Locating the Air Compressor on a Freightliner: A Complete Guide

When it comes to maintaining and repairing a Freightliner truck, it is essential to have a good understanding of the various components and their locations. One crucial component that every trucker should be familiar with is the air compressor. The air compressor plays a vital role in the truck’s operation, as it is responsible for pressurizing the air braking system. In this guide, we will explore the different locations where you can find the air compressor on a Freightliner truck.

Freightliner trucks typically have two main locations where the air compressor can be found. The first and most common location is under the hood, near the engine. This placement allows for easy access and maintenance. To locate the air compressor in this position, simply open the hood and look for a cylindrical-shaped component connected to the engine. It is usually black or silver in color and has several hoses and wires attached to it. Additionally, you may also find the air dryer, which is responsible for removing moisture from the compressed air, located nearby.

The second location where the air compressor can be found is on the side or rear of the truck’s frame. This placement is more common in larger Freightliner trucks or those with specialized configurations. To locate the air compressor in this position, you will need to get underneath the truck and look along the frame rails, often near the rear axle. The air compressor will typically be housed in a protective casing and connected to the truck’s air tanks and other components.

Regardless of the location, it is crucial to regularly inspect and maintain the air compressor on your Freightliner truck. This includes checking for leaks, ensuring proper lubrication, and replacing any worn-out parts. By understanding the different locations where the air compressor can be found, you will be better equipped to perform these maintenance tasks and keep your truck running smoothly on the road.

Step-by-Step Instructions for Locating the Air Compressor

1. Consult the vehicle’s manual:

Start by consulting the vehicle’s manual to find information on the air compressor’s location. The manual may include diagrams or descriptions that can help you locate the air compressor.

2. Look for the air compressor on the engine:

In most Freightliner trucks, the air compressor is located on the engine. Start by looking around the engine compartment for a cylindrical-shaped component with multiple connections and hoses. The air compressor is typically attached to the engine block.

3. Check under the vehicle:

If you can’t find the air compressor on the engine, check under the vehicle. Look for a component mounted low in the chassis, near the engine. The air compressor may be shielded by a metal cover or located near other components such as the fuel tank or batteries.

4. Follow the air lines:

If you’re still having trouble locating the air compressor, follow the air lines from the air tanks to the compressor. Trace the lines from the air tanks back to the engine compartment or under the vehicle. The air compressor is typically connected to the air tanks through these lines.

5. Use a flashlight:

If the air compressor is located in a hard-to-see area, use a flashlight to help you locate it. Shine the light into tight spaces or under the vehicle to get a better view of the components. This can make it easier to spot the air compressor.

Remember, if you’re unsure about locating the air compressor, it’s always best to consult a professional or refer to the vehicle’s manual for accurate information. The location of the air compressor can vary depending on the specific model and year of the Freightliner truck.

Preparing for the Search

To locate the air compressor on a Freightliner, it is important to gather the necessary tools and resources before beginning the search. This will help ensure a smooth and efficient process. Here are some steps to prepare for the search:

1. Familiarize yourself with the Freightliner Model

Before starting the search, it is important to have a good understanding of the specific Freightliner model you are working with. Each model may have slight variations in the location of the air compressor. Refer to the vehicle’s manual or consult online resources to learn more about your specific model.

2. Review the Air Compressor System Diagram

To locate the air compressor, it can be helpful to review the air compressor system diagram. This diagram will provide a visual representation of the various components and their interconnections. It can be found in the vehicle’s manual or online. Understanding the system layout will assist in narrowing down the potential locations of the air compressor.

3. Gather the Necessary Tools

Before beginning the search, gather the necessary tools to facilitate the process. This may include a flashlight, a wrench set, a socket set, and a mirror. The flashlight will help illuminate hard-to-reach areas, while the wrench and socket sets will be useful for removing any necessary components. The mirror can be used to inspect hidden areas that are not easily accessible.

4. Identify Potential Locations

Based on your knowledge of the Freightliner model and the air compressor system diagram, make a list of potential locations where the air compressor may be located. These may include the engine compartment, under the chassis, or inside the cabin. Having a list will help narrow down the search area and prevent wasted time and effort.

By following these preparatory steps, you can set yourself up for a successful search to locate the air compressor on your Freightliner.

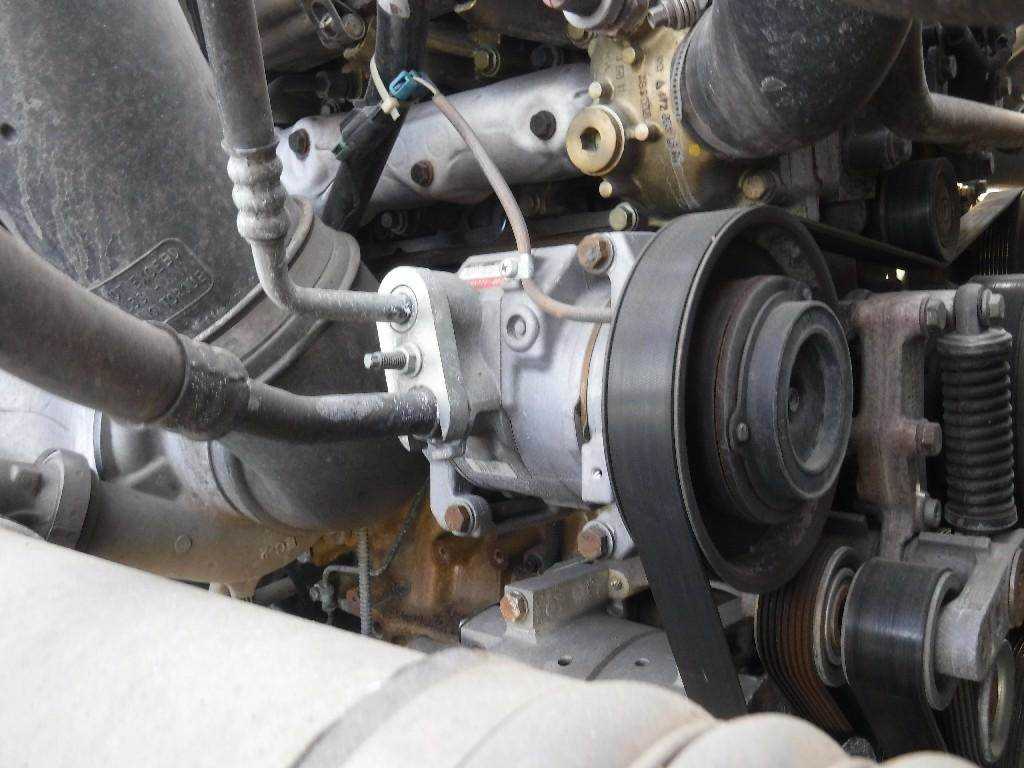

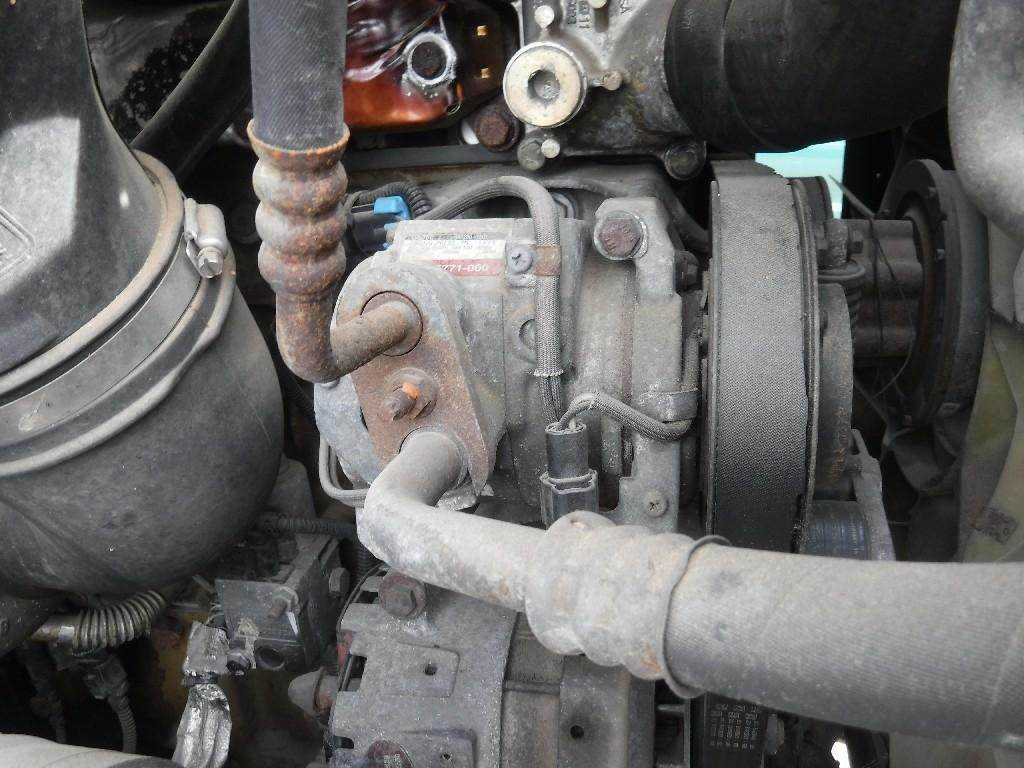

Looking in the Engine Compartment

Locating the air compressor in a Freightliner truck requires a thorough inspection of the engine compartment. The air compressor is an essential component of the truck’s air braking system, so it is usually located near the engine to ensure optimal performance.

To begin your search, open the hood of the Freightliner truck and secure it in place using the designated latch. Take a moment to familiarize yourself with the different components in the engine compartment, as this will make it easier to locate the air compressor.

Next, look for a cylindrical-shaped device with metal tubing connected to it. This is usually the air compressor. It is commonly positioned on the driver’s side of the engine compartment, although its exact location may vary depending on the model and year of the truck.

Once you have identified the air compressor, inspect it for any signs of damage or leaks. Look for oil residue, loose fittings, or worn-out belts. These could indicate a malfunctioning air compressor that requires maintenance or replacement.

If you are still unable to locate the air compressor in the engine compartment, consult the Freightliner truck’s user manual or contact the manufacturer for further assistance. They will be able to provide specific instructions based on the model and year of your truck.

Overall, finding the air compressor in a Freightliner truck’s engine compartment is a straightforward process. With a little patience and a keen eye, you’ll be able to locate this crucial component and ensure the proper functioning of your truck’s air braking system.

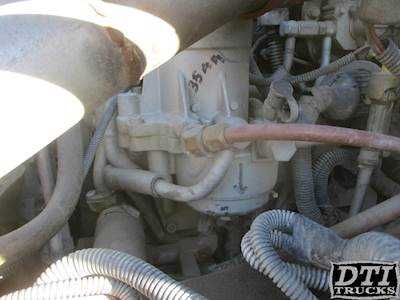

Checking Under the Vehicle

If you are trying to locate the air compressor on a Freightliner, checking under the vehicle is a crucial step. Start by parking the vehicle on a level surface and engaging the parking brake to ensure safety. Look for the air brake system components, which are usually located on the underside of the vehicle.

Inspect the area underneath the chassis, specifically near the rear axle, as the air compressor is often mounted in this region. Use a flashlight to get a clearer view of the components and look for any signs of leaks, damage, or loose connections. These issues can indicate a problem with the air compressor, and it may need to be repaired or replaced.

Pay close attention to the air lines and fittings connected to the air compressor. Ensure that they are securely fastened and free from cracks or damage. If you notice any issues, it is essential to address them promptly to maintain the proper functioning of the air brake system.

Additionally, check for any protective covers or panels that may be covering the air compressor. These covers are designed to shield the compressor from debris and ensure its longevity. If any covers are missing or damaged, they should be replaced to provide adequate protection for the air compressor.

Overall, checking under the vehicle is an important step in locating and inspecting the air compressor on a Freightliner. Taking the time to thoroughly examine the components and address any issues will help to maintain the performance and safety of the air brake system.

Identifying Components of the Air Compressor

When it comes to locating the air compressor on a Freightliner, it’s important to first identify the various components that make up the system. Understanding these components will help you troubleshoot any issues and perform regular maintenance.

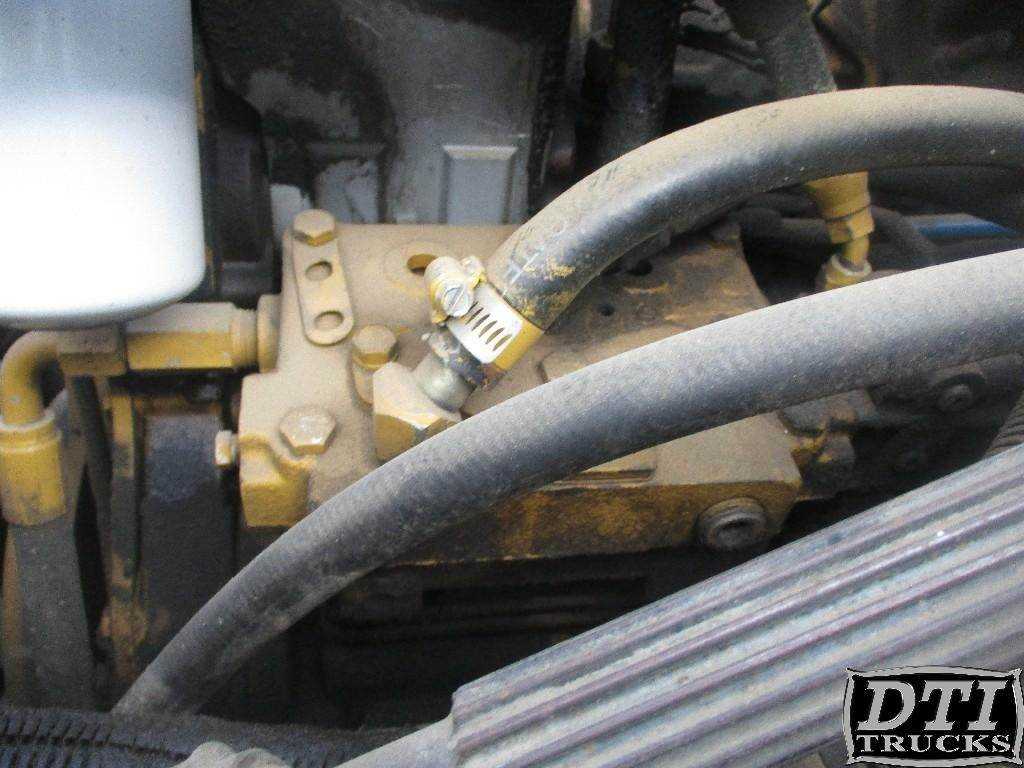

Pressure Switch

The pressure switch is a crucial component of the air compressor system. It monitors the air pressure in the system and shuts off the compressor when the desired pressure is reached. This helps prevent over-pressurization and keeps the system running smoothly.

Tank Drain Valve

The tank drain valve is responsible for removing any excess water or moisture that accumulates in the air tank. It is important to regularly drain the tank to prevent water buildup, as this can affect the performance of the air compressor and other components in the system.

Air Filter

The air filter is designed to remove any dust, debris, or contaminants from the air before it enters the compressor. This helps prolong the life of the compressor and ensures that clean, filtered air is delivered to the system.

Pressure Relief Valve

The pressure relief valve is a safety feature that releases air from the system if the pressure exceeds a certain limit. This helps prevent damage to the compressor and other components and ensures safe operation of the system.

Check Valve

The check valve prevents air from flowing back into the compressor when it is not running. This helps maintain the pressure in the system and prevents any backflow that could damage the compressor.

By familiarizing yourself with these components and their functions, you will be better equipped to locate and maintain the air compressor on your Freightliner. Remember to consult your vehicle’s manual for specific instructions and guidelines.

Understanding the Air Compressor Tank

The air compressor tank is a critical component of the air compressor system in a Freightliner. It is responsible for storing compressed air that is used to power various systems in the vehicle. The tank is typically made of a sturdy material such as steel or aluminum to withstand the high pressure of the compressed air.

Capacity: The capacity of the air compressor tank determines how much compressed air it can store. Larger capacity tanks are able to hold more air, which can be beneficial for applications that require a higher volume of compressed air.

Pressure Rating: The pressure rating of the air compressor tank refers to the maximum pressure it can safely hold. It is important to ensure that the tank’s pressure rating matches or exceeds the operating pressure of the air compressor system to avoid any potential safety hazards.

Drain Valve: The tank is equipped with a drain valve, which is used to remove any condensation or moisture that accumulates inside the tank. Regularly draining the tank helps prevent rust and corrosion, which can compromise the integrity of the tank.

Mounting Location: The air compressor tank is typically mounted in a secure location on the Freightliner, such as the frame rail or behind the cab. The mounting location should provide easy access for maintenance and should be protected from road debris or other potential hazards.

Inspection and Maintenance: It is important to regularly inspect the air compressor tank for any signs of damage or corrosion. Any issues should be promptly addressed to ensure the tank’s reliability and safety. Regular maintenance includes draining the tank, inspecting and replacing the tank’s fittings, and checking for any leaks.

Overall, understanding the air compressor tank is crucial for the proper functioning and maintenance of the air compressor system in a Freightliner. By ensuring the tank is in good condition and properly maintained, operators can rely on a steady supply of compressed air for various vehicle systems.

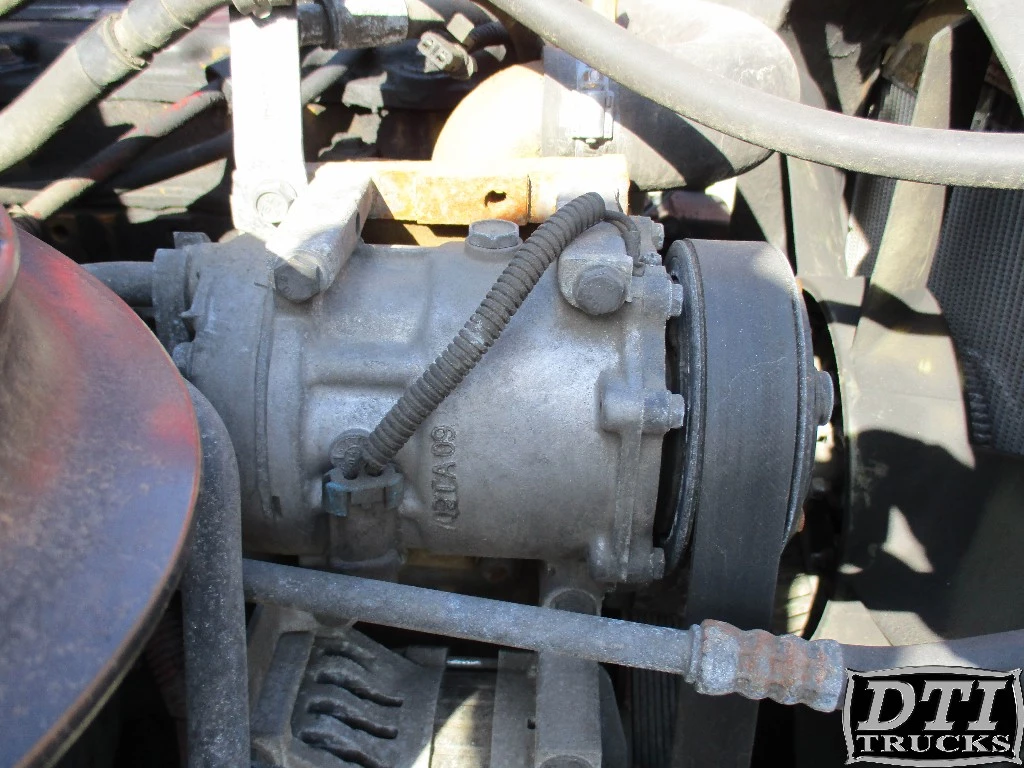

Recognizing the Air Compressor Pump

The air compressor pump is an essential component of a Freightliner truck’s air system. It is responsible for pressurizing the air and ensuring proper functioning of various pneumatic systems, such as the brakes and suspension. Recognizing the air compressor pump is crucial for maintenance and troubleshooting purposes.

Location: The air compressor pump is typically located on the engine block of the Freightliner truck. It is usually positioned towards the front of the engine and can be identified by its cylindrical shape and the presence of different hoses and connectors.

Appearance: The air compressor pump is a metal cylinder that is often painted black or another dark color. It has a pulley attached to one end, which is connected to the engine’s crankshaft via a belt. The pump itself has various fittings and ports, including an inlet for air intake and outlets for delivering compressed air to other parts of the truck.

Other Components: The air compressor pump is usually accompanied by other components that are part of the air system. These may include an air dryer, pressure relief valve, and air governor. These components work together to ensure efficient air compression, filtration, and regulation.

Maintenance: It is important to regularly inspect and maintain the air compressor pump to ensure it continues to function properly. This may involve checking for leaks, monitoring the belts and pulleys, and replacing any worn-out or damaged parts. Regular maintenance can help prevent costly breakdowns and ensure the overall performance of the air system.

Troubleshooting: If there are issues with the air system, recognizing the air compressor pump can help in troubleshooting the problem. Common problems related to the air compressor pump may include a loss of air pressure, abnormal noises, or excessive vibration. By identifying the pump and its associated components, such as hoses and fittings, it becomes easier to pinpoint the cause of the issue and take appropriate measures to resolve it.

In conclusion, recognizing the air compressor pump on a Freightliner truck is essential for maintenance and troubleshooting purposes. Understanding its location, appearance, and associated components can help ensure the proper functioning of the air system and prevent potential issues. Regular maintenance and prompt troubleshooting are key to maintaining the performance and reliability of the air compressor pump and the overall air system.

Locating the Air Compressor Pressure Switch

The air compressor pressure switch on a Freightliner is an essential component that helps regulate the air pressure in the air compressor system. It is responsible for turning the compressor on and off once the set pressure levels are reached.

The pressure switch is typically located near the air compressor itself, which is usually found on the engine. However, the exact location may vary depending on the specific model and year of the Freightliner truck.

To locate the air compressor pressure switch, start by locating the air compressor. It is usually a cylindrical-shaped device attached to the engine. Look for the air lines connected to the compressor, as the pressure switch is usually located in close proximity to these lines.

Once you have located the air compressor, visually scan the surrounding areas for a small device attached to the compressor or nearby. The pressure switch is often cylindrical in shape and will have electrical wires connected to it. It may also have a small lever or knob that can be adjusted to set the desired pressure levels.

If you are having trouble finding the pressure switch, consult the Freightliner truck’s manual or contact a professional mechanic for assistance. They will be able to provide specific guidance for locating the pressure switch on your particular model.

It is important to note that the air compressor pressure switch is a crucial component of the air compressor system. If you are experiencing issues with your air compressor or suspect a problem with the pressure switch, it is recommended to have it inspected and repaired by a qualified technician. This will ensure the proper functioning of the air compressor system and maintain the safety of your Freightliner truck.

FAQ:

Where is the air compressor located on a Freightliner truck?

The air compressor is typically located on the engine of a Freightliner truck, usually on the passenger side.

How do I know if the air compressor on my Freightliner truck is working properly?

To check if the air compressor is working properly, you can listen for any unusual noises coming from the compressor, check the air pressure gauges in the truck’s cabin, or have a trained mechanic inspect it for you.

What are the common signs of a faulty air compressor on a Freightliner truck?

Some common signs of a faulty air compressor on a Freightliner truck include reduced air pressure, loud or unusual noises coming from the compressor, and air leaks.

Can I replace the air compressor on my Freightliner truck myself?

While it is possible to replace the air compressor on your Freightliner truck yourself, it is recommended to have a trained mechanic do the job, as it can be a complex task that requires knowledge of the truck’s engine and air system.

How often should the air compressor on a Freightliner truck be inspected?

The air compressor on a Freightliner truck should be inspected regularly, preferably during routine maintenance checks. It is recommended to consult the truck’s manual or a mechanic to determine the specific inspection schedule.

What are some tips for maintaining the air compressor on a Freightliner truck?

Some tips for maintaining the air compressor on a Freightliner truck include regularly checking the air pressure, avoiding overloading the compressor, keeping it clean and free from debris, and addressing any issues or malfunctions promptly.

Are there any safety precautions to consider when working with the air compressor on a Freightliner truck?

Yes, when working with the air compressor on a Freightliner truck, it is important to follow safety precautions such as wearing protective gear, ensuring the truck is properly supported and secured, and disconnecting the power source before performing any maintenance or repairs.

Video: