Reusing or Recycling Old Air Compressors: Sustainable Options

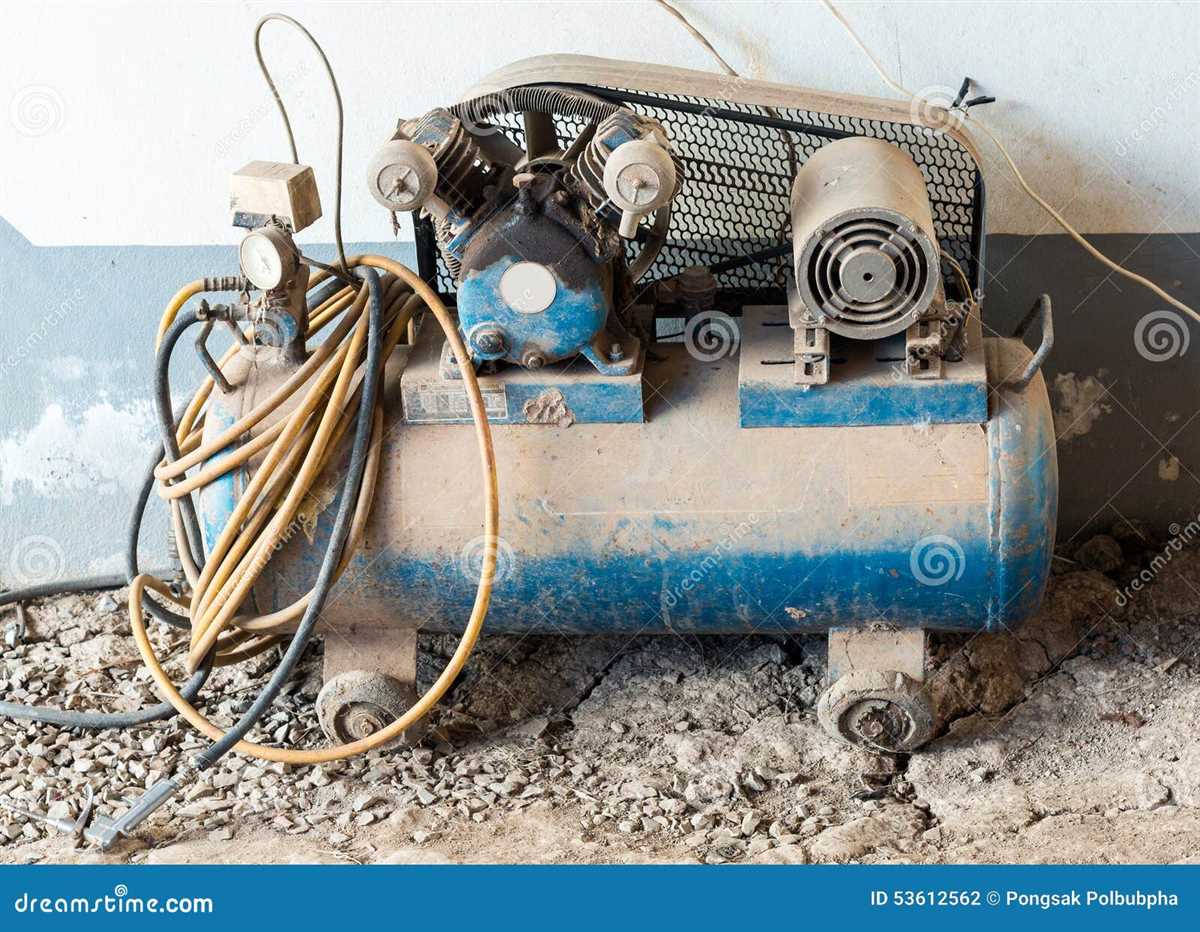

In today’s world, sustainability is more important than ever. With the increasing focus on reducing waste and conserving resources, finding ways to reuse or recycle old equipment has become crucial. Air compressors, commonly used in a variety of industries, are no exception. Instead of simply discarding old air compressors, there are several sustainable options available that can help minimize environmental impact and even provide economic benefits.

One option for reusing old air compressors is to refurbish and repair them. Many times, older models can still be functional with some maintenance and repairs. By refurbishing old air compressors, not only can they continue to be used, but it also helps to reduce the need for new manufacturing and the associated environmental impact.

Another sustainable option for old air compressors is recycling. While it may not always be possible to refurbish or repair a compressor, recycling ensures that its components are properly disposed of and can be used in the manufacturing of new products. This helps to conserve resources and reduce the demand for raw materials.

Furthermore, some companies even offer buyback programs for old air compressors. This allows individuals or businesses to sell their old equipment back to the manufacturer or a third-party vendor, who can then refurbish or recycle the compressors. These buyback programs provide a financial incentive for individuals or businesses to properly dispose of their old air compressors while also reducing waste.

In conclusion, reusing or recycling old air compressors offers sustainable options that not only minimize environmental impact but can also provide economic benefits. By refurbishing, repairing, or recycling old compressors, resources can be conserved, waste can be reduced, and the demand for new equipment can be mitigated. It is important for individuals and businesses to explore these sustainable options and make responsible choices when it comes to the disposal of old air compressors.

Benefits of Reusing or Recycling Old Air Compressors

Reusing or recycling old air compressors brings several benefits, both for the environment and for businesses. Here are some key advantages:

1. Environmental Conservation

By reusing or recycling old air compressors, we can reduce the amount of waste that ends up in landfills or incinerators. This helps to conserve natural resources and minimizes the environmental impact of manufacturing new compressors.

2. Energy Efficiency

Old air compressors often consume more energy than newer models. By reusing or recycling them, businesses can replace outdated machines with more energy-efficient options. This not only reduces electricity consumption but also lowers carbon emissions and operating costs.

3. Cost Savings

Reusing or recycling old air compressors can be a cost-effective solution for businesses. Instead of investing in a brand new compressor, they can choose to refurbish or repair their existing machinery. This saves money on purchasing new equipment and reduces maintenance expenses in the long run.

4. Resource Conservation

Reusing old air compressors helps to conserve valuable resources, such as metal, plastics, and other materials used in their construction. By extending the lifespan of these machines, we can contribute to a more sustainable use of finite resources and reduce the need for new production.

5. Corporate Social Responsibility

Engaging in reusing or recycling old air compressors aligns with the principles of corporate social responsibility. It demonstrates a commitment to environmental stewardship and responsible waste management practices, improving the company’s reputation among customers, employees, and other stakeholders.

In conclusion, reusing or recycling old air compressors offers many benefits, including environmental conservation, energy efficiency, cost savings, resource conservation, and corporate social responsibility. By adopting sustainable practices in compressor management, businesses can contribute to a greener future while also enjoying the advantages of reduced waste and improved efficiency.

Environmental Impact

The disposal of old air compressors can have a significant environmental impact. When air compressors are not properly disposed of, they can release harmful substances into the environment. For example, some air compressors contain refrigerants or oils that can leak out and contaminate soil, water, and air. This contamination can have harmful effects on plant and animal life.

Additionally, the manufacturing of new air compressors requires the extraction and processing of raw materials like metals and plastics. These processes can contribute to deforestation, habitat destruction, and air and water pollution. By reusing or recycling old air compressors, we can reduce the demand for new ones and minimize these negative environmental impacts.

Reusing old air compressors is a sustainable option that helps to reduce waste and conserve resources. By finding new uses for these machines, we can extend their lifespan and prevent them from ending up in landfills. This approach reduces the need for new production and reduces the associated environmental impacts.

Recycling old air compressors is another eco-friendly option. When air compressors are recycled, their materials can be recovered and reused in the manufacturing of new products. This reduces the need for virgin materials and saves energy that would be required for the extraction and processing of these materials. Recycling also helps to divert waste from landfills and reduce pollution associated with the disposal of air compressors.

Resource Conservation

When it comes to old air compressors, resource conservation is a key consideration. Reusing or recycling these compressors helps to conserve valuable resources such as metals, plastics, and energy.

By reusing old air compressors, we can extend their lifespan and reduce the need for producing new ones. This conserves the raw materials used in manufacturing, such as steel and aluminum. Additionally, reusing compressors reduces the demand for new production, which in turn reduces energy consumption and greenhouse gas emissions associated with manufacturing processes.

Recycling old air compressors is another sustainable option for resource conservation. Through recycling, the valuable materials contained within the compressors can be extracted and reused in the production of new products. This reduces the need for mining and processing new raw materials, conserving natural resources and reducing energy consumption and environmental impact.

In addition to conserving materials and energy, reusing or recycling old air compressors can also benefit the economy by creating opportunities for repair and refurbishment services, as well as recycling facilities. These activities can generate jobs and promote local economic growth.

Overall, resource conservation is a critical aspect of sustainable options for old air compressors. By reusing or recycling these compressors, we can contribute to the conservation of valuable resources, reduce energy consumption, and promote economic growth.

Economic Benefits

Reusing or recycling old air compressors can provide various economic benefits for businesses and individuals.

Cost savings

One of the significant economic benefits of reusing or recycling old air compressors is cost savings. Instead of purchasing a brand new air compressor, businesses can save money by opting for refurbished or recycled ones. Refurbished compressors are typically priced lower than new ones, making them a cost-effective option. Additionally, by recycling old air compressors, businesses can avoid disposal costs and potentially receive financial incentives or tax credits for participating in recycling programs.

Extended equipment lifespan

By reusing or recycling old air compressors, businesses can extend the lifespan of their equipment. This translates into long-term cost savings as there is no need to replace the compressor prematurely. Proper maintenance, repairs, and refurbishment can help ensure that the compressor continues to function efficiently, saving businesses money on expensive replacements.

Opportunities for resale

When businesses or individuals choose to recycle their old air compressors, they may have the opportunity to resell the refurbished units. There is a market for used air compressors, and by refurbishing and reselling them, businesses can generate additional revenue. This not only benefits the business financially but also contributes to a circular economy by ensuring the continued use of resources instead of adding to landfill waste.

Job creation

The recycling and refurbishment of old air compressors can also have positive economic impacts by creating job opportunities. Recycling facilities require a workforce to handle the disassembly, sorting, and refurbishment processes. Additionally, there can be job opportunities in the sales and distribution of refurbished air compressors. This can help stimulate the local economy and provide employment opportunities for individuals in the community.

Overall, reusing or recycling old air compressors offers a range of economic benefits, including cost savings, extended equipment lifespan, opportunities for resale, and job creation. These benefits make it a sustainable and financially viable option for businesses and individuals alike.

Energy Efficiency

Importance of Energy Efficiency in Old Air Compressors

Energy efficiency plays a crucial role in the reusing or recycling of old air compressors. By improving the energy efficiency of these machines, we can reduce the overall energy consumption and minimize the environmental impact.

Upgrading and Retrofitting to Improve Energy Efficiency

One way to improve the energy efficiency of old air compressors is by upgrading and retrofitting them with newer technologies. This may involve replacing outdated components with more efficient ones or adding energy-saving features. These upgrades can significantly reduce energy waste and improve the overall performance of the equipment.

Regular Maintenance and Inspections

Regular maintenance and inspections are essential for ensuring the energy efficiency of old air compressors. Proper lubrication, cleaning, and calibration of the equipment can help optimize its performance and minimize energy wastage. Additionally, regular inspections can identify and address any potential issues or malfunctioning parts that may negatively impact energy efficiency.

Consideration of Energy Ratings

When reusing or recycling old air compressors, it is important to consider their energy ratings. Energy-efficient compressors are designed to minimize energy consumption and reduce environmental impact. By selecting compressors with high energy ratings, we can contribute to sustainable practices and ensure efficient use of resources.

Education and Training

Providing education and training to operators and maintenance personnel is vital for ensuring energy efficiency in old air compressors. By raising awareness about energy-saving practices and techniques, we can enhance the understanding of how to operate and maintain the compressors in an energy-efficient manner. This can lead to improved efficiency, reduced energy waste, and extended equipment lifespan.

Monitoring and Optimization

Implementing monitoring systems and optimization strategies can also contribute to the energy efficiency of old air compressors. By continuously monitoring the performance and energy consumption of the equipment, we can identify areas for improvement and implement necessary adjustments. This could include optimizing the pressure settings, reducing idle times, or implementing load-shedding techniques to minimize energy waste.

Incentives for Energy Efficiency

Offering incentives for energy-efficient practices in reusing or recycling old air compressors can encourage businesses and individuals to prioritize energy efficiency. These incentives can take the form of tax credits, rebates, or grants, which can offset the costs associated with upgrading or retrofitting old compressors. By providing these incentives, we can promote the adoption of sustainable solutions and contribute to a more energy-efficient future.

Extended Service Life

The goal of reusing or recycling old air compressors is to extend their service life as much as possible. By properly maintaining and repairing these machines, they can continue to function effectively for many years. Regular inspections and maintenance can help identify any potential issues and prevent major breakdowns. Additionally, investing in high-quality replacement parts when needed can also help prolong the service life of the compressor.

Proper Maintenance

Proper maintenance is crucial for extending the service life of old air compressors. This includes regular cleaning to remove dust and debris, changing filters and lubricating parts as recommended by the manufacturer. It is also important to regularly check the oil levels and inspect for any leaks or unusual noises. By following a maintenance schedule, operators can catch any potential issues early and prevent them from developing into major problems.

Quality Repairs and Parts

When repairs are necessary, it is important to use high-quality replacement parts. This ensures that the air compressor is restored to its original functionality and reduces the risk of future breakdowns. Using genuine manufacturer parts or parts from reputable suppliers can help prolong the service life of the machine. In addition, properly trained technicians should be hired to perform the repairs to ensure that the work is done correctly and efficiently.

Upgrades and Retrofits

Another option for extending the service life of old air compressors is to consider upgrades or retrofits. Upgrading certain components or adding new features can improve the efficiency and performance of the machine, making it more sustainable and cost-effective. Retrofits, on the other hand, involve modifying the existing compressor to meet updated industry standards or environmental regulations. These upgrades and retrofits can help extend the useful life of the compressor and ensure that it remains in compliance with current requirements.

Alternative Uses

If an old air compressor is no longer suitable for its original purpose, it may still have potential for alternative uses. For example, the compressor can be repurposed for applications such as inflating tires, powering small tools or even as a backup air source in case of emergencies. By finding alternative uses for old compressors, their lifespan can be extended and their environmental impact reduced.

In summary, extended service life is a key goal when reusing or recycling old air compressors. Through proper maintenance, using high-quality parts, considering upgrades or retrofits, and finding alternative uses, these machines can continue to be used effectively, reducing waste and promoting sustainability.

Reduced Waste Generation

One of the key benefits of reusing or recycling old air compressors is the reduction of waste generation. Instead of disposing of the entire air compressor as waste, which can contribute to landfill pollution, reusing or recycling allows for the extraction of valuable materials and components that can be used again or repurposed.

Lower landfill waste: By reusing or recycling old air compressors, the amount of waste that ends up in landfills is reduced. This helps to preserve natural resources and reduce the environmental impact of waste disposal.

Resource conservation: In the process of reusing or recycling old air compressors, valuable resources such as metals, plastics, and electronic components can be extracted and used again. This helps to conserve resources and reduce the need for virgin materials.

Economic benefits: Reusing or recycling old air compressors can also have economic benefits. The extraction of valuable materials can be sold or used in other manufacturing processes, providing a source of income and reducing the need for new material purchases.

Extended product lifespan: By reusing or recycling old air compressors, the lifespan of the product is extended. This reduces the overall demand for new air compressors and the resources required to manufacture them, contributing to a more sustainable economy.

Regulatory compliance: There are also legal and regulatory requirements in many countries regarding the disposal of electronic waste. By reusing or recycling old air compressors, companies and individuals can ensure compliance with these regulations and avoid potential penalties or fines.

Supporting the Circular Economy

Reusing or recycling old air compressors can greatly contribute to supporting the circular economy, which aims to minimize waste and maximize the use of resources. By extending the lifespan of air compressors through reuse or recycling, we can reduce the need for new production and minimize the environmental impact associated with manufacturing and disposal.

1. Reuse: Giving Old Air Compressors a Second Life

One sustainable option for old air compressors is to give them a second life through reuse. This can be achieved by refurbishing and repairing the compressors to ensure they are in good working condition. Reusing old air compressors not only reduces the demand for new production but also saves energy and resources that would have been used in manufacturing a new compressor.

2. Recycling: Transforming Old Compressors into New Products

If an old air compressor is beyond repair or no longer functional, recycling it is the next best option. Recycling involves breaking down the compressor into its constituent parts, such as metal, plastic, and electronic components, and processing them to create new products or materials. Through recycling, valuable materials can be extracted and used in other industries, reducing the need for virgin resources.

3. Ensuring Responsible Recycling Practices

When recycling old air compressors, it is important to ensure responsible recycling practices are followed to minimize negative environmental impacts. This includes proper handling and disposal of hazardous materials, such as refrigerants and oils, as well as adhering to recycling regulations and guidelines. Working with certified recycling facilities or engaging with manufacturer take-back programs can help ensure that the recycling process is carried out responsibly.

Overall, supporting the circular economy through reusing or recycling old air compressors not only reduces waste and conserves resources but also contributes to the reduction of greenhouse gas emissions and the preservation of natural ecosystems.

Compliance with Sustainable Practices

When it comes to reusing or recycling old air compressors, it is crucial to ensure that the process complies with sustainable practices. This means taking into consideration the environmental impact of disposing of the equipment and finding ways to minimize it.

1. Environmental Impact Assessment: Before deciding on the appropriate course of action for old air compressors, it is important to conduct an environmental impact assessment. This assessment will help determine the potential negative effects of various disposal methods and assist in choosing the most sustainable option.

2. Recycling and Repurposing: One sustainable option for old air compressors is recycling. Materials such as metal, plastic, and rubber can be salvaged and reused, reducing the need for extracting and manufacturing new resources. Additionally, parts of the compressor may still be in working condition and can be repurposed for other applications, further extending their lifespan.

3. Proper Disposal: If recycling or repurposing is not possible, it is important to ensure proper disposal of old air compressors. This may involve taking them to a specialized recycling center or contacting an authorized waste management company to handle the equipment in an environmentally responsible manner.

4. Awareness and Education: Promoting awareness and educating individuals and organizations about the sustainable practices involved in reusing or recycling old air compressors can contribute to a larger adoption of these practices. This can be done through public campaigns, workshops, or online resources that provide information on the benefits and methods of sustainable disposal.

5. Legislation and Policy Support: Governments and regulatory bodies can play a crucial role in enforcing sustainable practices for the disposal of old air compressors. Implementing legislation and policies that incentivize recycling and penalize improper disposal can help create a more sustainable system.

FAQ:

Why should I consider reusing or recycling my old air compressor?

There are several reasons why you should consider reusing or recycling your old air compressor. Firstly, it reduces the amount of waste that ends up in landfills, helping to protect the environment. Additionally, reusing or recycling your old air compressor can also save you money by allowing you to repurpose or sell it instead of buying a new one. Finally, it is a more sustainable option as it conserves resources and reduces the need for new manufacturing.

How can I reuse my old air compressor?

There are various ways you can reuse your old air compressor. If it is still in working condition, you can repurpose it for different applications such as inflating tires or powering tools. You can also consider donating it to a local organization or school that might have a use for it. Another option is to sell it online or through classified ads to someone who is in need of an air compressor.

Can I recycle my old air compressor?

Yes, you can recycle your old air compressor. However, it is important to note that not all recycling centers accept air compressors due to the hazardous materials they may contain. It is recommended to check with your local recycling center for specific guidelines on how to properly dispose of your old air compressor. They may require certain parts to be removed or have specific instructions for safe disposal.

What are the environmental benefits of reusing or recycling old air compressors?

Reusing or recycling old air compressors has several environmental benefits. Firstly, it helps to reduce the amount of waste that ends up in landfills, conserving valuable landfill space. Additionally, by reusing or recycling old air compressors, fewer new resources are needed for manufacturing new ones, which helps to conserve natural resources. It also reduces the energy and emissions associated with manufacturing, as reusing or recycling requires less energy compared to producing new air compressors.

Where can I donate my old air compressor?

You can donate your old air compressor to various organizations or schools that might have a use for it. Local trade schools, vocational training centers, or community centers might be interested in accepting your donation. You can also reach out to non-profit organizations or charities that focus on providing tools and equipment to those in need. Make sure to contact these organizations beforehand to check if they are currently accepting donations and if your air compressor meets their requirements.

Can I sell my old air compressor?

Yes, you can sell your old air compressor if it is still in working condition or if it can be repaired. There are various online platforms, auction websites, or classified ads where you can list your air compressor for sale. Make sure to provide accurate information about the condition of the compressor and include clear photos. Additionally, you can also check with local tool shops or equipment resellers to see if they would be interested in purchasing your old air compressor.

Are there any regulations for disposing of old air compressors?

There may be regulations for disposing of old air compressors due to the hazardous materials they may contain. It is recommended to check with your local recycling center or waste management facility for specific guidelines on how to properly dispose of your old air compressor. They will have information on any required procedures, such as removing certain parts or handling specific components, to ensure the safe disposal of the compressor.

Video: