How to Jumpstart an Air Conditioner Compressor

An air conditioner compressor is an essential component of any AC system. It is responsible for compressing and circuling the refrigerant, allowing the system to cool and dehumidify the air. However, there may be times when the compressor fails to start up, leaving you with a hot and uncomfortable space. In such situations, knowing how to jumpstart the compressor can come in handy, as it may save you from costly repairs or a complete AC replacement.

Jumpstarting an air conditioner compressor involves providing an external jolt of electricity to kickstart the motor. Before attempting this process, it is important to understand that it should only be done if you are experienced with electrical work and have the necessary tools. It is also important to ensure that the power to the AC unit is turned off before attempting any jumpstarting activities.

There are a few steps involved in jumpstarting an air conditioner compressor. First, you will need to locate the capacitor, which is a small cylindrical device that stores an electrical charge and helps start the motor. The capacitor is typically located near the compressor and can be identified by its two or three sets of smaller wires running to it. Make sure to discharge the capacitor by touching a screwdriver to the terminals to prevent any electrical shock.

Once the capacitor is discharged, you can proceed with jumpstarting the compressor. Use a multimeter to test and ensure that power is reaching the compressor and that there is no issue with the wiring. Next, connect a set of jumper cables to the positive and negative terminals on the compressor to provide the necessary jolt of electricity. This should be done carefully and with caution to avoid any shorts or electrical hazards.

Why Jumpstart an Air Conditioner Compressor is Important

The proper functioning of an air conditioner compressor is crucial for the overall performance and efficiency of the cooling system. When the compressor fails to start on its own, jumpstarting it becomes necessary to avoid further damage and expensive repairs.

Prevents Damage: Jumpstarting an air conditioner compressor can help prevent damage to other components of the cooling system. When the compressor fails to start, it can put additional strain on the motor and other electrical parts, leading to their premature failure.

Restores Cooling: A failed compressor means no cooling. By jumpstarting it, you can restore the cooling function of your air conditioner and ensure a comfortable indoor environment, especially during hot summer months.

Saves Money: Jumpstarting an air conditioner compressor is a cost-effective solution compared to replacing the entire cooling system. It allows you to fix the problem without having to invest in a new compressor or air conditioner, saving you a significant amount of money.

Improves Energy Efficiency: A properly functioning compressor is essential for the energy efficiency of the air conditioning unit. By jumpstarting the compressor, you can ensure that it operates at its optimal level, which helps reduce energy consumption and lowers your electricity bills.

Extends Lifespan: Jumpstarting an air conditioner compressor promptly can extend its lifespan. By addressing the problem early on, you prevent further damage and ensure that the compressor lasts longer, reducing the need for frequent repairs or replacements.

Enhances Indoor Air Quality: A malfunctioning compressor can impact the air quality in your home. By jumpstarting the compressor and restoring the cooling function, you can improve ventilation and filtration, leading to better indoor air quality and a healthier living environment.

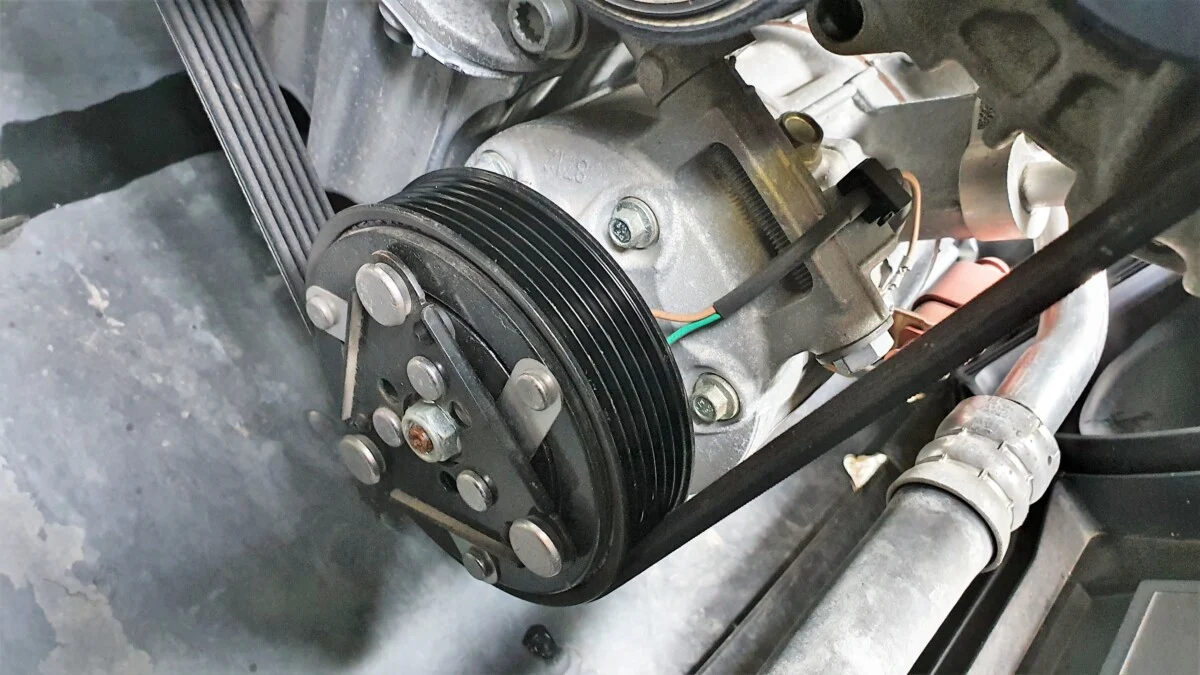

What is an Air Conditioner Compressor?

An air conditioner compressor is a critical component of an air conditioning system that is responsible for compressing refrigerant gas and pumping it through the rest of the system. It plays a crucial role in the cooling process by pressurizing the refrigerant, which allows it to absorb heat from the indoor environment and then release it outdoors. Without a properly functioning compressor, an air conditioning unit would not be able to cool the air effectively.

The compressor is typically located in the outdoor unit of the air conditioning system. It consists of a motor, a piston, and a cylinder. The motor drives the piston, which compresses the refrigerant gas by reducing its volume. As the refrigerant is compressed, its temperature and pressure increase, making it ready to release heat through the condenser coil. The compressed refrigerant then flows through the rest of the system, where it undergoes a cooling process and is returned to the compressor to repeat the cycle.

The compressor is often considered the heart of an air conditioning system because it does the majority of the work in the cooling process. It requires a significant amount of electrical energy to operate and is typically the most expensive component to replace or repair if it fails. Regular maintenance and proper care are essential to ensure the longevity and efficiency of the compressor.

Importance of Regular Maintenance

Regular maintenance is crucial for keeping your air conditioner compressor in good working order. By performing routine maintenance tasks, you can ensure that your compressor remains efficient and reliable, while also prolonging its lifespan.

Improved Efficiency

Regular maintenance of your air conditioner compressor helps ensure that it operates at peak efficiency. Over time, components can become dirty or worn, which can affect the compressor’s ability to cool the air. By regularly cleaning and inspecting the compressor, you can keep it running at its optimal efficiency, which can result in lower energy bills and a more comfortable indoor environment.

Reduced Breakdowns

By performing regular maintenance and inspections, you can identify and address any potential issues before they lead to a major breakdown. Small problems, like loose or worn-out parts, can be fixed quickly and easily during routine maintenance, preventing more significant and costly repairs in the future. Regular maintenance can help you avoid unexpected breakdowns and the inconvenience and discomfort that comes with them.

Prolonged Lifespan

Regularly maintaining your air conditioner compressor can help extend its lifespan. By keeping the compressor clean and well-maintained, you can prevent excessive wear and tear on the components, which can lead to premature failure. With proper maintenance, you can enjoy reliable cooling performance and avoid the need for a costly replacement unit.

Improved Air Quality

A well-maintained air conditioner compressor can help improve the air quality in your home. Regular maintenance tasks, such as cleaning or replacing filters, can remove dust, pollen, and other pollutants from the air. This can be especially beneficial for individuals with allergies or asthma, as it can help reduce symptoms and provide a healthier indoor environment.

In summary, regular maintenance is essential for keeping your air conditioner compressor running smoothly and efficiently. It can improve efficiency, reduce breakdowns, extend the lifespan of the compressor, and contribute to better air quality. By incorporating regular maintenance into your routine, you can enjoy the benefits of a well-functioning air conditioning system for years to come.

Signs that Your Compressor Needs Jumpstarting

If you notice that your air conditioner is not providing cool air or is not turning on at all, it may be a sign that your compressor needs jumpstarting. The compressor is a vital component of the air conditioning system, responsible for compressing the refrigerant and circulating it through the system. When the compressor fails to start, it can disrupt the entire cooling process.

One common sign that your compressor needs jumpstarting is if you hear clicking noises coming from the unit when you try to turn it on. This clicking sound indicates that the compressor is attempting to start but is not able to do so. In some cases, you may also hear a humming sound, which suggests that the compressor is receiving power but is not able to start efficiently.

Another sign that your compressor needs jumpstarting is if you notice a significant decrease in cooling performance. If your air conditioner is blowing warm or only slightly cool air, it may be due to a compressor issue. This can occur when the compressor is not functioning optimally and is unable to properly cool the refrigerant before it circulates through the system.

In addition, if you notice a tripped circuit breaker or blown fuse when you try to turn on your air conditioner, it could be an indication that your compressor needs jumpstarting. When the compressor fails to start, it can cause an overload on the electrical circuit, resulting in the tripping of a breaker or blowing of a fuse.

If you experience any of these signs, it is important to address the issue promptly as a malfunctioning compressor can lead to further damage to the air conditioning system. Contacting a professional HVAC technician who specializes in compressor repair and jumpstarting can help diagnose and resolve the issue effectively.

Steps to Jumpstart an Air Conditioner Compressor

1. Check the Power Source

Before attempting to jumpstart your air conditioner compressor, make sure that it is receiving power. Check that the unit is properly plugged in and that the circuit breaker or fuse is not tripped. If the power source is functioning correctly, proceed to the next step.

2. Inspect the Capacitor

The capacitor is an essential component of the air conditioner compressor. It stores electrical energy and helps start the motor. Inspect the capacitor for any visible signs of damage, such as swelling or leakage. If the capacitor is damaged, it may need to be replaced before jumpstarting the compressor.

3. Locate the Reset Button

Many air conditioner compressors have a reset button that can be used to jumpstart the unit. Locate the reset button, which is typically located near the motor or control panel. Press and hold the reset button for a few seconds to attempt to restart the compressor.

4. Use a Capacitor Tester

If the reset button does not work, you can use a capacitor tester to check the capacitor’s functionality. Disconnect the power supply to the compressor and remove the capacitor. Connect the tester to the capacitor and follow the manufacturer’s instructions to determine if it is working properly. If the capacitor is faulty, replace it with a new one.

5. Call a Professional

If the above steps do not successfully jumpstart your air conditioner compressor, it is best to call a professional HVAC technician. They have the expertise and tools to diagnose and repair any issues with the compressor. Attempting to fix complex electrical components without proper knowledge can be dangerous and may cause further damage.

Remember to always prioritize safety when working with electrical appliances. If you are unsure or uncomfortable with jumpstarting your air conditioner compressor, it is best to consult a professional before attempting any repairs.

The Tools You’ll Need

In order to jumpstart an air conditioner compressor, you will need a few specific tools to ensure a successful restart. These tools include:

- A multimeter: This tool is essential for testing electrical currents and determining if there is a power issue with the compressor.

- A set of insulated screwdrivers: Insulated screwdrivers are necessary to safely work with electrical components and prevent electrical shocks.

- Alligator clip leads: These leads are used to temporarily bypass faulty components and help in troubleshooting the compressor.

- A pressure gauge: This tool is used to measure the pressure in the air conditioning system and determine if it is within the correct range.

- A refrigerant charging kit: If low refrigerant levels are suspected, a refrigerant charging kit will be necessary to add refrigerant to the system.

In addition to these tools, it is also helpful to have a flashlight, gloves, and safety glasses on hand to ensure your safety while working on the compressor. It is important to remember to always follow proper safety precautions and consult a professional if you are unsure about any steps in the process.

Precautions to Take Before Jumpstarting

Before attempting to jumpstart an air conditioner compressor, it is important to take certain precautions to ensure safety and prevent further damage.

1. Turn off the power:

Before performing any maintenance or repairs, always turn off the power supply to the air conditioning unit. This will help prevent electric shock and minimize the risk of injury.

2. Wear protective gear:

When working with an air conditioner compressor, it is important to wear the appropriate protective gear, such as safety goggles and gloves. This will provide protection against any potential electrical or mechanical hazards.

3. Disconnect the unit:

Prior to jumpstarting the compressor, disconnect the air conditioning unit from its power source. This can be done by unplugging the unit or switching off the circuit breaker. It is essential to prevent any electricity from flowing to the compressor during the jumpstart process.

4. Inspect the compressor:

Take a few moments to visually inspect the compressor and surrounding components. Look for any signs of damage, such as frayed wires, leaks, or broken parts. If any issues are detected, it is best to consult a professional technician for further assistance.

5. Check the refrigerant levels:

Before jumpstarting the compressor, ensure that the refrigerant levels are sufficient. Low refrigerant levels can cause the compressor to malfunction and may indicate a larger problem. If the refrigerant levels are low, it is recommended to contact a professional to address the issue.

6. Follow manufacturer instructions:

Always refer to the manufacturer’s instructions and guidelines when jumpstarting an air conditioner compressor. Each unit may have specific requirements and procedures that should be followed to ensure proper operation.

By taking these precautions before jumpstarting an air conditioner compressor, you can minimize the risk of injury and potential damage to the unit. If you are unsure about any step or encounter any difficulties, it is always best to seek professional assistance.

Common Mistakes to Avoid

1. Improper Power Supply

One common mistake to avoid when jumpstarting an air conditioner compressor is using an improper power supply. It is important to check the manufacturer’s specifications and requirements for the specific compressor model you are working with. Using a power supply that is not compatible with the compressor can result in damage to the unit and potential safety hazards.

2. Incorrect Wiring Connections

Another mistake to avoid is making incorrect wiring connections when jumpstarting the compressor. It is crucial to carefully follow the wiring diagram provided by the manufacturer. Failure to do so can lead to electrical malfunctions and damage to the compressor or other components of the air conditioning system.

3. Overheating the Compressor

Overheating the compressor is a common mistake that can be easily avoided. It is essential to provide proper ventilation and cooling for the compressor during jumpstarting and operation. Failure to do so can cause the compressor to overheat, leading to decreased performance, potential damage, and shortened lifespan.

4. Using Incorrect Refrigerant

Using the incorrect refrigerant can have serious consequences for the compressor. It is important to use the refrigerant specified by the manufacturer’s guidelines. Using the wrong refrigerant can result in damage to the compressor, decreased efficiency, and system failure.

5. Ignoring Safety Precautions

One of the biggest mistakes to avoid is ignoring safety precautions. Jumpstarting an air conditioner compressor can be hazardous if proper safety measures are not taken. Always ensure that the power is disconnected, wear appropriate protective gear, and follow all safety guidelines provided by the manufacturer.

6. Rushing the Process

Rushing the jumpstarting process is a mistake that can lead to errors and potential damage. Take the time to carefully review the manufacturer’s instructions, double-check the connections, and ensure that all necessary steps are followed. Being patient and thorough can prevent costly mistakes and ensure the successful jumpstart of the air conditioner compressor.

7. Lack of Proper Maintenance

One common mistake that can affect the performance of the compressor is a lack of proper maintenance. Regular maintenance, such as cleaning the filters and coils, lubricating moving parts, and checking refrigerant levels, is essential for optimal compressor performance. Neglecting maintenance can lead to decreased efficiency, increased energy consumption, and potential compressor failure.

8. Not Consulting a Professional

Jumpstarting an air conditioner compressor may require advanced technical knowledge and expertise. If you are unsure about the process or have any doubts, it is best to consult a professional HVAC technician. They have the experience and knowledge to ensure the proper jumpstarting of the compressor without causing any damage or safety risks.

FAQ:

What should I do when my air conditioner compressor is not starting?

If your air conditioner compressor is not starting, there are a few steps you can take to try and jumpstart it. First, check to make sure the power to the unit is on and that the thermostat is set correctly. If everything seems to be in order, you can try resetting the compressor by turning off the power to the unit and then turning it back on after a few minutes. Additionally, you can check the circuit breaker to see if it has tripped and reset it if necessary. If none of these steps work, it is best to contact a professional HVAC technician to diagnose and repair the issue.

Is it possible to jumpstart an air conditioner compressor on my own?

Yes, it is possible to jumpstart an air conditioner compressor on your own. However, it is important to exercise caution and follow safety guidelines. To jumpstart the compressor, you can start by turning off the power to the unit and letting it sit for a few minutes. Then, you can turn the power back on and see if the compressor starts. If it still does not start, you can try using a capacitor tester to check if the capacitor is faulty and needs to be replaced. If you are unsure about any of these steps or do not feel comfortable working with electrical components, it is best to contact a professional HVAC technician.

What are the common reasons for an air conditioner compressor to fail?

There are several common reasons for an air conditioner compressor to fail. One reason is a lack of regular maintenance, such as not cleaning or changing the air filters on a regular basis. This can cause the unit to overheat and put strain on the compressor. Another common reason is a refrigerant leak, which can cause the compressor to work harder and eventually fail. Other possible causes include electrical issues, such as faulty wiring or a malfunctioning thermostat, as well as a faulty capacitor or a blocked or damaged condenser coil. Regular maintenance and inspections by a professional HVAC technician can help prevent these issues and extend the life of the compressor.

When should I call a professional to jumpstart my air conditioner compressor?

If you have tried the basic troubleshooting steps and have not been able to jumpstart your air conditioner compressor, it is best to call a professional HVAC technician. They have the knowledge and expertise to diagnose and repair the issue safely and efficiently. Additionally, if your unit is still under warranty, attempting to jumpstart it on your own may void the warranty. It is also important to note that working with electrical components can be dangerous if you do not have the proper training or experience, so it is always best to leave it to the professionals.

Video: