Testing the Efficiency of an Air Conditioner Compressor: A Comprehensive Guide

When it comes to air conditioning, the efficiency of the compressor is crucial. The compressor is the heart of the air conditioning system, responsible for pressurizing the refrigerant and maintaining the flow of cool air. Testing the efficiency of an air conditioner compressor is essential in ensuring that the system is functioning optimally, resulting in increased energy savings and improved cooling performance.

There are several factors that can impact the efficiency of an air conditioner compressor. These include the design and construction of the compressor, the quality of the refrigerant, the condition of the cooling coils, and the overall system maintenance. Without regular testing and maintenance, a compressor can become inefficient, leading to higher energy consumption and reduced cooling capacity.

One of the most common methods used to test the efficiency of an air conditioner compressor is the performance test. This involves measuring the compressor’s ability to produce a specified cooling capacity and comparing it to the manufacturer’s specifications. The test typically involves monitoring the compressor’s power consumption, refrigerant pressure, and temperature differentials to determine its efficiency.

Another important test is the leak test, which determines whether the compressor is losing refrigerant. A refrigerant leak can result in reduced cooling capacity and increased energy consumption. By identifying and repairing any leaks, the compressor’s efficiency can be restored, improving the overall performance of the air conditioning system.

In addition to these tests, regular maintenance, such as cleaning the coils, lubricating moving parts, and replacing worn components, is essential for ensuring the efficiency of an air conditioner compressor. This comprehensive guide will provide detailed instructions and best practices for testing and maintaining the efficiency of an air conditioner compressor, allowing homeowners and HVAC professionals to keep their air conditioning systems running at peak performance.

Overview of an Air Conditioner Compressor

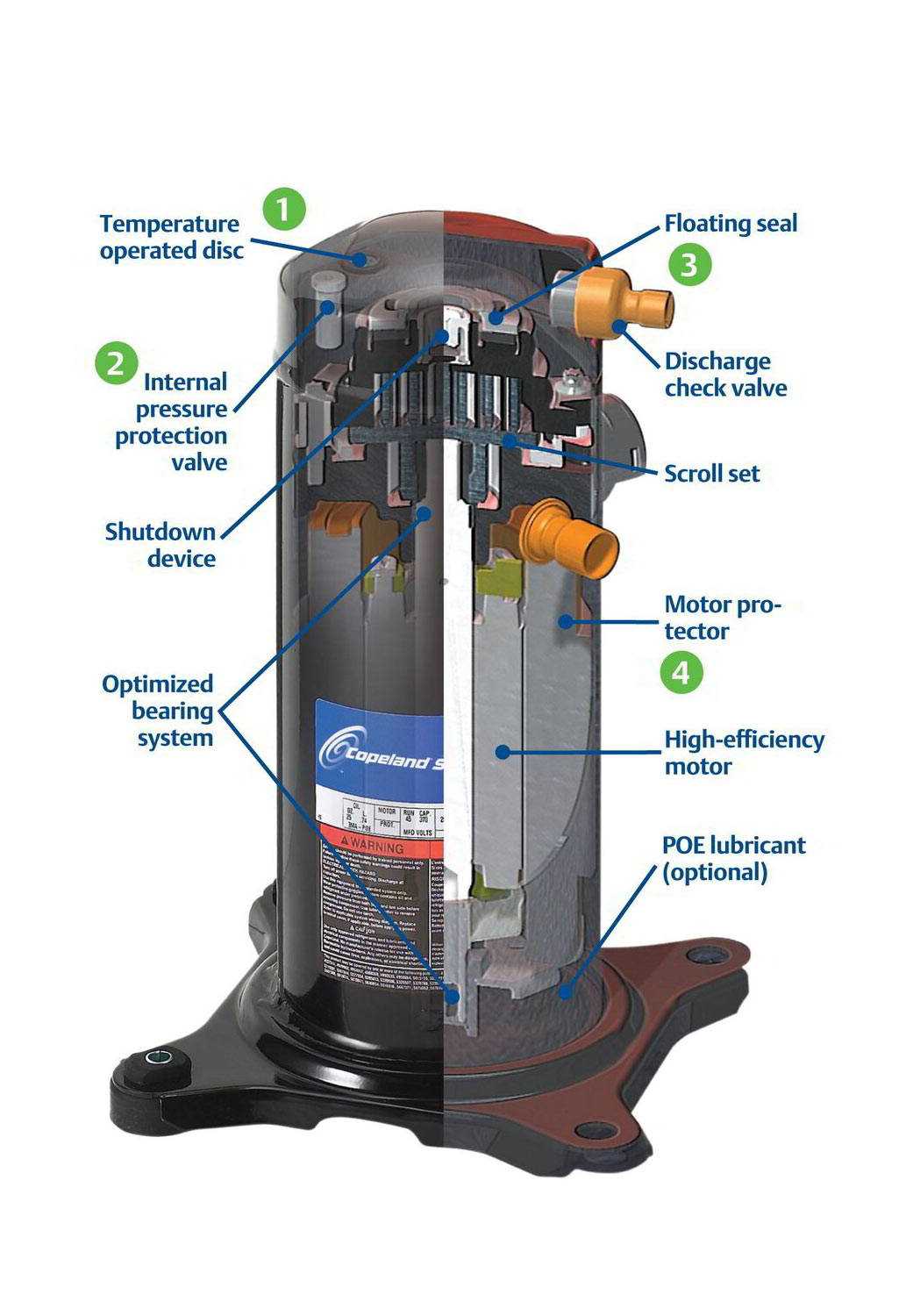

An air conditioner compressor is a vital component of an air conditioning system. It is responsible for compressing the refrigerant gas, which in turn helps cool the air in a room or an entire building. The compressor plays a crucial role in the overall performance and efficiency of an air conditioner.

Types of Compressors

There are several types of compressors used in air conditioning systems, including reciprocating compressors, rotary compressors, and scroll compressors. Each type has its own advantages and disadvantages, and the choice of compressor depends on various factors such as cost, cooling capacity, and noise levels.

Working Principle

The working principle of an air conditioner compressor involves a cycle of compression and expansion. The compressor sucks in low-pressure refrigerant gas and compresses it to a high-pressure state. This high-pressure gas then moves to the condenser, where it releases heat and transforms back into a liquid. The liquid refrigerant then passes through the expansion valve, which reduces its pressure, causing it to evaporate and absorb heat from the surrounding air. The cycle repeats to maintain a continuous flow of cool air.

Efficiency Testing

Efficiency testing is crucial to determine the performance of an air conditioner compressor. This involves measuring various parameters such as power consumption, cooling capacity, and coefficient of performance (COP). By conducting efficiency tests, technicians can assess the compressor’s energy efficiency and make necessary adjustments or repairs to improve its performance. Additionally, efficiency testing helps in identifying potential issues or malfunctions that may hinder the compressor’s performance and overall efficiency.

Regular Maintenance

To ensure the optimal performance and efficiency of an air conditioner compressor, regular maintenance is essential. This includes cleaning or replacing air filters, checking refrigerant levels, lubricating moving parts, and inspecting electrical connections. Regular maintenance not only improves the lifespan of the compressor but also helps in preventing potential breakdowns and reducing energy consumption.

Conclusion

The air conditioner compressor is a critical component in the functioning of an air conditioning system. Understanding its functioning, different types, and the importance of efficiency testing and maintenance is essential for ensuring the efficient cooling of any space and prolonging the lifespan of the air conditioner compressor.

Importance of Testing the Efficiency

The efficiency of an air conditioner compressor is a crucial factor to consider when evaluating its performance. Testing the efficiency allows you to determine how well the compressor is able to convert electrical energy into cooling power. This information is essential for making informed decisions about the effectiveness and cost-efficiency of the air conditioning system.

Energy savings: Testing the efficiency of the compressor helps identify any potential energy wastage. Inefficient compressors consume more electricity, resulting in higher energy bills. By testing the efficiency, you can identify any issues and take corrective measures to optimize the performance of the compressor. This can lead to significant energy savings and reduce the environmental impact.

Performance evaluation: Testing the efficiency provides valuable insights into the performance of the air conditioner compressor. By determining the power output and energy consumption, you can assess how well the compressor is functioning. This information is crucial for evaluating the overall performance of the air conditioning system and ensuring it meets the desired cooling requirements.

Equipment longevity: A compressor that operates at peak efficiency is less likely to experience premature wear and tear. By testing the efficiency, you can identify any issues that may be putting strain on the compressor and causing it to work harder than necessary. Correcting these issues can help extend the lifespan of the compressor, ultimately reducing maintenance costs and the need for frequent replacements.

Environmental impact: Testing the efficiency of an air conditioner compressor directly influences its environmental impact. Inefficient compressors consume more energy, which leads to higher greenhouse gas emissions. By optimizing the efficiency of the compressor, you can reduce the carbon footprint of the air conditioning system and contribute to environmental sustainability.

Regulatory compliance: In some regions, there may be regulations and standards in place regarding the efficiency of air conditioning systems. By testing the efficiency of the compressor, you can ensure compliance with these regulations and avoid potential penalties or restrictions. Additionally, maintaining an efficient compressor can help meet sustainability goals and align with corporate social responsibility initiatives.

Factors Affecting the Efficiency

Type of Refrigerant

The type of refrigerant used in an air conditioner compressor can significantly affect its efficiency. Some refrigerants are more efficient at transferring heat than others, which can result in lower energy consumption and higher cooling performance. Refrigerants with higher thermodynamic properties, such as R410A, tend to have better efficiency ratings compared to older refrigerants like R22. It is important to choose a compressor with a refrigerant that is compatible with your specific cooling needs.

Compressor Size

The size of the compressor is another important factor that can impact its efficiency. A compressor that is too small for the cooling load of the space will have to work harder and consume more energy to maintain the desired temperature. On the other hand, a compressor that is too large may cycle on and off frequently, leading to energy wastage. It is essential to select a compressor that is properly sized for the cooling requirements of the area to ensure optimal efficiency.

Operating Conditions

The operating conditions of an air conditioner compressor play a crucial role in its efficiency. Higher ambient temperatures, excessive humidity levels, and dirty or clogged condenser coils can cause the compressor to work harder and decrease its overall efficiency. Regular maintenance, including cleaning and inspecting the condenser coils, can help optimize the compressor’s performance and ensure efficient operation.

Airflow and Duct Design

The airflow and duct design within the cooling system can impact the compressor’s efficiency. Insufficient airflow due to restricted or poorly designed ducts can lead to inadequate cooling and increased energy consumption. Proper duct design, regular cleaning, and adequate airflow throughout the system are important factors in maximizing the compressor’s efficiency.

Thermostat Settings

The thermostat settings of the air conditioner can affect its efficiency. Setting the temperature too low can result in excessive energy consumption, while setting it too high may not provide sufficient cooling. It is recommended to set the thermostat at an optimal temperature that balances comfort and energy efficiency. Programmable thermostats can also be utilized to adjust temperature settings based on occupancy and time of day, further enhancing efficiency.

Insulation and Building Envelope

The level of insulation and the overall design of the building envelope can impact the efficiency of the air conditioner compressor. Poor insulation and air leaks can allow cool air to escape and hot air to enter, causing the compressor to work harder to maintain the desired temperature. Proper insulation, weatherstripping, and sealing of air leaks can help reduce energy consumption and improve the efficiency of the compressor.

Maintenance and Regular Servicing

Regular maintenance and servicing of the air conditioner compressor are essential for maintaining its efficiency. Dirty filters, clogged coils, and worn-out components can hinder the compressor’s performance and increase energy consumption. It is important to schedule regular maintenance, including filter replacements, coil cleanings, and inspection of the compressor, to ensure optimal efficiency and prolong the life of the system.

Cooling Capacity

The cooling capacity of an air conditioner compressor is an important factor to consider when testing its efficiency. Cooling capacity refers to the amount of heat that an air conditioner can remove from a room in a given period of time. It is measured in British Thermal Units (BTUs) per hour, or in kilowatts (kW).

When testing the cooling capacity of an air conditioner compressor, several factors should be taken into account. These include the size of the room, the ambient temperature, and the desired temperature. The cooling capacity needed will vary depending on these factors.

To determine the cooling capacity of an air conditioner compressor, a heat load calculation is typically performed. This calculation takes into account the heat sources in the room, such as sunlight, appliances, and occupants, as well as the insulation and ventilation of the space.

Once the cooling capacity of an air conditioner compressor is known, it can be compared to the actual cooling output of the unit. This allows for an assessment of its efficiency. If the cooling capacity is significantly lower than the actual cooling output, it may indicate that the compressor is not operating at its optimal level.

Overall, a comprehensive understanding of the cooling capacity of an air conditioner compressor is essential for testing its efficiency. By accurately evaluating its cooling capacity, one can ensure that the compressor is functioning properly and providing the desired cooling performance.

Compressor Type

When it comes to air conditioners, there are different types of compressors that are used to cool the air. The type of compressor used can have an impact on the efficiency and performance of the air conditioner.

Reciprocating Compressor

A reciprocating compressor is one of the most common types of compressors used in air conditioners. It works by using a piston inside a cylinder to compress the refrigerant gas. As the piston moves up and down, it creates a suction and compression cycle that helps cool the air. Reciprocating compressors are known for their durability and reliability.

Rotary Compressor

A rotary compressor is another type of compressor that is often used in air conditioners. It works by using rotating blades or vanes to compress the refrigerant gas. This type of compressor is known for its smooth and quiet operation. Rotary compressors are often used in small window or portable air conditioners.

Both reciprocating and rotary compressors have their advantages and disadvantages. Reciprocating compressors are more efficient and can handle higher temperatures, but they can be noisier. On the other hand, rotary compressors are quieter, but they are less efficient at higher temperatures.

Overall, the type of compressor used in an air conditioner can impact its efficiency, performance, and noise level. It’s important to consider these factors when choosing an air conditioner for your space.

Refrigerant

The refrigerant is a vital component in an air conditioner compressor. It plays a crucial role in the cooling process by absorbing heat from the indoor air and releasing it outside. The refrigerant is a special substance that undergoes a phase change from a low-pressure gas to a high-pressure liquid and back again. This phase change allows it to transfer heat efficiently.

Types of Refrigerants

There are several types of refrigerants commonly used in air conditioning systems. The most widely used refrigerants include hydrochlorofluorocarbons (HCFCs), hydrofluorocarbons (HFCs), and a new generation of refrigerants known as hydrofluoroolefins (HFOs). HCFCs and HFCs have been phased out due to their ozone-depleting and global warming potential, and HFOs are considered a more environmentally friendly alternative.

Properties of Refrigerants

Refrigerants have specific properties that make them suitable for use in air conditioning systems. These properties include low boiling points, high heat transfer coefficients, and low viscosity. Furthermore, refrigerants must be stable, non-toxic, non-flammable, and non-corrosive to ensure safe and efficient operation of the compressor.

Refrigerant Leaks

One common issue with air conditioning systems is refrigerant leaks. Over time, the refrigerant can escape from the system due to wear and tear or damage to the compressor or refrigerant lines. Refrigerant leaks can lead to decreased cooling efficiency and increased energy consumption. Regular maintenance and inspections are important to identify and repair any refrigerant leaks promptly.

Regulations and Standards

Due to the environmental impact of certain refrigerants, there are regulations and standards in place to regulate their use and disposal. For example, the Montreal Protocol is an international agreement aimed at phasing out the use of ozone-depleting substances, including some refrigerants. Compliance with these regulations is crucial to minimize the environmental impact of air conditioning systems.

Methods for Testing the Efficiency

1. Temperature Differential Test:

One method for testing the efficiency of an air conditioner compressor is the temperature differential test. This test involves measuring the temperature of the air entering and exiting the compressor and calculating the difference in temperature, also known as the temperature differential. A higher temperature differential indicates a more efficient compressor, as it means the compressor is effectively cooling the air.

2. Energy Consumption Test:

Another method for testing compressor efficiency is the energy consumption test. This test involves measuring the amount of energy consumed by the compressor over a set period of time. A more efficient compressor will consume less energy, as it is able to cool the air more effectively with less power. To perform this test, a watt meter or energy monitor can be used to measure the energy consumption of the compressor.

3. Performance Analysis:

Performing a comprehensive performance analysis can also provide insights into the efficiency of an air conditioner compressor. This involves measuring and evaluating various performance parameters such as cooling capacity, air flow rate, and power input. By comparing these parameters to industry standards and manufacturer specifications, it is possible to determine the efficiency of the compressor.

4. Efficiency Ratings:

Efficiency ratings, such as the Seasonal Energy Efficiency Ratio (SEER) or the Energy Efficiency Ratio (EER), can also be used to test the efficiency of an air conditioner compressor. These ratings provide a standardized measurement of the cooling efficiency of a compressor. A higher SEER or EER rating indicates a more efficient compressor.

5. Heat Pump Performance Test:

If the air conditioner compressor functions as a heat pump, a heat pump performance test can be used to assess its efficiency. This test involves measuring the amount of heat output produced by the compressor for a given amount of electrical energy input. A more efficient heat pump compressor will produce more heat output per unit of energy input.

Overall, there are several methods available for testing the efficiency of an air conditioner compressor. By combining these methods and evaluating the results, it is possible to gain a comprehensive understanding of the compressor’s performance and efficiency.

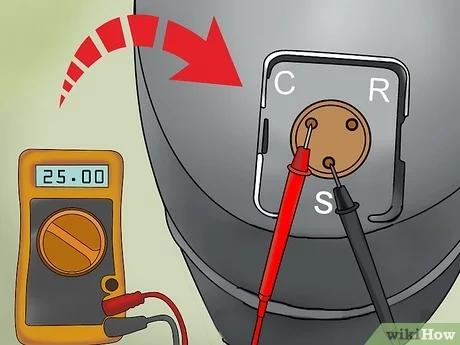

Measuring Power Consumption

To effectively test the efficiency of an air conditioner compressor, it is important to measure the power consumption. By accurately measuring how much power the compressor is drawing, you can determine how efficiently it is operating. This information is crucial for evaluating the overall performance of the air conditioner and identifying potential energy-saving opportunities.

One common method of measuring power consumption is using a watt meter. A watt meter is a device that is connected between the power outlet and the air conditioner compressor. It measures the amount of electrical power being used by the compressor in real-time. This allows for accurate and precise measurements of power consumption.

When using a watt meter, it is important to ensure that the air conditioner is operating under normal conditions. This means that all other electrical appliances should be turned off, and there should be no other significant power draws in the vicinity. This will help to ensure that the measurements obtained are accurate and represent the true power consumption of the air conditioner compressor.

It is also important to take multiple measurements over a period of time to account for any variations in power consumption. This can be done by recording the power consumption at regular intervals, such as every hour or every day, and then calculating an average. By averaging multiple measurements, you can obtain a more reliable and representative value for the power consumption of the air conditioner compressor.

In addition to measuring power consumption, it is also helpful to monitor other factors that can affect the efficiency of the air conditioner compressor. This includes factors such as ambient temperature, humidity levels, and airflow. By taking into account these factors, you can gain a more comprehensive understanding of how the compressor is performing and identify any potential issues or areas for improvement.

Calculating Cooling Output

Calculating the cooling output of an air conditioner compressor is an essential step in determining the efficiency of the system. This measurement is typically expressed in British Thermal Units (BTUs) or tons and represents the amount of heat that the compressor can remove from a space within a specific time frame.

One way to calculate the cooling output is by measuring the temperature difference in the air before and after it passes through the evaporator coil. This temperature difference, also known as the temperature split, can provide an estimate of the amount of heat that is being removed from the air. However, it is important to note that this method does not take into account other factors such as humidity or the thermal properties of the space being cooled.

Another method to calculate the cooling output is by measuring the power consumption of the compressor. The power consumption can be measured using an electrical meter and is typically expressed in watts or kilowatts. By multiplying the power consumption by the coefficient of performance (COP) of the compressor, the cooling output in BTUs or tons can be determined. The COP is a measure of the compressor’s efficiency and represents the ratio of cooling output to power consumption.

It is also possible to calculate the cooling output by taking into account the airflow rate and the temperature difference across the evaporator coil. The airflow rate can be measured using an anemometer, while the temperature difference can be measured using temperature sensors. By multiplying the airflow rate by the specific heat capacity of air and the temperature difference, the cooling output in BTUs or tons can be calculated. However, it is important to ensure that the measurements are accurate and representative of the actual operating conditions of the air conditioner.

In summary, calculating the cooling output of an air conditioner compressor is a crucial step in evaluating its efficiency. There are several methods available, including measuring the temperature difference, power consumption, or airflow rate. It is important to choose the appropriate method based on the specific requirements and limitations of the testing situation.

Temperature Differential Test

The temperature differential test is an important step in testing the efficiency of an air conditioner compressor. It measures the difference in temperature between the air entering the air conditioner and the air leaving the air conditioner. This test helps to determine if the compressor is effectively cooling the air.

To perform the temperature differential test, start by placing a thermometer in the supply air duct, which is where the cooled air is distributed. Take note of the temperature reading. Next, place another thermometer in the return air duct, which is where the warm air is drawn into the air conditioner. Again, take note of the temperature reading.

Calculate the temperature difference by subtracting the temperature in the return air duct from the temperature in the supply air duct. A temperature differential of between 14 to 20 degrees Fahrenheit is generally considered to be optimal. If the temperature differential is lower than this range, it could indicate a problem with the compressor such as low refrigerant levels or a malfunctioning valve. On the other hand, if the temperature differential is higher than this range, it could indicate a problem with the airflow or excessive refrigerant levels.

It is important to note that the temperature differential test should be performed under normal operating conditions, which means the air conditioner should be running for at least 10 to 15 minutes before the test is conducted. Additionally, it is recommended to perform the test on a warm day when the outside temperature is above 80 degrees Fahrenheit.

FAQ:

What is an air conditioner compressor and how does it work?

An air conditioner compressor is a device that pressurizes and circulates refrigerant gas to remove heat from the air inside a building. It works by compressing the refrigerant gas, causing its temperature and pressure to increase. This high-pressure gas then flows into the condenser, where it is cooled and condensed back into a liquid.

Why is testing the efficiency of an air conditioner compressor important?

Testing the efficiency of an air conditioner compressor is important to ensure that it is operating at its optimal performance. An inefficient compressor can lead to higher energy consumption, reduced cooling capacity, and increased utility bills. Regular testing allows for the early detection of any problems or malfunctions, allowing for prompt repairs or replacement.

What are some signs that an air conditioner compressor may not be operating efficiently?

Some signs that an air conditioner compressor may not be operating efficiently include reduced cooling capacity, longer cooling cycles, unusual noises or vibrations, and increased energy consumption. If you notice any of these signs, it is recommended to have your compressor tested by a professional.

How is the efficiency of an air conditioner compressor measured?

The efficiency of an air conditioner compressor is typically measured by its coefficient of performance (COP). The COP is calculated by dividing the cooling capacity of the system by the electrical power input. A higher COP indicates a more efficient compressor.

What are some common tests used to evaluate the efficiency of an air conditioner compressor?

Some common tests used to evaluate the efficiency of an air conditioner compressor include measuring the temperature difference across the evaporator and condenser coils, monitoring the refrigerant pressures and temperatures, and analyzing the electrical power consumption. These tests can provide valuable insights into the performance and operation of the compressor.

Can the efficiency of an air conditioner compressor be improved?

Yes, the efficiency of an air conditioner compressor can be improved through regular maintenance and cleaning. This includes keeping the coils clean, ensuring proper refrigerant charge, and lubricating the moving parts. Additionally, upgrading to a more efficient compressor model or optimizing the overall system design can also improve efficiency.

Video:

![The Experimental Method of Testing the Efficiency of Warning and Cryptic Coloration in Protecting Animals From Their Enemies [ 1912 ]](https://m.media-amazon.com/images/I/31ny0ljP6EL._SS520_.jpg)