Maximizing Air Compressor CFM: Tips and Techniques

When it comes to using an air compressor, one of the most important considerations is the CFM, or cubic feet per minute, that it can deliver. CFM is a measure of airflow, and having a higher CFM can make a big difference in the performance and efficiency of your air compressor. In this article, we will discuss some tips and techniques for maximizing air compressor CFM.

One way to maximize CFM is to choose the right size of air compressor for your needs. It’s important to consider not only the tools you will be using, but also the number of tools that will be in use at the same time. A larger air compressor may be necessary if you will be running multiple tools simultaneously, while a smaller one may suffice for a single tool.

Another factor to consider is the length and diameter of the air hose. A longer hose or a smaller diameter can restrict airflow and reduce the CFM. It’s best to use the shortest and widest hose possible for your application to minimize pressure drop and maximize CFM.

The condition of your air compressor is also important for maximizing CFM. Regular maintenance and cleaning can help keep the compressor running efficiently and prevent clogs or blockages in the air flow. It’s also a good idea to check the air filter regularly and replace it when necessary to ensure optimal airflow and CFM.

In conclusion, maximizing air compressor CFM is essential for the performance and efficiency of your tools. By choosing the right size of air compressor, using the appropriate size and length of air hose, and maintaining the compressor properly, you can ensure that you are getting the maximum CFM and getting the most out of your air compressor.

Understanding Air Compressor CFM

When it comes to air compressors, understanding CFM (cubic feet per minute) is crucial for selecting the right compressor for your needs. CFM refers to the amount of air flow that the compressor can provide, and it plays a vital role in the performance and efficiency of various air-powered tools and equipment.

CFM Requirements:

Before purchasing an air compressor, it is important to determine the CFM requirements of the tools or equipment you plan to use. Each tool will have a specific CFM rating, and it is essential to choose a compressor that can meet or exceed the required CFM. Using an undersized compressor can lead to poor performance and inefficient operation of the tools.

Factors Affecting CFM:

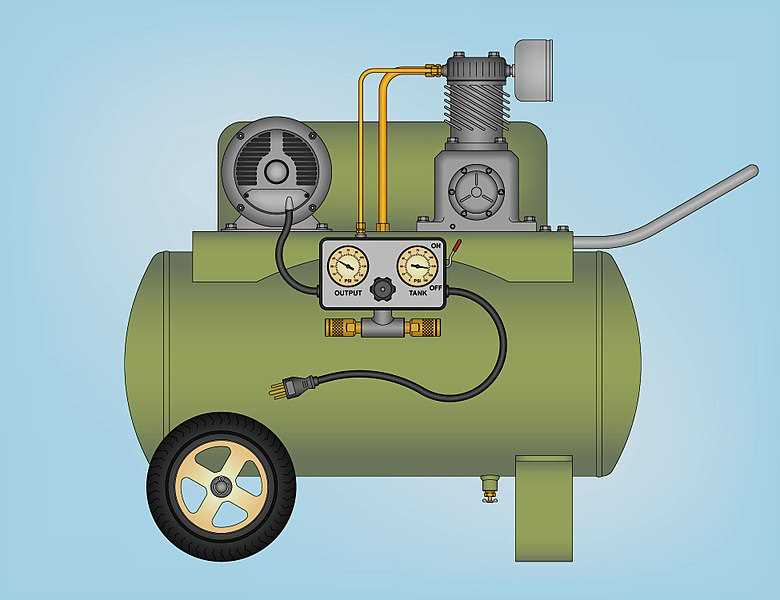

Several factors can affect the CFM output of an air compressor. These include the size of the air tank, the motor horsepower, and the compressor’s duty cycle. A larger tank size generally allows for a higher CFM output, while a more powerful motor can generate greater air flow. The duty cycle, which refers to the compressor’s operating time in relation to its rest time, also affects CFM as it determines how long the compressor can sustain a certain CFM output.

Improving CFM:

If you find yourself needing more CFM than your current compressor can provide, there are a few techniques you can try to improve the CFM output. One option is to add additional air tanks to increase the storage capacity and allow for more consistent air flow. Another option is to use a larger compressor or one with a higher horsepower rating. Additionally, ensuring proper maintenance and cleaning of the compressor, including regular filter replacements, can help optimize the CFM output.

Conclusion:

In summary, understanding the CFM requirements of your air-powered tools and equipment is essential for selecting the right air compressor. Factors such as tank size, motor horsepower, and duty cycle can affect the CFM output, and taking steps to improve CFM can enhance the performance and efficiency of the compressor. By considering these factors and making informed decisions, you can maximize the CFM of your air compressor and ensure optimal operation of your tools and equipment.

Choosing the Right Air Compressor

Consider the Required CFM

When choosing an air compressor, it is important to consider the amount of cubic feet per minute (CFM) required for your specific application. Different tools and equipment have different CFM requirements, so it is vital to choose a compressor that can deliver the necessary airflow.

Determine the Maximum Pressure

Another important factor to consider when selecting an air compressor is the maximum pressure it can generate. The maximum pressure is typically measured in pounds per square inch (PSI). It is crucial to match the compressor’s maximum pressure to the requirements of your tools and equipment to ensure proper functionality.

Choose a Suitable Power Source

Air compressors can be powered by various sources, including electricity, gasoline, and diesel. The choice of power source will depend on your specific needs and the availability of the power source. Electric compressors are commonly used for indoor applications, while gas or diesel-powered compressors are more suitable for outdoor or remote locations.

Consider the Size and Portability

The size and portability of the air compressor can also be important factors to consider. If you have limited space or need to transport the compressor frequently, a smaller, more compact unit may be preferable. However, if you have a dedicated space or require a higher CFM output, a larger, stationary compressor might be more suitable.

Assess Noise Level and Maintenance Requirements

Noise level and maintenance requirements are other aspects to consider when choosing an air compressor. If noise is a concern, look for compressors with lower decibel ratings. Additionally, consider the maintenance requirements of the compressor, such as regular oil changes and filter replacements, and ensure that you are willing to commit to the necessary maintenance tasks.

In summary, when choosing an air compressor, it is crucial to consider the required CFM, the maximum pressure, the power source, the size and portability, as well as the noise level and maintenance requirements. By carefully evaluating these factors, you can select the right air compressor that meets your specific needs and ensures efficient operation for your tools and equipment.

Optimizing Air Compressor CFM

When it comes to maximizing the CFM (cubic feet per minute) of an air compressor, there are several tips and techniques that can be used to optimize its performance. By following these strategies, you can ensure that your air compressor is providing the highest possible CFM output for your specific needs.

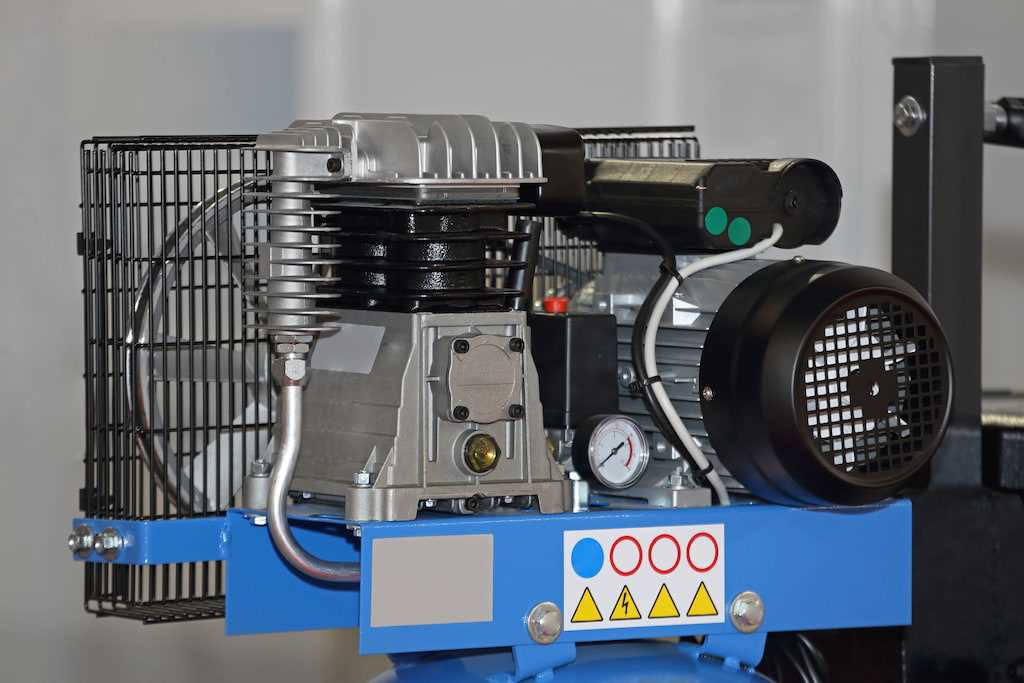

Proper maintenance

Regular maintenance is essential for optimizing the CFM of an air compressor. This includes cleaning or replacing air filters, checking and adjusting the oil level, and inspecting the compressor components for any signs of wear or damage. By keeping your air compressor in good working condition, you can ensure that it is able to operate at peak efficiency and deliver maximum CFM output.

Optimal operating conditions

The environment in which the air compressor is operated can also have a significant impact on its CFM output. To optimize CFM, it is important to operate the compressor in a well-ventilated area with a consistent temperature. Additionally, ensuring that the compressor is properly sized for the intended workload can help prevent overloading and maximize CFM output.

Using the right tools and accessories

The tools and accessories used with an air compressor can also affect its CFM performance. Choosing tools and accessories that have a lower CFM requirement can help maximize the CFM output of the compressor. Additionally, using properly sized hoses and connectors can minimize pressure drops and ensure that the full CFM output is delivered to the tool.

Optimizing air pressure

Adjusting the air pressure to the optimal level can also help maximize CFM. Higher air pressure does not necessarily mean higher CFM output. In fact, excessive air pressure can result in energy waste and reduced CFM. By finding the right balance between air pressure and CFM, you can optimize the performance of your air compressor.

In conclusion, optimizing the CFM of an air compressor involves regular maintenance, creating optimal operating conditions, using the right tools and accessories, and optimizing air pressure. By implementing these strategies, you can ensure that your air compressor is operating at its highest possible CFM output, providing you with the power and efficiency you need for your various tasks and applications.

Upgrading Air Compressor Components

1. Upgrading the Motor

One of the first components you may consider upgrading on your air compressor is the motor. An upgraded motor can provide more power and efficiency, allowing your compressor to produce a higher CFM output. Look for motors with higher horsepower ratings and reliable brands known for their durability and performance.

2. Installing a Larger Air Tank

If you want to maximize your air compressor’s CFM output, consider upgrading to a larger air tank. A larger tank will provide more storage capacity for compressed air, allowing your compressor to deliver a higher CFM output for longer durations. Make sure to choose a tank that is compatible with your compressor’s specifications and fits within your available space.

3. Upgrading the Air Filters

Upgrading the air filters on your air compressor is another effective way to improve its CFM output. High-quality air filters can help remove dust, dirt, and other contaminants from the air supply, preventing them from clogging the compressor’s internal components. Look for filters with a high filtration efficiency and consider adding additional filtration stages for optimal air quality.

4. Upgrading the Pressure Regulator

The pressure regulator plays a crucial role in controlling the output pressure of your air compressor. Upgrading to a more precise and adjustable pressure regulator can help you fine-tune the CFM output according to your specific needs. Look for regulators with accurate pressure control and easy adjustment mechanisms to optimize your compressor’s performance.

5. Adding a Secondary Intercooler

If your air compressor operates at higher temperatures, adding a secondary intercooler can be a beneficial upgrade. An intercooler helps cool down the compressed air between stages, improving its density and allowing the compressor to produce a higher CFM output. Consider adding an intercooler that matches your compressor’s airflow and cooling requirements.

6. Retrofitting Variable Speed Drives

For even greater control over your compressor’s CFM output, consider retrofitting variable speed drives. These drives allow you to adjust the motor’s speed according to your needs, maximizing energy efficiency and delivering the desired CFM output. Consult with a professional to ensure compatibility and proper installation of variable speed drives on your air compressor.

By upgrading various components of your air compressor, you can significantly improve its CFM output. Whether it’s upgrading the motor, installing a larger air tank, or adding a secondary intercooler, these upgrades can enhance your compressor’s performance and meet your specific needs for air supply. Prioritize quality components from reputable brands and consider consulting with experts for proper installation and compatibility.

Maintaining Air Compressor Performance

Regular maintenance is essential for maximizing the performance and longevity of an air compressor. Proper maintenance ensures that the compressor operates efficiently and avoids potential breakdowns or malfunctions.

1. Check and clean the air filter regularly

The air filter plays a crucial role in maintaining the performance of an air compressor. It prevents dust and debris from entering the system and causing damage. Regularly check and clean the air filter to ensure proper airflow and prevent clogs. If the filter is damaged or worn out, replace it immediately.

2. Monitor and maintain proper oil levels

Oil is an important component for lubricating and cooling the compressor. Regularly check the oil level and add more if necessary. Be sure to use the recommended oil type for the specific compressor model. Additionally, change the oil according to the manufacturer’s instructions to prevent buildup of contaminants and ensure optimal performance.

3. Inspect and tighten connections

Frequent vibrations can cause connections to become loose over time, resulting in air leaks and decreased performance. Regularly inspect all connections and fittings, and tighten them if necessary. This helps to maintain the proper pressure and prevent air loss during operation.

4. Drain moisture from the tank

Moisture can accumulate in the air tank, leading to corrosion and reduced performance. Regularly drain the moisture from the tank to prevent these issues. This can be done by opening the tank drain valve and allowing the water to flow out. Ensure that the tank is fully drained before closing the valve.

5. Schedule professional maintenance

While regular maintenance can be done by the user, it is important to schedule professional maintenance on a regular basis. A professional technician can perform more in-depth inspections and tests to identify any potential issues and ensure that the compressor is operating at its best.

By following these maintenance tips, you can ensure that your air compressor remains in optimal condition, maximizing its performance and prolonging its lifespan.

Increasing Air Compressor CFM

If you want to increase the CFM (cubic feet per minute) of your air compressor, there are several techniques and tips you can use. Increasing the CFM can be beneficial in various applications, such as powering air tools or operating air-powered machinery more efficiently.

1. Upgrade to a larger compressor

One way to increase the CFM is to upgrade to a larger air compressor. A larger compressor will have a higher capacity, allowing it to deliver more air per minute. Consider the specific needs of your application and choose a compressor that can meet or exceed those requirements.

2. Check and clean the air filters

Dirty or clogged air filters can restrict the airflow and reduce the CFM output of your compressor. Regularly check and clean the air filters to ensure they are free of debris and dust. If necessary, replace them with new filters to improve the airflow and increase the CFM.

3. Reduce pressure drop

Pressure drop can occur in the air lines and fittings, reducing the CFM output of the compressor. Inspect the air lines and fittings for leaks or restrictions and repair or replace them as needed. Minimizing pressure drop will help maximize the CFM output of your compressor.

4. Use larger diameter air hoses

Using larger diameter air hoses can help reduce pressure drop and increase the CFM output. When the air has to travel through smaller diameter hoses, it can experience more resistance, resulting in decreased CFM. Switching to larger diameter hoses will allow for better airflow and increased CFM.

5. Optimize compressor settings

Make sure your compressor is operating at its optimal settings. Adjust the pressure regulator to the appropriate level for your application. Running the compressor at a lower pressure can help increase the CFM output. Check the manufacturer’s recommendations for your specific compressor model.

By following these tips and techniques, you can increase the CFM output of your air compressor and maximize its efficiency in various applications. Remember to regularly maintain and inspect your compressor to ensure optimal performance.

Using Accessories to Maximize CFM

When it comes to maximizing CFM output from your air compressor, using the right accessories can make a big difference. Here are a few tips and techniques for getting the most out of your compressor:

1. High-flow couplers and connectors

Upgrading your couplers and connectors to high-flow versions can greatly improve airflow and increase CFM output. Standard couplers and connectors often have restrictions that limit the amount of air that can flow through them. By switching to high-flow options, you can reduce these restrictions and allow more air to pass through, increasing the overall CFM.

2. Larger diameter hoses

The size of your air hose can also impact CFM output. Using a larger diameter hose allows for greater airflow, reducing the amount of pressure drop and increasing the overall CFM. It’s recommended to use a hose with a diameter of at least 3/8 inch or larger for maximum CFM performance.

3. Air storage tanks

Adding an air storage tank to your compressor setup can help maximize CFM output, especially when using tools or equipment that require short bursts of high-pressure air. The storage tank acts as a buffer, providing a reserve of compressed air that can be released quickly when needed, ensuring a continuous and steady supply of CFM.

4. Regulators and filters

Using regulators and filters can also help maximize CFM output by ensuring a consistent and clean air supply. Regulators allow you to adjust the pressure to match the requirements of your tools or equipment, while filters help remove any contaminants from the air, preventing them from affecting performance and reducing CFM.

By utilizing these accessories and techniques, you can optimize your air compressor’s CFM output and ensure you have enough airflow for your specific needs. Remember to always check the manufacturer’s recommendations and guidelines for your particular compressor model to ensure compatibility and maximum performance.

FAQ:

What is CFM and why is it important in air compressors?

CFM stands for cubic feet per minute and it measures the airflow rate of an air compressor. CFM is important because it determines the compressor’s ability to power air tools and equipment.

How can I increase the CFM of my air compressor?

There are several ways to increase the CFM of an air compressor. One way is to use a larger air tank, as it can store more air and release it at a higher rate. Another method is to use a compressor with a higher horsepower rating or multiple compressors in parallel. Additionally, improving the intake and exhaust systems, as well as reducing air leaks, can also help increase the CFM.

What is the difference between CFM and PSI?

CFM measures the airflow rate, while PSI (pounds per square inch) measures the pressure of the air. CFM is important for powering air tools, as it determines the volume of air that can be delivered. PSI, on the other hand, is important for the functionality and safety of the tools, as it determines the force with which the air is delivered.

Can I increase the CFM of my air compressor by changing the nozzle size?

Changing the nozzle size of an air compressor can affect the airflow rate, but it may not necessarily increase the CFM. The CFM is mainly determined by the capabilities of the compressor itself, such as its horsepower and tank size. Changing the nozzle size can impact the pressure and efficiency, but it may not significantly increase the CFM.

What are some tips for maximizing the CFM of an air compressor?

Some tips for maximizing the CFM of an air compressor include: using the appropriate size and type of air hoses, minimizing the length and number of bends in the hoses, ensuring proper maintenance and cleaning of the compressor, minimizing air leaks, and using regulators and filters to optimize the airflow.

Why is it important to match the CFM requirements of air tools with the CFM of the compressor?

Matching the CFM requirements of air tools with the CFM of the compressor is important to ensure that the tools operate at their optimal performance. If the CFM of the compressor is too low for the tool, it will not deliver enough air, resulting in reduced power and efficiency. On the other hand, if the CFM of the compressor is too high for the tool, it can lead to excessive pressure and potentially damage the tool.

Video: