Methods for Removing Water from Air Compressor Lines

Water can be a common issue in air compressor lines, causing a range of problems such as corrosion, reduced efficiency, and damage to equipment. To ensure optimal performance and prevent costly repairs, it is important to effectively remove water from the compressed air system.

One method for removing water from air compressor lines is through the use of air dryers. Air dryers work by cooling the compressed air and condensing the moisture, which can then be removed through a drain. There are different types of air dryers, including refrigerated dryers, desiccant dryers, and membrane dryers, each with their own advantages and applications.

Another commonly used method is the installation of water separators. These devices remove water from the compressed air through centrifugal force or gravity. Water separators typically consist of a series of baffles or filters that separate the water droplets from the airflow, allowing the water to collect in a sump, which can then be drained.

Additionally, regular maintenance and inspection of the compressed air system is crucial for preventing water contamination. This includes checking for leaks in the system, properly draining condensate from air receivers and dryers, and ensuring proper filtration. By implementing these methods and practices, you can effectively remove water from air compressor lines and prolong the life and efficiency of your compressed air system.

Importance of Removing Water from Air Compressor Lines

Water is a common byproduct of air compression, and if not properly removed from air compressor lines, it can cause a range of problems and inefficiencies. Removing water from air compressor lines is critical for maintaining the performance and longevity of the compressor system.

One of the main reasons why water must be removed from air compressor lines is to prevent corrosion. When water is allowed to accumulate in the system, it can cause rust and damage to the compressor components, leading to reduced efficiency and potential breakdowns. By removing water, the risk of corrosion is significantly reduced, helping to extend the lifespan of the compressor system.

Another important reason for removing water from air compressor lines is to prevent moisture-related issues in downstream equipment. Moisture in the compressed air can negatively impact the performance and reliability of pneumatic tools, valves, and other equipment that rely on dry air. By removing water from the compressed air, the risk of equipment malfunctions and downtime is greatly reduced.

Furthermore, removing water from air compressor lines can significantly improve energy efficiency. Water in the system causes increased friction and resistance, which leads to higher energy consumption. By eliminating water, the compressor can operate more efficiently, reducing energy costs and saving money in the long run.

There are various methods available for removing water from air compressor lines. These include the use of moisture separators, refrigerated air dryers, and desiccant air dryers, among others. The choice of method depends on factors such as the level of moisture in the air, the required dryness, and the specific application.

In conclusion, the importance of removing water from air compressor lines cannot be overstated. It helps prevent corrosion, improves the performance of downstream equipment, enhances energy efficiency, and extends the lifespan of the compressor system. By investing in proper water removal methods, businesses can ensure reliable and efficient operation of their air compressors.

Gravity Drainage Method

The gravity drainage method is a simple and effective way to remove water from air compressor lines. It takes advantage of the natural force of gravity to allow the water to flow out of the system.

To implement this method, you need to install a drain valve at the lowest point of the air compressor system. This valve should be positioned in a way that allows easy access for regular maintenance. When the valve is opened, water will flow out of the system due to gravity.

It is important to note that the gravity drainage method may not be suitable for all situations. If the air compressor system is installed in a location where it is not possible to position the drain valve at the lowest point, an alternative method may need to be used.

Regular maintenance is crucial for the gravity drainage method to be effective. The drain valve should be checked and opened periodically to ensure that any accumulated water is drained from the system. This will help prevent water buildup and potential damage to the air compressor and connected equipment.

Moisture Separator Method

The moisture separator method is a common and effective way to remove water from air compressor lines. It utilizes a specialized device called a moisture separator, which is typically installed at the location where the compressed air is being used.

How it works: The moisture separator works by using a combination of gravity and centrifugal force to separate water droplets from the compressed air. As the air passes through the moisture separator, it is forced to change direction, causing the heavier water droplets to be thrown against the walls of the separator. The water then falls down into a collection bowl at the bottom of the separator, while the dry air continues through the system.

Advantages:

- Effective water removal: The moisture separator method is highly effective at removing water from compressed air, ensuring that the air remains dry and free of moisture-related issues.

- Easy to install: Moisture separators are typically easy to install and can be integrated into existing air compressor systems without major modifications.

- Low maintenance: Once installed, moisture separators require minimal maintenance, making them a cost-effective solution for water removal.

Considerations:

- Proper sizing: It’s important to choose a moisture separator that is properly sized for the volume and pressure of the compressed air system to ensure efficient water separation.

- Regular drain maintenance: The collection bowl of the moisture separator should be regularly drained to prevent water buildup and maintain optimal performance.

Conclusion: The moisture separator method is a reliable and efficient way to remove water from air compressor lines. By utilizing a moisture separator, you can ensure that your compressed air remains dry and free of moisture-related issues, improving the performance and longevity of your equipment.

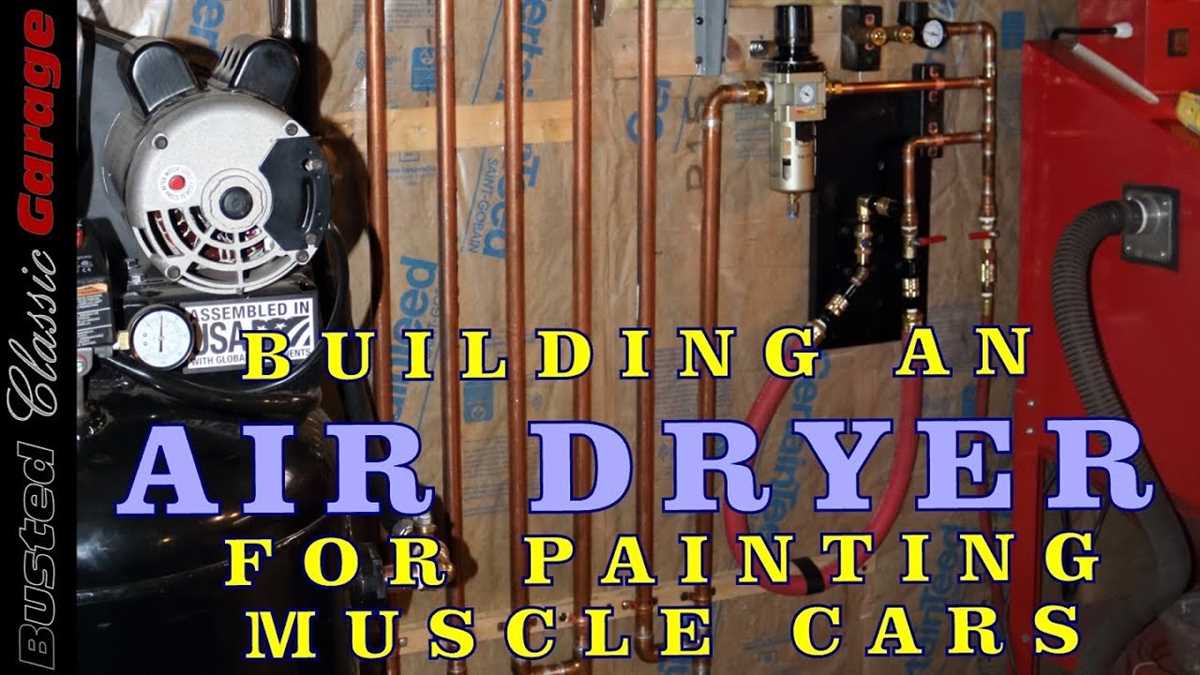

Air Dryer Method

The air dryer method is one of the most effective ways to remove water from air compressor lines. It involves using an air dryer, which is a device designed to remove moisture from compressed air. The air dryer works by cooling the air, causing the moisture in the air to condense into water droplets, which can then be separated and drained from the system.

There are different types of air dryers available, including refrigerated dryers, desiccant dryers, and membrane dryers. Refrigerated dryers use a refrigeration system to cool the air and remove moisture, while desiccant dryers use a desiccant material to absorb the moisture. Membrane dryers, on the other hand, use a permeable membrane to separate the moisture from the compressed air.

Once the air has been dried, it can be further filtered to remove any remaining contaminants, such as oil or dirt particles. This can be done using filters, such as coalescing filters or particulate filters. These filters are designed to capture and remove small particles from the air, ensuring that it is clean and dry before it is used in pneumatic tools or equipment.

Using an air dryer to remove water from air compressor lines has several benefits. It helps prevent corrosion and damage to pneumatic equipment, improves the efficiency of the compressor system, and ensures that the compressed air is clean and dry. This method is particularly useful in industries where dry and clean air is crucial, such as in manufacturing, automotive, and food processing.

Condensate Traps Method

A condensate trap is a device used to remove water from air compressor lines. It works by collecting the condensation that forms in the compressed air and draining it out of the system. This method is effective in preventing water buildup and reducing the risk of damage to the compressor and other equipment.

How it Works:

- Condensate traps are typically installed at the lowest point in the air compressor system, where water naturally accumulates.

- The trap consists of a small reservoir or chamber that collects the condensed water. It is designed with a drain valve that can be opened to release the water.

- As the compressed air flows through the system, it carries moisture with it. When the air enters the trap, it cools down, causing the moisture to condense and collect in the reservoir.

- Once enough water has accumulated in the trap, the drain valve is opened to release the water. This can be done manually or automatically, depending on the design of the trap.

Benefits:

- The condensate traps method is a reliable and cost-effective way to remove water from air compressor lines.

- It helps prevent water from reaching sensitive equipment, such as pneumatic tools or machinery, which can be damaged if exposed to moisture.

- Avoiding water buildup in the system also helps maintain consistent air pressure and improve overall performance.

- This method is relatively easy to install and requires minimal maintenance.

Considerations:

While condensate traps are effective in removing water from air compressor lines, it’s important to ensure that the traps are properly sized and installed to handle the anticipated condensate flow. Additionally, regular inspection and maintenance of the traps are important to ensure their continued functionality.

Automatic Drain Valve Method

The automatic drain valve method is an effective way to remove water from air compressor lines. This method involves installing an automatic drain valve at the lowest point of the air compressor system. The automatic drain valve is designed to open and close automatically to drain the water that accumulates in the system.

When the compressor is running, the automatic drain valve remains closed, allowing the air to flow through the system. However, when the compressor stops, the pressure in the system drops, and the automatic drain valve opens, allowing the water to drain out. This ensures that the water is drained from the system without requiring manual intervention.

Automatic drain valves are available in various designs, including float-operated valves, timer-controlled valves, and electronic sensing valves. Float-operated valves use a float to detect the water level and open the valve when the water reaches a certain level. Timer-controlled valves open and close based on a preset time schedule. Electronic sensing valves use sensors to detect water accumulation and open the valve when necessary.

The automatic drain valve method is convenient and reliable, as it eliminates the need for manual draining of water from the air compressor lines. This helps prevent the build-up of moisture, which can lead to corrosion, damage to equipment, and decreased efficiency. By regularly maintaining and inspecting the automatic drain valve, you can ensure that it is functioning properly and effectively removing water from the system.

Maintenance Tips for Water Removal from Air Compressor Lines

1. Regular Draining

One of the most important maintenance tips for removing water from air compressor lines is to regularly drain the system. Over time, condensation and moisture can build up inside the lines, leading to decreased efficiency and potential damage. By draining the system on a regular basis, you can remove this excess water and prevent it from causing problems.

2. Install a Water Trap

To further minimize the amount of water in your air compressor lines, consider installing a water trap. This device works by capturing any water vapor that may be present in the compressed air, preventing it from entering the lines. A water trap can be easily attached to your air compressor system and should be checked periodically to ensure it is not full of water.

3. Use a Refrigerated Dryer

If you frequently deal with high levels of moisture in your air compressor lines, investing in a refrigerated dryer may be beneficial. These devices work by cooling the compressed air and removing moisture through condensation. They are particularly effective in environments with high humidity levels where water buildup is a common issue.

4. Monitor Ambient Temperature

The ambient temperature can have a significant impact on the amount of moisture in your air compressor lines. In colder climates, condensation is more likely to occur. To prevent water buildup, it is important to monitor the ambient temperature and adjust your drainage schedule accordingly. Additionally, consider insulating your air compressor lines to maintain a more consistent temperature and minimize the risk of condensation.

5. Use Desiccant Dryers

For applications that require extremely dry air, using desiccant dryers can be an effective solution. These dryers use a desiccant material to absorb moisture from the compressed air, resulting in air that is virtually free of water vapor. Desiccant dryers are often used in industries such as painting, electronics, and pharmaceuticals where moisture can cause damage or affect the quality of the final product.

6. Conduct Regular Inspections

In addition to regular maintenance tasks, it is important to conduct regular inspections of your air compressor lines. Look for signs of water buildup, such as rust or corrosion, and take immediate action to address any issues. Regular inspections will help you catch problems early on and prevent costly repairs or replacements in the future.

In conclusion, maintaining water removal from air compressor lines requires consistent attention and proper maintenance. By regularly draining the system, installing water traps, using refrigerated dryers, monitoring ambient temperature, utilizing desiccant dryers, and conducting regular inspections, you can effectively remove water from your air compressor lines and ensure optimal performance.

FAQ:

What are the common methods to remove water from air compressor lines?

There are several common methods to remove water from air compressor lines. These include using a water separator, installing a moisture trap, using a refrigerated air dryer, using a desiccant air dryer, and using a coalescing filter.

What is a water separator and how does it work?

A water separator is a device used to remove water from compressed air. It works by using centrifugal force to separate the water droplets from the compressed air. As the air passes through the water separator, it is forced to change direction, causing the heavier water droplets to be thrown against the walls of the separator and then collected at the bottom for drainage.

What is a moisture trap and how does it work?

A moisture trap, also known as a condensate drain, is a device used to remove water from compressed air. It works by allowing the compressed air to cool down, causing the water vapor to condense into liquid form. The moisture trap then collects the condensed water and drains it out of the system to prevent it from entering the air lines.

What is a refrigerated air dryer and how does it work?

A refrigerated air dryer is a device used to remove moisture from compressed air. It works by cooling the compressed air to a temperature where the water vapor condenses into liquid form. The condensed water is then separated from the air and drained out of the system. The cooled and dried air is then reheated before it enters the air lines.

What is a desiccant air dryer and how does it work?

A desiccant air dryer is a device used to remove moisture from compressed air. It works by passing the compressed air through a bed of desiccant material, such as silica gel or activated alumina. The desiccant material adsorbs the moisture from the air, leaving it dry. The desiccant material needs to be periodically regenerated by either heating or purging it, depending on the type of dryer.

What is a coalescing filter and how does it work?

A coalescing filter is a device used to remove liquid water and oil aerosols from compressed air. It works by passing the compressed air through a fine filter media that captures the liquid droplets and oil aerosols. The captured contaminants then coalesce into larger droplets and are drained out of the system. The coalescing filter helps to improve the quality of the compressed air by removing moisture and oil.

What is the best method for removing water from air compressor lines?

The best method for removing water from air compressor lines depends on several factors, including the specific application, the level of moisture in the compressed air, and the desired air quality. For general applications, a combination of a water separator and a refrigerated air dryer or a desiccant air dryer may be the most effective solution. However, it is recommended to consult with an expert to determine the best method for a specific situation.

Video: