Understanding SCFM: Explaining the Meaning of SCFM on an Air Compressor

When it comes to air compressors, one of the key specifications that users need to understand is SCFM. SCFM, which stands for Standard Cubic Feet per Minute, is an important measurement in determining the performance and efficiency of an air compressor. It indicates the volume of air that the compressor can deliver at a specific pressure level.

SCFM takes into account both the pressure and temperature of the air. This means that it provides a standardized measurement, allowing users to compare the performance of different air compressors more accurately. By knowing the SCFM rating of an air compressor, users can determine whether it will be able to meet their specific needs and requirements.

It’s important to note that the SCFM rating of an air compressor is typically provided at a specific pressure level, known as the “cut-in” pressure. This is because the compressor’s performance can vary depending on the pressure it is operating at. The SCFM rating will decrease as the pressure increases, and vice versa.

Understanding SCFM is essential for anyone using or considering purchasing an air compressor. By knowing the SCFM rating, users can ensure that the compressor will be able to deliver the necessary volume of air for their intended applications. Whether it’s for powering tools, inflating tires, or running pneumatic machinery, understanding SCFM will help users make informed decisions and maximize the efficiency of their air compressors.

What is SCFM?

The term SCFM stands for Standard Cubic Feet per Minute, and it is a unit of measure used to quantify the volumetric flow rate of compressed air. SCFM helps in understanding the amount of air that an air compressor can deliver at a given pressure level.

Definition: SCFM is the flow rate of air at a specific set of standard conditions, which include a temperature of 68 degrees Fahrenheit (20 degrees Celsius), a pressure of 14.7 pounds per square inch absolute (psia), and a relative humidity of 0%. These conditions are often referred to as standard temperature and pressure (STP).

The SCFM rating of an air compressor is an important specification as it determines the compressor’s ability to power air tools and equipment. It represents the maximum airflow capacity that the compressor can provide, allowing users to select the appropriate compressor for their specific needs.

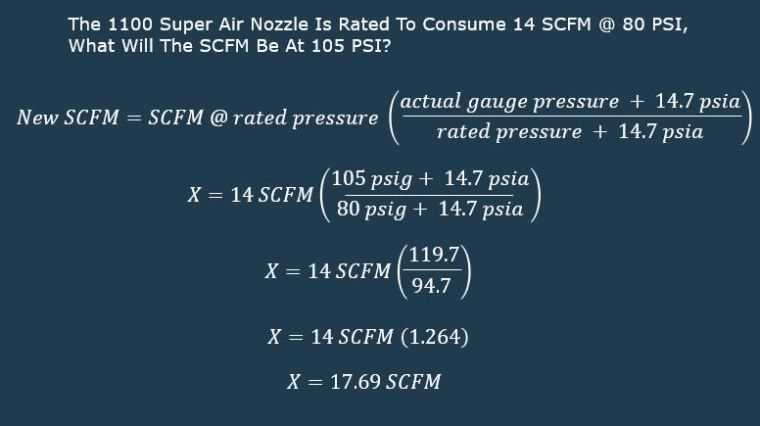

Calculating SCFM: To calculate the SCFM of an air compressor, the actual cubic feet per minute (ACFM) must be adjusted to the standard conditions. This can be done using the ideal gas law equation, which takes into account the temperature, pressure, and humidity differences between the actual conditions and the standard conditions.

Importance: Understanding SCFM is crucial for ensuring that an air compressor can meet the air demand of various applications. Different tools and equipment require different SCFM levels to operate effectively. Having a lower SCFM rating than what is required can lead to inadequate air supply and reduced performance, while having a higher rating can result in unnecessary power consumption and cost.

In conclusion, SCFM is a measure of the volumetric flow rate of compressed air at standard conditions and plays a significant role in determining the suitability and performance of an air compressor for various applications.

Importance of SCFM

SCFM, or Standard Cubic Feet per Minute, is a crucial measurement when it comes to air compressors. It represents the volume of air that the compressor can deliver at a standard reference condition of temperature and pressure. Understanding SCFM is important for various reasons.

One of the key reasons why SCFM is important is because it determines the efficiency and effectiveness of an air compressor. By knowing the SCFM rating, users can ensure that the compressor meets their specific requirements and can deliver the necessary amount of air for their applications.

Another important aspect is that SCFM helps in determining the proper sizing and selection of air tools and equipment. Different tools require different amounts of air to operate efficiently, and by considering the SCFM rating, users can select the appropriate tools and ensure optimal performance.

The accuracy of SCFM rating also plays a significant role in determining the cost-effectiveness of using an air compressor. If the SCFM rating is not accurate or if the compressor cannot deliver the required SCFM, it may result in inefficient operations, increased energy consumption, and unnecessary expenses.

Additionally, understanding SCFM is essential for maintaining a safe working environment. By ensuring that the air compressor can deliver the necessary SCFM, users can prevent pressure drops or inadequate airflow that could potentially compromise the performance and safety of air-powered equipment.

In summary, SCFM is a critical measurement that directly impacts the performance, efficiency, and safety of air compressors. By understanding and considering the SCFM rating, users can select the appropriate equipment, optimize operations, and ensure a cost-effective and safe working environment.

Understanding the Meaning of SCFM

What is SCFM?

SCFM stands for Standard Cubic Feet per Minute and it is a unit of measurement used to quantify the volumetric flow rate of gases, specifically air, through a system. It is a standardized measure which takes into account the pressure, temperature, and humidity of the air to provide an accurate representation of the true flow rate.

How is SCFM different from CFM?

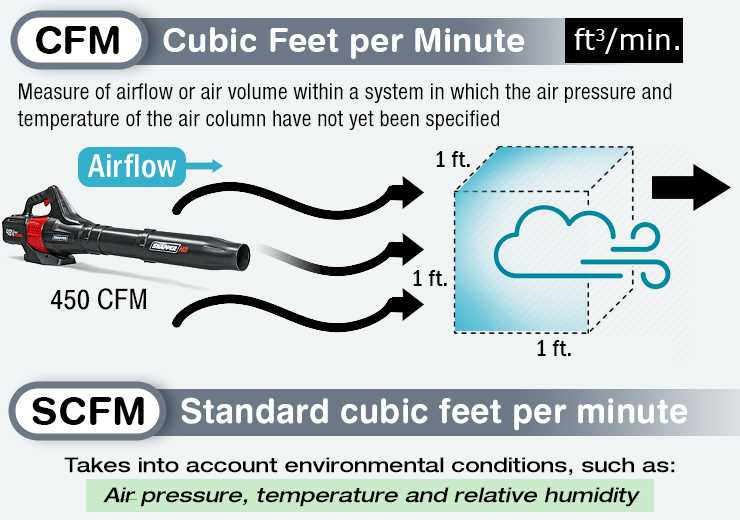

While both SCFM and CFM measure the flow rate of air, there is one key difference between them. CFM stands for Cubic Feet per Minute and it represents the flow rate of air under standard conditions, usually at sea level (14.7 pounds per square inch absolute pressure and 68 degrees Fahrenheit). SCFM, on the other hand, adjusts for variations in pressure, temperature, and humidity, providing a more accurate measurement.

Why is SCFM important in air compressors?

For air compressors, understanding the SCFM rating is crucial as it helps determine the compressor’s capacity and ability to supply a sufficient amount of air. The SCFM rating indicates the maximum flow rate the compressor can sustain at a given pressure, usually measured in pounds per square inch (psi). Operating an air compressor at or near its SCFM rating ensures optimal performance and prevents potential issues such as overheating or inadequate air supply.

Factors affecting SCFM

Several factors can affect the SCFM of an air compressor. These include the compressor’s displacement, compression ratio, efficiency, and the size and length of the pipes and hoses used in the system. It is important to consider these factors when selecting an air compressor, as they will determine its overall performance and ability to meet the required air supply demands in various applications.

Comparing SCFM ratings

When comparing the SCFM ratings of different air compressors, it is important to ensure that the measurements are taken at the same conditions. Some manufacturers may provide SCFM ratings at different pressures or temperatures, making it difficult to accurately compare the performance of different compressors. Taking into account the specific conditions under which the SCFM rating is provided will help in making an informed decision when selecting an air compressor.

Definition of SCFM

SCFM stands for Standard Cubic Feet per Minute. It is a unit of measurement used to describe the volumetric flow rate of air or other gases in a system. SCFM represents the amount of air that passes through a specific point in a system within one minute, at a standardized set of conditions.

Standard conditions refer to a specific set of parameters that are used as a basis for comparison. These conditions include a standard temperature, pressure, and humidity. In the case of SCFM, the standard conditions are typically defined as a temperature of 68 degrees Fahrenheit (20 degrees Celsius), a pressure of 14.7 pounds per square inch absolute (PSIA), and a relative humidity of 0%.

The use of SCFM allows for accurate and consistent comparisons between different air compressor systems. By measuring the flow rate in SCFM, users can understand how much air their compressor can deliver and compare it to the requirements of their specific applications.

It is important to note that the SCFM measurement is dependent on the specific conditions of the system. If the temperature, pressure, or humidity deviate from the standard conditions, the actual flow rate may vary. Therefore, it is crucial to consider the actual operating conditions when evaluating the performance of an air compressor system.

How is SCFM Measured?

The measurement of SCFM (Standard Cubic Feet per Minute) is an important parameter for evaluating the performance and efficiency of an air compressor. It indicates the volume of air that a compressor can deliver at a standard condition. To measure SCFM, several factors need to be considered.

1. Inlet Conditions: The measurement of SCFM starts with the determination of the inlet conditions, which include temperature, pressure, and humidity. These factors affect the density of the air and can significantly impact the SCFM measurement.

2. Calibration: Air compressors need to be properly calibrated to achieve accurate SCFM measurements. Calibration involves adjusting the compressor settings and measuring the air flow rate using instruments like flow meters or anemometers.

3. Standardization: SCFM measurements are standardized to a specific set of conditions known as the “standard reference conditions.” These conditions typically include a temperature of 68°F (20°C), atmospheric pressure of 14.7 psi (1 bar), and a relative humidity of 0%. This standardization allows for consistent and comparable SCFM measurements across different air compressors.

4. Calculation: Once the air compressor is calibrated and the inlet conditions are determined, the SCFM can be calculated using mathematical formulas. These formulas take into account the actual measured flow rate, the density of the air, and the standard reference conditions.

Overall, measuring SCFM requires careful consideration of various factors and proper calibration of the air compressor. Accurate SCFM measurements are essential for determining the performance and efficiency of an air compressor, as well as for comparing different models or evaluating the suitability of a compressor for specific applications.

SCFM vs. CFM: What’s the Difference?

When it comes to air compressors, two common terms you may come across are SCFM and CFM. These acronyms refer to different units of measurement and understanding the difference between them is crucial for selecting the right air compressor for your needs.

What is SCFM?

SCFM stands for “Standard Cubic Feet per Minute” and it represents the flow rate of air under standard conditions. Standard conditions are typically defined as a temperature of 68 degrees Fahrenheit (20 degrees Celsius), a pressure of 14.7 pounds per square inch (psi), and a relative humidity of 35%. SCFM takes into account the effects of temperature, pressure, and humidity on the volume of air.

What is CFM?

CFM stands for “Cubic Feet per Minute” and it represents the flow rate of air without taking into account any standard conditions. CFM is a measurement of the actual volume of air that an air compressor can deliver at a given time, regardless of temperature, pressure, or humidity.

While SCFM factors in the air’s temperature, pressure, and humidity, CFM is a more straightforward measurement that directly reflects the compressor’s capacity. CFM is commonly used to compare different air compressors and determine their performance levels.

Key Differences

The main difference between SCFM and CFM lies in the consideration of standard conditions. SCFM factors in the effects of temperature, pressure, and humidity, providing a standardized measurement. On the other hand, CFM represents the actual volume of air delivered by the compressor, without any adjustments for different environmental factors.

When comparing air compressors, it is important to consider both SCFM and CFM values. SCFM can give you an idea of the compressor’s efficiency and performance under standardized conditions, while CFM provides a direct indication of the compressor’s capacity. Ultimately, the CFM rating is often more relevant for practical purposes, as it directly reflects the compressor’s ability to deliver the required amount of air for your specific application.

In Conclusion

The difference between SCFM and CFM lies in the consideration of standard conditions. SCFM takes into account temperature, pressure, and humidity, while CFM represents the actual volume of air delivered by the compressor. Understanding these terms is crucial for selecting the right air compressor that meets your specific needs and requirements.

SCFM and CFM Explained

SCFM stands for Standard Cubic Feet per Minute, while CFM stands for Cubic Feet per Minute. These are important units of measurement used to quantify the flow rate of air in an air compressor.

When you see the term SCFM, it means that the measurement has been standardized to a specific set of conditions, usually at sea level and at a specific temperature and humidity. This standardization allows for accurate comparison between different air compressors, as it eliminates the variables that can affect the performance of the compressor.

The CFM, on the other hand, represents the actual flow rate of air that the compressor is capable of delivering. It does not take into account the standardization of conditions and may vary depending on factors such as altitude, temperature, and humidity.

It is important to note that SCFM is a theoretical measurement and may not reflect the actual performance of the compressor in real-world conditions. The actual CFM may be lower than the SCFM due to the factors mentioned earlier.

When choosing an air compressor, it is essential to consider both the SCFM and CFM values. The SCFM value can give you an idea of the compressor’s performance under ideal conditions, while the CFM value will give you a better understanding of its real-world capabilities.

To summarize, SCFM and CFM are both measurements of airflow in an air compressor. SCFM is a standardized measurement, while CFM represents the actual flow rate. Both are important when evaluating the performance of an air compressor and should be considered when making a purchasing decision.

When to Use SCFM and CFM

1. Choosing the Right Air Compressor

When selecting an air compressor, both SCFM (Standard Cubic Feet per Minute) and CFM (Cubic Feet per Minute) are important metrics to consider. SCFM is commonly used to measure the air volume at standard conditions, while CFM refers to the actual volume of air delivered by the compressor. Understanding both values will help determine the appropriate compressor size for your specific needs.

2. Calculating Air Tool Requirements

SCFM and CFM are crucial when calculating the air requirements for specific tools and equipment. Different tools have different air consumption rates, which are typically listed in terms of SCFM or CFM. By knowing these values, you can ensure that your air compressor provides enough air flow to operate your tools effectively and efficiently.

3. Comparing Different Compressor Models

When comparing air compressor models, it is essential to consider both SCFM and CFM. While CFM provides the actual delivered air volume, SCFM helps to standardize the comparison by considering the air conditions. By comparing the SCFM ratings of different models, you can determine which compressor offers the most efficiency and meets your specific air flow requirements.

4. Optimizing Efficiency and Performance

Understanding both SCFM and CFM can help optimize the performance and efficiency of your air compressor. By matching the SCFM and CFM ratings of your compressor with the air demands of your tools and equipment, you can ensure that the compressor operates at its maximum potential. This will not only result in better tool performance but also increase the lifespan of your compressor.

Therefore, it is important to consider both SCFM and CFM when selecting an air compressor, calculating air tool requirements, comparing compressor models, and optimizing efficiency and performance. By understanding these measurements, you can make informed decisions regarding your air compressor needs and ensure optimal air flow for your applications.

Factors Affecting SCFM

The SCFM (Standard Cubic Feet per Minute) of an air compressor is influenced by several factors. These factors can affect the performance and efficiency of the compressor, ultimately determining the amount of air that can be delivered by the machine.

1. Compressor Capacity

The capacity of the air compressor, usually measured in gallons, plays a significant role in determining the SCFM. A higher capacity air compressor will have the ability to deliver a larger volume of air per minute, resulting in a higher SCFM rating.

2. Compression Ratio

The compression ratio refers to the ratio of the discharge pressure to the suction pressure. Higher compression ratios increase the pressure of the air, but also decrease the volume of air delivered per minute. As a result, the SCFM rating of the compressor may be lower.

3. Inlet Air Temperature and Pressure

The temperature and pressure of the inlet air can also affect the SCFM rating. Warmer air has lower density, which means that a lower volume of air is delivered per minute. Similarly, lower pressure at the inlet will result in a lower SCFM rating.

4. System Leakages and Restrictions

Leakages and restrictions in the air compressor system can cause a decrease in the SCFM rating. Any leaks or blockages in the system will result in a loss of pressure, reducing the amount of air that can be delivered per minute.

5. Use of Air Tools and Accessories

The type and number of air tools and accessories connected to the air compressor can also impact the SCFM rating. Each tool or accessory has a specific air consumption rate, and the cumulative air consumption should be within the capacity of the compressor to maintain the desired SCFM rating.

In conclusion, several factors affect the SCFM rating of an air compressor, including the compressor’s capacity, compression ratio, inlet air temperature and pressure, system leakages and restrictions, as well as the use of air tools and accessories. It is important to consider these factors when choosing and using an air compressor to ensure optimal performance and efficiency.

Air Pressure

Air pressure refers to the force exerted by air particles on a surface. It is the result of the collisions between air molecules and the surface they come in contact with. Air pressure can be measured using various units, such as pounds per square inch (psi), atmospheres (atm), or pascals (Pa).

The pressure of the air around us is known as atmospheric pressure. At sea level, the average atmospheric pressure is about 14.7 psi or 1 atm. However, this pressure can vary depending on factors such as altitude, weather conditions, and the presence of any external forces.

Barometric pressure is a term used to describe the atmospheric pressure measured by a barometer. A barometer is a device that measures the weight or pressure of the air. It consists of a glass tube filled with mercury or a liquid and is used to determine changes in atmospheric pressure.

Understanding air pressure is crucial in many applications, including the design and operation of air compressors. Air compressors are used to increase the pressure of air by reducing its volume. The compressed air can then be used in various industrial processes, such as powering pneumatic tools or operating machinery.

When choosing an air compressor, it is important to consider the required air pressure for your specific applications. Different tools and equipment may have different pressure requirements, and it is essential to select an air compressor that can deliver the necessary air pressure consistently.

In conclusion, air pressure plays a vital role in many aspects of our daily lives. Understanding the concepts and principles associated with air pressure is crucial for various applications, ranging from weather forecasting to the operation of air compressors.

FAQ:

What does SCFM mean on an air compressor?

SCFM stands for Standard Cubic Feet per Minute and it is a measure of the volume of air that an air compressor can deliver at a given pressure level. It is a standardized measurement that allows for comparison between different air compressors.

How is SCFM calculated?

SCFM is calculated by measuring the volume of air that an air compressor can deliver per minute and then adjusting it to standard conditions of temperature and pressure. This ensures that the measurement is consistent and can be compared across different compressors.

Why is SCFM important for an air compressor?

SCFM is important because it allows you to determine the capability of an air compressor to deliver the volume of air that you need for a given application. By knowing the SCFM rating, you can make sure that the compressor you choose is capable of meeting your requirements.

What is the difference between SCFM and CFM?

The main difference between SCFM and CFM is that SCFM takes into account the standard conditions of temperature and pressure, while CFM does not. SCFM is a more accurate measurement because it provides a standardized basis for comparing different air compressors.

Video: