Understanding the Operation of a Rotary Screw Air Compressor

A rotary screw air compressor is a type of mechanical device used to compress air. It works by trapping air between two helical rotors and compressing it as the rotors rotate. This type of compressor is commonly used in various industries, such as manufacturing, construction, and automotive, due to its high efficiency and reliability.

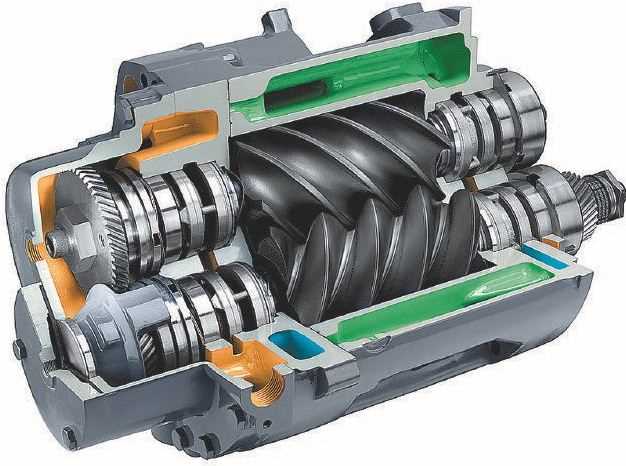

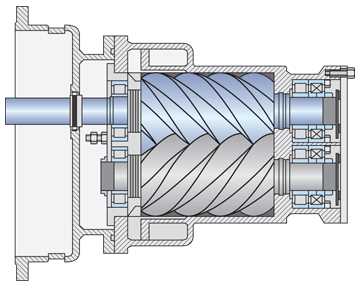

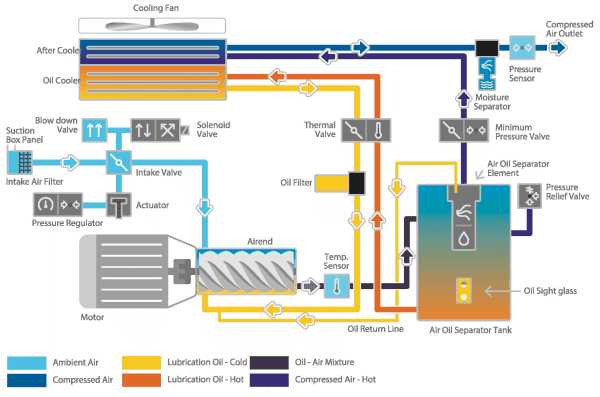

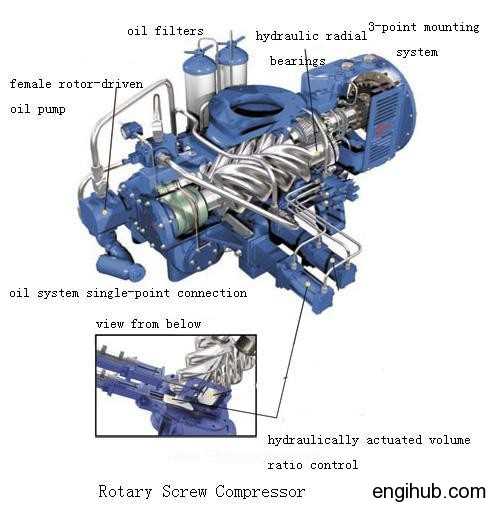

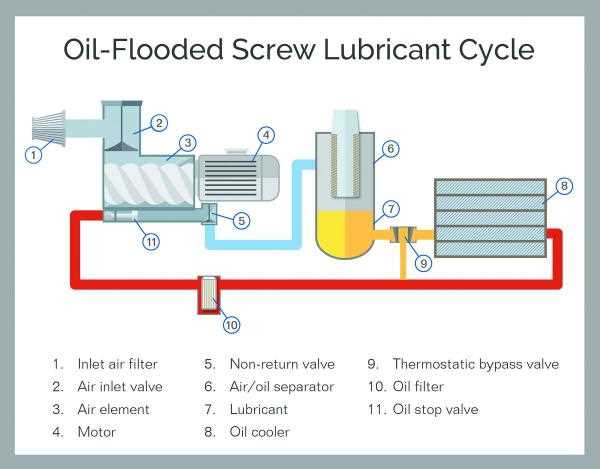

The main components of a rotary screw air compressor include the rotors, housing, air intake filter, oil separator, air/oil cooler, and control panel. The rotors are the heart of the compressor and are responsible for compressing the air. The housing provides a sealed environment for the compression process, while the air intake filter cleans the incoming air before it enters the compressor.

In the compression process, the rotors mesh together, trapping a volume of air between them. As the rotors rotate, the trapped air is compressed and gradually expelled out of the compressor through the discharge outlet. To ensure efficient operation and prevent overheating, the air/oil cooler is used to cool down the compressed air and lubrication oil. The oil separator separates the compressed air and oil, allowing the oil to be recycled back into the compressor for lubrication.

The control panel of a rotary screw air compressor allows the operator to monitor and adjust various parameters, such as the pressure, temperature, and operating mode. It also provides safety features, such as pressure relief valves and automatic shutdown systems, to prevent any potential damage or accidents.

In conclusion, a rotary screw air compressor is a crucial component in many industries, providing a reliable and efficient source of compressed air. Understanding its operation and components can help ensure its proper maintenance and performance, ultimately contributing to the smooth operation of various manufacturing and construction processes.

What is a Rotary Screw Air Compressor?

A rotary screw air compressor is a type of air compressor that uses two rotating screws to compress air. It is commonly used in industrial settings for various applications such as powering pneumatic tools and machinery, supplying compressed air to production lines, and providing air for HVAC systems.

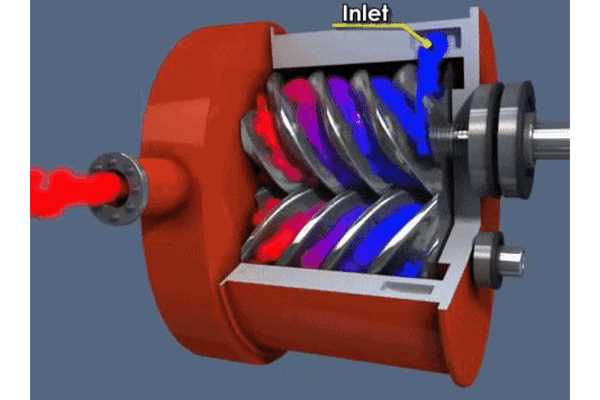

The compressor works by trapping air between the two rotors and compressing it as the rotors rotate. The screws have large helical grooves that mesh together, creating a seal and forcing the air to move towards the outlet. This continuous flow of air allows for efficient and consistent compression.

Rotary screw air compressors are known for their high efficiency and reliability. They are capable of providing a constant supply of compressed air with minimal vibration and noise. These compressors can also operate at high pressures, making them suitable for a wide range of applications.

One of the advantages of rotary screw compressors is their ability to provide continuous duty operation. They can run continuously without the need for frequent stops and starts, making them ideal for applications that require a constant supply of compressed air.

These compressors are available in various sizes and configurations to accommodate different needs. They can be stationary or portable, oil-lubricated or oil-free, and single-stage or multi-stage. The specific model and features will depend on the intended application and operating conditions.

Overview of Rotary Screw Air Compressor

A rotary screw air compressor is a type of positive displacement compressor that uses rotating screws to compress air. It is commonly used in industrial applications where a constant supply of compressed air is needed.

The compressor consists of two interlocking helical screws that trap and compress air as they rotate. The air is drawn into the compressor through an intake valve, which is then compressed and discharged through an outlet valve.

One of the key advantages of a rotary screw air compressor is its high efficiency. The continuous compression process allows for a steady output of compressed air, without the pulsations that are common with other types of compressors.

Rotary screw air compressors are also known for their quiet operation. The screw design helps to reduce noise levels, making them ideal for use in environments where noise is a concern.

These compressors are available in various sizes and capacities to meet the specific needs of different applications. They can be used for a wide range of tasks, such as powering pneumatic tools, operating machinery, and providing clean air for manufacturing processes.

In addition to their efficiency and quiet operation, rotary screw air compressors are also known for their durability and reliability. With proper maintenance, they can provide many years of trouble-free service.

Overall, a rotary screw air compressor is a versatile and reliable solution for providing a constant supply of compressed air in industrial settings. Its efficient operation and low noise levels make it an attractive choice for many applications.

How Does a Rotary Screw Air Compressor Work?

A rotary screw air compressor is a type of air compressor that utilizes two interlocking helical rotors to compress air and produce pressurized air. This type of compressor is commonly used in industrial settings and is known for its efficiency and reliability.

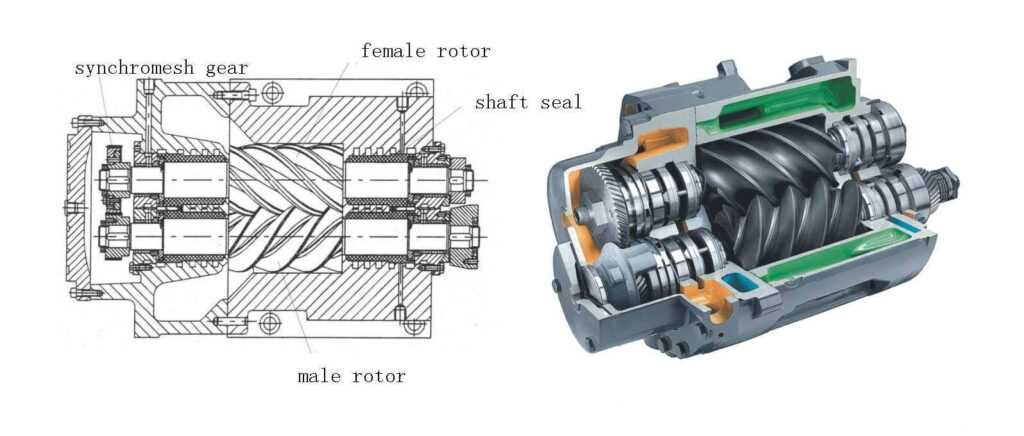

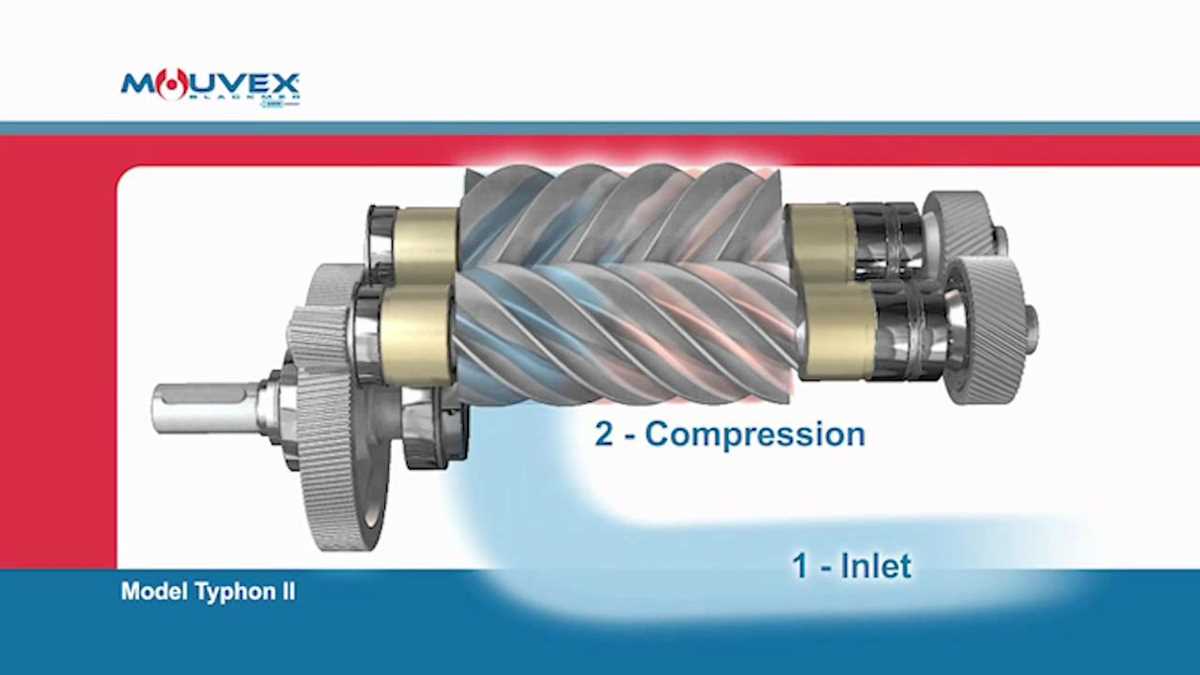

The operation of a rotary screw air compressor involves several key components. The two main components are the male and female rotors, which are typically made of high-quality steel and are precision-engineered to mesh together. As the rotors rotate, the air that enters the compressor is trapped between the rotors and the casing, and is compressed as the rotors continue to rotate.

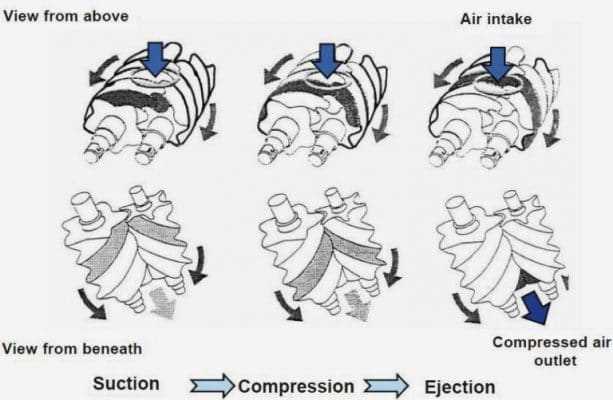

The compression process in a rotary screw air compressor can be broken down into four main stages:

- Inlet: The intake valve opens, and outside air is drawn into the compressor through a filter to remove any contaminants. The air then enters the compression chamber, where it is trapped between the rotors and the casing.

- Compression: As the rotors rotate, the air is compressed between the rotors and the casing. This compression process reduces the volume of the air and increases its pressure.

- Discharge: Once the air is compressed to the desired pressure, it is discharged from the compressor through an outlet valve. This pressurized air is then ready for use in various applications.

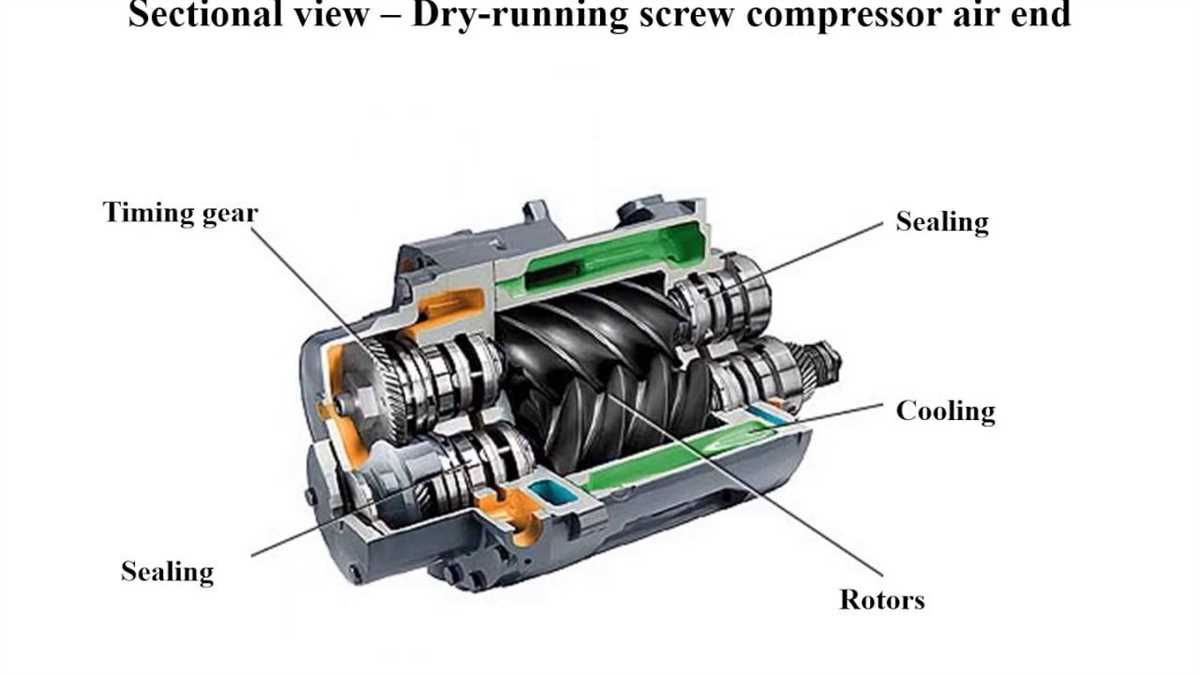

- Cooling: During the compression process, the air can become heated. To prevent overheating, rotary screw air compressors are equipped with cooling mechanisms, such as intercoolers and aftercoolers. These coolers help to reduce the temperature of the compressed air before it is discharged.

Overall, the design and operation of a rotary screw air compressor make it a highly efficient and reliable source of pressurized air. Its ability to continuously compress air ensures a steady supply of compressed air for various industrial applications.

Advantages of Using Rotary Screw Air Compressor

The rotary screw air compressor offers several advantages over other types of air compressors.

- Higher efficiency: Rotary screw air compressors are known for their high efficiency, which means they can produce more compressed air using less energy. This makes them a cost-effective choice for many industrial applications.

- Continuous operation: Unlike reciprocating air compressors, which have to cycle on and off to maintain pressure, rotary screw air compressors can operate continuously. This makes them ideal for applications where a constant supply of compressed air is required.

- Quiet operation: Rotary screw air compressors are designed to operate with minimal noise. This is especially important in settings where noise pollution is a concern, such as hospitals, schools, and offices.

- Low maintenance: Rotary screw air compressors are built to be durable and require minimal maintenance. This saves time and money on repairs and keeps the compressor running smoothly for extended periods.

In addition to these advantages, rotary screw air compressors also offer flexibility in terms of pressure and flow rate. They can be adjusted to meet different requirements and are compatible with a wide range of tools and equipment.

Overall, the use of a rotary screw air compressor can improve productivity, reduce energy consumption, and provide a reliable source of compressed air in various industrial and commercial settings.

Applications of Rotary Screw Air Compressor

1. Industrial Use

A rotary screw air compressor is widely used in various industrial applications due to its high efficiency and reliability. It is commonly used in manufacturing plants, automotive industries, chemical plants, and construction sites. The compressor provides a continuous supply of compressed air, which is essential for running pneumatic tools, operating machinery, and powering various processes.

2. HVAC Systems

Rotary screw air compressors are widely used in HVAC (Heating, Ventilation, and Air Conditioning) systems. These compressors play a crucial role in providing the required compressed air for cooling and ventilation purposes. They help in maintaining the desired air quality, temperature, and humidity levels in commercial buildings, hospitals, shopping malls, and other large-scale facilities.

3. Food and Beverage Industry

In the food and beverage industry, a rotary screw air compressor is used for various applications. It is commonly used for bottling, canning, packaging, and processing operations. The compressed air provided by the compressor is used for powering pneumatic machines, air knives, and air-operated conveyor systems. It ensures the hygiene and safety of food and beverage products by preventing contamination.

4. Oil and Gas Industry

The oil and gas industry heavily relies on rotary screw air compressors for various operations. These compressors are used for drilling, pipeline construction, gas compression, and storage operations. They provide the necessary compressed air for powering drilling rigs, pneumatic valves, and other equipment. The compressors are designed to withstand harsh environments and provide reliable performance in remote locations.

5. Pharmaceutical Industry

In the pharmaceutical industry, a clean and reliable source of compressed air is essential for maintaining hygiene and safety standards. Rotary screw air compressors are commonly used to supply compressed air for various processes, such as mixing, filling, and packaging medications. These compressors are designed to meet the strict regulations and guidelines set by the industry.

In conclusion, rotary screw air compressors have a wide range of applications in various industries. They provide a continuous and reliable source of compressed air, making them essential for powering pneumatic tools, operating machinery, and maintaining optimal air quality in different processes. Their efficiency, reliability, and ability to withstand demanding environments make them a preferred choice for industrial and commercial applications.

Factors to Consider When Choosing a Rotary Screw Air Compressor

Choosing the right rotary screw air compressor for your needs requires careful consideration of various factors. Here are some important factors to keep in mind:

1. Required Air Flow:

Determine the air flow requirements of your application. This is usually expressed in cubic feet per minute (CFM). Make sure to choose a rotary screw air compressor that can provide the required CFM to meet your needs.

2. Pressure Rating:

Consider the pressure rating needed for your application. The pressure rating is typically measured in pounds per square inch (PSI). It is important to choose a rotary screw air compressor that can deliver the required PSI for your specific requirements.

3. Power Source:

Consider the power source available at your location. Rotary screw air compressors can be powered by electricity or gas. Choose a compressor that is compatible with your power source to ensure efficient and reliable operation.

4. Size and Portability:

Consider the available space and portability requirements. Rotary screw air compressors come in various sizes and configurations. Choose a compressor that can fit within your available space and can be easily moved if necessary.

5. Noise Level:

If noise is a concern for your application, consider the noise level produced by the rotary screw air compressor. Some compressors are designed to operate quietly, which can be important in environments where noise control is necessary.

6. Maintenance Requirements:

Consider the maintenance requirements of the rotary screw air compressor. Some units may require more frequent maintenance, while others may have extended maintenance intervals. Determine how often maintenance tasks need to be performed and choose a compressor that fits your available resources and schedule.

7. Brand and Quality:

Consider the reputation and quality of the brand you are considering. Research the manufacturer and read customer reviews to ensure you are choosing a reliable and well-made rotary screw air compressor.

By considering these factors, you can make an informed decision when choosing a rotary screw air compressor that meets your specific needs and requirements.

Maintenance and Troubleshooting of Rotary Screw Air Compressor

Maintenance

Maintaining a rotary screw air compressor is essential to ensure its efficient operation and prolong its lifespan. Here are some key maintenance tasks:

- Regularly check and change the oil to maintain proper lubrication of the compressor’s internal components.

- Clean or replace the air filter to prevent dust and debris from entering the compressor system.

- Inspect the belts and pulleys for any signs of wear or damage, and replace them if necessary.

- Check and tighten any loose bolts or fittings to prevent air leakage.

- Monitor the compressor’s temperature and pressure levels to ensure they are within the recommended range.

Troubleshooting

Even with proper maintenance, issues may still arise with a rotary screw air compressor. Here are some common troubleshooting steps:

- If the compressor fails to start, check the power supply and ensure it is connected properly.

- If the compressor is producing insufficient air pressure, check for any air leaks and repair them as necessary.

- If the compressor is making unusual noise, inspect the bearings and replace them if damaged.

- If there is excessive oil carryover in the compressed air, check the separator element and replace it if necessary.

- If the compressor is running but not producing any air, check the intake valve and clean or replace it if needed.

It is important to consult the manufacturer’s manual or seek professional assistance for any complex maintenance or troubleshooting tasks.

Costs and Efficiency of Rotary Screw Air Compressor

Operating Costs

Rotary screw air compressors offer cost savings in the long run due to their energy efficiency. These compressors operate at a higher capacity than reciprocating compressors, resulting in lower operating costs. They use a rotary screw mechanism that requires less energy to turn the air into pressure, reducing electricity usage. Additionally, these compressors have lower maintenance costs as they have fewer moving parts that can wear out over time.

Energy Efficiency

Rotary screw air compressors are designed with energy efficiency in mind. They have a high air output combined with low energy consumption, making them an economical choice for businesses. These compressors use a rotary screw mechanism that can supply a constant flow of compressed air, ensuring that the air pressure remains stable without frequent stops and starts. This efficiency allows businesses to save on energy costs while maintaining reliable air pressure for their operations.

Types of Rotary Screw Compressors

Oil-injected screw compressors:

These compressors inject oil into the compression chamber to cool and lubricate the internal components. The oil also helps to seal the gaps between the screws, minimizing air leakage. This type of compressor is more common and cost-effective.

Oil-free screw compressors:

These compressors do not use oil for lubrication and cooling. Instead, they use other methods such as water or air cooling. Oil-free compressors are suitable for applications where oil contamination is a concern, such as in food and pharmaceutical industries. However, they are generally more expensive and require more maintenance compared to oil-injected compressors.

Factors Affecting Efficiency

- Compressor size: A correctly sized compressor is essential for optimal efficiency. A compressor that is too small will result in inadequate air supply, while a compressor that is too large will consume unnecessary energy.

- Pressure control: Maintaining consistent and appropriate air pressure helps to optimize efficiency. Using pressure regulators and controls can ensure that the compressor operates at the required pressure levels.

- Air leaks: Identifying and fixing air leaks in the compressed air system can significantly improve efficiency. Leaks waste compressed air and require the compressor to work harder, leading to increased energy consumption.

- Proper maintenance: Regular maintenance and servicing of the compressor are crucial for maintaining efficiency. This includes cleaning or replacing air filters, checking and adjusting belts and pulleys, and inspecting and repairing any worn-out components.

Conclusion

Rotary screw air compressors offer cost savings through their energy efficiency and low operating costs. These compressors are designed to provide a constant flow of compressed air while minimizing energy consumption. Choosing the appropriate compressor size, maintaining consistent air pressure, addressing air leaks, and conducting regular maintenance are all factors that contribute to enhancing efficiency and reducing costs in the long run.

FAQ:

What is a rotary screw air compressor?

A rotary screw air compressor is a type of air compressor that uses two helical screws to compress air. It is commonly used in industrial applications to provide a continuous supply of compressed air.

How does a rotary screw air compressor work?

A rotary screw air compressor works by using two helical screws (rotors) that rotate in opposite directions. As the screws turn, air is trapped between them and the compressor housing, and is compressed as the screws come together. This compressed air is then discharged at high pressure.

What are the advantages of a rotary screw air compressor?

A rotary screw air compressor offers several advantages over other types of compressors. It provides a continuous supply of compressed air, has a high output capacity, operates quieter than reciprocating compressors, and requires less maintenance.

How should a rotary screw air compressor be maintained?

Maintaining a rotary screw air compressor involves regular checks and maintenance tasks. This includes checking and changing the oil, inspecting and replacing filters, cleaning the compressor’s cooling system, and regularly monitoring the compressor’s performance and functions.

Video: