How to Remove Water from Air Compressor Tank: Effective Methods and Tips

Water buildup in an air compressor tank can cause a variety of issues, including reduced efficiency and corrosion. Removing water from the tank is essential for maintaining the compressor’s performance and extending its lifespan. In this article, we will discuss effective methods and tips for removing water from an air compressor tank.

1. Drain the tank regularly: The most straightforward method of removing water from an air compressor tank is to regularly drain it. Most air compressors are equipped with a drain valve at the bottom of the tank. Simply open the valve and allow the water to drain out. Make sure to do this after each use or at least once a month.

2. Use an air dryer: An air dryer is a device specifically designed to remove moisture from compressed air. It works by passing the compressed air through a desiccant material that absorbs the water vapor. Air dryers are an effective solution for removing water from an air compressor tank, especially in high-humidity environments.

3. Install a condensate separator: A condensate separator is a device that separates moisture from the compressed air stream before it reaches the tank. It works by using centrifugal force to remove the water droplets from the air. Installing a condensate separator can significantly reduce the amount of water buildup in the compressor tank.

4. Insulate the air compressor: In colder climates, condensation can occur more frequently in the compressor tank. Insulating the air compressor and piping can help prevent this by reducing the temperature difference between the compressed air and the surrounding environment. This, in turn, reduces the amount of condensation and water buildup in the tank.

5. Check for air leaks: Air leaks in the compressor system can introduce moisture into the tank. Regularly inspect the system for any leaks and promptly repair them to prevent water buildup. Additionally, ensure that all fittings and connections are tight and properly sealed to minimize air leakage.

By following these effective methods and tips, you can effectively remove water from your air compressor tank and keep it running at its best. Regular maintenance and proper care will not only improve the compressor’s performance but also prolong its overall lifespan.

Understanding the Importance of Removing Water from Air Compressor Tank

An air compressor tank is a crucial component of any air compressor system. It stores compressed air, which is used in various applications such as powering pneumatic tools or inflating tires. However, one common issue that can occur with air compressor tanks is the accumulation of water.

Water in the air compressor tank can cause several problems. Firstly, water condenses in the tank due to the compression and cooling of air, resulting in the accumulation of moisture. This moisture can mix with the oil in the system, leading to a decrease in lubrication effectiveness and potential damage to the compressor components.

Furthermore, the presence of water in the tank can cause corrosion and rusting of the tank walls and other internal components. This can significantly reduce the lifespan of the air compressor system and compromise its performance.

To prevent these issues, it is essential to properly remove water from the air compressor tank on a regular basis. This can be done through various methods and techniques, such as draining the tank, using moisture traps or filters, and implementing proper maintenance practices.

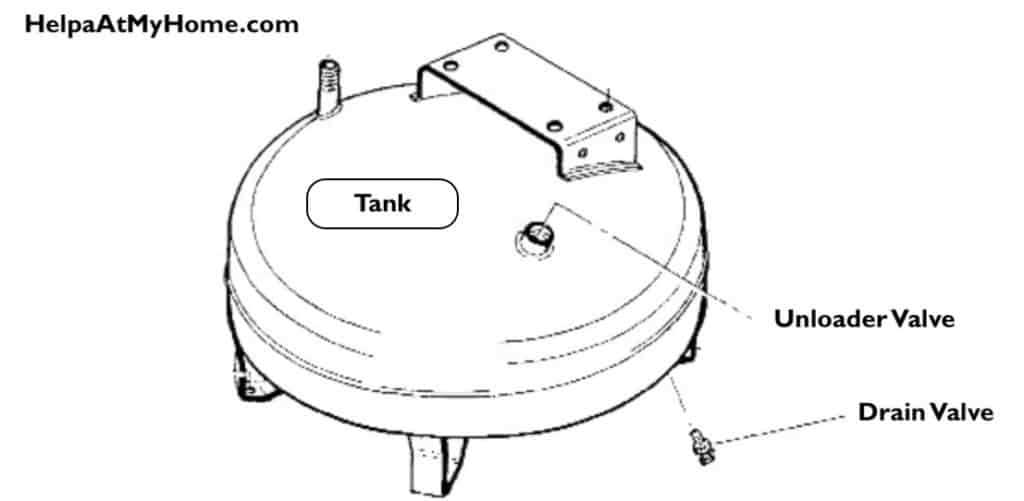

- Draining the tank: Regularly draining the tank to remove accumulated water is a simple and effective method. This can be done by opening the drain valve at the bottom of the tank and allowing the water to flow out. It is important to do this when the compressor is not pressurized and in a safe manner.

- Moisture traps or filters: Installing moisture traps or filters in the air compressor system can help capture and remove water vapor before it reaches the tank. These devices use desiccants or filtration media to absorb or trap moisture and prevent it from entering the tank.

- Maintenance practices: Implementing proper maintenance practices, such as regularly checking for leaks or damaged components, can help prevent water from entering the tank in the first place. Additionally, monitoring the humidity levels in the compressor area and controlling condensation can also aid in reducing the accumulation of water in the tank.

By understanding the importance of removing water from the air compressor tank and implementing appropriate methods and maintenance practices, you can ensure the longevity and optimal performance of your air compressor system.

Damaging Effects of Moisture in the Air Compressor Tank

Moisture buildup in an air compressor tank can have various damaging effects, affecting both the performance and lifespan of the equipment. Understanding these effects is crucial for proper maintenance and operation of the air compressor.

1. Corrosion:

One of the most significant damaging effects of moisture in the air compressor tank is corrosion. When moisture combines with the metal surfaces inside the tank, it creates a perfect environment for rust and corrosion to develop. Over time, the corrosion can weaken the tank’s structure, leading to leaks or even tank failure.

2. Reduced Efficiency:

Moisture in the air compressor tank can reduce the efficiency and performance of the equipment. When compressed air passes through the tank, the moisture can mix with the air, resulting in lower air quality. This can affect the performance of tools and machinery powered by the compressed air, leading to less efficient operation.

3. Contamination:

Moisture in the air compressor tank can also cause contamination issues. As the moisture accumulates, it can mix with dirt, oil, and other impurities in the tank. This contaminated air can then be transferred to the tools and machinery, potentially causing damage or malfunctions.

4. Freezing:

In colder climates, moisture in the air compressor tank can freeze and cause operational problems. When the compressed air containing moisture reaches low temperatures, it can freeze and block the air passages, affecting the flow and pressure. This can result in reduced performance or even equipment failure.

To prevent these damaging effects, it is essential to regularly remove the water from the air compressor tank using effective methods and maintain proper ventilation and drainage systems. Additionally, using moisture traps or filters can help minimize moisture buildup and protect the equipment from these detrimental effects.

Signs of Water Accumulation in the Air Compressor Tank

Water accumulation in an air compressor tank can cause several issues and affect the performance and lifespan of the equipment. It is important to be aware of the signs that indicate water buildup in the tank in order to address the problem promptly. Here are some common signs to look out for:

- Moisture in the air output: If you notice water droplets coming out of the air hose with the compressed air, it is a clear indication of water accumulation in the tank.

- Reduced air pressure: Water taking up space in the tank can decrease the amount of air that can be stored and compressed, leading to reduced air pressure during operation.

- Banging or knocking sounds: Excessive water in the tank can cause the compressor to produce banging or knocking sounds as it tries to compress the air and water mixture.

- Rust or corrosion: Over time, water sitting in the tank can cause rust or corrosion to develop on the inside walls, fittings, and components of the air compressor.

If you observe any of these signs, it is important to take immediate action to remove the water from the air compressor tank. Ignoring the problem can lead to damage to the equipment and result in costly repairs or replacements. Regular maintenance and proper drainage of the tank can help prevent water accumulation and ensure the efficient operation of the air compressor.

Effective Methods to Remove Water from Air Compressor Tank

Condensation is a common problem in air compressor tanks, as the pressure and temperature changes can cause moisture to accumulate. This water can damage the compressor and air tools, leading to reduced performance and potentially costly repairs. Fortunately, there are several effective methods to remove water from an air compressor tank.

1. Drain the Tank Regularly

One of the simplest and most important methods is to regularly drain the tank. This involves opening the drain valve at the bottom of the tank to release any accumulated water. It is recommended to do this after each use or at regular intervals, depending on the usage frequency. This will prevent the water from building up and causing potential damage.

2. Use an Air Dryer

An air dryer is an effective tool for removing moisture from compressed air. It typically consists of a desiccant material that absorbs the water vapor, allowing dry air to pass through. The air dryer can be installed at the outlet of the compressor or at the point of use. This method is especially useful for applications where a high level of dryness is required.

3. Install a Water Separator

A water separator, also known as a moisture separator, is another effective method to remove water from an air compressor tank. It works by using centrifugal force to separate the water droplets from the compressed air. The separated water can then be drained out of the tank. Installing a water separator at the outlet of the compressor or at the point of use can significantly reduce the amount of moisture in the compressed air.

4. Use a Refrigerated Air Dryer

A refrigerated air dryer is a more advanced method to remove water from an air compressor tank. It uses a refrigeration system to cool the compressed air, causing the moisture to condense and separate from the air. The condensed water is then drained out of the system. Refrigerated air dryers are especially effective in applications where a low dew point is required.

Overall, these effective methods can help remove water from an air compressor tank, ensuring the optimal performance and longevity of the compressor and air tools. Regular maintenance and monitoring of the moisture levels are essential to prevent any potential damage caused by water accumulation.

Method 1: Drain the Tank Regularly

One effective method for removing water from an air compressor tank is to regularly drain the tank. Over time, moisture can accumulate inside the tank, and if left unchecked, it can cause damage to the compressor and affect the quality of the compressed air.

Here are the steps to drain the tank regularly:

- Turn off the compressor: Before draining the tank, make sure to turn off the compressor and unplug it from the power source. This will ensure your safety during the process.

- Locate the drain valve: The drain valve is usually located at the bottom of the tank. It may be a small knob or a valve that can be opened or closed. Consult your compressor’s manual if you’re not sure where the drain valve is.

- Prepare a drainage area: Place a bucket or a container below the drain valve to collect the water that will be released from the tank. Make sure the container is large enough to hold the water without overflowing.

- Open the drain valve: Use a wrench or pliers to open the drain valve and allow the water to flow out. Be cautious as the water might be hot or under pressure. Keep a safe distance from the valve.

- Monitor the drainage: As the water flows out of the tank, keep an eye on the color and consistency. If you notice any oil or contaminants in the water, it may indicate a problem with the compressor and you should seek professional assistance.

- Close the drain valve: Once all the water has been drained from the tank, close the drain valve securely to prevent any air leaks.

By following these steps and regularly draining the tank, you can effectively remove water from your air compressor and ensure its optimal performance and longevity.

Method 2: Install a Water Separator

Another effective method to remove water from an air compressor tank is to install a water separator. A water separator is a device that is specifically designed to separate water droplets from compressed air, preventing them from entering the tank.

A water separator is usually installed in the air line just before the air enters the tank. It works by passing the compressed air through a filter that captures and collects the water droplets. The filtered air then continues into the tank, ensuring that no water enters it.

Installing a water separator is a relatively simple process. Begin by turning off the air compressor and relieving any pressure in the tank. Then, locate the air line that connects to the tank and identify a suitable location for the water separator. It is recommended to install the separator as close to the tank as possible for maximum effectiveness.

Next, cut the air line at the chosen location using a pipe cutter or a hacksaw. Attach the water separator to the cut section of the air line using appropriate fittings or connectors. Make sure the connections are tight and secure to prevent any air or water leaks.

Once the water separator is securely attached, turn on the air compressor and allow it to build up pressure. Monitor the separator and check for any signs of water accumulation. If you notice any water, drain it out using the separator’s designated drain valve. Regularly drain the water separator to ensure optimal performance and prevent water from entering the air compressor tank.

By installing a water separator, you can effectively remove water from your air compressor tank and prevent potential issues such as rust, corrosion, and damage to your tools or equipment. Remember to follow the manufacturer’s instructions when installing and maintaining the water separator to ensure its proper functioning.

Method 3: Use a Desiccant Dryer

A desiccant dryer is another effective method to remove water from an air compressor tank. This type of dryer uses a drying agent called a desiccant, which absorbs moisture from the compressed air.

To use a desiccant dryer, you will need to install it in line with your air compressor system. The dryer typically consists of two chambers filled with desiccant beads. As the compressed air flows through the dryer, the desiccant beads attract and trap the water vapor, leaving behind dry air.

Desiccant dryers are available in different sizes and designs, so it’s important to choose one that is suitable for your air compressor system. Some dryers may require regular maintenance, such as replacing the desiccant beads or cleaning the chambers. Be sure to follow the manufacturer’s instructions for proper installation and maintenance.

One advantage of using a desiccant dryer is that it can remove not only water vapor but also other contaminants, such as oil and dirt particles, from the compressed air. This can help improve the quality of the air and prevent damage to your air tools and equipment.

However, it’s worth noting that desiccant dryers can be more expensive compared to other methods of water removal. They also require regular monitoring and maintenance to ensure they are functioning properly. If you have a small air compressor system or do not require extremely dry air, you may consider other methods of water removal.

Tips for Preventing Water Accumulation in the Air Compressor Tank

Air compressor tanks can accumulate water over time due to the natural condensation process. However, excessive water buildup can cause damage to the tank and affect the compressor’s performance. Here are some tips to prevent water accumulation in the air compressor tank:

1. Drain the tank regularly

Regularly draining the tank is essential to prevent water buildup. Open the drain valve and let the water drain out completely. This should be done after each use or at least once a month, depending on the frequency of use. Ensure that the tank is completely empty before closing the drain valve to prevent any residual moisture from accumulating.

2. Install a moisture trap

A moisture trap, also known as a water separator, can be installed in the air compressor system. This device is designed to remove moisture from the compressed air before it enters the tank. It prevents water from reaching the tank and reduces the chances of water accumulation. Make sure to empty the moisture trap regularly to prevent clogging.

3. Use an air dryer

An air dryer is another effective solution to prevent water accumulation in the air compressor tank. It removes moisture from the compressed air by cooling it and then condensing the water vapor. The dried air is then released into the tank, reducing the chances of water buildup. Regular maintenance and cleaning of the air dryer are necessary to ensure its proper functioning.

4. Keep the compressor in a dry and well-ventilated area

Moisture in the air can easily be absorbed by the tank if the compressor is exposed to humid conditions. To prevent water accumulation, it is important to store the compressor in a dry and well-ventilated area. Avoid placing it in areas with high humidity or near water sources. If necessary, use a dehumidifier or install proper ventilation to reduce moisture in the surrounding air.

5. Inspect and repair any leaks

Leaks in the air compressor system can contribute to water accumulation in the tank. Regularly inspect the system for any signs of leaks and promptly repair them. This will help maintain the integrity of the system and prevent moisture from entering the tank.

By following these tips, you can effectively prevent water accumulation in the air compressor tank and ensure its optimal performance and longevity.

FAQ:

What are some effective methods to remove water from an air compressor tank?

There are several effective methods to remove water from an air compressor tank. One method is using a drain valve to release the water manually. Another method is using an automatic drain valve that releases water periodically. Additionally, you can use a moisture trap or water separator to remove water from the compressed air.

How often should I remove water from my air compressor tank?

The frequency of removing water from your air compressor tank depends on various factors such as the humidity levels in your environment, the usage of the compressor, and the tank’s capacity. However, it is generally recommended to drain the tank daily or at least once a week to prevent the buildup of excess water.

What are the consequences of not removing water from an air compressor tank?

If you do not remove water from an air compressor tank, it can lead to various issues. The presence of water in the tank can cause rust and corrosion, reducing the lifespan of the tank and other components. It can also lead to decreased efficiency and performance of the air compressor, as water can mix with the compressed air and affect its quality.

Can I use a regular shop vacuum to remove water from an air compressor tank?

No, using a regular shop vacuum to remove water from an air compressor tank is not recommended. Shop vacuums are not designed to handle water and may not be able to effectively remove it from the tank. It is best to use a drain valve, automatic drain valve, or other specialized methods to remove water from the air compressor tank.

Are there any additional tips to prevent water buildup in an air compressor tank?

Yes, there are additional tips to prevent water buildup in an air compressor tank. One tip is to install a moisture trap or water separator in the air line to remove moisture before it reaches the tank. Additionally, you can use an air dryer to further remove moisture from the compressed air. Regular maintenance, including checking and replacing filters as needed, can also help prevent water buildup.

Video: