How to Repair a Compressor in an Air Conditioner

The compressor is a crucial component of an air conditioner, as it is responsible for compressing and circulating the refrigerant in the system. However, just like any other mechanical part, a compressor can sometimes malfunction and may require repair. If you are experiencing issues with the compressor in your air conditioner, it is important to diagnose the problem and take appropriate steps to fix it.

One common problem with a compressor is a faulty motor. The motor can become worn out or damaged over time, resulting in poor performance or complete failure. In such cases, it is usually necessary to replace the motor or repair any issues that may be causing it to malfunction. Another possible issue could be a refrigerant leak, which can cause the compressor to overheat and eventually fail. Detecting and fixing any leaks is crucial to prevent further damage to the compressor.

Additionally, a compressor may fail due to electrical problems, such as a blown fuse or a faulty capacitor. These issues can interrupt the flow of electricity to the compressor, causing it to stop working. In such cases, the faulty electrical component will need to be replaced or repaired. It is important to note that repairing a compressor can be a complex task and may require professional expertise. If you are not confident in your ability to repair the compressor, it is recommended to seek help from a qualified technician.

In conclusion, repairing a compressor in an air conditioner involves diagnosing the issue and taking appropriate steps to fix it. It is crucial to address any motor, refrigerant, or electrical problems to prevent further damage to the compressor. While some repairs can be done by homeowners, it is advisable to seek professional help if you are unsure or inexperienced in compressor repairs. Proper maintenance and regular inspections can help prevent compressor issues and ensure the optimal performance of your air conditioner.

What is a compressor in an air conditioner?

A compressor is a crucial component of an air conditioner that plays a vital role in cooling the air. It is responsible for compressing the refrigerant gas, which is then pumped through the system to absorb heat from the indoor air and release it outside. The compressed refrigerant is then sent to the condenser, where it is cooled and turned back into a liquid form, ready for the cycle to repeat.

The compressor is often referred to as the heart of an air conditioner, as it enables the refrigeration process and helps maintain the desired temperature. It works by increasing the pressure and temperature of the refrigerant gas, allowing it to absorb heat from the indoor environment. This process is crucial in transforming the air conditioner into an effective cooling device that can create a comfortable indoor environment.

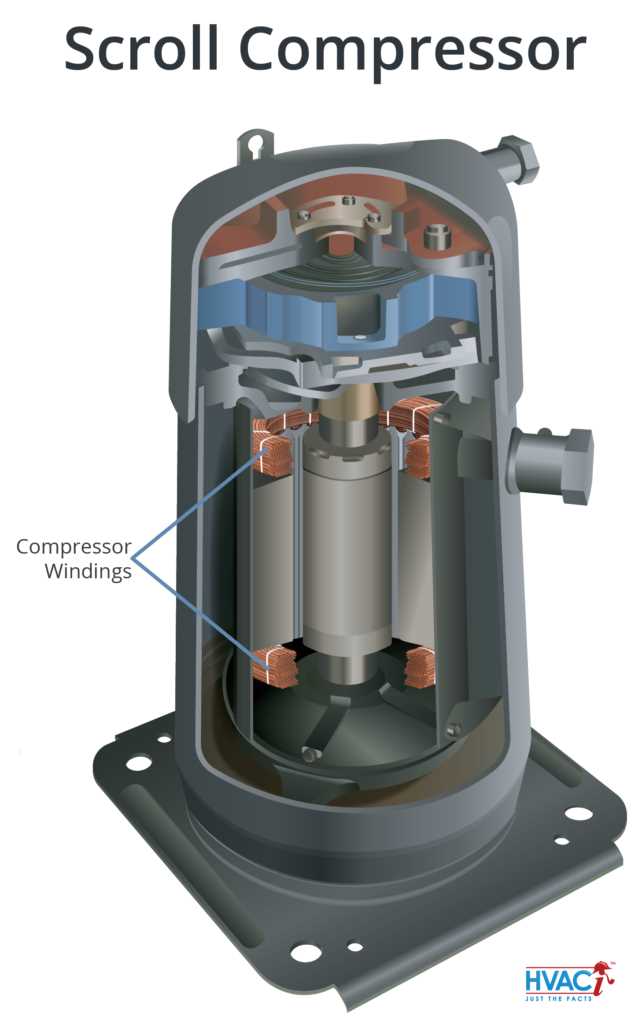

Compressors come in various types, including reciprocating compressors, rotary compressors, and scroll compressors. Each type has its own unique design and operating characteristics, but they all serve the same purpose of compressing the refrigerant gas and facilitating the cooling process.

Although compressors are typically reliable and durable, they can sometimes experience issues that require repair or replacement. Common compressor problems include refrigerant leaks, electrical faults, and mechanical failures. In such cases, it is essential to consult a professional HVAC technician who can diagnose and fix the problem to ensure the optimal performance of the air conditioner.

Importance of a functioning compressor

A functioning compressor is a crucial component of an air conditioning unit. It plays a key role in the cooling process by compressing refrigerant gas and converting it into a high-pressure, high-temperature vapor. This vapor is then condensed into a liquid form, releasing heat and cooling the air. Without a functioning compressor, the air conditioner will not be able to cool the air effectively.

One of the main reasons why a functioning compressor is important is because it determines the overall efficiency of the air conditioning system. A well-functioning compressor will ensure that the system operates at its maximum efficiency, providing optimal cooling performance while minimizing energy consumption. On the other hand, a faulty or inefficient compressor will lead to reduced cooling capacity and increased energy usage, resulting in higher utility bills.

Another reason why a functioning compressor is essential is for the comfort and well-being of the occupants. During hot summer months, a properly working air conditioning system with a functioning compressor can provide a cool and comfortable indoor environment. It helps regulate the temperature and humidity levels, creating a more pleasant living or working space. In addition, a functioning compressor also helps filter out airborne particles and contaminants, improving indoor air quality.

In terms of maintenance and repair, a functioning compressor is important because it allows for more cost-effective solutions. If a compressor is faulty or damaged, it may be possible to repair or replace specific components rather than having to replace the entire air conditioning unit. This can save both time and money for the homeowner or business owner. However, if a compressor is beyond repair, it will need to be replaced, which can be a more costly endeavor.

In conclusion, a functioning compressor is of utmost importance for the efficient operation, cooling performance, comfort, and energy efficiency of an air conditioning system. Regular maintenance and timely repairs are necessary to ensure the longevity and optimal functioning of the compressor.

Signs of a faulty compressor

A compressor is a vital component of an air conditioner that is responsible for compressing low-pressure refrigerant into high-pressure gas. When the compressor starts to fail, it can affect the overall performance of the air conditioning unit. Here are some signs that indicate a faulty compressor:

- Loud or unusual noises: If you hear loud banging, clanging, or grinding noises coming from your air conditioner, it could be a sign of a faulty compressor. These noises usually indicate internal damage or worn-out parts.

- Poor cooling performance: If your air conditioner is no longer cooling your space as effectively as it used to, it could be due to a faulty compressor. A failing compressor may not be able to properly pressurize the refrigerant, resulting in reduced cooling efficiency.

- Tripped circuit breaker: If the circuit breaker for your air conditioner trips frequently, it could be due to a faulty compressor. A compressor that is drawing too much current or short-circuiting can cause the circuit breaker to trip as a safety measure.

- Frequent on/off cycling: If your air conditioner continuously turns on and off in short intervals, it could be a sign of a failing compressor. This behavior, known as short cycling, can be caused by a faulty compressor unable to maintain the desired pressure levels.

- Frozen evaporator coil: A faulty compressor can cause the evaporator coil to freeze. If you notice ice buildup on the coil, it indicates a problem with the compressor. This can lead to poor cooling performance and decreased airflow.

If you notice any of these signs, it is important to address the issue promptly to avoid further damage and costly repairs. Contact a professional HVAC technician to diagnose and repair the faulty compressor in your air conditioner.

Lack of cooling

If your air conditioner is not producing enough cool air or is not cooling at all, it could be due to several reasons.

1. Dirty air filter:

A dirty air filter can block the airflow and restrict the cooling capacity of the air conditioner. Check the air filter and clean or replace it if necessary. Regularly cleaning or replacing the air filter is essential for the efficient operation of the air conditioner.

2. Insufficient refrigerant:

If the air conditioner does not have enough refrigerant, it will struggle to cool the air. Low refrigerant levels could be a result of a leak in the system. A professional technician would need to locate and fix the leak, and then recharge the refrigerant to restore the cooling capacity.

3. Faulty compressor:

The compressor is responsible for compressing the refrigerant and circulating it through the system. If the compressor is faulty or damaged, it may not be able to properly cool the air. In this case, repair or replacement of the compressor may be necessary.

4. Blocked condenser coil:

The condenser coil of the air conditioner can become blocked with dirt, debris, or vegetation, reducing its ability to release heat. Regularly cleaning the condenser coil and removing any obstructions can improve the cooling efficiency of the air conditioner.

5. Malfunctioning thermostat:

The thermostat controls the temperature settings of the air conditioner. A malfunctioning thermostat may not accurately sense the temperature or send the appropriate signals to the cooling system. Checking and calibrating the thermostat or replacing it, if necessary, can help resolve this issue.

If you are experiencing a lack of cooling in your air conditioner, it is best to consult a professional technician to diagnose the exact cause and perform any necessary repairs. Regular maintenance and timely repairs can help ensure the efficient and reliable cooling performance of your air conditioner.

Noises from the compressor

If you notice unusual noises coming from your air conditioner compressor, it could indicate a problem that needs to be addressed. Ignoring these noises can lead to further damage and potentially costly repairs. Here are some common noises you may hear from the compressor and what they could mean:

Rattling sound

A rattling sound coming from the compressor could indicate loose components or debris that have gotten trapped inside. This could be caused by a loose fan blade or screws, or it could be an indication of a failing compressor motor. It is important to have a professional technician inspect and fix any loose parts or clean out any debris to prevent further damage.

Banging or knocking sound

If you hear a banging or knocking sound coming from the compressor, it could mean that the internal parts have become loose or are worn out. This could be due to a faulty motor mount or worn bearings. Continuing to run the air conditioner with these issues could cause the compressor to fail completely. It is recommended to turn off the unit and call a professional to diagnose and repair the problem.

Hissing or buzzing sound

Hissing or buzzing noises coming from the compressor could indicate a refrigerant leak. The hissing sound is caused by the refrigerant escaping from the system, while the buzzing sound could be due to a failing compressor motor. A refrigerant leak can cause the air conditioner to lose cooling capacity and can be harmful to the environment. It is important to have a professional technician locate and fix the leak to prevent further damage and ensure proper cooling.

If you hear any of these noises from your air conditioner compressor, it is best to have a professional technician inspect and repair the issue. Trying to fix the problem yourself could lead to further damage or injury. Regular maintenance and inspections of your air conditioner can help prevent compressor issues and extend the lifespan of your unit.

Diagnosing and repairing a faulty compressor

Step 1: Check for unusual noises

One of the first signs of a faulty compressor is unusual noises coming from the air conditioner unit. If you hear grinding, clicking, or buzzing sounds, it may indicate a problem with the compressor. These noises could be caused by loose or damaged components within the compressor, and immediate attention is needed to prevent further damage.

Step 2: Inspect the compressor for leaks

A faulty compressor can also cause refrigerant leaks, which can be identified by oil stains or puddles around the air conditioner unit. Refrigerant leaks not only affect the cooling efficiency of the air conditioner but can also lead to damage to other components. Inspect the compressor, refrigerant lines, and connections for any signs of leaks.

Step 3: Check the compressor’s electrical connections

A faulty compressor may also be caused by electrical issues, such as loose or damaged electrical connections. Check the wiring and terminals connected to the compressor for any signs of corrosion, fraying, or looseness. Properly functioning electrical connections are essential for the compressor to operate efficiently and safely.

Step 4: Test the compressor’s functionality

To test the functionality of a faulty compressor, a multimeter can be used to measure the voltage at the compressor terminals. Ensure that the power to the air conditioner is turned off before conducting any tests. A reading of zero or significantly low voltage may indicate a faulty compressor that needs to be repaired or replaced.

Step 5: Consult a professional technician

If you have gone through the preliminary steps and determined that the compressor in your air conditioner is faulty, it is recommended to consult a professional technician for further diagnosis and repair. Attempting to repair the compressor yourself without proper knowledge or experience can lead to more significant damage or personal injury. A qualified technician will be able to accurately diagnose the problem and recommend the appropriate solution, whether it be repairing or replacing the compressor.

In conclusion, diagnosing and repairing a faulty compressor in an air conditioner requires careful inspection, testing, and professional expertise. By following the steps outlined above, you can identify the signs of a faulty compressor and take the necessary steps to ensure the proper functioning of your air conditioning system.

Visual inspection

Before attempting any repairs on a compressor in an air conditioner, it is important to conduct a visual inspection to identify any obvious issues or damage. This step can help in determining the cause of the problem and whether a repair is necessary.

Start by inspecting the exterior of the compressor unit for any signs of physical damage. Look for dents, cracks, or signs of corrosion on the casing. Pay close attention to the fan blades to ensure they are not bent or broken.

Next, check the electrical connections to the compressor. Look for loose or frayed wires, and ensure that all connections are secure. In particular, inspect the capacitor for any visible signs of damage or leakage. A damaged capacitor may be responsible for compressor failure.

Inspect the refrigerant lines for any signs of leakage. Look for oil stains or wet spots around the fittings and connections. A refrigerant leak can cause the compressor to work harder and eventually fail.

If you notice any unusual noises coming from the compressor, such as grinding or rattling, it may be an indication of internal damage. In such cases, it is best to contact a professional technician for further diagnosis and repair.

Overall, conducting a thorough visual inspection can provide valuable insight into the condition of a compressor in an air conditioner. It can help in identifying potential problems and determining the appropriate course of action for repair.

Testing the compressor motor

Testing the compressor motor is an important step in diagnosing and repairing a compressor in an air conditioner. The compressor motor is responsible for compressing the refrigerant and circulating it through the system, so it’s crucial to ensure that it is functioning properly.

Visual inspection: Start by visually inspecting the compressor motor for any signs of damage or wear. Look for frayed wires, loose connections, or burnt components. If you notice any of these issues, they may indicate a problem with the compressor motor.

Electrical testing: Using a multimeter, you can test the electrical components of the compressor motor. Check the resistance of the windings to ensure they are within the manufacturer’s specifications. A reading that is significantly higher or lower than the recommended range could indicate a problem.

Running amps: You can also test the running amps of the compressor motor to ensure it is operating at the correct level. Use a clamp meter to measure the current draw of the motor while it is running. Compare the reading to the manufacturer’s specifications to determine if the motor is functioning properly.

Start capacitor: If the compressor motor is not starting, it may be due to a faulty start capacitor. You can test the start capacitor using a capacitance meter or an ohmmeter. A reading that is significantly different from the rated capacitance or an open circuit reading may indicate a faulty capacitor.

Oil level: Lastly, check the oil level in the compressor motor. Low oil level can lead to overheating and mechanical failure. Make sure the oil level is within the recommended range and top it up if necessary.

By testing the compressor motor thoroughly, you can identify any issues and determine the appropriate repairs or replacements needed to get the air conditioner up and running efficiently again.

Replacing the compressor

Step 1: Turn off the power

Before replacing the compressor in your air conditioner, it is important to turn off the power supply. This will ensure your safety and prevent any damage to the electrical components.

Step 2: Remove the old compressor

Start by removing the refrigerant from the system. This can be done by using a refrigerant recovery machine. Once the refrigerant is removed, disconnect the electrical connections and tubing from the compressor. Make sure to label each connection to avoid confusion when installing the new compressor.

Step 3: Install the new compressor

Before installing the new compressor, check its compatibility with your air conditioner model. Ensure that the new compressor has the same specifications as the old one. Place the new compressor in the same position as the old one and reconnect the electrical connections and tubing.

Step 4: Recharge the system

Once the new compressor is installed, it is necessary to recharge the system with the appropriate amount of refrigerant. This can be done by using a refrigerant charging kit. Follow the manufacturer’s instructions to ensure the correct amount of refrigerant is added to the system.

Step 5: Test the air conditioner

After completing the installation and recharging process, turn on the power supply and test the air conditioner. Check for any unusual noises or leaks. Monitor the room temperature to ensure the air conditioner is working properly.

By following these steps, you can successfully replace the compressor in your air conditioner and restore its functionality.

Preventive maintenance for the compressor

Regular preventive maintenance is crucial to ensure the optimal performance and longevity of the compressor in an air conditioner. By following a few simple steps, you can minimize the risk of compressor failure and costly repairs.

Clean the air filters

One of the most important maintenance tasks for the compressor is to regularly clean or replace the air filters. Dirty or clogged filters can restrict the airflow, leading to increased strain on the compressor. This can ultimately result in overheating and potential damage. Clean the filters at least once a month or as recommended by the manufacturer.

Inspect and clean the condenser coils

The condenser coils, located in the outdoor unit of the air conditioner, are responsible for releasing heat from the system. Over time, the coils can accumulate dirt, debris, and even mold, obstructing the heat transfer process. Regularly inspect and clean the condenser coils using a soft brush or vacuum cleaner. This will help maintain optimal airflow and prevent compressor issues.

Check the refrigerant levels

Low refrigerant levels can put additional strain on the compressor and may lead to inadequate cooling. It is essential to check the refrigerant levels regularly and top up if necessary. However, refrigerant levels should only be checked and refilled by a qualified technician to ensure proper handling and prevent environmental damage.

Ensure proper ventilation

The compressor needs proper ventilation to dissipate heat effectively. Make sure that the outdoor unit is not obstructed by any objects or vegetation that can restrict airflow. Keep a clear space around the unit and remove any debris that may accumulate around it, such as leaves or grass clippings. This will help prevent overheating and potential compressor failure.

Schedule annual maintenance

While some maintenance tasks can be performed by homeowners, it is highly recommended to schedule annual professional maintenance for the entire air conditioning system, including the compressor. Trained technicians can inspect and service the unit thoroughly, addressing any potential issues before they escalate. Investing in regular professional maintenance can save you from costly repairs and extend the lifespan of your compressor.

FAQ:

Why is my air conditioner compressor not working?

If your air conditioner compressor is not working, it could be due to a variety of reasons. Some common causes include a faulty capacitor, a broken motor, or a refrigerant leak. It is best to contact a professional technician to diagnose and repair the issue.

Can I repair a compressor in an air conditioner by myself?

Repairing a compressor in an air conditioner can be a complex task and should be left to professionals. It requires specialized skills and equipment. Attempting to repair it yourself may cause further damage or even lead to personal injury. It is recommended to contact a qualified technician for any compressor repairs.

What are the signs that my air conditioner compressor needs repair?

There are several signs that may indicate your air conditioner compressor needs repair. These include unusual noises coming from the unit, reduced cooling performance, a tripped circuit breaker, or the compressor not turning on at all. If you notice any of these signs, it is best to contact a technician to diagnose and fix the issue.

How long does it take to repair a compressor in an air conditioner?

The duration of compressor repairs in an air conditioner can vary depending on the specific issue and the availability of parts. In some cases, it may take a few hours, while in others, it could take several days if extensive repairs are required. It is best to consult with the technician handling the repair for a more accurate time estimate.

What is the cost of repairing a compressor in an air conditioner?

The cost of repairing a compressor in an air conditioner can vary widely depending on factors such as the extent of the damage, the brand of the unit, and the labor charges of the technician. On average, compressor repairs can range from $500 to $1500. It is recommended to obtain quotes from multiple technicians to compare prices and choose the best option.

Video: