Understanding the Functioning of an Air Compressor Pressure Switch

An air compressor pressure switch is a crucial component in the operation of an air compressor. It plays a vital role in controlling the pressure levels within the compressor and ensures safe and efficient operation. In this article, we will delve into the inner workings of an air compressor pressure switch and explore its functions in detail.

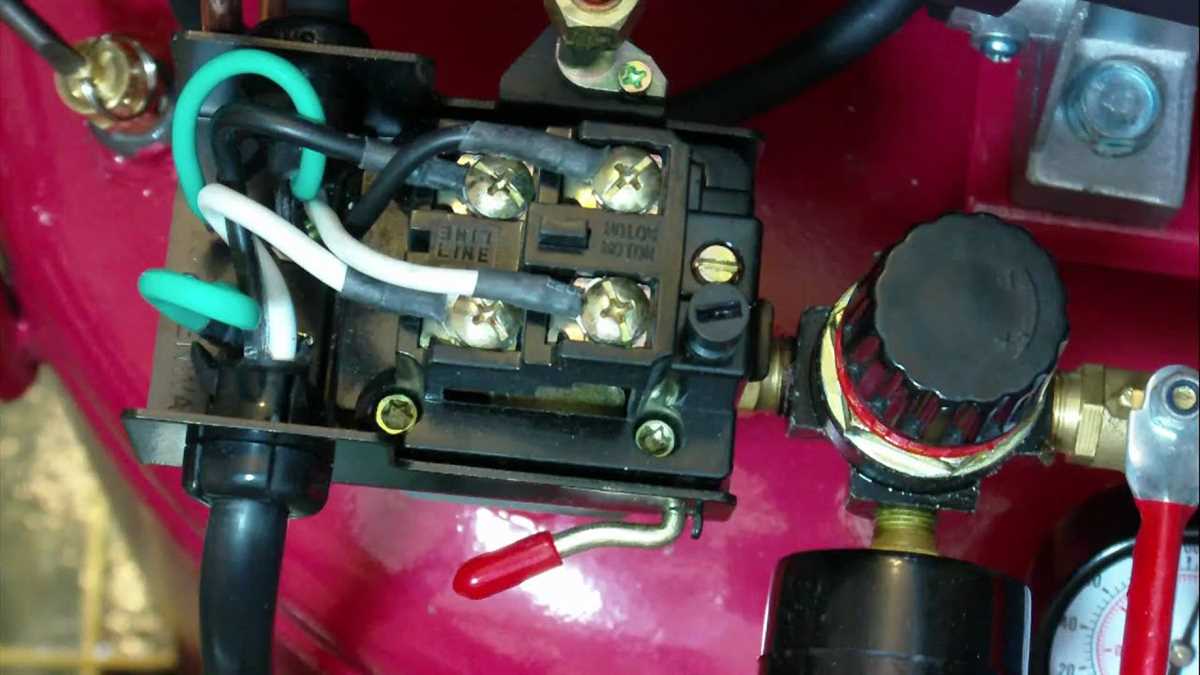

The pressure switch is typically located near the air tank of the compressor and is connected to the motor and the pressure gauge. Its primary function is to monitor the pressure levels in the tank and activate or deactivate the motor accordingly. When the pressure in the tank reaches the minimum set limit, the pressure switch sends a signal to the motor to start, and it continues running until the pressure reaches the maximum set limit, at which point it signals the motor to stop.

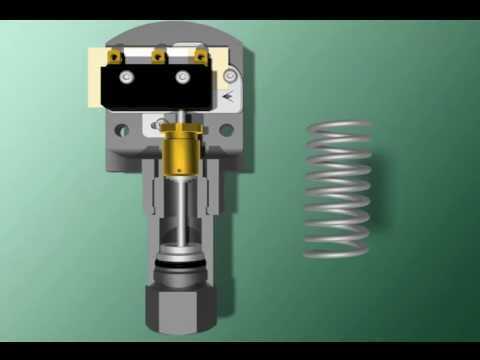

To understand the functioning of the pressure switch, it is important to know about the two main components: the spring and the diaphragm. The spring is responsible for applying pressure to the diaphragm, which moves in response to changes in pressure. When the pressure inside the tank is low, the spring pushes the diaphragm up, allowing the switch to make contact and close the electrical circuit, which starts the motor. As the pressure increases, the diaphragm moves down, releasing the pressure on the switch and opening the circuit to stop the motor.

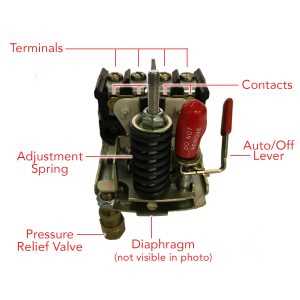

In addition to controlling the motor, the pressure switch also has various safety features. For instance, it is equipped with a manual on/off lever, allowing the user to manually control the operation of the compressor. It also has an automatic shut-off feature, which shuts down the compressor if the pressure exceeds a certain limit, preventing any damage or accidents. Some pressure switches also have adjustable pressure settings, allowing users to customize the cut-on and cut-off pressure according to their specific needs.

In conclusion, an air compressor pressure switch is a vital component that ensures the safe and efficient operation of an air compressor. It functions by monitoring the pressure levels in the tank and activating or deactivating the motor accordingly. Understanding the inner workings of the pressure switch can help users troubleshoot any issues and maximize the performance of their air compressor.

What is an Air Compressor Pressure Switch?

An air compressor pressure switch is an essential component of an air compressor system that controls the operations of the compressor. It is responsible for monitoring the air pressure in the compressor tank and activating or deactivating the compressor motor accordingly.

Air Pressure Sensing: This pressure switch is equipped with a pressure sensor that measures the air pressure inside the compressor tank. It continuously monitors the pressure and sends signals to the compressor motor for operation.

Pressure Settings: The pressure switch allows the user to set the desired pressure limits for the compressor. These settings can be adjusted to meet specific application requirements. Once the pressure reaches the upper limit, the pressure switch cuts off the power to the compressor motor, preventing over-pressurization. On the other hand, if the pressure drops below the lower limit, the switch activates the motor to start the compressor and increase the pressure to the desired level.

Automatic Control: The pressure switch is designed to provide automatic control for the compressor system. It eliminates the need for manual monitoring and operation of the compressor. Once the pressure settings are configured, the switch takes care of maintaining the desired pressure levels by turning the motor on and off as needed.

Safety Features: Air compressor pressure switches often come with safety features to ensure the proper functioning and protection of the compressor system. These can include overload protection, thermal cut-off, and manual reset options to prevent damage to the compressor and ensure safe operation.

Indicator Lights: Some pressure switches are equipped with indicator lights that provide visual feedback on the status of the compressor. These lights can indicate whether the compressor is running, whether the pressure is within the desired range, and if any safety features have been triggered.

Overall, an air compressor pressure switch plays a crucial role in the functioning of an air compressor system by monitoring and controlling the air pressure, ensuring safe and efficient operation.

Importance of Air Compressor Pressure Switch

The air compressor pressure switch is an essential component in the operation of an air compressor. It helps regulate the pressure levels within the compressor system, ensuring efficient performance and preventing damage to the equipment.

One of the main functions of the pressure switch is to monitor the pressure levels in the air compressor tank. When the pressure reaches a certain predetermined level, the switch will automatically shut off the compressor, preventing over-pressurization of the tank. This not only helps increase the lifespan of the compressor but also ensures the safety of the operator and other nearby components.

Another important role of the pressure switch is to control the starting and stopping of the compressor motor. When the pressure drops below a certain level, the switch will activate the motor to engage the compressor. Once the desired pressure is reached, the switch will then deactivate the motor, preventing unnecessary energy consumption and reducing wear and tear on the motor.

The pressure switch also allows for manual adjustment of the pressure settings, providing flexibility in meeting different air pressure requirements for various tasks. Additionally, some pressure switches are equipped with built-in gauges, allowing the operator to easily monitor the pressure levels in real-time.

Overall, the air compressor pressure switch plays a crucial role in maintaining the optimal performance and safety of an air compressor system. It ensures proper pressure regulation, prevents over-pressurization, controls motor operation, and allows for easy pressure adjustments. Without a functioning pressure switch, the air compressor may experience damage, decreased efficiency, and potential safety hazards.

Working Principle

Air compressor pressure switches are designed to monitor and control the pressure inside an air compressor tank. The working principle of these switches is relatively simple but crucial for the safe and efficient operation of the compressor.

When the air pressure inside the compressor tank reaches a certain level, the pressure switch detects it and automatically shuts off the compressor. On the other hand, if the pressure drops below a certain threshold, the switch turns the compressor back on.

The pressure switch consists of two main components: a pressure sensor or switch element and an electrical control circuit. The pressure sensor is typically a diaphragm or a piston, which reacts to changes in air pressure. When the pressure reaches the desired level, the sensor triggers the switch to cut off power to the compressor motor. Conversely, when the pressure drops, the sensor allows the switch to activate the motor and restart the compressor.

The electrical control circuit is responsible for controlling the operation of the pressure switch. It includes terminals for electrical connections, such as the power supply, compressor motor, and any additional accessories or safety devices. The control circuit also typically includes adjustable settings for the pressure range, allowing the user to set the desired operating conditions for the compressor.

Overall, the working principle of an air compressor pressure switch involves the detection of air pressure changes and the automatic control of the compressor’s motor. This ensures that the compressor operates within safe pressure limits and optimizes its performance, preventing the risk of overpressure or damage to the equipment.

How does an Air Compressor Pressure Switch Work?

The air compressor pressure switch is a critical component in controlling the operation of an air compressor. It is responsible for monitoring the pressure inside the air compressor tank and regulating the compressor’s on/off cycles. The pressure switch acts as a safety device to prevent over-pressurization and damage to the compressor.

When the air compressor is turned on, the pressure switch detects the initial pressure in the tank. Once the pressure drops below a certain level, known as the cut-in pressure, the pressure switch signals the compressor motor to start running. As the compressor pumps air into the tank, the pressure inside begins to rise.

As the pressure in the tank reaches a specified level, known as the cut-out pressure, the pressure switch will stop the compressor motor. This prevents the tank from becoming over-pressurized and potentially causing damage. The pressure switch continuously monitors the pressure levels and will cycle the compressor on and off as necessary to maintain a consistent pressure range.

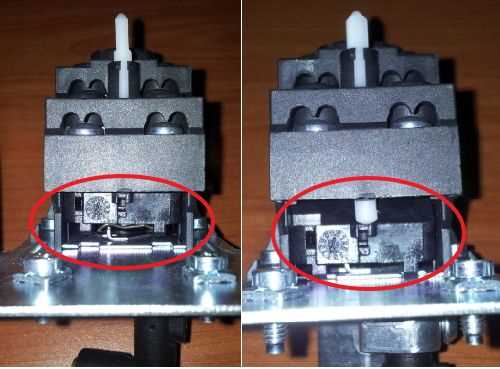

The pressure switch functions using a set of electrical contacts that are controlled by a diaphragm or bellows mechanism. As the tank pressure changes, it causes the diaphragm or bellows to expand or contract. This movement activates the electrical contacts, which in turn control the operation of the compressor motor.

Some pressure switches also have adjustable settings, allowing the user to manually adjust the cut-in and cut-out pressure levels to suit specific needs. This flexibility allows for customization based on the desired pressure range for different applications.

In summary, the air compressor pressure switch plays a crucial role in regulating the operation of an air compressor. It constantly monitors the pressure inside the tank and controls the compressor’s on/off cycles to maintain a safe and efficient working pressure range.

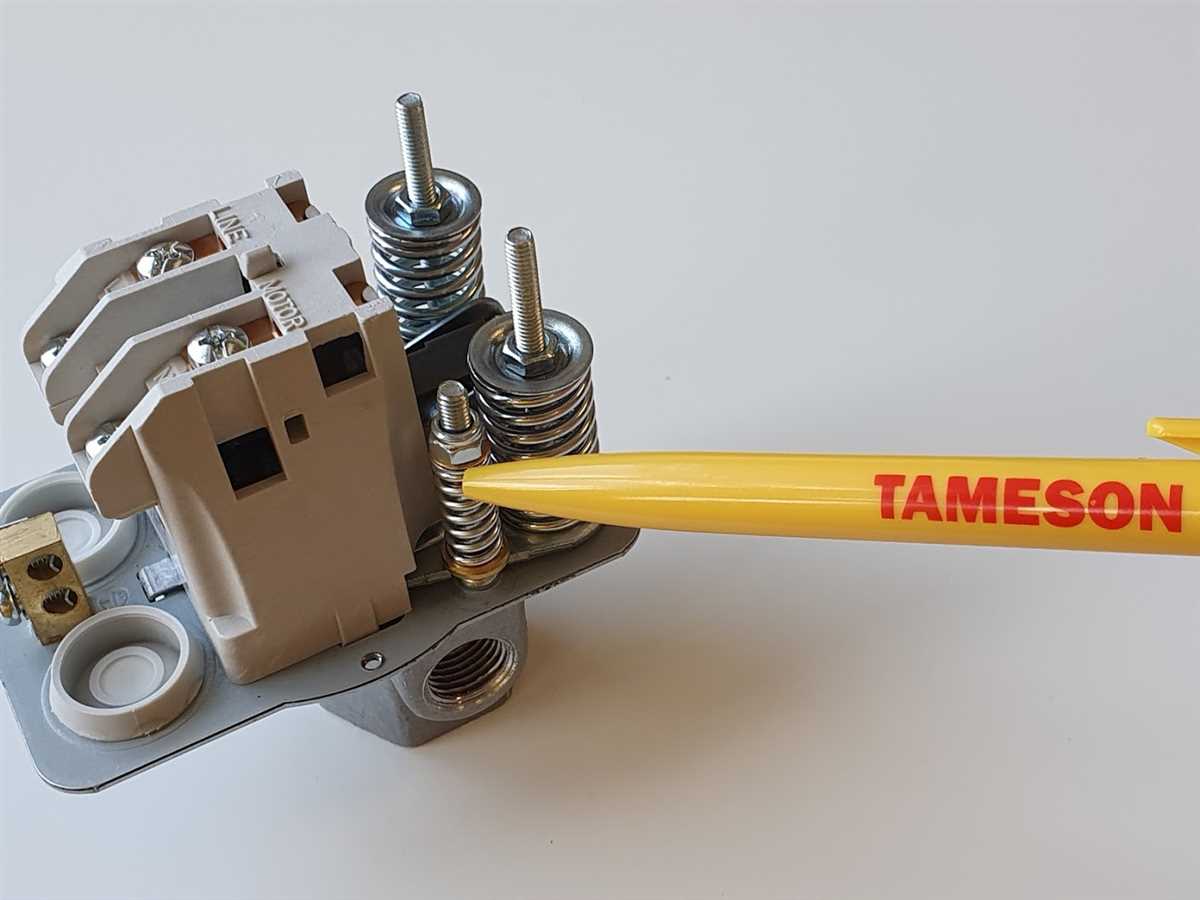

Key Components of an Air Compressor Pressure Switch

The air compressor pressure switch is a crucial component that helps to regulate the pressure in an air compressor system. It consists of several key components that work together to ensure the proper functioning of the switch.

1. Switch Body

The switch body is the main housing of the pressure switch. It is typically made of durable materials such as metal or plastic. The switch body houses all the other components and provides protection and support.

2. Pressure Sensor

The pressure sensor is a sensitive device that measures the air pressure in the compressor system. It is usually a diaphragm or a small piston that moves in response to changes in pressure. The pressure sensor is responsible for detecting when the pressure reaches the preset limit and triggers the switch to turn the compressor on or off.

3. Adjustment Mechanism

The adjustment mechanism allows the user to set the desired pressure level at which the switch should activate. It usually consists of a set of adjustment screws or knobs that can be turned to increase or decrease the pressure limit. This feature provides flexibility and customization options for different applications.

4. Electrical Contacts

The electrical contacts are the key components that control the electrical circuit of the compressor. When the pressure reaches the preset limit, the contacts either open or close to turn the compressor motor on or off. This enables the switch to regulate the pressure and prevent overloading or damage to the compressor.

5. Pressure Relief Valve

The pressure relief valve is a safety feature that is often included in the pressure switch. It is designed to release excess pressure from the system when it exceeds a certain threshold. This helps to prevent damage to the compressor or other components in the system due to excessive pressure.

Overall, these key components work together to ensure the proper functioning and safety of an air compressor pressure switch. By regulating the pressure in the system, the pressure switch helps to maintain optimal performance and prevent any potential issues or damage.

Adjustment and Settings

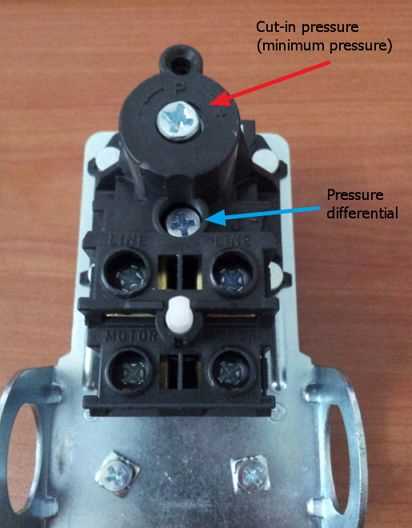

When it comes to adjusting and setting up an air compressor pressure switch, there are several factors to consider. The first step is to determine the desired cut-in and cut-out pressure settings. The cut-in pressure is the pressure at which the compressor will start running, while the cut-out pressure is the pressure at which the compressor will stop running.

Most pressure switches have adjustable settings, allowing the user to set specific pressure thresholds. This adjustment is typically done using a screwdriver or similar tool to turn the pressure adjustment screw. It is important to refer to the manufacturer’s instructions and guidelines for the specific pressure switch being used, as the adjustment process may vary.

In addition to setting the cut-in and cut-out pressures, it is also important to adjust the differential pressure, also known as the pressure band or pressure range. This is the difference between the cut-in and cut-out pressures, and it determines how much the pressure can fluctuate before the compressor starts or stops. Adjusting the differential pressure allows for more precise control over the compressor’s operation.

Some pressure switches also have additional settings, such as a manual on/off switch or an adjustable unloader valve. The manual on/off switch allows for manual control over the compressor, while the unloader valve relieves pressure from the compressor’s discharge line when it stops running, preventing the compressor from starting under load.

It is important to properly adjust and set up the air compressor pressure switch to ensure safe and efficient operation. Improper settings can lead to issues such as excessive pressure buildup, frequent cycling of the compressor, or insufficient pressure for the intended applications. Regular monitoring and adjustment of the pressure switch settings may be necessary to maintain optimal performance.

How to Adjust an Air Compressor Pressure Switch?

1. Familiarize Yourself with the Pressure Switch

Before you can adjust the air compressor pressure switch, it’s important to understand its components and how they work. Familiarize yourself with the switch, taking note of the different adjustments available.

2. Turn off the Power

Before making any adjustments, it’s crucial to turn off the power to the air compressor. This ensures your safety and prevents any accidental startup during the adjustment process.

3. Locate the Pressure Adjustments

On the pressure switch, locate the adjustment screws or nuts. These are usually labeled “cut-in” and “cut-out.” The “cut-in” adjustment determines when the compressor starts, and the “cut-out” adjustment determines when the compressor stops.

4. Adjust the “Cut-In” Pressure

Using a screwdriver or wrench, turn the “cut-in” adjustment screw or nut clockwise to increase the pressure, or counterclockwise to decrease it. Start by adjusting in small increments and testing the compressor’s functioning after each adjustment.

5. Adjust the “Cut-Out” Pressure

Similarly, use a screwdriver or wrench to adjust the “cut-out” pressure. Turning the screw or nut clockwise will increase the pressure, while turning it counterclockwise will decrease it. Again, make small adjustments and test the compressor after each change.

6. Test the Adjusted Pressure

Once you have made the desired adjustments, turn on the power and test the air compressor’s functioning. Make sure it starts and stops at the appropriate pressures. If necessary, repeat the adjustment process until you achieve the desired results.

7. Document the Adjustments

It’s a good practice to document any adjustments made to the air compressor pressure switch. This will make it easier to revert to previous settings or reference the changes in the future.

8. Seek Professional Help, if Needed

If you’re unsure about adjusting the pressure switch or encounter any difficulties, it’s advisable to seek professional assistance. A qualified technician can provide guidance and ensure the adjustments are made correctly.

By following these steps, you can successfully adjust an air compressor pressure switch to suit your specific needs. Remember to prioritize safety and make small, incremental adjustments to achieve the desired pressure settings.

Recommended Settings for Air Compressor Pressure Switch

Adjusting the settings on an air compressor pressure switch is crucial for achieving optimal performance and prolonging the lifespan of your air compressor. By setting the pressure switch correctly, you can ensure that the compressor stops and starts at the desired pressure levels, preventing over-pressurization or unnecessary cycling.

Pressure Cut-In Setting

The pressure cut-in setting determines the minimum pressure at which the compressor will start running. It is usually set slightly below the desired operating pressure. This allows for a small buffer and prevents the compressor from starting and stopping too frequently. The pressure cut-in setting should be adjusted based on the specific requirements of your air compressor and the tools or equipment you will be using.

Pressure Cut-Out Setting

The pressure cut-out setting determines the maximum pressure at which the compressor will shut off. It is important to set this value to the appropriate level to prevent over-pressurization. Operating the compressor above its recommended maximum pressure can lead to equipment failure or safety hazards. Therefore, it is essential to consult the manufacturer’s guidelines or the technical specifications of your air compressor to determine the correct pressure cut-out setting.

Differential Setting

The differential setting, also known as the pressure switch range or pressure band, determines the difference between the cut-in and cut-out pressures. This setting influences the cycling frequency of the compressor. A larger differential setting will result in fewer cycles, while a smaller differential setting will lead to more frequent cycling. It is important to find the right balance between energy efficiency and maintaining consistent pressure levels. Consider the specific requirements of your application and the capabilities of your compressor when adjusting the differential setting.

Pressure Gauge Calibration

It is recommended to regularly calibrate the pressure gauge on your air compressor to ensure accurate readings. A calibrated gauge will provide reliable pressure measurements, allowing you to set the pressure switch more precisely. Calibration should be performed according to the manufacturer’s instructions or using a calibrated pressure reference device. This will help maintain the overall functionality and performance of your air compressor.

Remember to always refer to the manufacturer’s guidelines and consult with professionals or experts if you are unsure about adjusting the settings on your air compressor pressure switch. Properly setting the pressure switch will enhance the efficiency and reliability of your air compressor, ensuring optimal performance for your specific application.

Safety and Maintenance

When using an air compressor with a pressure switch, it is important to prioritize safety and perform regular maintenance to ensure proper functioning and avoid any accidents or damage.

1. Safety precautions:

- Always read and follow the manufacturer’s instructions and safety guidelines.

- Wear appropriate protective gear, such as safety glasses and ear protection, when operating the air compressor.

- Make sure the air compressor is placed on a stable surface to prevent any accidents or tip-overs.

- Keep the work area clean and free from any possible obstructions or hazards.

- Never leave the air compressor unattended while it is running.

2. Regular maintenance:

- Check the pressure switch regularly for any signs of wear or damage, such as cracks or frayed wires.

- Inspect the air compressor’s hoses and fittings for any leaks or damage. Replace any faulty components immediately.

- Clean the air filter regularly to prevent dust and debris from entering the compressor and affecting its performance.

- Drain any accumulated moisture from the air compressor’s tank to prevent rust and corrosion.

- Ensure that the pressure switch is properly calibrated and adjusted for the desired pressure levels.

By following these safety precautions and performing regular maintenance, you can ensure safe operation and prolong the lifespan of your air compressor pressure switch.

Importance of Safety Measures

Safety measures are essential when working with an air compressor pressure switch. These measures help prevent accidents, injuries, and damage to the equipment. Adhering to safety guidelines not only ensures the well-being of the operator but also extends the lifespan of the pressure switch.

By following these safety measures, operators can ensure the safe and efficient functioning of an air compressor pressure switch. It is important to prioritize safety at all times when working with this equipment to prevent accidents and protect both individuals and the equipment itself.

FAQ:

What is the purpose of an air compressor pressure switch?

An air compressor pressure switch is designed to control the pressure levels within an air compressor. It automatically turns the compressor on and off based on the predefined pressure settings.

How does an air compressor pressure switch work?

An air compressor pressure switch works by monitoring the pressure levels in the compressor’s air tank. When the pressure drops below a certain level, the switch activates the electrical circuit, which turns the compressor on. Once the pressure reaches the upper limit, the switch breaks the circuit and shuts off the compressor.

What are the different pressure settings on an air compressor pressure switch?

An air compressor pressure switch typically has two pressure settings: the cut-in pressure and the cut-out pressure. The cut-in pressure is the level at which the switch turns the compressor on, while the cut-out pressure is the level at which the switch shuts off the compressor.

Can the pressure settings on an air compressor pressure switch be adjusted?

Yes, the pressure settings on an air compressor pressure switch can be adjusted. Most pressure switches have adjustable screws or knobs that allow users to customize the cut-in and cut-out pressure levels according to their specific needs.

What are the potential issues with an air compressor pressure switch?

Some potential issues with an air compressor pressure switch include: improper pressure settings, faulty electrical connections, and a malfunctioning pressure switch itself. It is important to regularly inspect and maintain the pressure switch to ensure it functions properly and prevent any potential problems.

Video: