Oil vs Oilless Air Compressor: Which One Reigns Supreme?

When it comes to air compressors, there are two main types: oil and oilless. Each type has its own advantages and disadvantages, and choosing the right one for your needs can make a big difference in performance and maintenance.

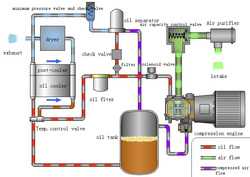

An oil air compressor, as the name suggests, uses oil to lubricate the moving parts of the compressor. This lubrication helps reduce friction and heat, allowing the compressor to operate more efficiently and quietly. Oil air compressors are generally more durable and have a longer lifespan compared to oilless compressors. However, they require regular oil changes and maintenance to ensure optimal performance.

On the other hand, an oilless air compressor does not require oil for lubrication. Instead, it uses specially designed materials and coatings to reduce friction and heat. This type of compressor is typically lighter and more portable than oil compressors, making it ideal for tasks that require mobility. Additionally, oilless compressors do not emit oil vapor, making them suitable for applications where oil contamination is a concern, such as in the medical and food industry.

When deciding between an oil and oilless air compressor, it is important to consider your specific needs and requirements. If durability, performance, and quiet operation are your top priorities, an oil air compressor may be the better choice. However, if portability, cleanliness, and freedom from oil contamination are more important to you, an oilless air compressor might be the way to go. Ultimately, the decision depends on the nature of your tasks and your personal preferences.

Regardless of which type you choose, it is crucial to properly maintain and care for your air compressor to ensure its longevity and optimal performance. Regular maintenance, such as checking for air leaks, cleaning filters, and monitoring oil levels (if applicable), will help prolong the life of your compressor and prevent costly repairs or replacements.

In conclusion, both oil and oilless air compressors have their own set of advantages and disadvantages. The choice between the two ultimately depends on your specific needs and priorities. Whether you prioritize durability and performance or portability and cleanliness, proper maintenance is key to getting the most out of your air compressor.

Pros and Cons of Oil Air Compressors

Oil air compressors have been widely used for their many benefits, but they also come with some drawbacks. Let’s take a closer look at the pros and cons of oil air compressors.

Pros:

- Durability: One of the biggest advantages of oil air compressors is their durability. The use of oil in the system helps to lubricate the moving parts, reducing friction and wear. This ultimately leads to a longer lifespan for the compressor.

- Quieter operation: Oil air compressors tend to be quieter than their oilless counterparts. The oil helps to dampen the sound produced by the compressor, making it a better choice for environments where noise is a concern.

- Higher efficiency: The lubrication provided by oil allows for smoother operation, resulting in higher efficiency. This means that oil air compressors can deliver more compressed air per unit of energy consumed.

- Better cooling: The oil in the system also serves as a coolant, helping to regulate the temperature of the compressor. This prevents overheating and extends the life of the compressor.

Cons:

- Maintenance: Oil air compressors require regular maintenance to ensure optimal performance. This includes changing the oil, cleaning filters, and checking for any leaks or damage.

- Oil contamination: While the oil in the system provides lubrication, it can also lead to oil contamination in the compressed air. This may not be suitable for certain applications where oil-free air is required.

- Higher cost: Oil air compressors are typically more expensive compared to oilless options. The initial cost and ongoing maintenance expenses can be a disadvantage for those on a tight budget.

- Environmental impact: The use of oil in air compressors can have an environmental impact. Oil leaks or spills from the compressor can contaminate the surrounding environment if not properly managed.

Overall, oil air compressors offer several benefits such as durability, quieter operation, higher efficiency, and better cooling. However, they do require regular maintenance, can lead to oil contamination, come with a higher cost, and have potential environmental implications. It is important to carefully consider these pros and cons when deciding whether an oil air compressor is the right choice for your specific needs.

Advantages and Disadvantages of Oilless Air Compressors

Advantages:

An oilless air compressor offers several advantages over its oil-based counterpart. One of the main advantages is that oilless compressors do not require regular lubrication, which eliminates the need for oil changes and reduces maintenance costs. This can save both time and money in the long run.

Another advantage of oilless air compressors is that they produce cleaner air. Since there is no oil involved in the compression process, there is no risk of oil contamination in the air supply. This is particularly beneficial in industries where clean and oil-free air is essential, such as food processing or medical applications.

Oilless compressors are also more lightweight and portable compared to oil-based compressors. They are often smaller in size and easier to move around, making them ideal for applications that require mobility or transportation.

Disadvantages:

While oilless air compressors have their advantages, they also have a few drawbacks worth considering. One disadvantage is that oilless compressors tend to run at higher temperatures compared to oil-based compressors. This can lead to increased wear and tear on the components, potentially reducing the lifespan of the compressor.

Another disadvantage is that oilless compressors are generally louder than their oil-based counterparts. The lack of lubrication means that there is more metal-on-metal contact, resulting in increased noise levels during operation. This can be a significant factor to consider, especially in noise-sensitive environments or if the compressor is used for prolonged periods.

Additionally, oilless compressors may have lower air delivery capacity compared to oil-based compressors. The absence of oil lubrication can result in less efficient compression, leading to lower airflow and potentially impacting performance in applications that require high volumes of compressed air.

In summary, oilless air compressors offer benefits such as reduced maintenance, cleaner air output, and portability. However, their higher operating temperatures, increased noise levels, and potentially lower airflow capacity may be disadvantages to consider depending on the specific application.

Performance Comparison: Oil vs Oilless Air Compressors

Oil Air Compressors

Oil air compressors have long been the standard in many industries due to their efficient performance and durability. These compressors use oil lubrication to reduce friction and heat, allowing for smooth and continuous operation even under heavy workloads. The oil also helps to seal and protect internal components, ensuring longevity and reliability.

When it comes to performance, oil air compressors offer higher air pressure and volume, making them suitable for demanding applications. They are capable of achieving higher CFM (cubic feet per minute) ratings, which means they can deliver more compressed air in a shorter amount of time. This makes them ideal for tasks such as sandblasting, spray painting, and operating pneumatic tools that require a high flow rate.

Oilless Air Compressors

Oilless air compressors, as the name suggests, do not require oil lubrication. Instead, they use advanced engineering techniques and materials to reduce friction and heat generation. These compressors are often preferred in industries where oil contamination is a concern, such as in food processing or pharmaceutical applications.

In terms of performance, oilless air compressors typically have a lower CFM rating compared to their oil counterparts. This means they may not be as suitable for high-demand tasks that require a large volume of compressed air. However, they are more compact and lightweight, making them easier to transport and store. Additionally, oilless compressors are generally quieter and require less maintenance since there is no oil to change or dispose of.

Comparing Performance

Overall, the choice between an oil air compressor and an oilless air compressor depends on the specific application and requirements. Oil air compressors provide higher performance in terms of air pressure and volume, making them better suited for demanding tasks. On the other hand, oilless air compressors offer benefits such as oil-free operation, portability, and reduced maintenance.

For industries that prioritize performance and can handle oil lubrication, an oil air compressor may be the preferred option. However, for applications where oil contamination is a concern or where portability and low maintenance are important, an oilless air compressor may be the better choice.

In conclusion, it is important to carefully consider the specific needs and constraints of the application before choosing between an oil or oilless air compressor. Proper selection can ensure optimal performance, durability, and efficiency for the desired task.

Maintenance Requirements for Oil Air Compressors

Oil air compressors require regular maintenance to ensure optimal performance and longevity. Proper maintenance can help prevent expensive repairs and downtime, as well as extend the lifespan of the compressor.

Regular Oil Changes

One of the most important maintenance tasks for oil air compressors is regular oil changes. The oil in the compressor lubricates the moving parts and helps to reduce friction and wear. Over time, the oil can become contaminated with dirt, moisture, and other impurities, which can reduce its effectiveness. Regularly changing the oil will help to keep the compressor running smoothly and prevent premature damage to the components.

Filter Replacement

In addition to regular oil changes, it is also important to regularly replace the filters in the compressor. The filters help to remove dirt, dust, and other particles from the air before it enters the compressor. Over time, these filters can become clogged and less effective, which can decrease the efficiency of the compressor. Regularly replacing the filters will help to maintain the proper airflow and protect the compressor from damage.

Inspections and Cleaning

Regular inspections and cleaning are also important for maintaining oil air compressors. This includes checking for any leaks, loose fittings, or other issues that could affect the performance of the compressor. It is also important to clean the compressor regularly to remove any dirt or debris that may accumulate on the exterior. This will help to prevent overheating and ensure that the compressor operates at its best.

Overall Care

In addition to these specific maintenance tasks, it is important to provide overall care for oil air compressors. This includes keeping the compressor in a clean and well-ventilated area, away from excessive heat or moisture. It is also important to use the compressor according to the manufacturer’s guidelines and avoid overworking or overloading it. Taking these precautions will help to prolong the life of the compressor and ensure that it continues to operate efficiently.

In conclusion, oil air compressors require regular maintenance to keep them running smoothly and prevent damage. This includes regular oil changes, filter replacement, inspections, cleaning, and overall care. By following these maintenance requirements, users can maximize the performance and lifespan of their oil air compressors.

Maintenance Requirements for Oilless Air Compressors

Oilless air compressors are known for their low maintenance requirements compared to their oil counterparts. However, that doesn’t mean they don’t require any maintenance at all. Here are some key maintenance requirements for oilless air compressors:

1. Regular Filter Cleaning

One essential maintenance task for oilless air compressors is regular filter cleaning. As these compressors rely on clean air for optimal performance, the filters need to be cleaned or replaced on a regular basis. This ensures that the air being compressed is free from any contaminants that can impact the compressor’s efficiency and longevity.

2. Inspection of Air Hoses and Connections

Another important maintenance requirement is to regularly inspect the air hoses and connections. Over time, these components can develop leaks or cracks, which can result in a decrease in air pressure and overall performance. By checking these areas regularly, you can identify any issues early on and prevent them from escalating.

3. Drain Moisture from the System

Moisture can accumulate in the air compressor system, especially during humid conditions. This moisture can cause corrosion and damage to the internal components of the compressor. To prevent this, it is important to drain any moisture from the system regularly. This can be done by using a moisture trap or condensate drain valve.

4. Lubrication of Moving Parts

While oilless air compressors don’t require oil for operation, they still have moving parts that need to be lubricated. It is important to follow the manufacturer’s guidelines for lubrication, as using the wrong type of lubricant can damage the compressor. Regular lubrication helps reduce friction and wear on the internal components, ensuring smooth operation and prolonging the compressor’s lifespan.

5. Regular Inspection and Maintenance Schedule

Lastly, it is crucial to establish a regular inspection and maintenance schedule for your oilless air compressor. This includes checking the overall condition of the compressor, monitoring its performance, and addressing any issues that arise promptly. By staying on top of maintenance tasks, you can prevent major breakdowns and ensure that your oilless air compressor continues to operate at its best.

In conclusion, while oilless air compressors have lower maintenance requirements compared to oil compressors, regular maintenance tasks are still necessary. By following these maintenance requirements, you can keep your oilless air compressor in optimal condition and extend its lifespan.

Environmental Impact: Oil vs Oilless Air Compressors

1. Oil Air Compressors

Oil air compressors have been widely used for various industrial applications, thanks to their high efficiency and durability. However, they have a significant environmental impact due to the oil used in their operation.

The use of oil in these compressors results in the release of harmful pollutants into the air. The combustion of oil during the compression process releases carbon dioxide (CO2) and other greenhouse gases, contributing to global warming and climate change.

In addition, the oil used in these compressors needs to be regularly changed and disposed of properly. Improper disposal of used oil can contaminate soil, water bodies, and pose a risk to human health and wildlife.

2. Oilless Air Compressors

Oilless air compressors, on the other hand, offer a greener alternative with a lower environmental impact. These compressors are designed to operate without the need for oil lubrication.

Without the use of oil, oilless air compressors eliminate the emissions of pollutants associated with oil air compressors, such as CO2 and other greenhouse gases.

Furthermore, since oil is not used in the compression process, there is no need for regular oil changes and disposal. This reduces the risk of oil contamination in the environment and the associated negative impacts.

Conclusion

In terms of environmental impact, oilless air compressors have a clear advantage over oil air compressors. By eliminating the need for oil lubrication, oilless compressors minimize air pollution and reduce the risk of oil contamination. This makes them a more sustainable and environmentally-friendly choice for various applications.

However, it’s important to consider other factors such as the specific requirements of the application and the performance characteristics when choosing between oil and oilless air compressors. Balancing both environmental impact and operational efficiency can help make the best decision for a given situation.

Cost Analysis: Oil vs Oilless Air Compressors

When it comes to air compressors, cost is an important factor to consider. The choice between an oil and oilless air compressor can have a significant impact on the overall cost of ownership. Let’s take a closer look at the cost analysis of these two types of compressors.

Initial Cost:

Oilless air compressors generally have a higher initial cost compared to oil lubricated compressors. This is because oilless compressors require more advanced technology and materials to achieve their oil-free operation. On the other hand, oil lubricated compressors have a simpler design and don’t require as many specialized components, resulting in a lower initial cost.

Maintenance Cost:

When it comes to maintenance, oilless compressors have an advantage. Since they don’t use oil for lubrication, there is no need for oil changes or filter replacements. This can result in lower maintenance costs over time. On the other hand, oil lubricated compressors require regular oil changes and filter replacements, which can increase maintenance expenses.

Energy Efficiency:

In terms of energy efficiency, oilless compressors tend to be more efficient. They are designed to minimize energy losses that can occur due to oil drag. This means that oilless compressors can help reduce energy consumption and lower electricity bills. Oil lubricated compressors, on the other hand, may have a slightly lower energy efficiency due to the friction and drag caused by the presence of oil.

Durability and Lifespan:

When it comes to durability, oil lubricated compressors tend to have a longer lifespan. The presence of oil provides better lubrication and reduces wear and tear on the internal components. Oilless compressors, while more efficient in terms of energy consumption, may have a shorter lifespan due to higher operating temperatures and increased stress on the components.

Conclusion:

When considering the cost of owning an air compressor, it’s important to weigh the initial cost, maintenance expenses, energy efficiency, and durability. While oilless compressors may have a higher initial cost, they can offer lower maintenance costs and higher energy efficiency. On the other hand, oil lubricated compressors may have a lower initial cost, but require regular oil changes and may have a longer lifespan. Ultimately, the choice between oil and oilless compressors will depend on the specific needs and budget of the user.

Choosing the Right Air Compressor for Your Needs

When it comes to choosing an air compressor, it’s important to consider your specific needs and requirements. There are different types of air compressors available on the market, each with their own benefits and drawbacks. By understanding the various options, you can select the right air compressor that will best suit your needs.

Consider the Required Air Pressure and Volume

One of the first factors to consider when choosing an air compressor is the required air pressure and volume. This will depend on the tasks you expect to perform with the compressor. For example, if you need an air compressor for light-duty tasks such as inflating tires or operating small tools, a portable and compact compressor with a lower psi range may suffice. On the other hand, if you plan to use the compressor for heavy-duty tasks that require a higher air pressure and volume, a larger and more powerful compressor may be necessary.

Assess the Power Source and Mobility

Another important consideration is the power source and mobility of the air compressor. Air compressors can be powered by electricity, gasoline, or diesel. Electric compressors are suitable for indoor use and have a continuous power supply, while gasoline and diesel compressors are more portable and can be used in remote locations without an electrical outlet. Additionally, consider the mobility of the compressor. If you need to move the compressor frequently, look for options with wheels and a lightweight design for easy transportation.

Think About Noise Levels and Maintenance

Noise levels and maintenance requirements are also crucial factors to consider. Some air compressors can be noisy, which could be a concern if you plan to use them in a residential or noise-sensitive area. Look for options that offer quieter operation if noise is a concern. Furthermore, evaluate the maintenance requirements of the compressor. Oil-lubricated compressors require regular oil changes and maintenance, while oilless compressors offer low maintenance requirements.

Consider Your Budget

Last but not least, consider your budget when choosing an air compressor. Air compressors are available at various price points, and the cost will depend on factors such as the type, size, and brand of the compressor. Set a budget and prioritize the features and specifications that are most important for your needs. It’s important to find the right balance between price and performance to ensure you get the best value for your money.

FAQ:

What is the difference between an oil and oilless air compressor?

An oil air compressor uses oil to lubricate the moving parts of the compressor, while an oilless air compressor uses other materials like Teflon or nonstick coatings to reduce friction.

Which type of air compressor is better for home use?

Both oil and oilless air compressors can be used for home applications, but oilless compressors tend to be more popular due to their lower maintenance requirements and cleaner operation.

Are oil air compressors more powerful than oilless ones?

No, the power of an air compressor is determined by factors like the motor size, pressure capacity, and tank size, not whether it is oil or oilless.

Do oilless air compressors last longer than oil ones?

Oil air compressors generally have a longer lifespan if they are properly maintained and the oil is regularly changed. However, oilless compressors can still last a long time with proper care.

Are there any downsides to using an oilless air compressor?

Oilless air compressors tend to be louder and generate more heat compared to oil compressors. They also require more frequent replacements of certain parts like the pistons and cylinders.

Can I use an oilless air compressor for painting?

Yes, oilless air compressors can be used for painting, but they may require additional filtration to ensure a clean and dry air supply.

Video: