Understanding the Mechanism of a Pressure Switch in an Air Compressor

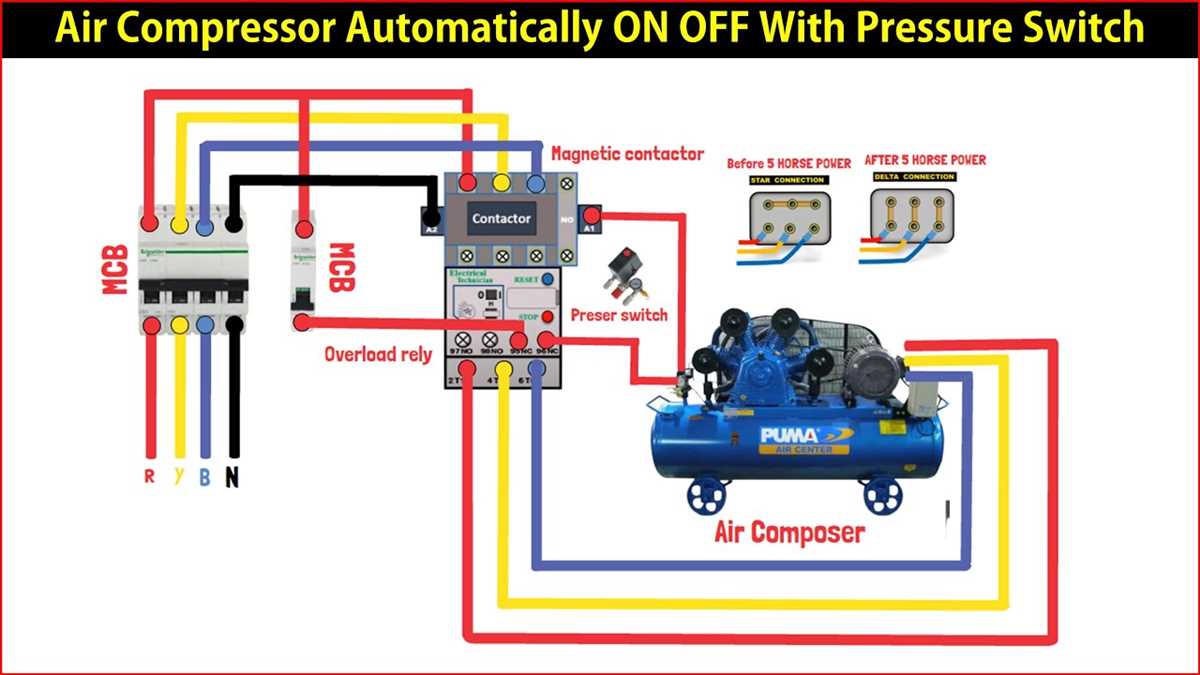

Pressure switches play a vital role in the functioning of an air compressor. They are responsible for monitoring the pressure level in the compressor and regulating its operation accordingly. A pressure switch acts as a control device that detects changes in pressure and sends a signal to the compressor to start or stop based on predefined thresholds.

The mechanism of a pressure switch is relatively simple yet crucial for the efficiency and safety of an air compressor. It consists of a diaphragm, a pressure sensor, and an electrical switch. When the pressure in the compressor reaches a certain threshold, the diaphragm flexes and activates the pressure sensor. The pressure sensor then triggers the electrical switch, either completing or breaking the circuit that controls the compressor motor.

One of the key functions of a pressure switch is to prevent excessive pressure in the air compressor. If the pressure exceeds a certain limit, the pressure switch will automatically shut off the compressor to prevent any damage or safety hazards. On the other hand, if the pressure drops too low, the pressure switch will signal the compressor to start again and restore the desired pressure level.

Understanding the mechanism of a pressure switch in an air compressor is essential for ensuring its proper operation and preventing any potential issues. By monitoring and regulating the pressure levels effectively, a pressure switch helps maintain the optimal performance of the compressor and prolong its lifespan. In addition, it enhances the overall safety by preventing over-pressurization and potential accidents that could occur if the pressure is not properly controlled.

The Anatomy of a Pressure Switch

A pressure switch is a vital component of an air compressor that controls its operation by monitoring the pressure levels within the system. It is responsible for automatically turning the compressor on and off based on the desired pressure settings.

A pressure switch typically consists of several key components. The first component is the housing, which encloses and protects the inner workings of the switch. The housing is usually made of durable materials like metal or plastic to withstand the rigors of the compressor’s environment.

The second component is the diaphragm, which is a flexible membrane that reacts to changes in pressure. The diaphragm is made of a material that can expand or contract as the pressure increases or decreases. This movement of the diaphragm triggers the switch mechanism, allowing it to control the flow of electricity and signaling the compressor to turn on or off.

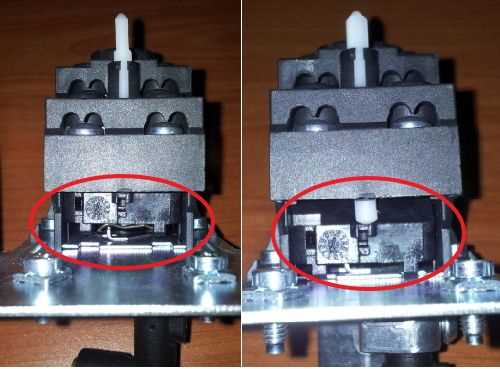

Inside the pressure switch, there are also electrical contacts that are responsible for completing or interrupting the circuit. When the pressure exceeds the set limit, the contacts close, allowing electricity to flow through and activate the compressor. Conversely, when the pressure drops below the set limit, the contacts open, breaking the circuit and stopping the compressor from operating.

In addition, some pressure switches may have adjustable settings that allow users to customize the pressure activation and deactivation points. These adjustable settings can be manipulated by turning screws or knobs on the pressure switch, allowing for precise control over the compressor’s operation.

The anatomy of a pressure switch showcases the intricate design and functionality that enables it to accurately monitor and control the pressure in an air compressor system. Its various components work in harmony to ensure the compressor operates efficiently and safely, preventing any potential damage or malfunction.

Understanding the Function of a Pressure Switch in an Air Compressor

A pressure switch is an essential component in an air compressor that is responsible for monitoring and controlling the pressure level within the system. It plays a crucial role in ensuring the compressor operates efficiently and safely. The main function of a pressure switch is to automatically regulate the compressor’s motor, turning it on and off at specific pressure points.

Pressure Sensing: The pressure switch is equipped with a sensing element, usually a diaphragm or a bellows, that detects changes in the air pressure. When the pressure in the system reaches a predetermined level, the sensing element is activated, initiating a response from the pressure switch.

Pressure Regulation: Once the pressure switch detects that the air pressure has reached a certain threshold, it sends a signal to the compressor’s motor to shut off, stopping the compression process. This prevents over-pressurization and potential damage to the compressor components.

Pressure Control: The pressure switch also controls the starting and stopping of the compressor’s motor based on the desired pressure range. When the pressure drops below a predetermined level, the pressure switch activates the motor, allowing it to start working again and restore the air pressure to the required level.

Safety Features: Many pressure switches include safety features such as overload protection and emergency shut-off. If the pressure in the system exceeds a certain limit, the pressure switch will activate these safety measures to prevent any damage or accidents from occurring.

Adjustability: Pressure switches often have adjustable settings, allowing users to set the desired pressure range for their specific application. This flexibility allows for customization to meet the requirements of different air compressor systems.

Indication: Some pressure switches are equipped with visual indicators, such as LED lights or gauges, to provide a visual representation of the pressure levels. This allows the user to easily monitor the system’s pressure status and make necessary adjustments as needed.

Overall, a pressure switch is a vital component in an air compressor that ensures optimal performance, efficiency, and safety. By accurately sensing, regulating, and controlling the pressure, it helps maintain the desired air pressure within the system and prevents any potential damage or dangers associated with over-pressurization.

How Does a Pressure Switch Work?

A pressure switch is a critical component of an air compressor as it helps to regulate the pressure levels and ensure the proper functioning of the compressor.

At its core, a pressure switch works by monitoring the air pressure inside the compressor tank and controlling the operation of the motor or pump based on the pressure levels. When the pressure in the tank reaches a certain pre-set level, the pressure switch will detect it and send a signal to stop the motor or pump, preventing the tank from overpressurizing. On the other hand, if the pressure drops below a certain threshold, the pressure switch will send a signal to start the motor or pump again, allowing the tank to build up pressure once more. This cyclical process helps to maintain a consistent and safe level of pressure within the compressor system.

The pressure switch consists of several key components that enable its functionality. One such component is the diaphragm, which is a flexible membrane that reacts to changes in pressure. When the pressure within the tank exceeds the set limit, the diaphragm is pushed upward, compressing a spring. This upward movement activates a set of electrical contacts, creating a connection that sends a signal to stop the motor or pump.

Another crucial component is the switch mechanism, which is responsible for opening and closing the electrical contacts. The switch mechanism typically consists of a lever arm that is connected to the diaphragm. When the diaphragm moves upward, it causes the lever arm to pivot, opening the electrical contacts and interrupting the power supply to the motor or pump. When the pressure drops below the set limit, the diaphragm returns to its original position, allowing the lever arm to close the electrical contacts and restore power to the motor or pump.

In addition to these components, many pressure switches also have adjustable pressure settings, allowing the user to customize the pressure levels at which the switch will activate. This feature is particularly useful for applications where different pressure levels are required, providing greater flexibility and control.

In summary, a pressure switch plays a crucial role in an air compressor by monitoring the pressure levels within the tank and controlling the operation of the motor or pump. It works by utilizing a diaphragm and a switch mechanism to open and close electrical contacts, which in turn, activate or deactivate the motor or pump based on the set pressure limits. Additionally, the pressure switch may have adjustable settings to accommodate different pressure requirements. By ensuring the proper functioning of the compressor and maintaining safe pressure levels, the pressure switch enhances the overall performance and longevity of the air compressor system.

Components of a Pressure Switch

A pressure switch is a critical component of an air compressor that helps regulate and control the pressure within the system. It consists of several key components that work together to monitor and adjust the pressure levels.

1. Switch Diaphragm:

The switch diaphragm is a flexible membrane that reacts to the changes in pressure. It is typically made of rubber or metal and is sensitive to even small pressure variations. When the pressure in the system reaches a certain level, the diaphragm flexes and triggers the switch mechanism.

2. Electrical Contacts:

The pressure switch contains electrical contacts that are responsible for opening and closing the circuit based on the diaphragm’s movement. When the pressure reaches a specific setpoint, the diaphragm actuates the electrical contacts, either closing or opening the circuit. This action controls the power supply to the compressor motor.

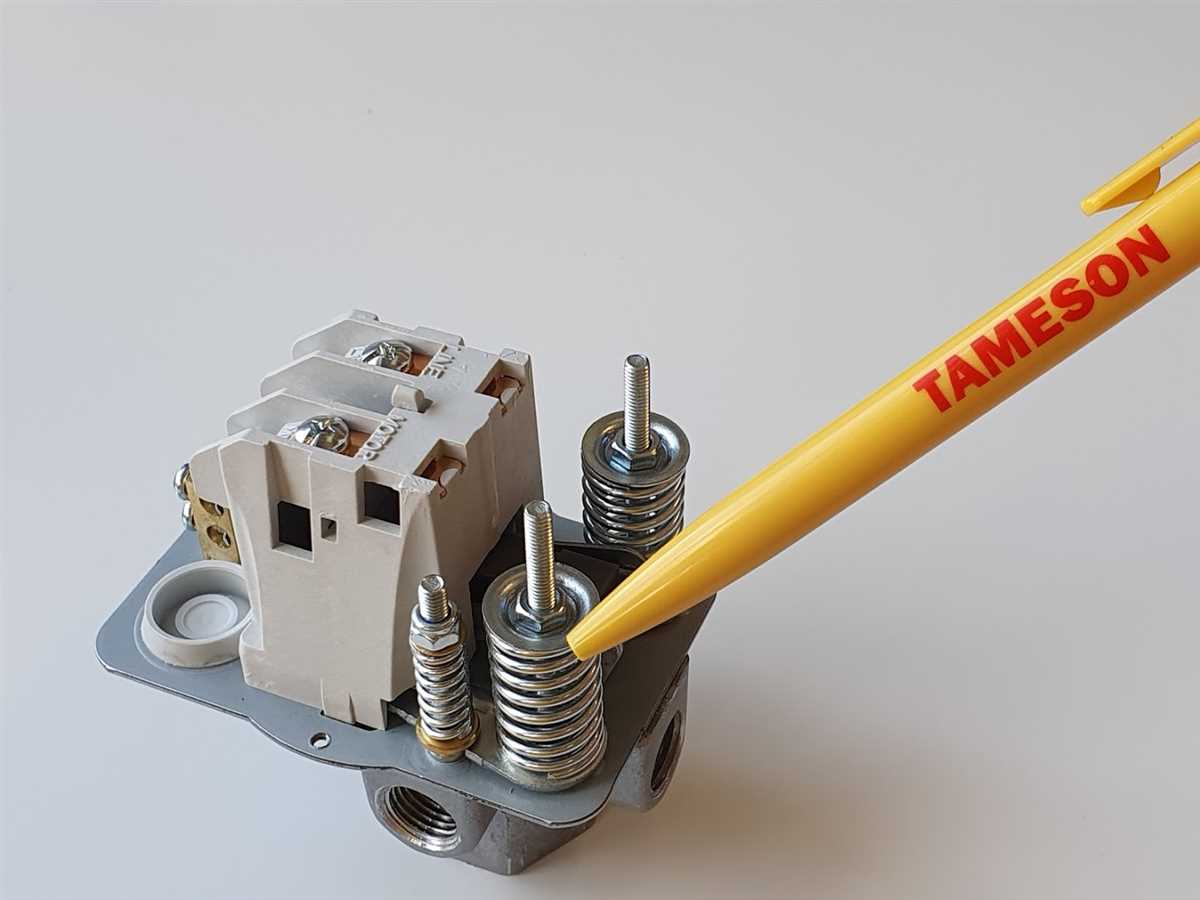

3. Mechanical Springs:

To provide stability and reliability, pressure switches are equipped with mechanical springs. These springs apply pressure to the switch diaphragm, helping it maintain a stable position and preventing rapid or unnecessary switching. The springs also contribute to the overall accuracy and repeatability of the switch’s pressure settings.

4. Adjustment Mechanism:

Pressure switches usually come with an adjustment mechanism that allows the user to set the desired pressure range. This can be done by turning a screw or knob that changes the tension on the switch diaphragm. By adjusting the tension, the user can effectively control the cut-in and cut-out pressures of the compressor system.

5. Housing and Connection Ports:

The pressure switch is housed in a protective casing made of metal or plastic. This housing not only provides physical protection to the internal components but also helps to insulate the switch from external environmental factors. The switch also features connection ports that allow the air compressor to be connected to the pressure switch, establishing the necessary pneumatic pathway.

Overall, the components of a pressure switch work in harmony to ensure that the air compressor operates within the desired pressure range, preventing overload or damage to the system. The diaphragm, electrical contacts, mechanical springs, adjustment mechanism, and housing all play integral roles in maintaining the correct pressure levels and regulating the air compressor’s performance.

The Role of Electrical Contacts in a Pressure Switch

Directing Electrical Current

The electrical contacts within a pressure switch play a crucial role in directing electrical current. When the air pressure in the compressor reaches a certain level, the contacts are designed to close, allowing the flow of electrical current to different components of the air compressor system. A pressure switch typically has two electrical contacts, known as normally open (NO) and normally closed (NC) contacts. These contacts control the flow of electricity to activate or deactivate various components depending on the air pressure.

Safety and Control

The electrical contacts in a pressure switch serve the important purpose of ensuring the safe operation of an air compressor. When the air pressure drops below the specified threshold, these contacts open, thus interrupting the flow of electrical current. This prevents the air compressor from operating under low pressure conditions, which can be potentially unsafe and detrimental to the overall performance of the compressor. The contacts also allow for precise control over the activation and deactivation of the compressor, ensuring optimal efficiency and preventing unnecessary wear and tear on the system.

Mechanical Integrity

The electrical contacts in a pressure switch are designed to provide reliable and long-lasting mechanical integrity. These contacts are typically made of durable and conductive materials such as silver or copper alloys. The design and material choice ensure that the contacts can withstand the electrical current and mechanical stress associated with frequent opening and closing cycles. Additionally, proper maintenance and periodic inspection of the contacts can help prevent corrosion and ensure their continued functionality.

Monitoring and Feedback

The electrical contacts within a pressure switch also provide a valuable monitoring and feedback mechanism. By integrating these contacts with other electrical components, such as relays or control panels, the air compressor system can receive real-time information about the air pressure levels. This allows for precise monitoring, control, and automation of the compressor’s operation. Feedback from the contacts can also facilitate system diagnostics, enabling timely detection and resolution of any potential issues or malfunctions.

In conclusion, the electrical contacts in a pressure switch play a vital role in the safe and efficient operation of an air compressor. They direct electrical current, ensure safety and control, provide mechanical integrity, and facilitate monitoring and feedback. These contacts are an essential component that helps an air compressor system function reliably and effectively.

Types of Pressure Switches

A pressure switch is a device used to control the operation of a system based on the pressure level. There are different types of pressure switches available in the market, each designed for specific applications and pressure ranges.

1. Diaphragm Pressure Switches

Diaphragm pressure switches are commonly used in air compressor systems. They use a flexible diaphragm that deflects under pressure, resulting in mechanical movement that activates the switch. These switches are suitable for low-pressure applications and provide reliable and accurate pressure control.

2. Piston Pressure Switches

Piston pressure switches are designed for high-pressure applications. They use a piston mechanism coupled with a spring to detect pressure changes. When the pressure reaches a certain point, the piston moves, activating the switch. These switches are commonly used in industrial settings and provide robust pressure control.

3. Vacuum Pressure Switches

Vacuum pressure switches are designed to detect negative pressure or vacuum levels. They are commonly used in applications that require monitoring of vacuum levels, such as vacuum pumps and systems. These switches typically use a diaphragm or piston mechanism to detect the vacuum and activate the switch.

4. Differential Pressure Switches

Differential pressure switches are used to monitor the difference in pressure between two points. They are commonly used in HVAC systems and fluid flow control applications. These switches have two pressure ports and are designed to activate the switch when the pressure difference exceeds a certain threshold.

Overall, the choice of pressure switch depends on the specific requirements of the system and the pressure range. It is important to select the appropriate type of pressure switch to ensure reliable and accurate pressure control in the air compressor system.

Common Issues with Pressure Switches

The pressure switch is a crucial component in an air compressor system, but it can experience certain issues that may affect its functionality. Here are some common issues that can occur with pressure switches:

1. Faulty or Stuck Contacts

One of the most common issues with pressure switches is faulty or stuck contacts. This can prevent the switch from properly sensing the pressure and initiating the necessary actions. If the contacts are worn out or corroded, they may not make proper contact or get stuck in the closed position, causing the compressor to continuously run or not start at all.

2. Inconsistent Pressure Readings

Another common issue is inconsistent pressure readings. This can happen due to a faulty pressure sensor or an inaccurate calibration. In some cases, the pressure switch may not accurately detect the pressure changes, leading to incorrect pressure readings and improper compressor operation.

3. Leaks

Leaks can also occur in pressure switches, particularly around the pressure ports or connections. These leaks can cause a drop in pressure, resulting in issues such as the compressor not turning on or off at the correct pressure levels. It is important to regularly check for leaks and repair them promptly to ensure the proper functioning of the pressure switch.

4. Overheating

Pressure switches can sometimes overheat due to excessive load or prolonged use. This can lead to overheated contacts or damage to the internal components, affecting the switch’s performance. To prevent overheating, it is essential to ensure proper ventilation, maintain correct wiring, and periodically inspect the pressure switch for any signs of overheating.

5. Electrical Problems

Electrical issues can also occur with pressure switches, such as loose or damaged wiring connections. These problems can lead to intermittent or complete failure of the switch. Regular inspection and maintenance of the electrical connections are necessary to avoid any electrical problems that may impact the performance of the pressure switch.

In conclusion, pressure switches in air compressor systems can encounter various common issues, including faulty or stuck contacts, inconsistent pressure readings, leaks, overheating, and electrical problems. Understanding these issues and addressing them promptly is crucial for maintaining the reliable and efficient operation of an air compressor system.

Benefits of Using a Pressure Switch in an Air Compressor

1. Safety

A pressure switch in an air compressor is an essential safety feature that helps prevent any potential accidents or damages. It constantly monitors the pressure levels within the compressor and automatically shuts off the compressor when the pressure reaches a certain limit, preventing it from over-pressurizing. This ensures that the air compressor operates within safe limits, reducing the risk of explosions or other hazardous situations.

2. Energy Efficiency

Using a pressure switch can help improve the energy efficiency of an air compressor. By setting the switch to the desired cut-in and cut-out pressure levels, the compressor will only operate when necessary, reducing idle time and saving energy. This can lead to significant cost savings in the long run and make the air compressor more environmentally friendly.

3. Extended Lifespan

A pressure switch can help prolong the lifespan of an air compressor by preventing excessive wear and tear. By ensuring that the compressor operates within its designed pressure range, the switch helps reduce the strain on the compressor components, such as the motor and the pump. This can result in fewer breakdowns and repairs, ultimately extending the overall lifespan of the air compressor.

4. Flexibility and Control

Pressure switches offer flexibility and control over the air compressor’s operation. Depending on the specific needs and applications, different pressure settings can be configured using the switch. This allows users to adjust the pressure levels according to their requirements, whether it is for inflating tires, powering tools, or operating pneumatic machinery. The ability to easily control and change the pressure settings adds versatility to the air compressor’s functionality.

5. Troubleshooting and Monitoring

Pressure switches also provide a way to troubleshoot and monitor the performance of an air compressor. By monitoring the pressure readings, users can identify any irregularities or issues with the compressor’s operation. This allows for timely maintenance and repairs, preventing any further damage or breakdowns. Additionally, pressure switches often have built-in indicators or alarms that can alert users to any unusual pressure fluctuations, providing an early warning system for potential problems.

In conclusion, using a pressure switch in an air compressor offers several benefits, including safety, energy efficiency, extended lifespan, flexibility, and troubleshooting capabilities. It is an important component that helps ensure the optimal performance and reliability of the air compressor, making it a valuable investment for any user.

FAQ:

What is a pressure switch in an air compressor?

A pressure switch in an air compressor is a device that controls the on and off cycle of the compressor motor. It monitors the pressure in the air tank and automatically stops the compressor when the desired pressure is reached, and starts it again when the pressure drops below a certain level.

How does a pressure switch work in an air compressor?

A pressure switch works by using a diaphragm and a set of electrical contacts. When the air pressure in the tank reaches the set point, the diaphragm inside the pressure switch expands and pushes against the contacts, causing them to close. This completes the electrical circuit and turns off the compressor. When the pressure drops below the set point, the diaphragm contracts and the contacts open, breaking the circuit and turning on the compressor.

What are the different types of pressure switches used in air compressors?

There are two main types of pressure switches used in air compressors: adjustable pressure switches and fixed pressure switches. Adjustable pressure switches allow for the adjustment of the set point, so the user can determine the desired pressure at which the compressor turns on and off. Fixed pressure switches have a preset set point and cannot be adjusted.

Can a pressure switch fail in an air compressor?

Yes, a pressure switch can fail in an air compressor. Over time, the electrical contacts inside the pressure switch may wear out or become corroded, causing them to malfunction. Additionally, the diaphragm inside the pressure switch can become damaged or develop leaks, leading to inaccurate pressure readings. Regular maintenance and inspection of the pressure switch is important to ensure proper functioning.

Is it possible to replace a pressure switch in an air compressor?

Yes, it is possible to replace a pressure switch in an air compressor. When replacing a pressure switch, it is important to choose a switch that is compatible with the specific model and specifications of the air compressor. The replacement process typically involves disconnecting the power supply, removing the old pressure switch, and installing the new one according to the manufacturer’s instructions.

Video: