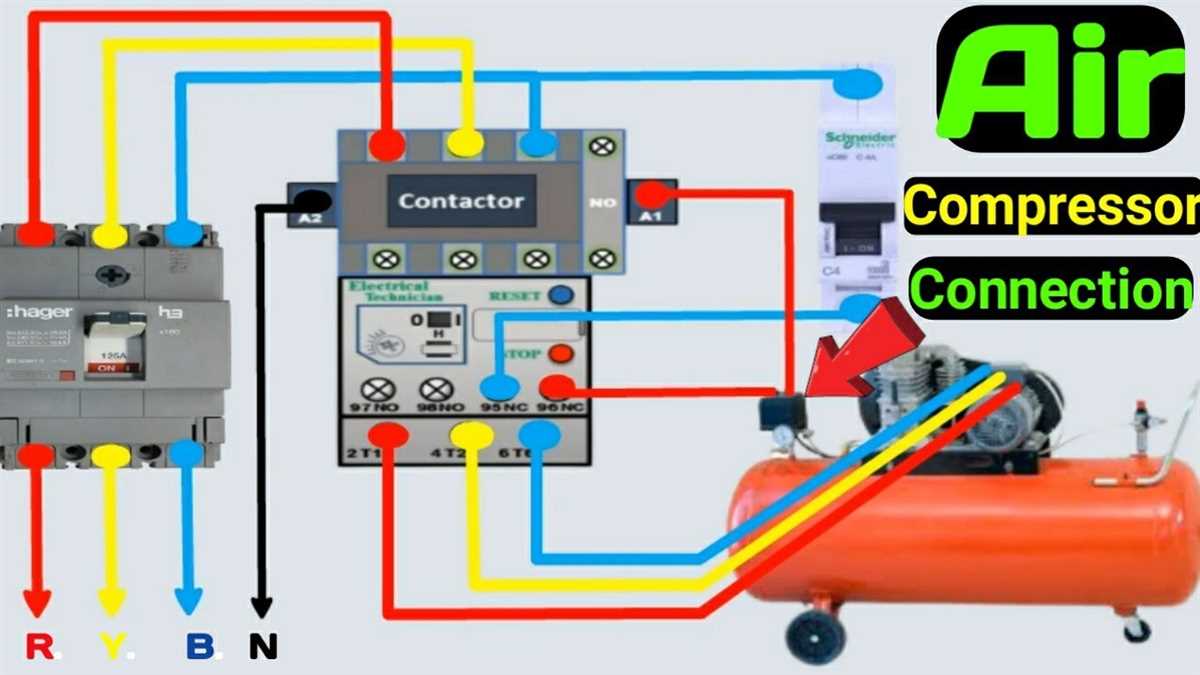

The Components of a 3 Phase Air Compressor

A 3 phase air compressor consists of several key components that work together to generate and supply compressed air. Understanding the different components of a 3 phase air compressor is essential for proper operation and maintenance of the system.

1. Motor:

The motor is a crucial component of a 3 phase air compressor as it provides the power to drive the compressor pump. It converts electrical energy into mechanical energy, which is then used to compress the air. The motor can be an induction motor or a synchronous motor, depending on the specific design of the air compressor.

2. Compressor Pump:

The compressor pump is responsible for drawing in ambient air and compressing it to a higher pressure. It consists of a cylinder, piston, and valves. As the piston moves down, it creates a vacuum that allows the air to enter the cylinder. As the piston moves up, the air is compressed and forced out through the discharge valve.

3. Pressure Switch:

The pressure switch is a control device that monitors the air pressure in the compressor tank. It automatically turns on the motor when the pressure drops below a certain level and turns off the motor when the pressure reaches a set upper limit. This ensures that the compressor operates within a safe pressure range and helps prevent the risk of overloading the system.

4. Air Receiver Tank:

The air receiver tank is a storage tank that holds the compressed air generated by the compressor pump. It acts as a reservoir, ensuring a steady supply of compressed air and reducing the load on the compressor motor. The tank also helps in cooling the compressed air and separating any moisture or contaminants present in the air.

5. Air Filters:

Air filters are used to remove dust, debris, and other particles from the compressed air before it is used in pneumatic tools or equipment. They help prevent damage to the tools and ensure clean and efficient operation. The air filters can be located both before and after the air receiver tank to ensure maximum filtration.

6. Safety Valves:

Safety valves are designed to release excess pressure from the compressor system to prevent the tank from over-pressurizing. They are typically set to open at a specific pressure above the maximum operating pressure of the compressor. Safety valves are an important safety feature that helps protect the system from potential damage and ensures safe operation.

Overall, the components mentioned above are essential for the proper functioning of a 3 phase air compressor. Each component plays a crucial role in generating, storing, and delivering compressed air efficiently and safely.

How a 3 Phase Air Compressor Works

A 3 phase air compressor is a powerful machine that is used to generate and store compressed air. It consists of several key components that work together to provide the necessary pressure to power tools and machinery.

At the core of a 3 phase air compressor is an electric motor, which is connected to a compressor pump. The motor, driven by three-phase electrical power, provides the mechanical energy needed to drive the compressor pump. This motor is designed to handle the high power requirements of an air compressor, allowing it to generate large volumes of compressed air.

The compressor pump itself is responsible for actually compressing the air. It typically consists of one or more pistons that move up and down within cylinders. As the pistons move, they create a partial vacuum on the downstroke, which draws air into the cylinder. On the upstroke, the pistons compress the air, increasing its pressure. This compressed air is then forced into a storage tank, ready to be used when needed.

In addition to the motor and compressor pump, a 3 phase air compressor also has a variety of control devices. These devices are designed to monitor and regulate the operation of the compressor, ensuring that it runs smoothly and efficiently. They may include pressure switches, safety valves, and gauges to monitor the pressure levels and prevent over-pressurization. Additionally, some air compressors may have filters and dryers to remove contaminants and moisture from the air, ensuring that the compressed air is clean and dry.

Overall, a 3 phase air compressor works by using an electric motor to power a compressor pump, which compresses air and stores it in a tank. The compressed air can then be used to power tools and equipment, making it a valuable resource in many industrial and commercial settings.

The Benefits of Using a 3 Phase Air Compressor

Efficiency: One of the key benefits of using a 3 phase air compressor is its efficiency. Unlike single phase compressors, which rely on a single power source, 3 phase compressors use three power sources, allowing for a more evenly distributed load. This results in smoother operation, reduced strain on the motor, and increased energy efficiency. Additionally, 3 phase compressors often have higher horsepower ratings, allowing them to handle larger air demands more easily.

Reliability: Another advantage of using a 3 phase air compressor is its reliability. With three power sources, 3 phase compressors are less likely to experience voltage drops or power surges, which can cause damage to the motor and other components. This reliability is especially important in industrial and commercial settings where a stable air supply is critical for productivity.

Durability: 3 phase air compressors are typically built to withstand heavy-duty use. They are designed with robust components and construction to handle the demanding requirements of industrial applications. This makes them more durable and less susceptible to wear and tear, resulting in longer service life and reduced maintenance costs.

Flexibility: Using a 3 phase air compressor provides greater flexibility in terms of power distribution. Industrial and commercial facilities often have 3 phase power available, making it convenient to use a 3 phase compressor. Additionally, 3 phase compressors can be more easily adapted to specific power supply configurations, allowing for easy integration into existing electrical systems.

Cost Savings: While 3 phase air compressors may have a higher initial cost compared to single phase compressors, they can offer significant cost savings in the long run. The increased energy efficiency of 3 phase compressors can result in lower electricity bills, and their durability can reduce the need for frequent repairs or replacements. Furthermore, the ability to handle larger air demands can result in increased productivity, further contributing to cost savings.

Noise Reduction: 3 phase air compressors are often quieter compared to single phase compressors. The balanced load distribution in 3 phase compressors results in smoother operation, reducing vibrations and noise levels. This can be particularly beneficial in settings where noise control is important, such as residential areas or noise-sensitive environments.

Common Applications for 3 Phase Air Compressors

Industrial Manufacturing

One of the most common applications for 3 phase air compressors is in industrial manufacturing. These compressors are used to power a wide range of pneumatic tools and equipment, such as air hammers, impact wrenches, and nail guns. They provide the necessary air pressure and volume to operate these tools efficiently, allowing for faster and more precise work in manufacturing processes.

Construction and Building

In the construction and building industry, 3 phase air compressors are essential for powering various tools and equipment. They are used for tasks such as operating jackhammers, pneumatic nail guns, spray painting, and powering air tools like sanders and grinders. The high air pressure and volume provided by these compressors are necessary for completing construction projects efficiently and effectively.

Automotive Repair and Service

3 phase air compressors are widely used in automotive repair and service shops. They are used to power air tools such as impact wrenches, pneumatic ratchets, and airbrushes. These compressors are crucial for efficient tire changing, engine repair, and other tasks that require the use of pneumatic tools in the automotive industry.

Painting and Finishing

For painting and finishing applications, 3 phase air compressors are often used to power spray guns and other pneumatic painting equipment. These compressors provide the necessary air pressure and volume to atomize paint and apply a uniform coat on surfaces. They are commonly utilized in industries such as automotive painting, furniture manufacturing, and commercial painting.

Food and Beverage Processing

In the food and beverage processing industry, 3 phase air compressors are used for various applications. They are often utilized to power pneumatic equipment used for packaging, filling, and sealing processes. These compressors ensure that the air used in food processing meets the required quality standards and does not contaminate the products.

Other Applications

Aside from the industries mentioned above, 3 phase air compressors find uses in other applications such as pharmaceutical manufacturing, HVAC systems, pneumatic conveying systems, and more. They provide the necessary air power for a wide range of industrial and commercial processes that require compressed air.

Considerations When Choosing a 3 Phase Air Compressor

1. Power Requirements

When choosing a 3 phase air compressor, one of the most important considerations is the power requirements. It is crucial to ensure that the compressor is compatible with the available power supply in your facility. 3 phase air compressors typically require a specific voltage and phase configuration, so it is essential to check the electrical specifications of the compressor and compare them with your power supply capacity.

2. Air Pressure and Flow

Another crucial factor to consider is the desired air pressure and flow rate. The air compressor should be able to provide the necessary pressure and flow to meet your specific requirements. It is essential to consider the type of applications you will be using the compressor for and choose a model that can deliver the appropriate air pressure and flow.

3. Tank Size

The size of the air tank is also an important factor to consider. The tank size determines the amount of compressed air that can be stored and used. Depending on your needs, you may require a larger tank for continuous use or a smaller tank for intermittent use. It is important to choose a tank size that can meet your specific usage requirements.

4. Noise Level

Noise level is another important consideration, especially if the compressor will be used in a noise-sensitive environment. Some 3 phase air compressors can be quite loud, so it is essential to choose a model that has a low noise level. Look for compressors that are designed with noise reduction features or have sound insulation to minimize noise during operation.

5. Durability and Maintenance

When choosing a 3 phase air compressor, it is essential to consider its durability and maintenance requirements. Look for compressors that are built with high-quality materials and components, as they are likely to be more durable and less prone to breakdowns. Additionally, consider the ease of maintenance and availability of spare parts for the compressor.

Overall, when choosing a 3 phase air compressor, it is important to consider factors such as power requirements, air pressure and flow, tank size, noise level, and durability. By carefully evaluating these considerations, you can select a compressor that will meet your specific needs and provide reliable performance for years to come.

Maintenance Tips for a 3 Phase Air Compressor

Check the air filters

Regularly inspect and clean the air filters of your 3 phase air compressor. Dirty air filters can restrict airflow and cause the compressor to work harder, leading to increased energy consumption and potential damage. Cleaning or replacing the air filters as needed will ensure optimal performance and longevity of your compressor.

Monitor the oil level

Keep an eye on the oil level in your 3 phase air compressor. Proper lubrication is essential for the smooth operation of the compressor’s moving parts. If the oil level is low, top it up with the recommended oil type and viscosity. Regularly changing the oil as per the manufacturer’s instructions will prevent excessive wear and extend the lifespan of your compressor.

Inspect the belts and hoses

Check the condition of the belts and hoses in your 3 phase air compressor. Over time, belts may become loose or worn out, and hoses may develop cracks or leaks. Replace any damaged belts or hoses to prevent further damage and ensure that the compressor operates at its full capacity. Regular maintenance and inspection of these components will help avoid costly repairs.

Drain the condensate

Condensate, a byproduct of compressed air, can accumulate in the tank of a 3 phase air compressor. Draining the condensate regularly is important to prevent corrosion inside the tank. Use the condensate drain valve to release any accumulated water. Additionally, consider installing a moisture trap or air dryer to remove excess moisture from the compressed air system.

Keep the compressor clean

Maintain a clean environment around the 3 phase air compressor and regularly remove any dust, debris, or other contaminants that may accumulate on the compressor’s surfaces. This will help prevent airflow restrictions, ensure proper cooling, and prevent premature wear and damage to the compressor components. Use a soft cloth or brush to clean the exterior surfaces of the compressor.

By following these maintenance tips, you can ensure the reliable performance and longevity of your 3 phase air compressor. Regular upkeep and inspection will help identify and address potential issues before they become major problems, saving you time and money in the long run. Consult the manufacturer’s manual for specific maintenance instructions and intervals.

FAQ:

What is a 3 phase air compressor?

A 3 phase air compressor is a type of air compressor that operates using three phases of electric power instead of a single phase. This allows for greater power output and efficiency.

What is the purpose of a 3 phase air compressor?

The purpose of a 3 phase air compressor is to generate and supply compressed air for various industrial applications. It is commonly used in manufacturing plants, automotive repair shops, and construction sites.

How does a 3 phase air compressor work?

A 3 phase air compressor works by using an electric motor to drive a piston or rotary element. The motor converts the electrical energy from the three-phase power supply into mechanical energy, which is used to compress the air.

What are the advantages of a 3 phase air compressor over a single phase compressor?

A 3 phase air compressor offers several advantages over a single phase compressor. It provides higher power output, which allows it to handle larger and more demanding applications. Additionally, it operates more efficiently and with less noise.

What are the key components of a 3 phase air compressor?

The key components of a 3 phase air compressor include the electric motor, compressor unit (piston or rotary), air receiver tank, pressure switch, and various valves and controls. Each component plays a vital role in the overall function of the compressor.

What maintenance is required for a 3 phase air compressor?

A 3 phase air compressor requires regular maintenance to ensure optimal performance and longevity. This includes checking and replacing filters, lubricating moving parts, inspecting electrical connections, and monitoring oil levels. It is also important to drain any accumulated moisture from the air receiver tank.

Video: