How to Troubleshoot and Repair an Air Compressor Pressure Switch

An air compressor pressure switch is responsible for controlling the operation of your air compressor by automatically turning it on and off at set pressure levels. However, like any electrical component, pressure switches can sometimes fail or malfunction, causing issues with your air compressor. In this article, we will guide you through the troubleshooting and repair process for an air compressor pressure switch.

One common issue with air compressor pressure switches is failure to turn on or off at the correct pressure levels. If your compressor is not turning on or off when it should, the first step is to check the pressure switch settings. Locate the pressure switch and visually inspect the pressure settings. Make sure the pressure settings are correct according to the manufacturer’s specifications. Adjust the pressure settings if necessary.

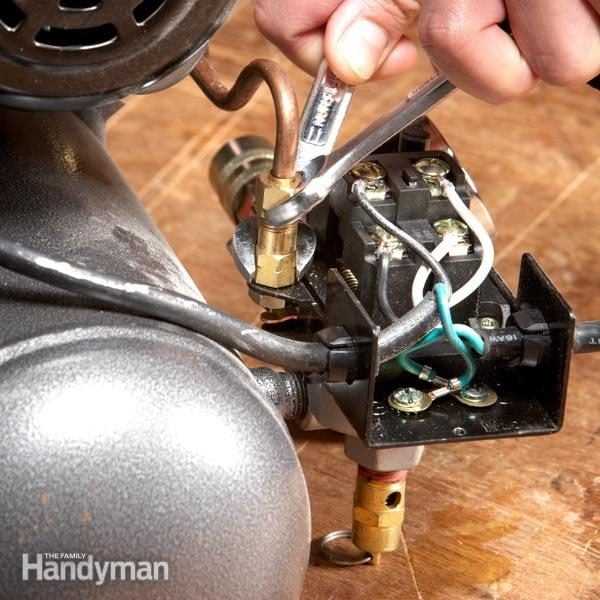

If adjusting the pressure settings does not resolve the issue, the next step is to check the electrical connections of the pressure switch. Ensure that the power supply is properly connected to the pressure switch and that there are no loose or corroded wires. Use a multimeter to check for continuity in the electrical circuit. If there is no continuity, there may be a problem with the wiring or the pressure switch itself.

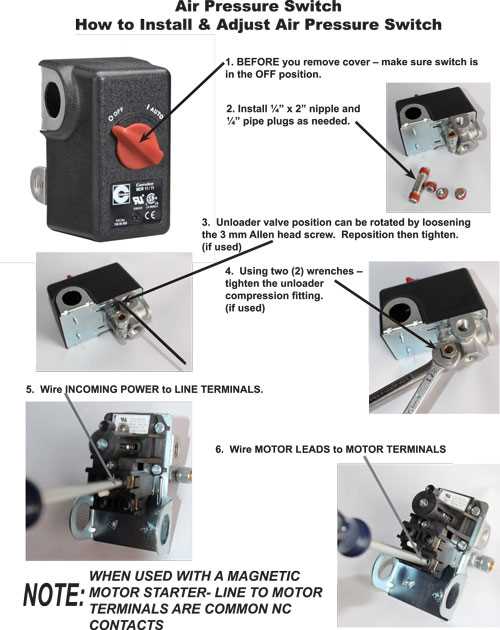

If the pressure switch is still not functioning correctly after checking the settings and electrical connections, it may need to be replaced. To replace the pressure switch, start by disconnecting the power supply to the air compressor. Remove the old pressure switch from its mounting location and disconnect the electrical connections. Install the new pressure switch in the same location and reconnect the electrical connections. Finally, reconnect the power supply and test the air compressor to ensure the pressure switch is working correctly.

In conclusion, troubleshooting and repairing an air compressor pressure switch involves checking the pressure settings, inspecting the electrical connections, and potentially replacing the pressure switch. By following these steps, you can ensure that your air compressor operates efficiently and reliably.

Understanding the Role of the Air Compressor Pressure Switch

The air compressor pressure switch is a crucial component of an air compressor as it helps to control and regulate the pressure within the system. It monitors the pressure levels and automatically turns the compressor on or off to maintain the desired pressure range.

The pressure switch typically consists of a mechanical switch that is connected to a diaphragm or a bellows. The diaphragm or bellows senses the pressure in the system and controls the switch accordingly. When the pressure in the system drops below the set limit, the switch activates the compressor to increase the pressure. Once the pressure reaches the upper limit, the switch turns off the compressor to prevent over-pressurization.

The pressure switch also plays an important safety role in the air compressor. It is responsible for protecting the compressor from excessive pressure that could lead to potential damage or failure. If the pressure switch fails to function properly, it may result in the compressor continuously running or not turning on at all, both of which can cause significant issues.

Understanding how the pressure switch operates and being able to troubleshoot and repair any issues that may arise is essential for maintaining the functionality and longevity of an air compressor. By properly maintaining and servicing the pressure switch, air compressor owners can ensure that their system operates efficiently and safely.

Signs of a Faulty Air Compressor Pressure Switch

A faulty air compressor pressure switch can cause various issues with the operation of your air compressor. Here are some common signs that indicate a problem with the pressure switch:

- Inconsistent pressure levels: If you notice that your air compressor is not maintaining a consistent pressure, it could be a sign of a faulty pressure switch. The switch may not be accurately sensing and adjusting the pressure, leading to fluctuations in the output.

- Failure to turn on or off: A malfunctioning pressure switch may prevent the air compressor from turning on or off properly. It could result in the compressor not starting at all or continuing to run even when the desired pressure level is reached.

- Noisy operation: A faulty pressure switch can cause excessive noise during the operation of the air compressor. This could be due to a malfunctioning switch mechanism or improper alignment.

- Leaking air: If you notice air leaking from the pressure switch, it is a clear indication of a problem. The switch may have a damaged diaphragm or a faulty seal, causing air to escape and affecting the overall performance of the compressor.

- Inaccurate pressure readings: A defective pressure switch can result in inaccurate pressure readings on the compressor’s gauge. This can make it challenging to monitor and adjust the pressure levels according to your needs.

If you experience any of these signs, it is important to troubleshoot and repair the air compressor pressure switch promptly. Ignoring the issue may lead to further damage to the compressor or inefficient operation. Consulting a professional or referring to the manufacturer’s guidelines can help you diagnose and fix the problem effectively.

Gathering the Required Tools

Before beginning the troubleshooting and repair process for an air compressor pressure switch, it is important to gather the necessary tools. Having the right tools on hand will make the process much easier and more efficient. Here are some of the essential tools that you will need:

- Socket set: A socket set with various sizes will be needed to remove and replace screws and bolts on the pressure switch.

- Screwdriver set: A set of screwdrivers will be necessary for removing and tightening screws on the pressure switch.

- Multimeter: A multimeter is an essential tool for testing the electrical connections and voltage of the pressure switch.

- Adjustable wrench: An adjustable wrench will be needed to loosen and tighten nuts and bolts on the pressure switch.

- Wire cutters/strippers: Wire cutters or strippers will be helpful for cutting and stripping wires for testing and making electrical connections.

- Teflon tape: Teflon tape should be applied to the threads of any fittings to ensure a proper seal and prevent leaks.

- Clean cloth: A clean cloth or rag will be useful for wiping away any dirt or debris on the pressure switch or surrounding area.

By gathering these tools before starting the troubleshooting and repair process, you can ensure that you have everything you need to successfully diagnose and fix any issues with your air compressor pressure switch.

Step-by-Step Guide to Troubleshooting the Switch

When troubleshooting an air compressor pressure switch, it is important to follow a step-by-step approach to identify and solve the problem. Here is a guide to help you troubleshoot the switch:

Step 1: Check for Power

The first step is to check if the pressure switch is receiving power. Verify that the circuit breaker or fuse for the air compressor is intact and that there is power to the outlet. If there is no power, check the wiring connections and replace any faulty components.

Step 2: Inspect the Pressure Switch

Next, inspect the pressure switch for any physical damage or signs of wear. Look for broken or loose wires, damaged connectors, or a deteriorated switch housing. If any issues are found, replace or repair the switch as necessary.

Step 3: Test the Switch Contacts

Using a multimeter set to the resistance or continuity mode, test the switch contacts to ensure they are working properly. Start by disconnecting the power and air supply to the compressor. Place the multimeter probes on the contacts and activate the switch. If there is no continuity or resistance, the contacts may be dirty or worn out and will need to be cleaned or replaced.

Step 4: Check for Pressure Build-up

Once the switch contacts are verified to be working, reconnect the power and air supply to the compressor. Turn on the compressor and observe if the pressure builds up to the cut-off point. If the pressure does not build up or reaches the cut-off point too quickly, there may be an issue with the switch settings or the compressor itself.

Step 5: Adjust or Replace the Switch

If the pressure does not build up or reaches the cut-off point too quickly, consult the user manual or manufacturer’s instructions to adjust the switch settings if possible. Alternatively, if the switch is functioning correctly but the compressor is not building up pressure, there may be an issue with the compressor’s valves, seals, or piston rings that will require further investigation or repair.

By following this step-by-step guide, you will be able to troubleshoot and identify the problem with your air compressor pressure switch. Remember to always prioritize safety and consult a professional if you are unsure about any aspect of the troubleshooting process.

Step-by-Step Guide to Repairing the Switch

1. Disconnect the power: Before beginning any repair work, always make sure to disconnect the power supply to the air compressor. This will prevent any accidental electrical shocks or injuries during the repair process.

2. Remove the cover: Use a screwdriver to remove the cover of the pressure switch. This will give you access to the internal components of the switch that may need to be repaired or replaced.

3. Inspect the contacts: Take a close look at the contacts inside the pressure switch. Check for any signs of damage, such as burn marks or corrosion. If the contacts are damaged, they will need to be replaced.

4. Clean the contacts: If the contacts are dirty or corroded, use a fine-grit sandpaper or contact cleaner to clean them. This will help improve the electrical connection and prevent any further issues.

5. Test the pressure switch: Use a multimeter to test the continuity of the pressure switch. This will help determine if the switch is functioning properly or if it needs to be replaced. Follow the manufacturer’s instructions for testing the switch.

6. Replace the switch: If the pressure switch is not functioning correctly, it will need to be replaced. Choose a new pressure switch that is compatible with your air compressor model and install it according to the manufacturer’s instructions.

7. Reassemble and test: Once the new pressure switch is installed, reassemble the cover and make sure all connections are secure. Reconnect the power supply and test the air compressor to ensure that the pressure switch is working properly.

8. Monitor and maintain: After repairing the pressure switch, it is important to regularly monitor and maintain the switch to prevent any future issues. Clean the contacts regularly and inspect for any signs of damage or wear. This will help prolong the lifespan of the pressure switch and ensure optimal performance of the air compressor.

Tips for Maintaining the Air Compressor Pressure Switch

Proper maintenance of the air compressor pressure switch is essential to ensure its efficient and reliable operation. Here are some tips to help you maintain your pressure switch:

Regular Cleaning

Regularly clean the pressure switch to remove dust, dirt, and debris that can accumulate over time. Use a soft cloth or brush to gently wipe the surface of the switch, taking care not to damage any electrical components.

Inspect for Wear and Tear

Inspect the pressure switch for any signs of wear and tear, such as loose connections, frayed wires, or cracked casing. Replace any damaged parts to prevent further issues and ensure the switch functions properly.

Check and Adjust the Settings

Periodically check the pressure settings on the switch and ensure they are set to the desired levels. Use a pressure gauge to verify that the switch is activating and deactivating at the correct pressure thresholds. Adjust the settings if necessary.

Monitor for Leaks

Regularly check for any air leaks around the pressure switch. Leaks can lead to a decrease in pressure and affect the overall performance of the air compressor. Repair any leaks promptly to maintain optimal functioning.

Keep the Area Clean and Dry

Ensure the area around the pressure switch is clean and dry. Moisture and debris can interfere with the switch’s operation and cause electrical issues. Use a clean, dry cloth to wipe any moisture or dirt away from the switch.

By following these maintenance tips, you can prolong the life of your air compressor pressure switch and ensure your compressor operates effectively and safely.

FAQ:

Why is my air compressor not turning on?

If your air compressor is not turning on, there could be several reasons for this. First, make sure that the power switch is turned on and that the power cord is plugged in securely. Next, check the circuit breaker to see if it has been tripped. If it has, reset the breaker and try turning on the compressor again. If the circuit breaker keeps tripping, there may be a problem with the wiring or motor of the compressor, and you may need to consult a professional for repair.

What should I do if my air compressor is not building pressure?

If your air compressor is not building pressure, you should first check the air filter to see if it is clogged or dirty. A dirty air filter can restrict airflow and prevent the compressor from building pressure. If the air filter is clean, check the intake valve to make sure it is not stuck open. If the intake valve is working properly, the problem may be with the pressure switch. You can try adjusting the cut-in and cut-out pressures on the pressure switch to see if that resolves the issue. If not, you may need to replace the pressure switch.

Why is my air compressor constantly running?

If your air compressor is constantly running, it could be due to a malfunctioning pressure switch. The pressure switch is responsible for turning the compressor on and off based on the desired pressure settings. If the pressure switch is stuck in the on position, it will continuously run the compressor, even if the desired pressure has been reached. In this case, you will need to replace the pressure switch to resolve the issue.

How can I adjust the cut-in and cut-out pressures on my air compressor pressure switch?

To adjust the cut-in and cut-out pressures on your air compressor pressure switch, you will need to locate the adjustment screws on the switch. The cut-in pressure is the pressure at which the compressor turns on, and the cut-out pressure is the pressure at which the compressor turns off. Using a screwdriver, you can turn the adjustment screws clockwise to increase the pressure settings, or counterclockwise to decrease them. It is important to refer to the manufacturer’s instructions for your specific model of air compressor pressure switch, as the location and type of adjustment screws may vary.

Why does my air compressor keep tripping the circuit breaker?

If your air compressor keeps tripping the circuit breaker, there may be an electrical issue causing the overload. First, check to make sure that the compressor is not drawing too much power for the circuit it is plugged into. If the circuit breaker is the appropriate size for the compressor, the problem may be with the motor or wiring of the compressor. In this case, it is best to consult a professional for repair, as electrical issues can be dangerous to work with.

What should I do if my air compressor is leaking air?

If your air compressor is leaking air, you should first check the fittings and connections to make sure they are tight and secure. A loose or damaged fitting can cause air to leak out. If the fittings are tight and there are no obvious leaks, the problem may be with the pressure switch. The pressure switch contains a valve that controls the flow of air into and out of the compressor. If this valve is damaged or worn, it may leak air. In this case, you will need to replace the pressure switch to stop the air leak.

How can I replace the pressure switch on my air compressor?

To replace the pressure switch on your air compressor, you will first need to disconnect the power and release the pressure from the compressor. Once the pressure has been released, you can remove the old pressure switch by disconnecting the electrical wires and unscrewing the switch from the compressor. Make sure to note the position of the wires and how they are connected before disconnecting them. Once the old pressure switch has been removed, you can install the new pressure switch by connecting the wires and screwing the switch into place. Finally, reconnect the power and test the compressor to ensure that the new pressure switch is working correctly.

Video: