How to Service an Air Compressor: Expert Tips and Step-by-Step Guide

Servicing an air compressor is an essential task that should be performed regularly to ensure its optimal performance and extend its lifespan. Regular maintenance and service can help prevent breakdowns and costly repairs, while also ensuring that the compressor operates efficiently. Whether you are a professional mechanic or a hobbyist, understanding the steps involved in servicing an air compressor can save you time, money, and frustration.

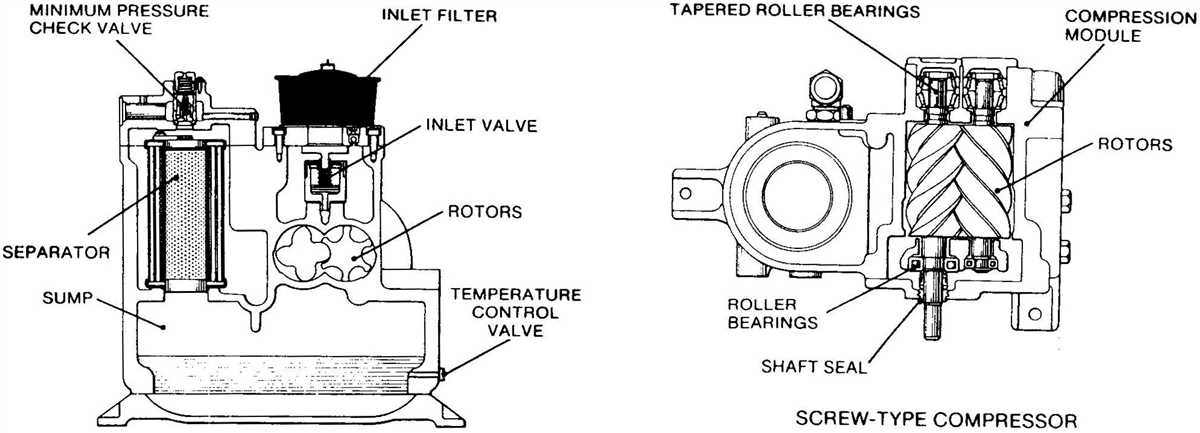

Before diving into the servicing process, it is important to understand the basic components of an air compressor. These include the tank, motor, pump, pressure switch, and safety relief valve. Each component plays a crucial role in the compressor’s operation and requires attention during the servicing process. By following a step-by-step guide and utilizing expert tips, you can effectively service your air compressor and keep it running smoothly.

One of the first steps in servicing an air compressor is to inspect the filters and clean or replace them if necessary. Clogged filters can restrict the airflow and put extra strain on the compressor, reducing its efficiency and potentially causing damage. Additionally, checking the oil levels and replenishing or changing the oil is crucial to ensure the compressor’s proper function. Regular oil changes can prevent overheating and maintain the compressor’s performance.

In addition to filter and oil maintenance, it is important to inspect the compressor’s belts, hoses, and fittings for any signs of wear or damage. Cracked hoses or loose fittings can lead to air leakage, reducing the compressor’s efficiency. Tightening loose connections and replacing damaged parts can help prevent air leaks and improve performance. Lastly, verifying the pressure settings and calibrating the pressure switch is essential to ensure safe and reliable operation.

In conclusion, servicing an air compressor is a vital task that should not be neglected. Regular maintenance, including filter cleaning or replacement, oil changes, inspection of belts and fittings, and checking pressure settings, can help prevent breakdowns and keep the compressor running smoothly. By following expert tips and a step-by-step guide, you can confidently service your air compressor, saving time and money in the long run.

Understanding the Importance of Servicing an Air Compressor

An air compressor is a vital component in many industries, helping to power various tools and machinery. To ensure that an air compressor performs efficiently and safely, regular servicing is of utmost importance. Regular servicing helps maintain the performance of the air compressor, extends its lifespan, and reduces the risk of breakdowns or malfunctions.

One of the main reasons why servicing an air compressor is crucial is to prevent any potential safety hazards. Over time, dust, debris, and other contaminants can accumulate in the compressor’s air intake and filters, leading to reduced airflow and increased risk of overheating. Regularly cleaning and maintaining the air compressor’s filters and other components will ensure proper airflow and prevent overheating, reducing the risk of accidents or fires.

Another benefit of servicing an air compressor is improved energy efficiency. When an air compressor is not properly maintained, it can consume more energy to operate, resulting in increased utility costs. Regular servicing includes checking and repairing any leaks, replacing worn-out parts, and ensuring proper lubrication. These maintenance tasks help optimize the compressor’s performance, reducing energy consumption and saving money in the long run.

Regular servicing also helps identify and address potential issues early on, preventing them from developing into major problems. By conducting routine inspections, technicians can identify worn-out parts, leaks, or other issues that may affect the compressor’s performance. Prompt repairs or replacements can be made, preventing further damage and expensive repairs down the line.

Lastly, servicing an air compressor ensures compliance with industry regulations and standards. Many industries have specific regulations regarding the maintenance and safety of air compressors. Regular servicing helps ensure that the compressor meets these requirements and operates within the prescribed guidelines. Compliance with these regulations is not only essential for the safety of the workers but also for avoiding any legal liabilities or penalties.

Benefits of Regular Air Compressor Maintenance

Regular maintenance of an air compressor is essential for maintaining its efficiency and ensuring its longevity. Here are some key benefits of performing regular maintenance on your air compressor:

1. Improved Performance

Regular maintenance helps to keep your air compressor operating at its optimal level. By cleaning and lubricating the various components, you can ensure smooth operation and prevent any issues that may affect performance. This includes checking and replacing filters, inspecting hoses and fittings, and adjusting pressure levels as needed.

2. Increased Lifespan

Proper maintenance can significantly extend the lifespan of your air compressor. By regularly inspecting and servicing the compressor, you can identify and address any potential problems before they escalate and cause major damage. This can save you the cost of expensive repairs or the need for premature replacement.

3. Energy Efficiency

A well-maintained air compressor operates more efficiently, resulting in reduced energy consumption. This not only helps to lower your energy bills but also reduces the strain on the compressor itself, leading to less wear and tear.

4. Enhanced Safety

Regular maintenance ensures that your air compressor is operating safely. By inspecting for leaks, checking pressure levels, and ensuring the proper functioning of safety features, you can minimize the risk of accidents or injuries. It is important to follow all safety procedures and guidelines when performing maintenance to keep yourself and others safe.

5. Cost Savings

Investing in regular maintenance can save you money in the long run. By identifying and addressing minor issues early on, you can prevent them from turning into major and costly problems. Additionally, a well-maintained air compressor is less likely to break down unexpectedly, reducing downtime and lost productivity.

In conclusion, regular maintenance of your air compressor offers numerous benefits, including improved performance, increased lifespan, energy efficiency, enhanced safety, and cost savings. Make sure to establish a routine maintenance schedule and follow manufacturer guidelines to keep your air compressor in top-notch condition.

Step 1: Safety Precautions

1.1 Wear safety goggles and gloves

Before starting any maintenance or servicing on an air compressor, it’s essential to protect your eyes and hands. Wear safety goggles that provide full coverage and gloves that are resistant to oil and chemicals. This will help prevent any potential injuries from flying debris, oil spills, or accidental contact with hot surfaces.

1.2 Disconnect power supply

Prior to servicing the air compressor, make sure to disconnect its power supply. This can be done by unplugging it from the electrical outlet or turning off the circuit breaker that controls the compressor. This precautionary measure will eliminate the risk of electric shock or accidental startup during the servicing process.

1.3 Release pressure from the compressor

Before attempting any maintenance or repair work, it’s crucial to release the pressure from the compressor tank. Turn off the compressor and open the air release valve to let out any remaining pressurized air. This will prevent any sudden release of stored energy and potential hazards when working on the compressor.

1.4 Ensure proper ventilation

When servicing an air compressor, make sure to work in a well-ventilated area. Air compressors can produce fumes and airborne particles that may be harmful to breathe in. If working indoors, open windows or doors to allow fresh air circulation. If working in a closed environment, consider using a ventilation fan or wearing a respirator mask.

1.5 Follow manufacturer’s instructions

Always refer to the manufacturer’s manual for specific safety precautions and guidelines when servicing your air compressor. Each compressor model may have unique safety requirements, so it’s important to familiarize yourself with the specific instructions provided by the manufacturer. Following these guidelines will help ensure your safety and the proper functioning of the air compressor.

1.6 Keep the work area clean and organized

Maintaining a clean and organized work area is essential for safety purposes. Remove any clutter, debris, or tripping hazards from the work area. This will help prevent accidents and allow for easier access to the compressor during servicing. Additionally, clean up any spills or oil leaks immediately to prevent slips or falls.

Protective Measures for Handling an Air Compressor

1. Wear appropriate protective gear

When servicing or handling an air compressor, it is important to wear the appropriate protective gear to ensure your safety. This may include safety glasses or goggles to protect your eyes from debris or compressed air, ear protection to prevent hearing damage from the noise produced by the compressor, and gloves to protect your hands from sharp edges or hot surfaces.

2. Ensure proper ventilation

Air compressors generate heat and exhaust air, so it’s essential to have proper ventilation in the area where the compressor is being used. Adequate ventilation will help dissipate heat and carry away any fumes or exhaust gases that may be released during operation. This will also help prevent the buildup of moisture, which can lead to rust and other damage to the compressor.

3. Inspect the compressor before use

Prior to using the air compressor, it’s important to inspect it for any signs of damage or wear. Check for any leaks, loose fittings, or worn-out components that could potentially cause injury or malfunction. If any issues are found, the compressor should be repaired or replaced before use.

4. Follow proper lifting techniques

Air compressors can be heavy, so it’s essential to use proper lifting techniques to avoid strain or injury. When lifting the compressor, bend at the knees and use your leg muscles to lift the weight, rather than your back. If the compressor is too heavy to lift on your own, ask for assistance or use lifting equipment to safely move it.

5. Use caution when working with electricity

Many air compressors are powered by electricity, so it’s important to take caution when working with electrical components. Ensure the compressor is unplugged before performing any maintenance or repairs. If you need to work on the electrical components, use insulated tools and ensure the power is disconnected. If you are unsure about working with electricity, it is best to consult a professional.

By following these protective measures, you can ensure your safety when handling an air compressor. Always prioritize safety and take the necessary precautions to avoid accidents or injuries.

Step 2: Checking the Oil Level

Gather the necessary tools

Before you begin checking the oil level of your air compressor, make sure you have the following tools on hand:

- A clean rag or paper towels

- An oil dipstick or sight glass

- The manufacturer’s manual or specification for oil type and oil level

Locate the oil dipstick or sight glass

Depending on the model of your air compressor, the oil dipstick or sight glass may be located in different places. Consult the manufacturer’s manual to locate this component. The dipstick is typically a metal rod with markings indicating the oil level, while the sight glass is a transparent window that allows you to visually check the oil level.

Clean the area around the oil dipstick or sight glass

Take your clean rag or paper towels and wipe away any dirt or debris around the oil dipstick or sight glass. This will ensure a clear view of the oil level and prevent any contamination.

Check the oil level

Now it’s time to check the oil level. If your air compressor has a dipstick, remove it completely and wipe it clean with the rag or paper towels. Then, reinsert the dipstick back into the oil reservoir and pull it out again. Take note of the oil level markings on the dipstick and compare it to the recommended level in the manufacturer’s manual.

If your air compressor has a sight glass, simply observe the oil level through the transparent window. The oil level should be within the range indicated by the manufacturer.

Refill or replace the oil if necessary

If the oil level is below the recommended level or if the oil appears dirty or contaminated, it may be necessary to refill or replace the oil. Refer to the manufacturer’s manual for the correct oil type and the procedure for adding or changing the oil.

Be sure to use the recommended oil type and never overfill the oil reservoir. Overfilling can lead to poor performance or damage to the air compressor.

Note: Checking the oil level of your air compressor should be done regularly to ensure optimal performance and longevity of the machine. Always refer to the manufacturer’s manual for specific instructions and recommendations.

Importance of Oil Level in Air Compressor

Proper lubrication

The oil level in an air compressor is crucial for the proper functioning of the machine. Oil serves as a lubricant, which helps to reduce friction between the moving parts of the compressor. It ensures smooth operation and prevents excessive wear and tear.

Cooling effect

In addition to lubrication, oil also plays a vital role in cooling the compressor. As the air compressor operates, it generates heat due to the compression process. The oil absorbs this heat and dissipates it, preventing the compressor from overheating. Maintaining the correct oil level is essential for efficient cooling and preventing damage to the compressor components.

Sealing and sealing components

The oil level in an air compressor is also important for sealing purposes. It helps to create a tight seal between the piston rings and cylinder walls, preventing any leakage of compressed air. Without proper sealing, the efficiency of the compressor is compromised, and it may result in air leakage and reduced performance.

Extended lifespan

Regularly monitoring and maintaining the oil level in your air compressor can significantly extend its lifespan. Adequate lubrication provided by the oil prevents excessive friction and wear on the internal components, reducing the risk of breakdowns and expensive repairs. By ensuring the oil level is correct, you can maximize the longevity of your compressor and keep it running smoothly for years to come.

Monitoring and maintenance

To ensure the importance of the oil level is maintained, it is essential to regularly monitor and maintain the oil in your air compressor. Check the oil level before each use and top up if necessary. Additionally, change the oil according to the manufacturer’s recommendations and keep track of oil changes in a maintenance log. Regular oil changes and proper oil level will help keep your air compressor in optimal condition, ensuring its efficiency and reliability.

Step 3: Cleaning or Replacing the Air Filter

One important step in servicing an air compressor is cleaning or replacing the air filter. The air filter is designed to remove impurities and contaminants from the air before it enters the compressor. Over time, the air filter can become clogged with dirt, dust, and debris, which can impede the airflow and reduce the efficiency of the compressor.

To clean the air filter, start by turning off the compressor and disconnecting it from the power source. Remove the air filter cover, which is typically located on the side or the top of the compressor. Carefully remove the filter from its housing, taking note of how it is positioned.

Inspect the filter for any visible signs of dirt or damage. If the filter is made of paper or foam, gently tap it against a hard surface to dislodge any loose particles. If the filter is severely clogged or damaged, it is recommended to replace it with a new one. Refer to the manufacturer’s instructions or consult the compressor’s manual for the appropriate replacement filter.

If the filter is still in good condition after cleaning, you can reuse it by reinstalling it back into its housing. Make sure to position it correctly, ensuring that it fits snugly and securely. Replace the air filter cover and reconnect the compressor to the power source.

Regularly cleaning or replacing the air filter is essential for maintaining the performance and longevity of your air compressor. A clean and functional air filter will ensure that the compressor receives clean air, preventing unnecessary wear and tear on its components. By following these steps, you can keep your air compressor running efficiently for years to come.

Significance of Air Filter in Air Compressor

The air filter is an essential component of an air compressor system as it plays a crucial role in ensuring the performance and longevity of the equipment. The primary function of the air filter is to remove impurities and contaminants from the air before it enters the compressor. By doing so, it helps prevent damage to the internal components and promotes efficient operation.

1. Clean Air Supply: The air filter ensures that only clean and filtered air is supplied to the compressor. This is important because the air drawn into the compressor from the surrounding environment may contain dust, dirt, pollen, and other debris. These contaminants can enter the compressor and accumulate on various components, leading to reduced efficiency and potential malfunctions.

2. Protection for Internal Components: The air filter acts as a barrier, preventing particles and contaminants from entering the compressor’s intake system. It captures and traps these contaminants, preventing them from reaching sensitive components such as valves, cylinders, pistons, and bearings. By keeping these internal parts clean, the air filter helps extend their lifespan and reduces the risk of breakdowns and costly repairs.

3. Improved Air Quality: In addition to protecting the compressor, the air filter also helps improve the overall air quality. When the air is filtered properly, it becomes cleaner and free from harmful particles. This is particularly important in industries where air quality is essential, such as medical facilities, laboratories, and manufacturing plants. By ensuring a clean air supply, the air filter contributes to a healthier work environment and higher product quality.

4. Energy Efficiency: A clogged or dirty air filter can restrict the airflow, causing the compressor to work harder to maintain the desired pressure levels. This increased workload can lead to higher energy consumption and increased operating costs. Regularly replacing or cleaning the air filter ensures that the compressor operates at optimal efficiency, saving energy and reducing expenses in the long run.

5. Maintenance and Longevity: Proper maintenance of the air filter is essential for the longevity of the air compressor. Regularly inspecting, cleaning, or replacing the air filter as recommended by the manufacturer helps prevent excessive wear and tear on the compressor. A well-maintained air filter allows the compressor to perform at its best and can extend its service life.

In conclusion, the air filter in an air compressor is of significant importance for ensuring a clean air supply, protecting internal components, improving air quality, increasing energy efficiency, and enhancing the equipment’s longevity. Regular maintenance of the air filter is crucial to reap these benefits fully.

Step 4: Inspecting and Tightening Connections

Properly inspecting and tightening connections is an important part of servicing an air compressor. Over time, the vibrations and pressure changes can cause connections to become loose, leading to leaks and inefficiencies in the system. By following these steps, you can ensure that all connections are secure and tight:

1. Visual Inspection

Start by visually inspecting all the connections in the air compressor system. Look for any signs of leaks or loose connections, such as air bubbles or oil residue around the joints. If you notice any issues, mark them for further investigation and tightening.

2. Tightening Procedure

Using a suitable wrench or tool, carefully tighten the connections that you marked during the visual inspection. Make sure not to overtighten, as this can damage the fittings or gaskets. Use a consistent amount of force to secure the connection, ensuring a proper seal without causing any damage.

3. Pressure Test

Once you have tightened all the connections, it is important to pressure test the system to ensure that there are no remaining leaks. Gradually increase the pressure in the system, monitoring the connections for any signs of air escaping. If you notice any leaks, repeat the tightening procedure or replace any damaged fittings.

4. Documentation

Finally, after inspecting and tightening all connections, it is important to document your servicing activities. Keep a record of the connections you inspected, any issues you found, and the actions you took to rectify the problems. This documentation will be useful for future reference and for tracking the maintenance history of your air compressor.

By following these steps, you can ensure that all connections in your air compressor system are secure and free from leaks. Regularly inspecting and tightening connections will help maintain the efficiency and reliability of your air compressor, and ultimately extend its lifespan.

Ensuring Proper Connections in an Air Compressor

Proper connections are crucial in maintaining the efficiency and safety of an air compressor. To ensure that your air compressor is functioning optimally, it is important to pay attention to the following key aspects of the connection system:

Tighten and Secure Fittings

Make sure all fittings and connections are tightly secured to prevent any leaks. Loose fittings can result in air leakage, which will reduce the overall efficiency of your air compressor. Regularly inspect fittings and tighten them if necessary, but be careful not to overtighten, as this can damage the connections.

Use Thread Sealant

Applying thread sealant on fittings that have pipe threads can help create a tight seal and prevent air leakage. Thread sealants come in various forms, such as tape or paste, and can be easily applied to the male threads before connecting the fittings. Ensure the sealant is compatible with your compressor’s materials and check for any manufacturer recommendations.

Inspect O-Rings

O-rings are commonly used in air compressor connections to create a tight seal. Regularly inspect the O-rings for any signs of damage or wear. If you notice any cracks, tears, or deterioration, replace the O-ring immediately to maintain proper sealing. Lubricating the O-rings with silicone grease can also help prolong their lifespan.

Check Hose Condition

Examine the condition of the hoses connected to your air compressor. Look for any signs of wear, such as cracks, bulges, or fraying. Damaged hoses can lead to air leakage and potential safety hazards. Replace any damaged hoses promptly to ensure a secure and efficient connection. Consider using reinforced hoses for added durability.

Verify Pressure Ratings

Check and verify the pressure ratings of all fittings and hoses to ensure they can handle the maximum pressure of your air compressor. Fittings or hoses with inadequate pressure ratings can fail under high pressure, leading to leaks or bursts. It is essential to use fittings and hoses that are suitable for the specific requirements of your air compressor.

By paying attention to these key aspects of the connection system, you can ensure that your air compressor operates smoothly and safely. Regular maintenance and inspections will help identify and address any issues promptly, preventing costly repairs and ensuring the longevity of your air compressor.

FAQ:

Why is it important to service an air compressor?

Servicing an air compressor is important because it helps maintain its efficiency and prolong its lifespan. Regular maintenance ensures that the compressor operates at its optimal level, prevents breakdowns, and reduces the risk of costly repairs.

How often should I service my air compressor?

The frequency of servicing an air compressor depends on its usage and the manufacturer’s recommendations. As a general guideline, it is recommended to service the compressor every 500-1000 hours of operation or at least once a year.

What are the basic steps to service an air compressor?

The basic steps to service an air compressor include checking the oil level, inspecting and cleaning the air filter, checking and tightening the bolts and connections, inspecting the hoses for any leaks or damages, and draining any moisture from the tank.

What types of oil should I use for my air compressor?

The type of oil to use for an air compressor depends on the manufacturer’s recommendations. Most air compressors use synthetic or mineral-based compressor oil. It is important to check the owner’s manual or consult the manufacturer to ensure using the correct oil type.

How can I clean the air filter of my air compressor?

To clean the air filter of an air compressor, you can start by removing the filter from its housing. You can then use compressed air or a vacuum cleaner to remove any dust or debris. If the filter is very dirty, you may need to wash it with mild soap and water, let it dry completely, and then reinstall it.

What are the signs that my air compressor needs servicing?

Some signs that indicate your air compressor needs servicing include decreased airflow, unusual noises or vibrations, oil leaks, excessive moisture in the compressed air, frequent overheating, and inconsistent pressure. If you notice any of these signs, it is important to service the compressor as soon as possible to prevent further damage.

Video: