Steps to Fix an Air Conditioner Compressor

The air conditioner compressor is one of the main components of an AC unit, responsible for providing cool air to your space. If your compressor is not functioning properly, it can cause your AC to blow warm air or not cool at all. In this article, we will discuss the steps to fix an air conditioner compressor and get your AC running smoothly again.

Step 1: Identify the Problem

Before attempting to fix the compressor, it is crucial to identify the problem accurately. There are several potential issues that can cause a compressor to malfunction, such as low refrigerant levels, a faulty capacitor, or a blocked condenser unit. Inspect the AC unit and compressor carefully to determine the exact cause of the problem.

Step 2: Clean or Replace Air Filters

Clogged or dirty air filters can put additional strain on the AC compressor, causing it to overheat and malfunction. Start by cleaning or replacing the air filters to ensure proper airflow and prevent any further damage to the compressor. This simple step can often solve minor issues and improve the overall performance of your air conditioner.

Step 3: Check the Refrigerant Levels

A low refrigerant level can cause the compressor to work harder than necessary, leading to overheating and eventual failure. Use a refrigerant pressure gauge to check the refrigerant levels in the AC unit. If the levels are low, it may indicate a leak that needs to be repaired. Consult a professional HVAC technician to fix any leaks and recharge the refrigerant if necessary.

Step 4: Inspect and Repair the Capacitor

The capacitor is responsible for providing the necessary electrical voltage to start the compressor. Over time, capacitors can become weak or faulty, preventing the compressor from starting. Use a multimeter to test the capacitor’s voltage and determine if it needs to be replaced. If the capacitor is damaged, replace it with a new one to restore proper functionality to the compressor.

Step 5: Clean the Condenser Unit

A dirty or blocked condenser unit can restrict airflow and cause the compressor to overheat. Inspect the condenser unit for any debris, leaves, or dirt that may be obstructing the airflow. Use a soft brush or a vacuum cleaner to clean the condenser fins gently. Removing any obstructions and ensuring proper airflow can help prevent compressor failure and extend the lifespan of your AC unit.

In conclusion, fixing an air conditioner compressor requires proper diagnosis and a systematic approach. By following these steps, you can identify and resolve common issues that may be causing your compressor to malfunction. However, if you are unsure or uncomfortable with performing these repairs yourself, it is recommended to seek professional help to ensure the safety and effectiveness of the repair.

Preparation for Repair

Before starting the repair process for the air conditioner compressor, it is important to take certain preparatory steps to ensure smooth execution and safety. These steps include:

- Gathering the necessary tools and equipment for the repair, such as a screwdriver, pliers, multimeter, refrigerant recovery machine, and safety goggles.

- Turning off the power supply to the air conditioning system by switching off the circuit breaker or disconnecting the power source.

- Removing any obstructions or debris around the air conditioner compressor unit to provide easy access for repair.

- Examining the compressor for any visible signs of damage, such as leaks, cracks, or loose connections.

- Checking the manufacturer’s manual or documentation for specific instructions on repairing the compressor.

- Taking necessary safety precautions, such as wearing protective clothing, gloves, and eyewear.

Taking these preparatory steps will ensure that the repair process is carried out efficiently and safely. It is important to prioritize safety and follow the manufacturer’s instructions to avoid any accidents or further damage to the air conditioner compressor.

Disconnect the Power

If you suspect that the air conditioner compressor is not functioning properly, the first step is to disconnect the power. This is crucial for ensuring your safety and preventing any further damage. Locate the circuit breaker or fuse box that controls the power supply to the air conditioner. Flip the switch or remove the fuse associated with the air conditioner to cut off the power completely.

Remember to always wear safety gloves and goggles when working with electrical components. This will protect you from any potential electrical shocks or accidents. Additionally, it is important to wait for a few minutes after disconnecting the power before performing any repairs or inspections. This allows any residual electrical charge to dissipate.

Once the power is disconnected, you can proceed with troubleshooting and fixing the air conditioner compressor. However, it is recommended to have a professional technician inspect and repair the compressor, as it can be a complex component to work on. They have the knowledge and expertise to diagnose and resolve any issues effectively and safely.

Clean the Compressor

Regular cleaning of the air conditioner compressor is essential to maintain its efficiency and prevent any potential issues. Here are the steps to clean the compressor:

- Turn off the power: Before starting the cleaning process, make sure to turn off the power supply to the air conditioner. This step is crucial to ensure your safety.

- Remove debris: Inspect the compressor unit and remove any leaves, dirt, or debris that may have accumulated on and around it. Use a brush or a vacuum cleaner to clean the outer surface of the compressor.

- Clean the condenser fins: The condenser fins are responsible for transferring heat from the compressor. Gently clean the condenser fins using a soft brush or a fin comb, making sure not to bend or damage them. Removing any dirt or debris from the fins will help improve airflow and prevent overheating.

- Clean the fan blades: Dust and dirt can also accumulate on the fan blades. Use a damp cloth or a brush to wipe the fan blades clean. Ensure that the blades are free from any obstructions that may hinder their movement.

- Check the drainage system: Inspect the drainage system and clear out any clogs or blockages. A clogged drainage system can cause water to back up and damage the compressor, so it is important to ensure that the drainage is clear.

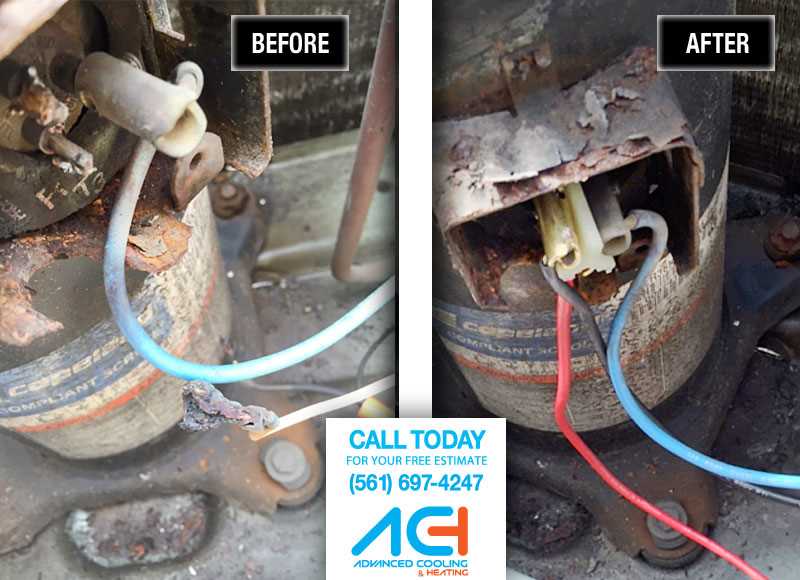

- Inspect the wiring: Take a look at the wiring connections and make sure they are secure. Loose or damaged wiring can lead to electrical issues and may affect the compressor’s performance.

Regularly cleaning the compressor will not only prolong its lifespan but also help maintain the overall efficiency of your air conditioner. It is recommended to perform this cleaning at least once a year or as needed, depending on the air quality and usage of the unit.

Check the Wiring

One of the first steps to fix an air conditioner compressor is to check the wiring. Faulty or damaged wiring can cause the compressor to malfunction. Start by inspecting the wiring connections and visually checking for any signs of fraying, fraying or corrosion. If you notice any issues, replace the damaged wires or connectors.

Next, use a multimeter to test the continuity of the wires. Disconnect the power supply to the air conditioner and remove the access panel to gain access to the compressor wiring. Set the multimeter to the continuity or ohms setting and touch the probes to the connectors on each wire. A reading of zero or close to zero indicates good continuity, while a high reading or no reading indicates a broken wire.

If any wires are found to be faulty, replace them with the appropriate gauge wire. It’s important to match the gauge and type of wire for proper function and safety. Additionally, make sure that all wires are securely connected to their respective terminals and that there is no loose connection.

Finally, check the wiring diagram or manual provided by the manufacturer to ensure that the correct wiring connections are being used. Referencing the diagram can help identify any wiring errors that may be causing the compressor to not work properly.

Inspect the Capacitor

One of the common reasons for an air conditioner compressor not working properly is a faulty capacitor. The capacitor is a small cylindrical device responsible for providing the initial boost of power to start the compressor motor. Over time, capacitors can become weak or fail completely, resulting in compressor malfunctions.

To inspect the capacitor, you will need to turn off the power to the air conditioner unit and remove the access panel. Once the panel is removed, locate the capacitor which is usually cylindrical in shape and has two or three terminals. Carefully examine the capacitor for any signs of physical damage such as bulging or leaking. These are clear indications that the capacitor needs to be replaced.

Another way to check the capacitor is by using a multimeter. Set the multimeter to the capacitance setting and touch the probes to the capacitor terminals. If the reading on the multimeter shows a capacitance value significantly lower than the capacitor’s rated value, it means the capacitor is faulty and needs to be replaced.

Replacing a capacitor is a relatively easy and inexpensive fix. You can purchase a new capacitor of the same specifications from a local HVAC supply store or online. Make sure to disconnect the wires from the old capacitor and connect them to the new one in the same configuration. Take note of the wire colors and their corresponding terminals to avoid any confusion during the installation process.

After installing the new capacitor, replace the access panel and restore power to the air conditioner unit. Turn on the unit and observe its operation. If the compressor starts running smoothly and the air conditioner cools properly, then the capacitor was indeed the issue. However, if the problem persists, it may be necessary to further inspect other components or seek professional help.

Replace Faulty Parts

One of the possible reasons for an air conditioner compressor not functioning properly is due to faulty parts. When diagnosing the issue, it is important to identify which specific component is causing the problem. Common faulty parts in an air conditioner compressor include the condenser fan motor, capacitor, relay, and thermostat.

Condenser Fan Motor

The condenser fan motor plays a crucial role in the cooling process of an air conditioner. If the motor is faulty, it may not be able to properly circulate the air, leading to reduced cooling capacity. To replace a faulty condenser fan motor, first, ensure that the power to the unit is turned off. Then, locate the motor near the condenser unit and disconnect the wires and mounting bolts. Install the new motor by connecting the wires correctly and securing it with the mounting bolts.

Capacitor

The capacitor is responsible for storing and releasing energy to start the compressor and fan motors. If the capacitor is faulty, the compressor may not turn on or may not run smoothly. To replace a faulty capacitor, first, turn off the power to the unit and discharge any stored electricity. Locate the old capacitor, which is usually cylindrical in shape, and disconnect the wires. Install the new capacitor by connecting the wires to the correct terminals.

Relay

The relay controls the flow of electricity to the compressor. If the relay is faulty, the compressor may not receive the necessary power to run. To replace a faulty relay, first, turn off the power to the unit. Locate the relay, which is usually located near the compressor, and disconnect the wires. Install the new relay by connecting the wires to the appropriate terminals.

Thermostat

The thermostat is responsible for regulating the temperature and turning the compressor on and off. If the thermostat is faulty, it may not properly communicate with the compressor, leading to inconsistent cooling. To replace a faulty thermostat, first, turn off the power to the unit. Locate the thermostat, usually mounted on a wall, and disconnect the wires. Install the new thermostat by connecting the wires to the correct terminals and securely mounting it on the wall.

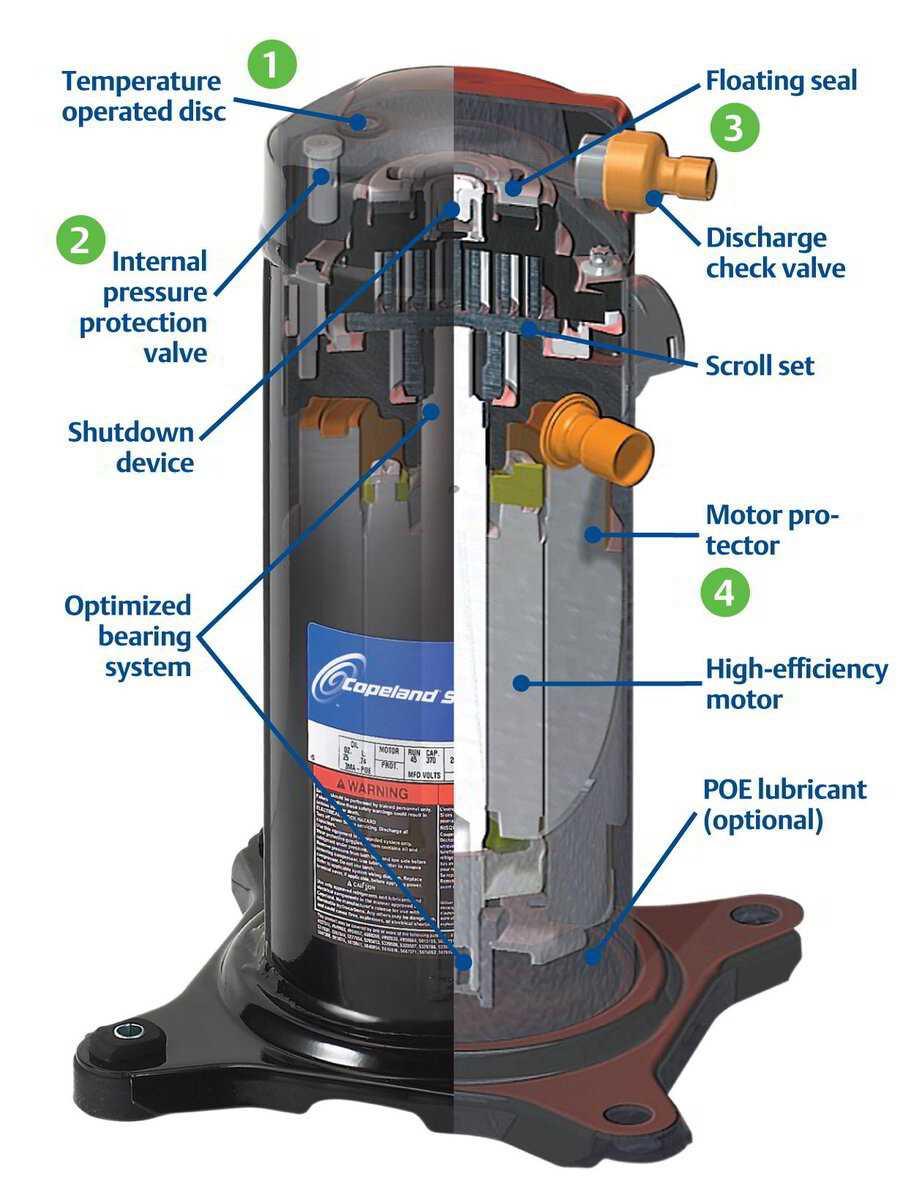

Reassemble the Compressor

After cleaning all the components of the air conditioner compressor, it is time to reassemble them. Begin by placing the piston back into the cylinder, making sure it is aligned properly. Use a lubricant to ensure smooth movement of the piston.

Next, reattach the cylinder head onto the compressor body. Tighten the bolts securely to prevent any air leaks. Check the gasket and replace it if necessary.

Once the cylinder head is in place, reinstall the valves. Make sure they are clean and free of any debris. Apply thread sealant to the valve threads before screwing them back into place.

After the valves are secured, reattach the crankshaft onto the compressor body. Make sure it is aligned correctly and spins freely. Use a torque wrench to tighten the bolts to the manufacturer’s specifications.

Finally, reconnect any electrical connections that were disconnected during the disassembly process. Double-check that all connections are secure and in the correct position.

In conclusion, reassembling the air conditioner compressor involves putting the piston, cylinder head, valves, and crankshaft back into place. It is important to ensure proper alignment, tighten all bolts securely, and reconnect any electrical connections. Following these steps will help ensure the compressor functions properly once it is reinstalled in the air conditioning unit.

Test the AC System

To properly diagnose and fix an air conditioner compressor, it is important to first test the AC system. Testing the AC system will help determine the root cause of the problem and guide the repair process.

1. Check for Power Supply

Start by checking if the air conditioner has a proper power supply. Make sure that the electrical circuit breaker or fuse for the AC unit is in the “On” position. If the breaker or fuse has been tripped, reset it and test the system again. If the power supply is intact, move on to the next step.

2. Inspect the Wiring

Inspect the wiring of the AC system for any signs of damage or loose connections. Check the wiring connections at the compressor and at the control panel. Make sure all wires are securely connected and there are no frayed or damaged wires. If any wiring issues are found, repair or replace the affected wires.

3. Test the Thermostat

Next, test the thermostat of the AC system to ensure it is functioning correctly. Adjust the thermostat settings to cool and set the temperature lower than the current room temperature. Listen for a clicking sound, which indicates that the thermostat is signaling the compressor to turn on. If the thermostat is not working or not sending a signal to the compressor, it may need to be replaced.

4. Check the Capacitor

The capacitor is a component that helps start the compressor motor. Inspect the capacitor for any signs of damage, such as swelling or leakage. Use a multimeter to test the capacitor’s capacitance and resistance. If the capacitor is faulty, it should be replaced.

5. Measure Refrigerant Levels

Finally, measure the refrigerant levels in the AC system. Low refrigerant levels can cause the compressor to work improperly or fail completely. Use a refrigerant pressure gauge to measure the pressure. If the pressure is too low, there may be a refrigerant leak that needs to be repaired. If the pressure is too high, the system may be overcharged with refrigerant.

By testing the AC system thoroughly, you can determine the cause of the compressor issue and take the necessary steps to fix it. If you are unsure how to perform any of these tests, it is recommended to seek professional help.

FAQ:

Why is my air conditioner compressor not working?

There could be several reasons for your air conditioner compressor not working. It could be due to a faulty motor, a blown fuse, low refrigerant levels, or a malfunctioning thermostat. To fix the problem, you should first check the power supply to the compressor, make sure all the fuses and circuit breakers are intact, and ensure that the thermostat is set to the correct temperature.

How can I fix a compressor that won’t turn on?

If your compressor won’t turn on, there are a few steps you can take to fix the issue. First, check if the power supply to the compressor is working properly. Make sure that the circuit breaker or fuse is not blown and that the electrical connections are secure. If the power supply is fine, you should also check the thermostat setting and adjust it if necessary. If none of these steps resolve the issue, it may be necessary to call a professional technician to repair or replace the compressor.

What should I do if my air conditioner’s compressor is making strange noises?

If your air conditioner’s compressor is making strange noises, such as grinding, squealing, or rattling, it may indicate a mechanical problem. You should first turn off the unit to prevent further damage and potential safety hazards. Then, check if any debris or foreign objects are lodged in the compressor. If so, remove them carefully. If the noises continue, it is recommended to call a professional technician to inspect and repair the compressor.

Can I fix a compressor that is leaking refrigerant by myself?

Fixing a compressor that is leaking refrigerant is not recommended as it requires specialized knowledge and equipment. Refrigerant leaks can be dangerous for both your health and the environment, so it is best to leave this task to a qualified technician. The technician will be able to identify the source of the leak and repair it properly, ensuring the safe and efficient operation of your air conditioner.

How can I prevent my air conditioner compressor from overheating?

To prevent your air conditioner compressor from overheating, you can take several preventive measures. First, make sure that the compressor is clean and free from dust or debris. Regularly clean or replace the air filters as well, as dirty filters can obstruct airflow and put extra strain on the compressor. Additionally, you should ensure that the refrigerant levels are correct and that the condenser coils are not blocked. If you notice any issues, it is recommended to have your air conditioner serviced by a professional technician.

What are the signs of a faulty air conditioner compressor?

There are several signs that may indicate a faulty air conditioner compressor. These include the air conditioner not producing cool air, unusual noises coming from the compressor, a build-up of frost or ice on the coils, or the unit constantly running without cycling off. If you notice any of these signs, it is advisable to have your air conditioner inspected by a qualified technician who can diagnose and repair the issue.

How much does it cost to repair or replace an air conditioner compressor?

The cost to repair or replace an air conditioner compressor can vary depending on several factors, such as the extent of the damage, the type of compressor, and the region where you live. In general, compressor repairs can range from $200 to $1500, while replacement costs can range from $1500 to $4000 or more. It is recommended to obtain quotes from multiple HVAC contractors to get a better idea of the specific costs for your situation.

Video: